High-mount stop lamp structure

A high-position brake light and lamp housing technology, applied in the direction of body, vehicle parts, streamlined body, etc., can solve the problems of low production efficiency, low efficiency, reduction, etc., to reduce product cost, simplify product design, and improve eye-catching effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

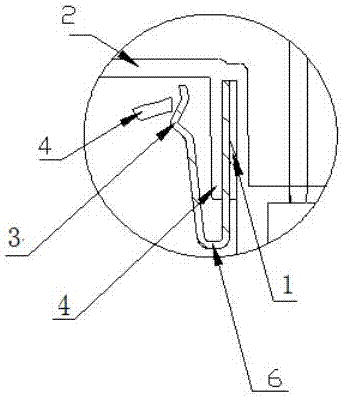

[0008] by figure 1 It is known that a high-position brake light structure is composed of a lampshade 1, a lamp housing 2, an LED circuit board 3, and a decorative cover 4. The lamp housing 2 is provided with four LED circuit board limit posts arranged in a symmetrical arrangement. , The lower two sides are provided with two decorative cover limit pins; the LED circuit board 3 is provided with through holes corresponding to the LED circuit board limit posts on the lamp housing 2, and the LED circuit board 3 is installed in the lamp housing 2. On the LED circuit board limit post, after the LED circuit board limit post limits the left, right, front and back of the LED circuit board 3, press the decorative cover 4 on the LED circuit board 3 in the lamp housing 2 and pass the decorative cover 4 After the limit pins of the decorative cover on both sides of the inner side limit the upper and lower positions of the LED circuit board 3, the lamp housing 2 and the lamp cover 1 are sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com