Transfer feeding method and device of two material intelligent delivery conveyer lines

A feeding device and conveying line technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low efficiency of transportation space, errors in distribution and packing operations, lack of automatic management, etc., to reduce Operation cost, quality improvement, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

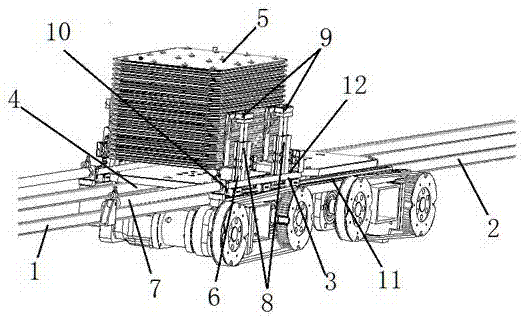

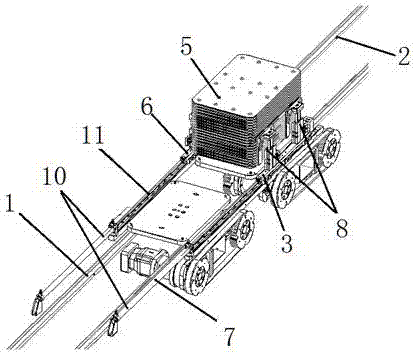

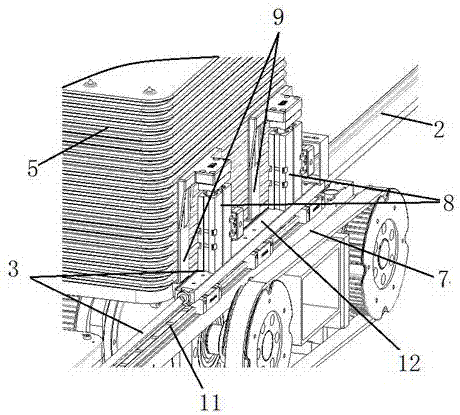

[0031] The accompanying drawing shows an embodiment of the present invention, and it can be seen from the accompanying drawings that the present invention relates to a device for transferring materials between two sections of a material intelligent distribution conveyor line, including the first section of the material intelligent distribution conveyor line 1, the second section The material intelligent distribution conveyor line 2 and the material intelligent distribution conveyor line transfer the feeding device 3 between the two sections. The end 4 of the first material intelligent distribution conveyor line 1 is connected to the head end of the second material intelligent distribution conveyor line 2. The transfer and feeding device 3 between the two sections of the distribution conveyor line is located at the junction of the two sections of the material intelligent distribution conveyor line, and the entire stack of materials is intelligently distributed. The end of the in...

Embodiment 2

[0038] The basic principle of the second embodiment is the same as that of the first embodiment, except that the structural form of the combination of the assembly line is different. It is a material intelligent distribution conveyor line that transfers and feeds between two sections, including the first section of the material intelligent distribution conveyor line, The second section of the material intelligent distribution conveyor line and the material intelligent distribution conveyor line pass the feeding device between the two sections. Then, the transfer feeding device between the two sections of the material intelligent distribution conveyor line is located at the junction of the two sections of the material intelligent distribution conveyor line. The end of the material intelligent distribution conveyor line is transferred to the head end of the second material intelligent distribution conveyor line.

[0039] Further, the transfer and feeding device between the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com