Patents

Literature

30results about How to "Reduce delivery errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

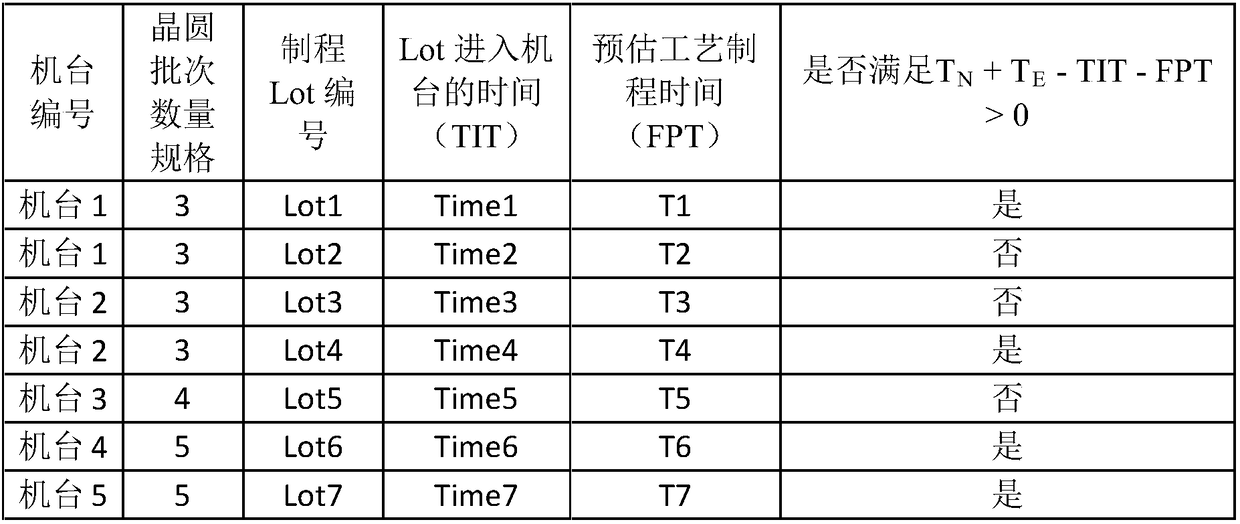

Real time dispatch system-based method and system for wafer batch dispatch under machine set

ActiveCN104977903AIncrease productivityAvoid the situation where the same batch of wafers are ordered at the same timeTotal factory controlProgramme total factory controlEngineering

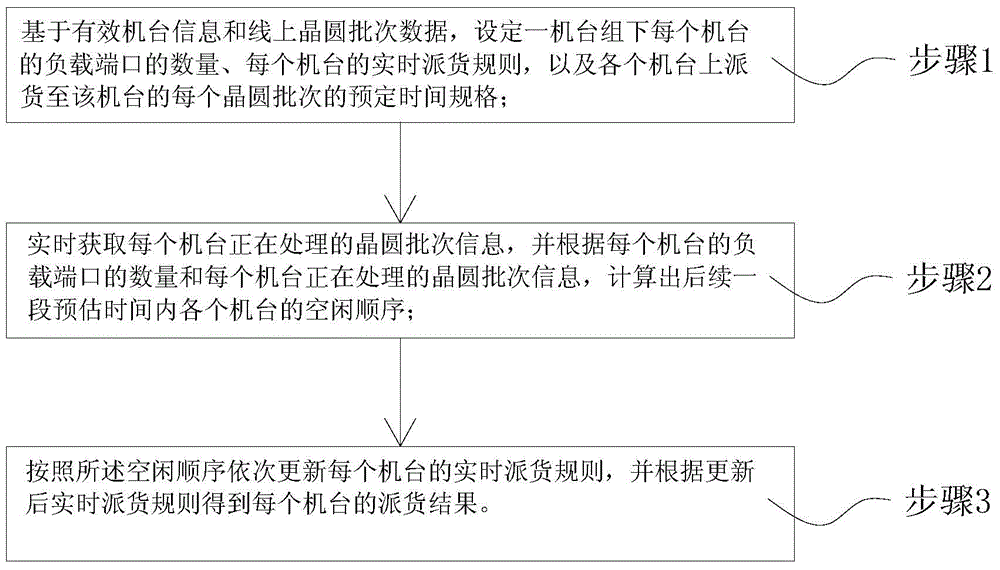

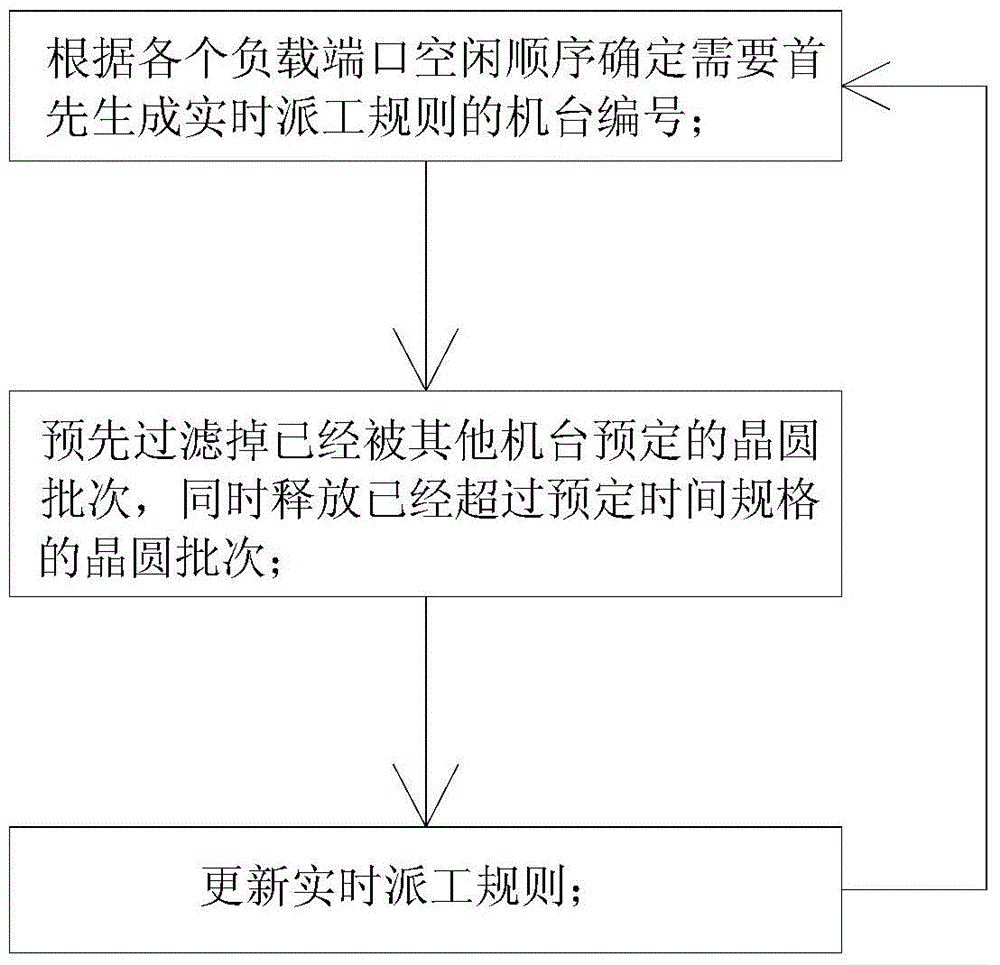

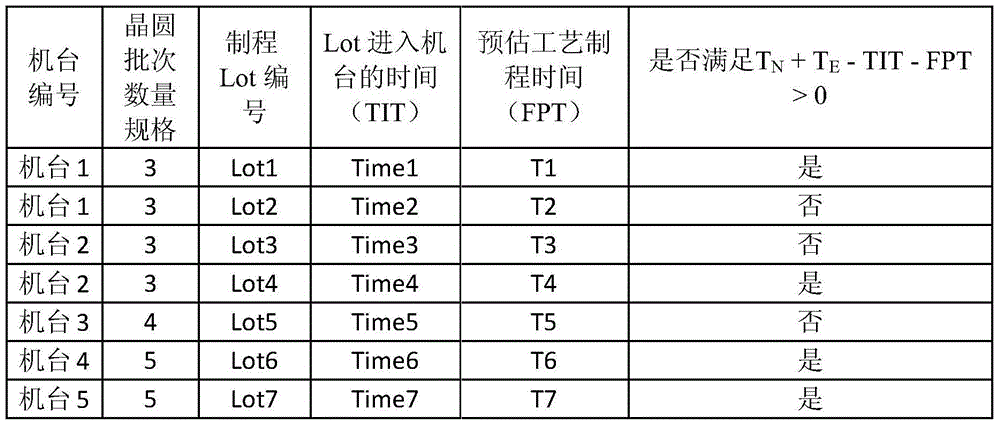

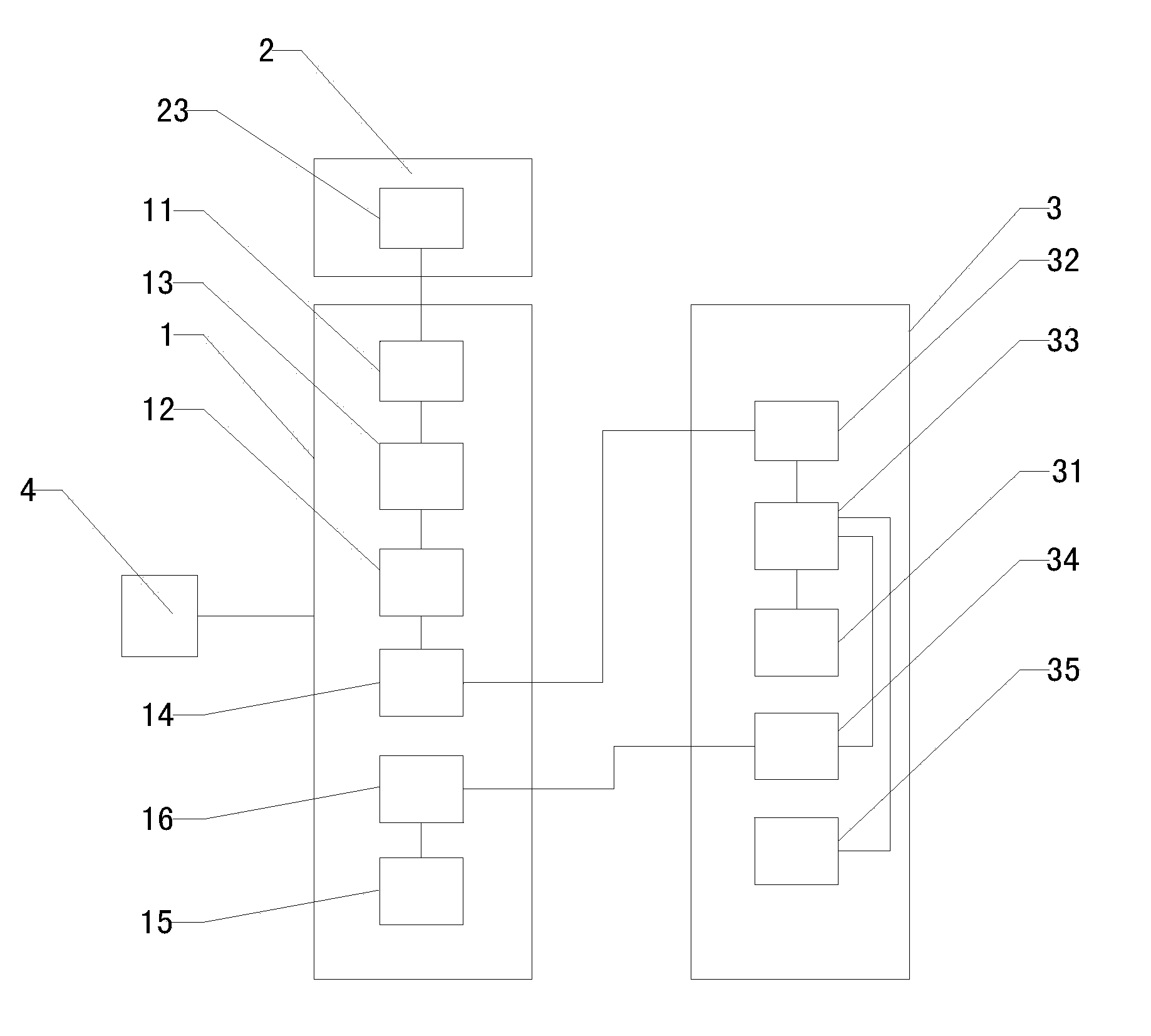

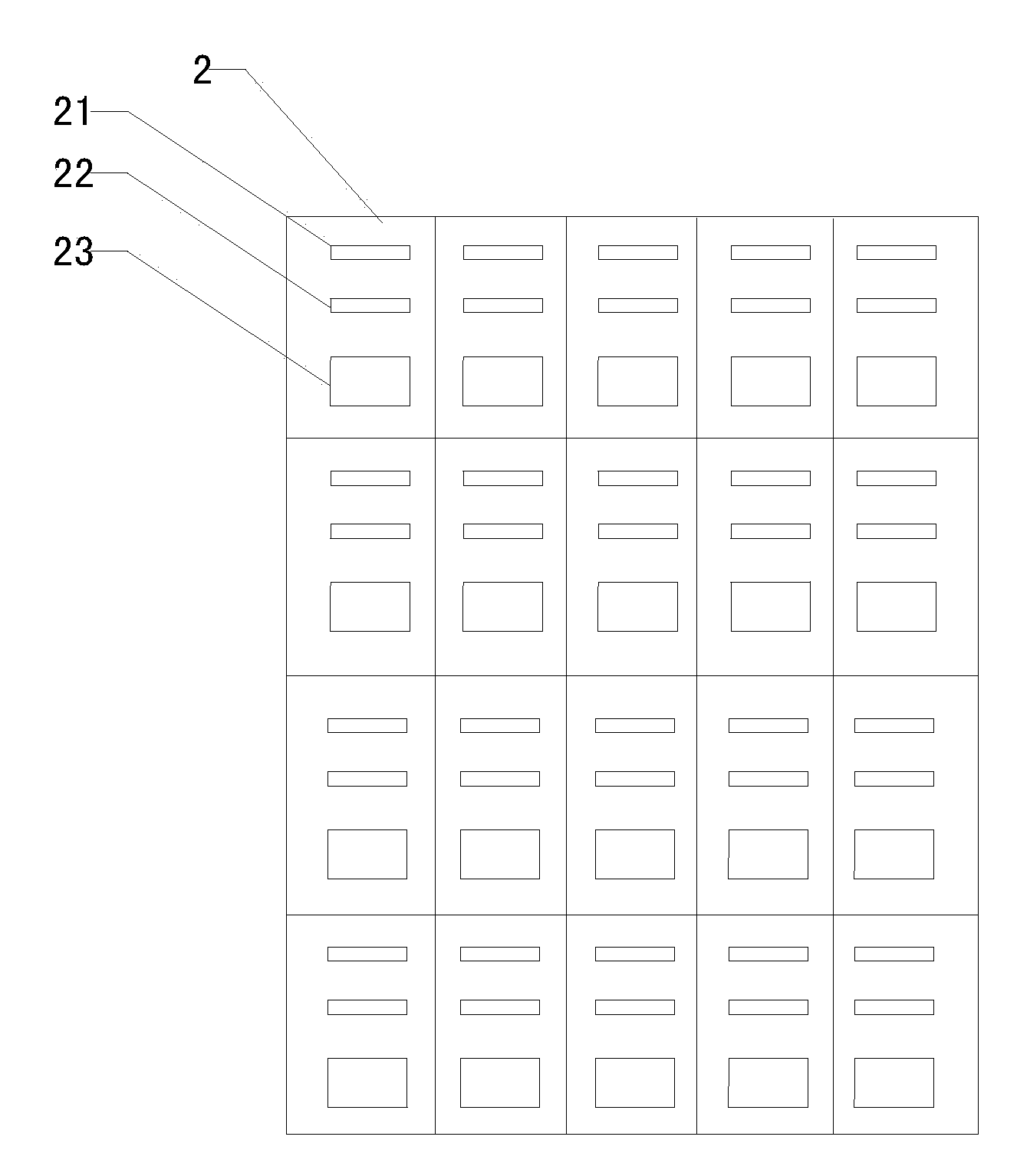

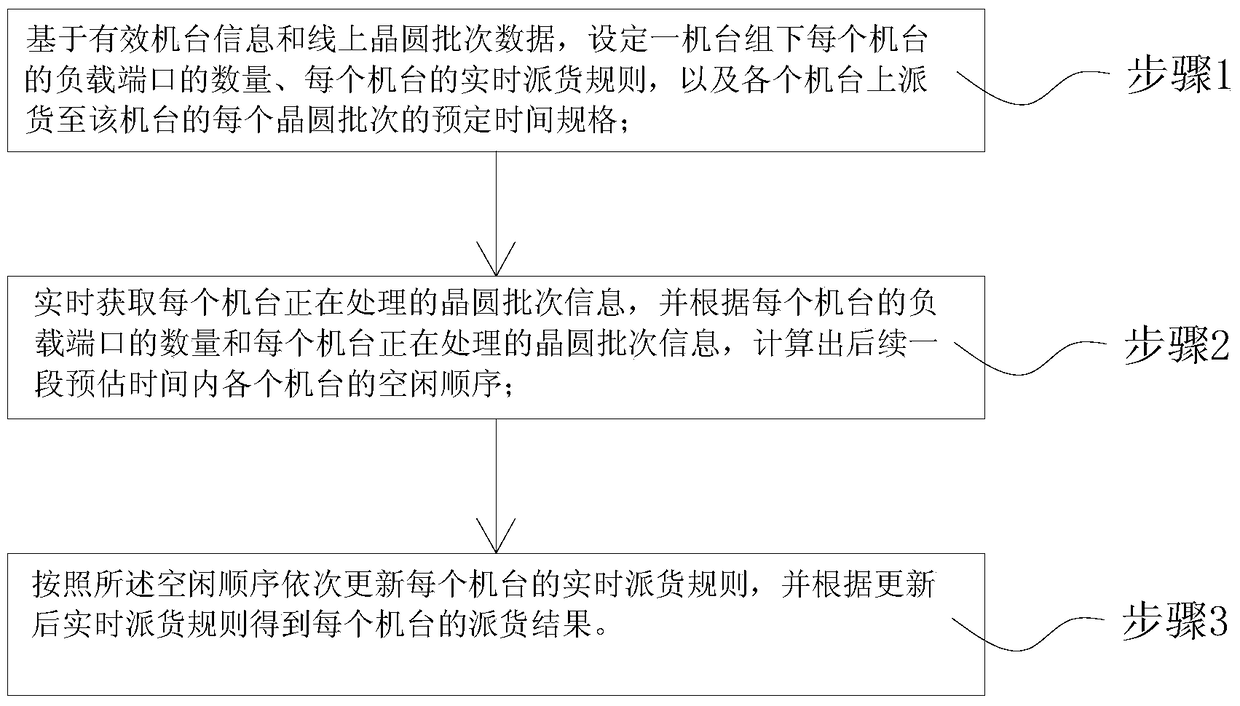

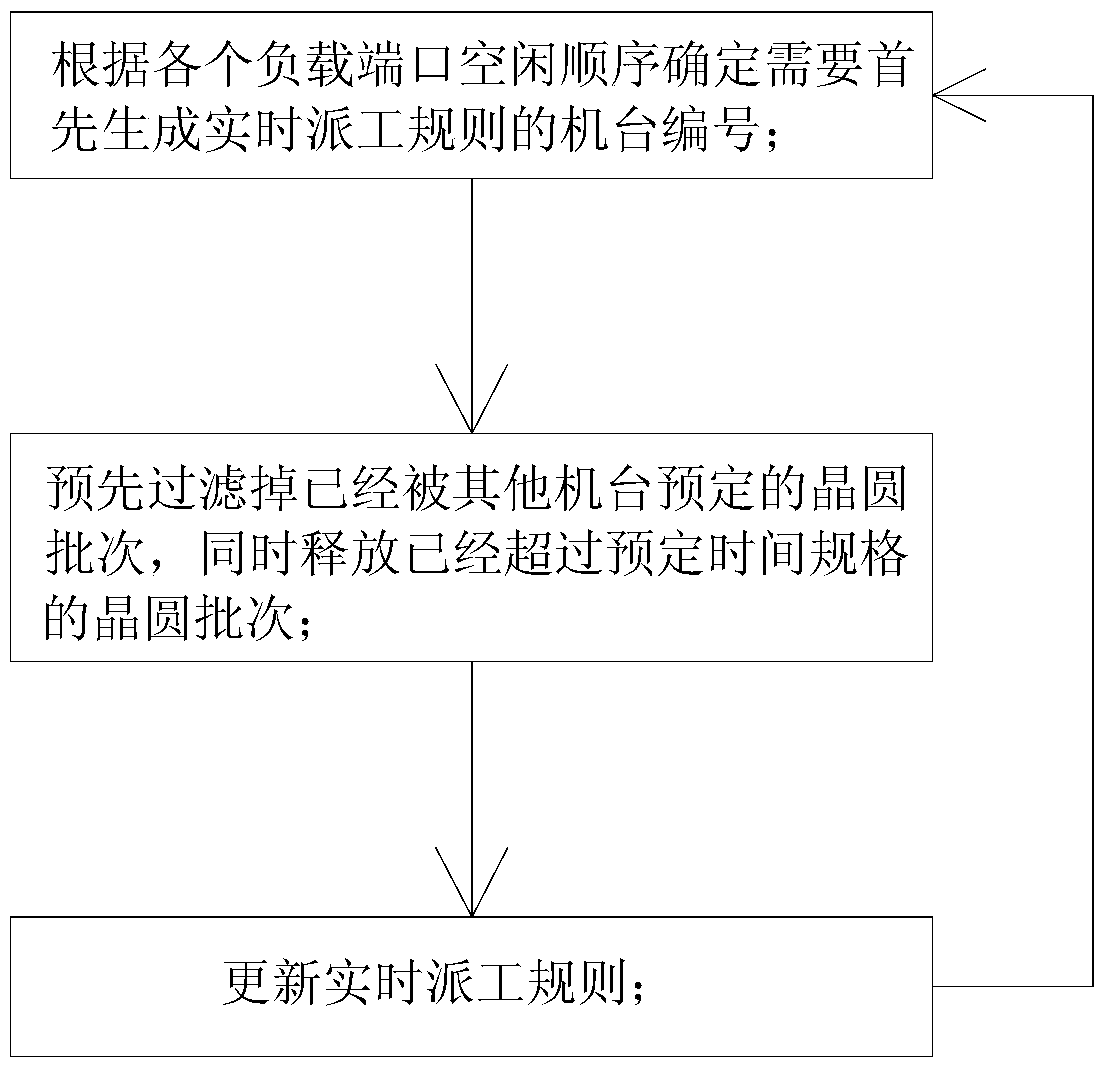

The invention provides a real time dispatch system-based method and system for wafer batch dispatch under a machine set. The method comprises steps of setting the number of load ports of each machine under a machine set, the real time dispatch rule of each machine, and the preset time specification of each wafer batch dispatched to a corresponding machine according to effective machine information and online wafer batch data; timely obtaining information of a wafer batch which is currently processed by each machine, and calculating an idle sequence of the machines within a follow-up period of estimated time according to the number of the load ports of each machine and the information of the wafer batch which is currently processed by each machine; and sequentially updating the real time dispatch rule of each machine according to the idle sequence, and obtaining a dispatch result of each machine according to the update real time dispatch rule. According to the invention, a phenomenon that machines under the same machine set preorder the same wafer batch during preordering of wafer batches can be prevented.

Owner:SEMICON MFG INT (SHANGHAI) CORP

PVC wrapping film

The invention discloses a PVC wrapping film which comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 10-20 parts of a plasticizer, 4-6 parts of butadiene-acrylonitrile rubber P83 powder, 1.5-2.5 parts of oleamide, 4-6 parts of a tribasic and dibasic heat stabilizer, 2-3 parts of CPE, 1-1.5 parts of ACR and 0.5-1.5 parts of stearic acid. The PVC wrapping film has the beneficial effects that (1) the film has high flexibility, damage difficulty, high bursting force resistance, impact resistance, tear resistance and high tension and can replace case packing; (2) a shrinkage ratio is large, articles can be tightly coated after thermal shrinkage, and if the film is made into a through bag of which two ends are open to be subjected to thermal shrinkage, the articles can be lifted at the two opening ends, the weight of 15KG can be borne, and the articles are convenient to carry; (3) the transparency is excellent, the light transmittance is 80 percent, products can be displayed and can be promoted invisibly, and a delivery error during the cargo movement link is reduced; (4) the film is moisture-proof, waterproof and dustproof, a packaging effect can be achieved, attractive appearance of the products can be realized, and the products are protected; (5) the PVC wrapping film is non-toxic, tasteless and pollution-free and belongs to an environment-friendly packaging material.

Owner:郭良来

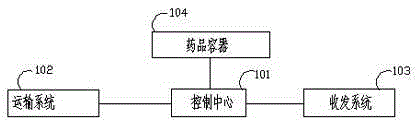

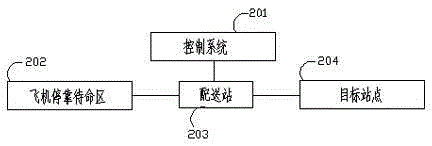

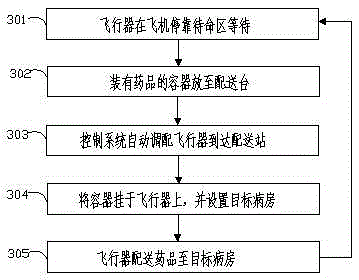

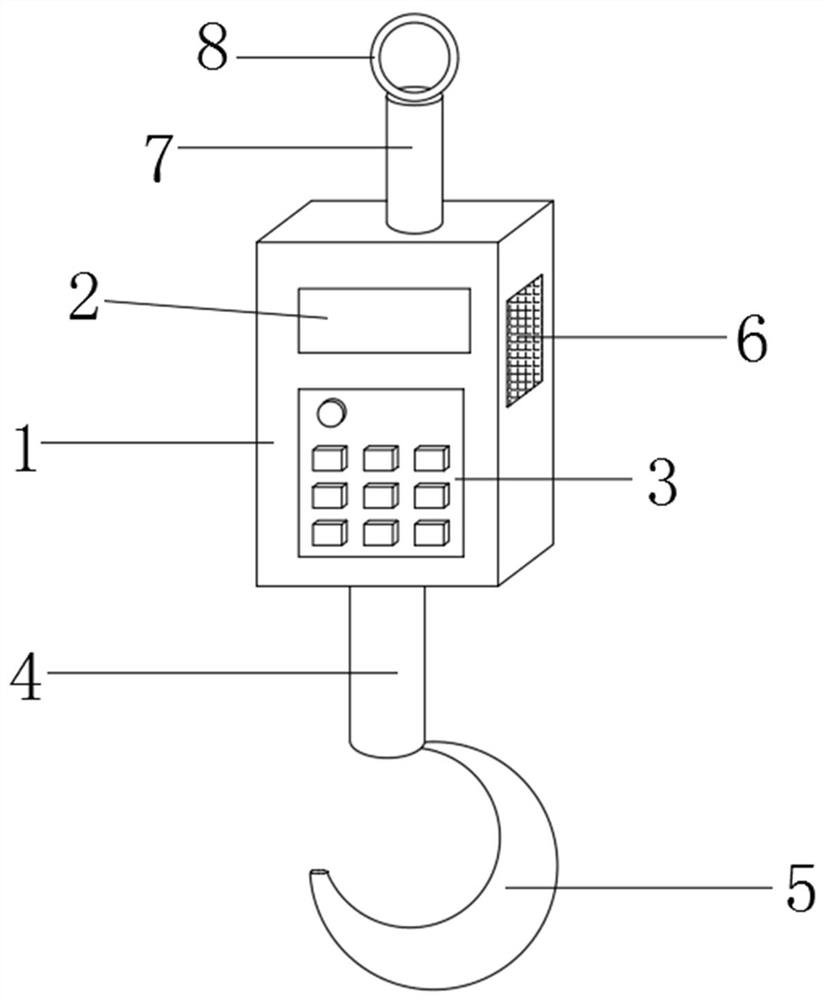

Automatic drug and to-be-inspected sample delivery system and delivery method for hospital

InactiveCN105404765ASolve the problem of delivery difficultiesSolve the time-consuming and laborious problem of manual deliveryComputer-assisted medicine prescription/deliverySpecial data processing applicationsTransport systemControl system

The invention discloses an automatic drug and to-be-inspected sample delivery system for a hospital. The system comprises a control center, a transport system, a receiving and sending system and a drug container, wherein the control center is connected with the transport system and the receiving and sending system; and the transport system adopts an aircraft for transportation. The invention furthermore discloses an automatic drug and to-be-inspected sample delivery method for the hospital. The method comprises the concrete steps that the aircraft at leisure waits in a holding apron of aircraft parking; drugs or to-be-inspected samples are put into the drug container and the drug container is put on a delivery table; the aircraft flies to the delivery table, the drug container is hung to the aircraft, and at the moment, a control system sets a target site; the aircraft delivers the drugs or the to-be-inspected samples to the target site; and the aircraft returns to the holding apron of aircraft parking for waiting. According to the delivery system and method, the drugs are delivered by using unmanned aerial vehicles, so that the problem of time and labor waste due to manual delivery is solved firstly and the construction is simple; and multi-thread parallel operation can be performed, so that compared with labor or vacuum tubes, a plurality of unmanned aerial vehicles not only are quick in delivery but also can perform coordinative operation.

Owner:湖南格尔智慧科技有限公司

Intelligent medical mobile nursing system

InactiveCN106651706AAccurate recordReal-time recordingData processing applicationsDrug dispensingMedical advice

The invention relates to a nursing system and especially relates to an intelligent medical mobile nursing system. By use of a patient identification system based on a radio frequency identification technology and a bar code identification technology, when a nurse operates for a patient at his bedside, double-code check is performed on the wristband of the patient and a medicine label by use of a PDA. The execution accuracy of doctor's advice is greatly improved, it is ensured that correct medical advice is performed on a correct patient in correct time, and medical mistakes and accidents caused by confirmation faults of patient identity are effectively avoided. Through combination with an automatic drug dispensing machine and an admixture service center, tracking and monitoring of the doctor's advice in a whole process is realized, actual execution time and executors of each link of the doctor's advice and transfusion are accurately recorded, and the execution process of the doctor's advice is traceable. According to the invention, space is expanded for technological progress in such a field, and the implementation effect is good.

Owner:苏州智康信息科技股份有限公司

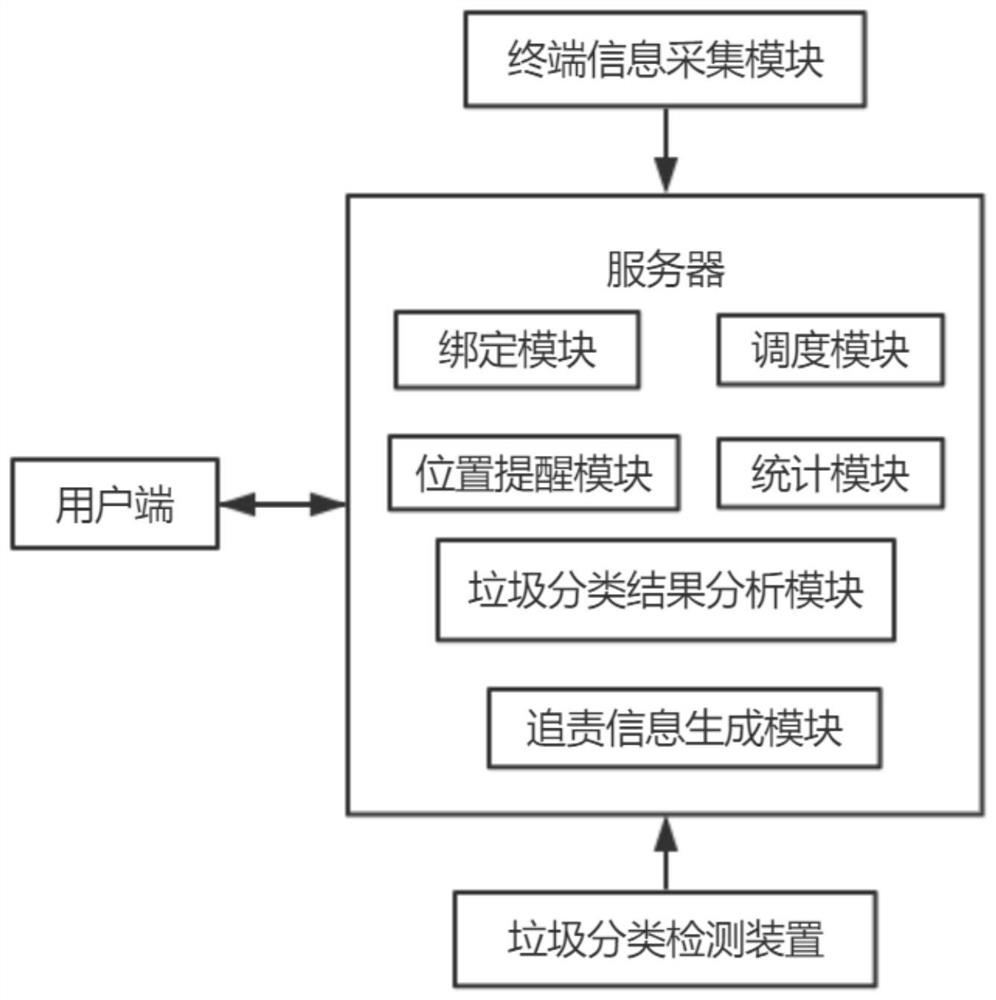

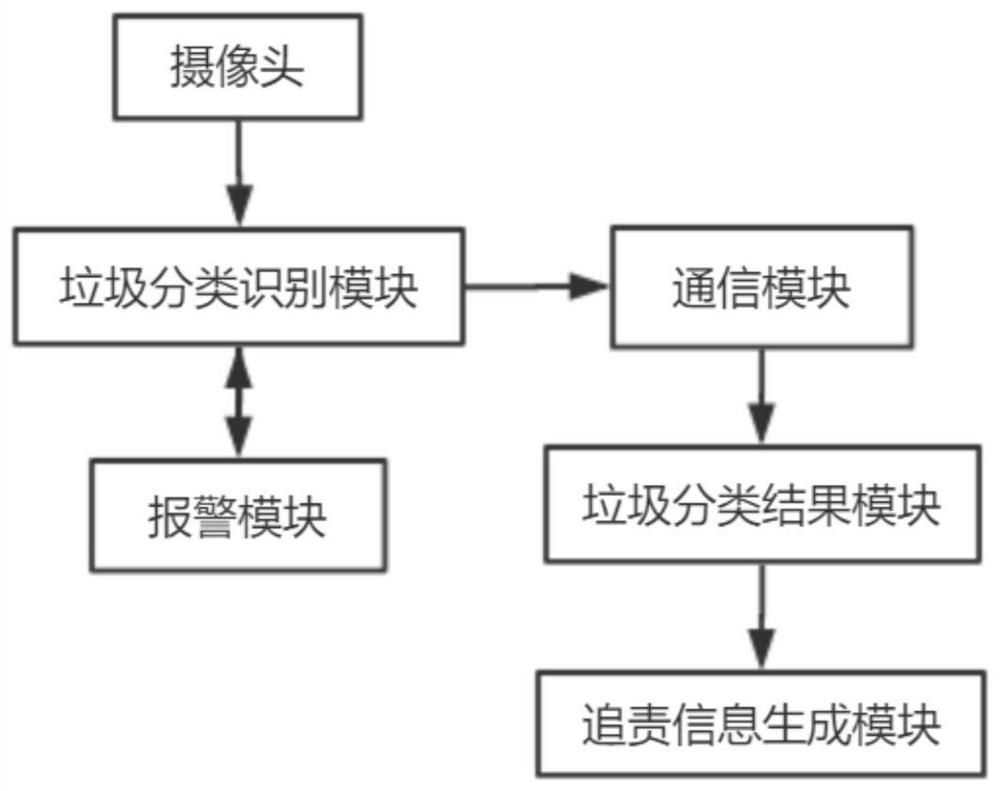

Urban waste classification treatment supervising system

InactiveCN111731702AReduce workloadTo achieve accountabilityWaste collection and transferRefuse receptaclesRefuse collectionWaste treatment

The invention relates to the technical field of waste treatment and in particular discloses an urban waste classified treatment supervising system. The urban waste classification treatment supervisingsystem comprises a user terminal, a binding module, a waste collecting device, a waste classification detection device, a waste classification result analyzing module and a responsibility claiming information generation module, wherein the user terminal is used for sending a waste classification request to a server; the binding module is used for binding received user basic information and the distributed waste collecting device together and generating RFID label information; the waste collecting device is provided with an RFID label carrying the RFID label information; the waste classification detection device is used for monitoring waste in the waste collecting device when recycling the waste to obtain monitoring information; the waste classification result analyzing module is used foranalyzing the monitoring information and judging whether a waste classification result is corrected or not, and sending incorrect waste classification result information to the responsibility claiminginformation generation module if the waste classification result is incorrect; and the responsibility claiming information generation module is used for generating responsibility claiming informationaccording to result information and sending the responsibility claiming information to the user terminal. By adopting the technical scheme, the workload of a cleaning worker can be reduced, and responsibility of a resident who classifies waste incorrectly can be traced.

Owner:滨南城市环境服务集团有限公司

High-speed filling machine

ActiveCN113307208ARealize online cleaning and sterilization functionReduce process gap timeSafety device in filling machineryLiquid storage tankElectric machinery

The invention relates to a high-speed filling machine. The high-speed filling machine comprises a workbench and a filling machine body arranged on the workbench. The filling machine body comprises a liquid storage tank, a filling assembly arranged on a liquid outlet of the liquid storage tank, and a control host. The filling assembly comprises a multi-pass rotating connector arranged at the liquid outlet, filling pipes connected to the multi-pass rotating connector, filling needles arranged on the filling pipes, a filling control valve, a filling rotary disc assembly arranged below the filling needles and used for bottle body transferring, a rotating support arranged between the filling rotating disc assembly and the multi-pass rotating connector, and a driving motor driving the rotating support to rotate. The filling rotating disc assembly is provided with filling stations which are distributed in an annular array mode, the filling pipes and the filling stations are arranged in a one-to-one correspondence mode, and the filling needles are located over the filling stations. Filling photoelectric sensing assemblies corresponding to the filling stations are arranged on the rotating support and connected with the data end of the control host, and the filling control valve and the driving motor are controlled by the control host. The high-speed filling machine has the effect of improving the continuity of the high-speed filling production.

Owner:上海拓达机电设备有限公司

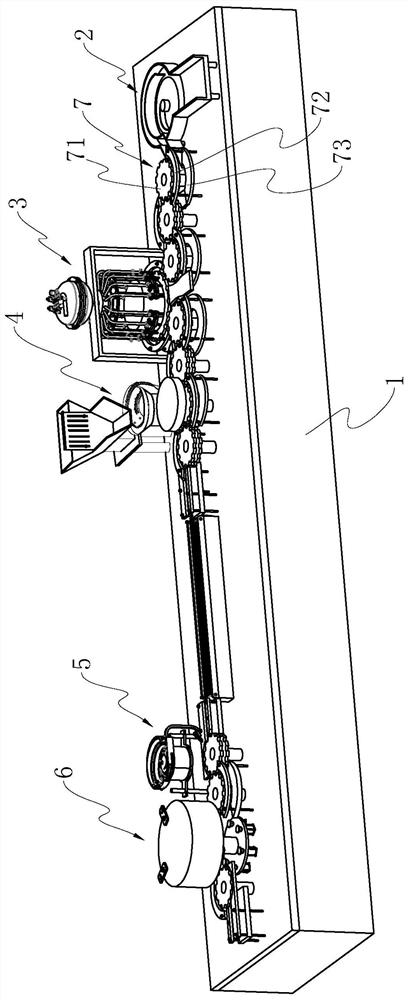

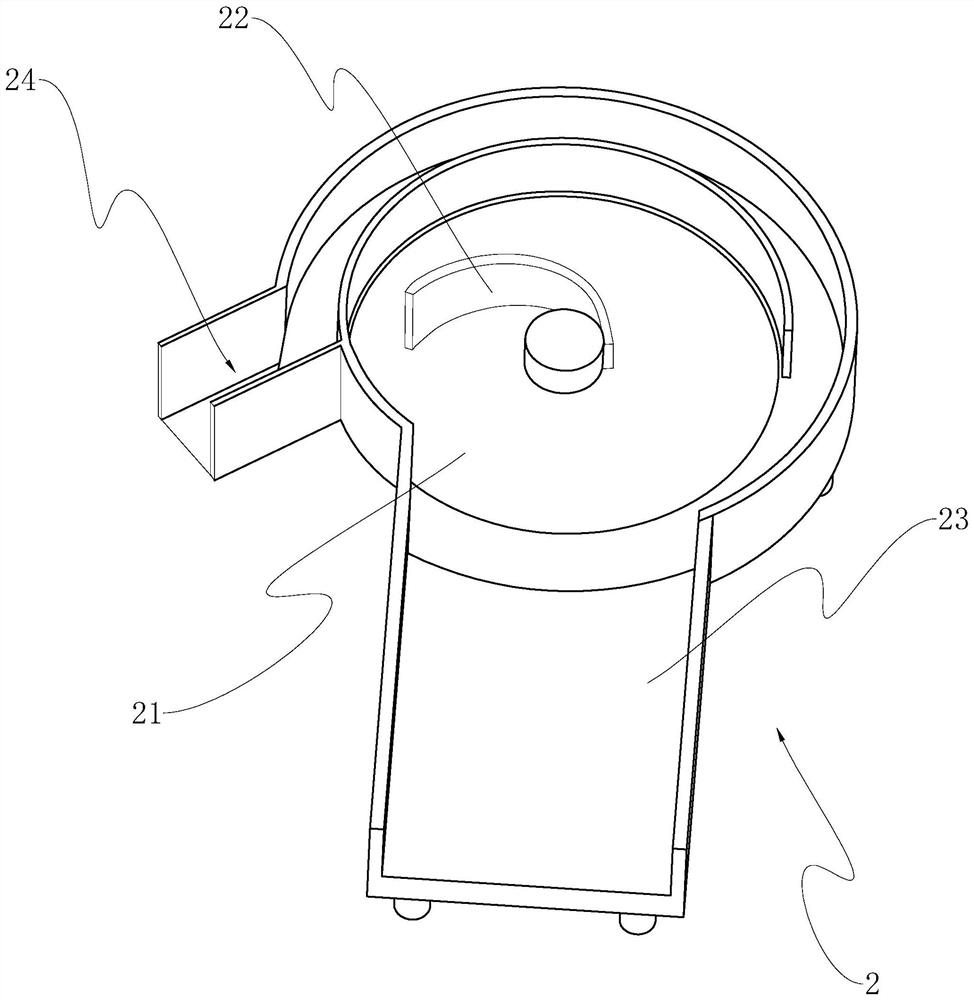

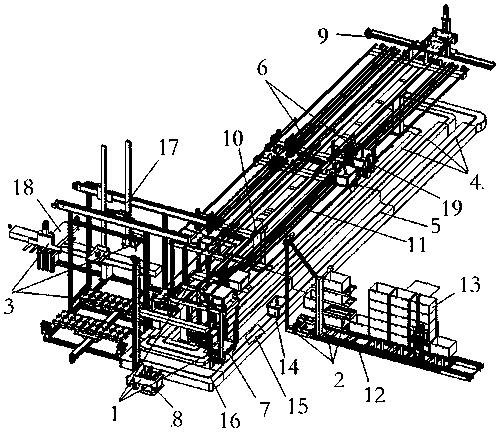

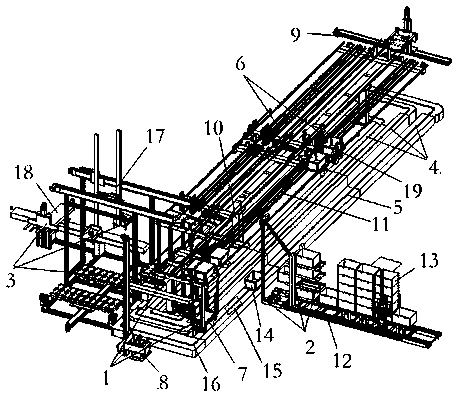

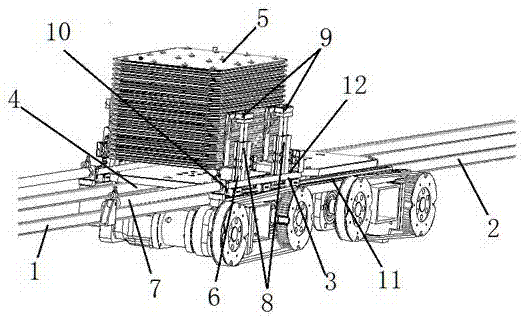

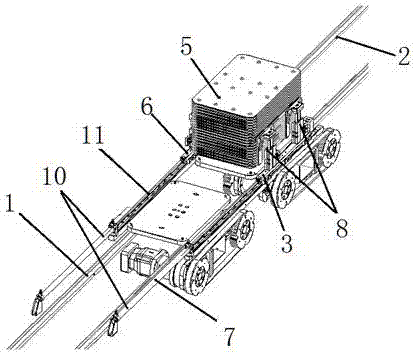

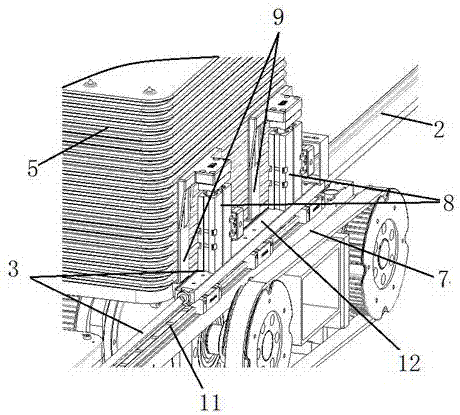

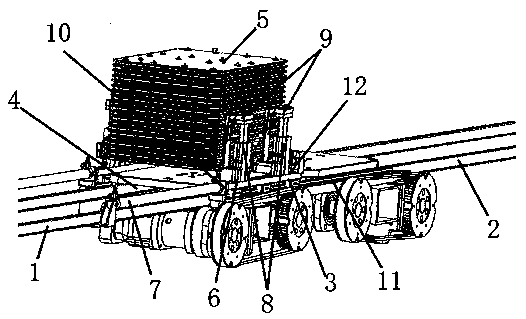

Material intelligent distribution and conveying line synchronous belt conveying method and device

InactiveCN107954141ASolving the challenges of smart distribution operationsReduce delivery errorsStorage devicesProduction lineDistribution system

The invention discloses a material intelligent distribution and conveying line synchronous belt conveying method and device. The method comprises the following steps that material intelligent distribution boxes are sent to the intelligent line production lines for stacking according to the size classification, and are sent to a material intelligent distribution box storage system for storage through a material intelligent distribution box conveying system, then the material intelligent distribution boxes are needed to perform automatically selecting and dividing according to needs by the material intelligent distribution box distribution system, and the separated material intelligent distribution boxes fall on a material intelligent distribution conveying line production line, and materialdistribution and loading operations are carried out through the material intelligent distribution and conveying line production line. The material intelligent distribution and conveying line synchronous belt conveying method and device are characterized in that the material intelligent distribution and conveying line production line is a multi-synchronous-belt operation line, and the material intelligent distribution and conveying line production line is divided into multiple operation lines on the horizontal plane, and each operation line corresponds to a material intelligent distribution box so as to meet the requirements of goods distribution of different materials.

Owner:LILING LVYUAN COMML & TRADING CO LTD

Intelligent material allocation and binning U-shaped assembly line operation method and device

ActiveCN107902310AReduce errorsFast Wholesale and DistributionPackaging automatic controlStacking articlesAssembly lineEngineering

The invention relates to an intelligent material allocation and binning U-shaped assembly line operation method and device. Bulk materials are contained into a storing container in a classified manneraccording to the object properties and sizes, and meanwhile, cargo delivering frames are classified and fed to an annular or U-shaped intelligent assembly operation line to be stacked; when allocation and binning are carried out, the cargo delivering frames are selected from the cargo delivering frame stacking position through the annular or U-shaped intelligent assembly operation line accordingto the logistics information, frame dividing is carried out, the divided cargo delivering frames are placed on a conveying device of the annular or U-shaped intelligent assembly operation line, and multi-station movement is carried out; cargoes needed by the cargo delivering frames are taken out from the storing container when movement is carried out by one station and are placed into specific cargo delivering frames of the annular or U-shaped intelligent assembly operation line, after all the cargoes of the cargo delivering frames are loaded, a mechanical arm is used for orderly stacking thecargo delivering frames to a tray according to cargo delivering information, then loading is carried out through a loading device, and the whole cargo allocation, binning and loading operation is completed.

Owner:LILING LVYUAN COMML & TRADING CO LTD

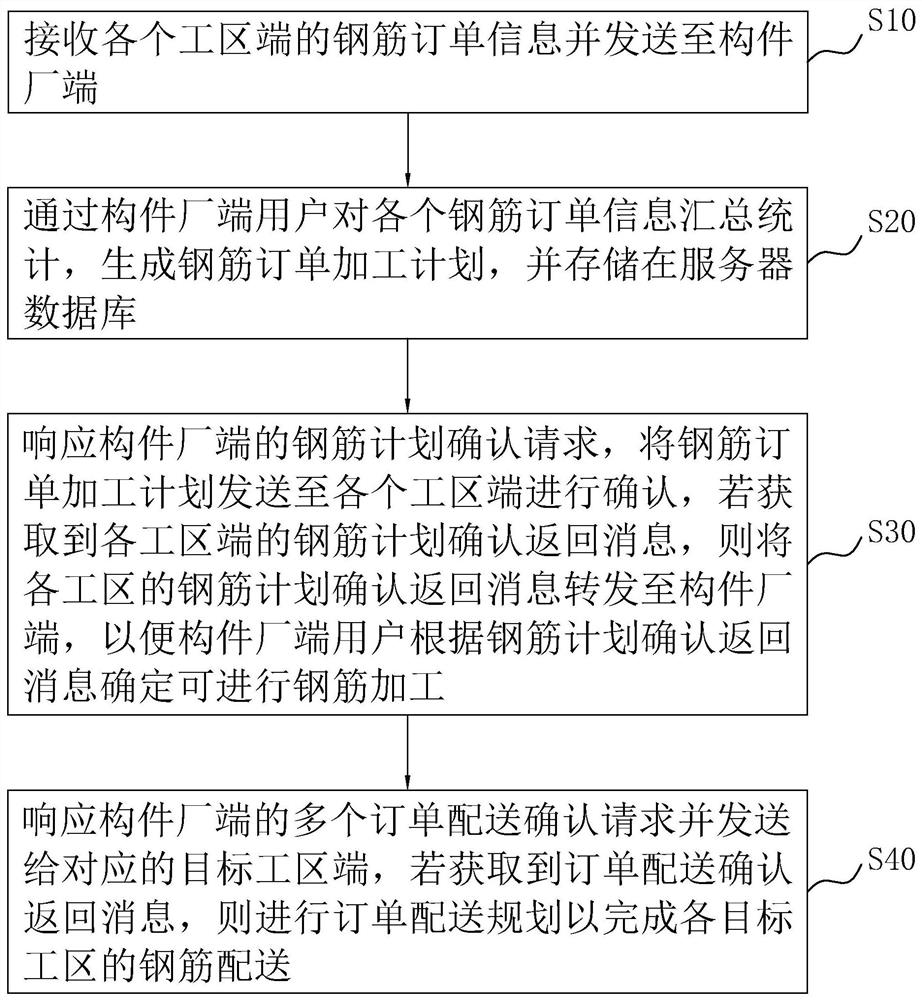

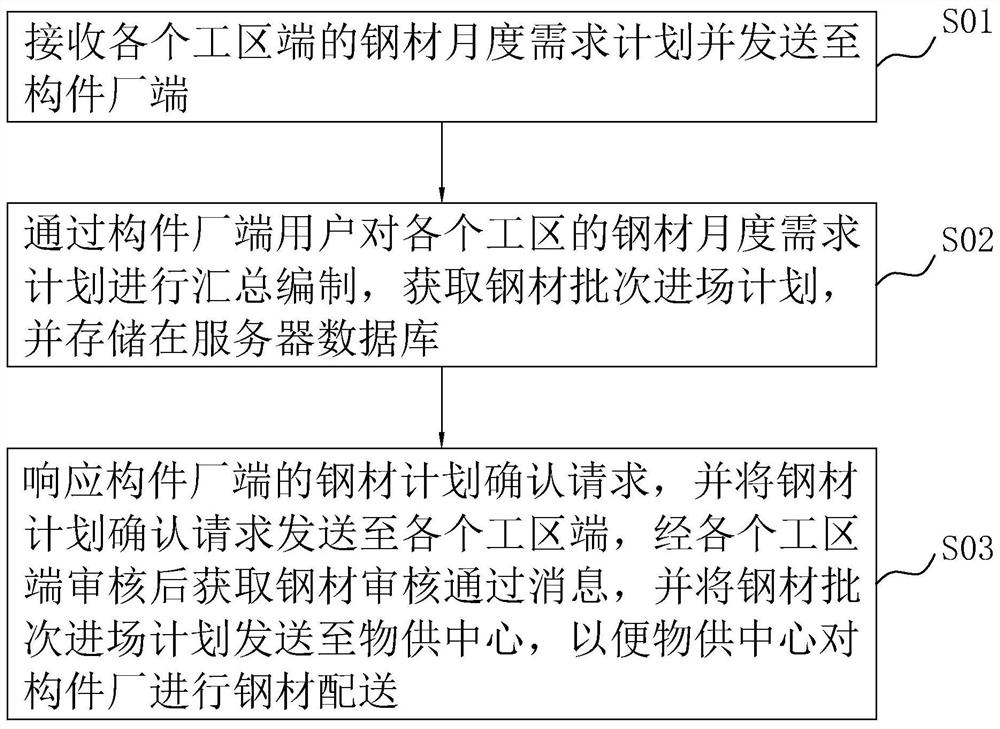

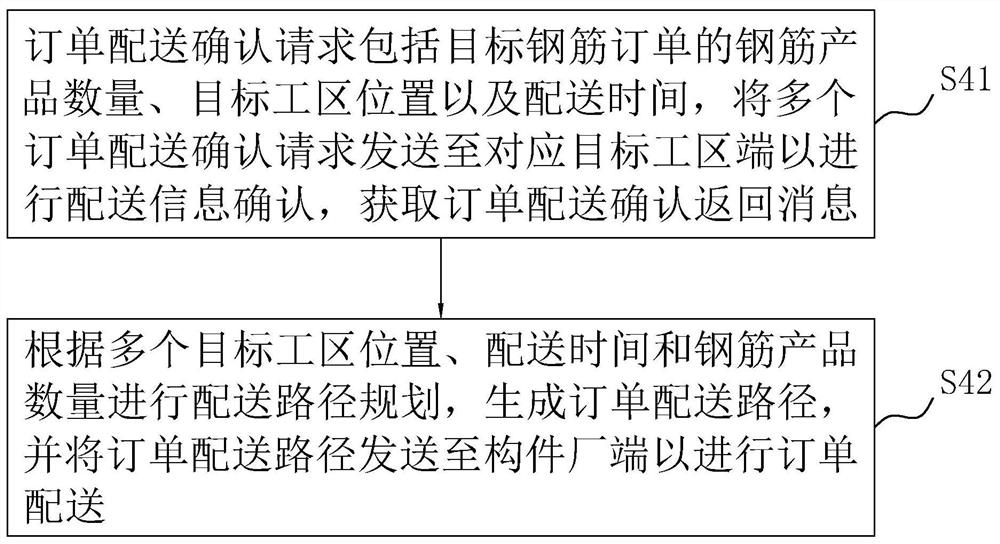

Reinforcing steel bar centralized processing and distribution method, system and device and medium

ActiveCN112288357AImprove scheduling abilityImprove inventory capacityOffice automationResourcesDistribution methodOrder processing

The invention relates to a reinforcing steel bar centralized processing and distribution method, system and device and a medium. The method comprises the steps: receiving steel bar order information of all work area ends and sending the same to a component factory end; summarizing and counting the rebar order information through a component factory end user to generate a rebar order processing plan; in response to the steel bar plan confirmation request of the component factory terminal, sending the steel bar order processing plan to each work area terminal for confirmation; if a steel bar plan confirmation return message of each work area terminal is obtained, forwarding the steel bar plan confirmation return message of each work area to the component factory terminal, wherein a componentfactory-side user determines that steel bar machining can be performed according to the steel bar plan confirmation return message; responding to a plurality of order delivery confirmation requests of the component factory side, sending the requests to the corresponding target work area sides; if an order delivery confirmation return message is obtained, carrying out order delivery planning to complete steel bar delivery of each target work area. Via the reinforcing steel bar centralized processing and distribution method, the machining efficiency and the machining quality of the steel bar component can be improved, and meanwhile the steel bar machining cost is reduced.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

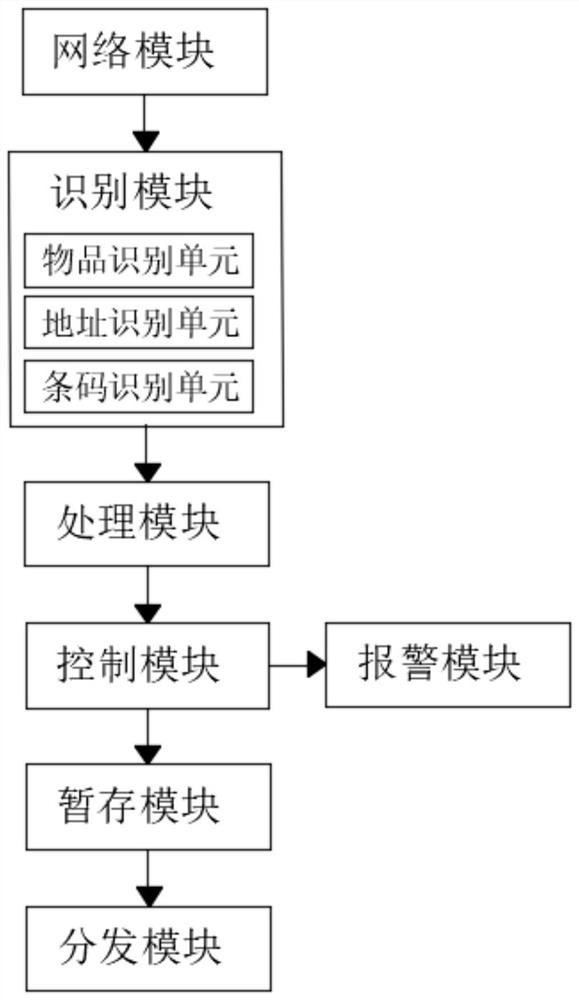

Hospital special article distribution robot checking system

PendingCN114626788AReduce delivery errorsImprove accuracyCo-operative working arrangementsLogisticsMedicineBarcode

The invention relates to the technical field of distribution robots, in particular to a hospital special article distribution robot checking system, which is characterized in that through cooperation of an identification module, a processing module and a control module, article appearance information is scanned and identified through an article identification unit; on the basis of article appearance information scanning, a bar code on an article is recognized through the bar code recognition unit, and then the scanned article appearance information and bar code information are transmitted to the central processing unit to be analyzed and processed, so that the robot can perform dual recognition and confirmation on the shape of the article and the bar code on the article; the address identification unit is used for identifying an address of an article needing to be distributed and scanning a to-be-stored address after the article is distributed, the identified distribution address and storage address information are transmitted to the central processing unit to be analyzed and checked, and the control module is used for controlling the distribution module to distribute the article after the identified distribution address and storage address information are consistent. And the delivery error of the robot is reduced.

Owner:昆山新正源机器人智能科技有限公司

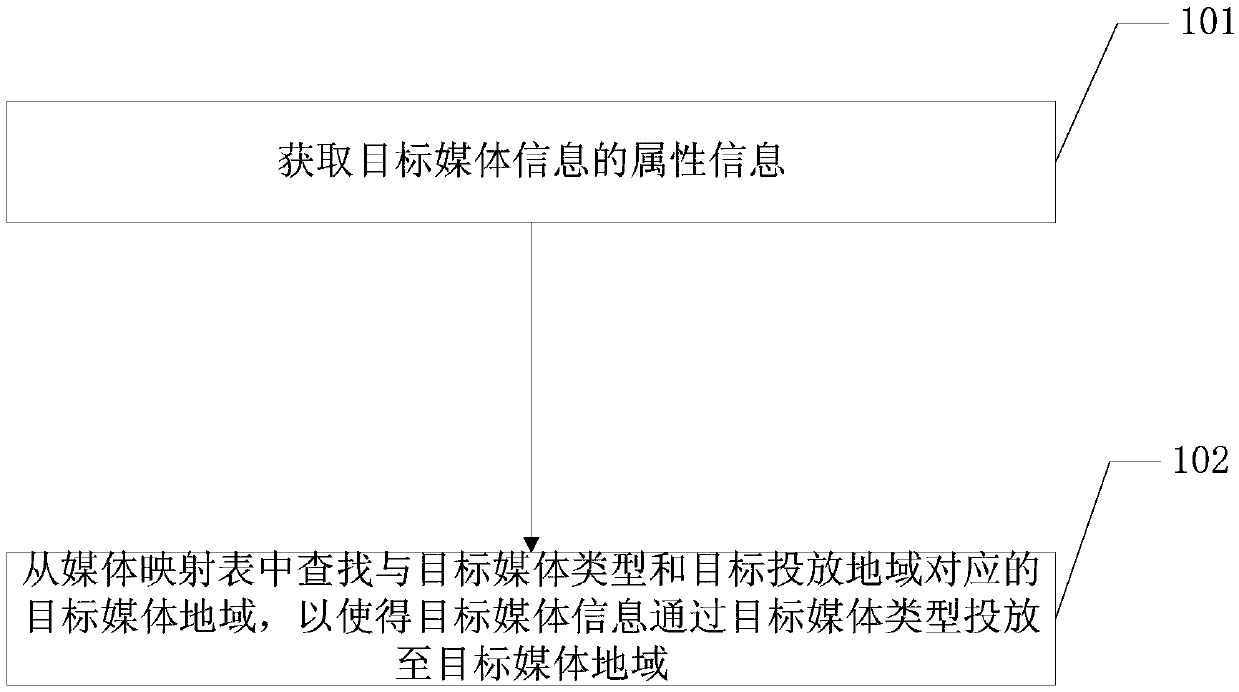

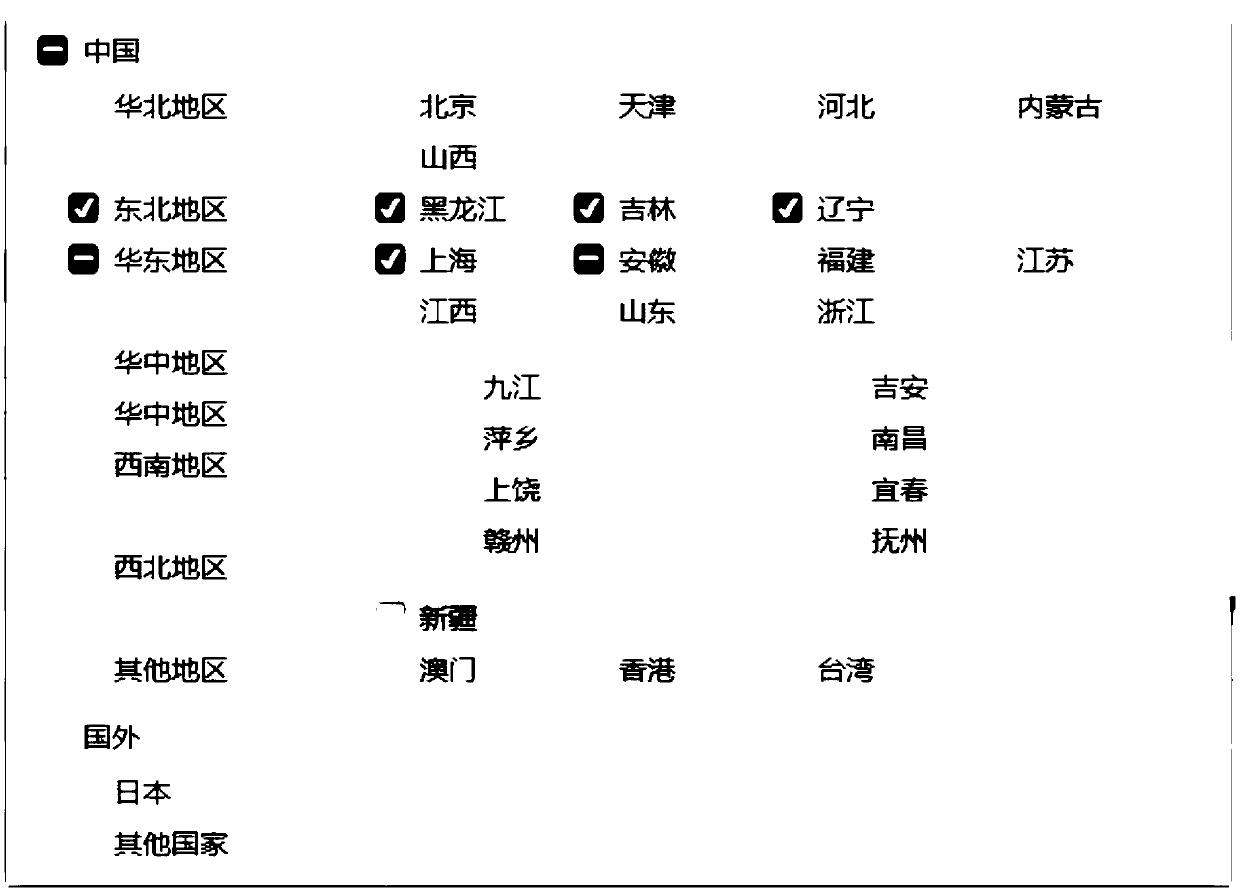

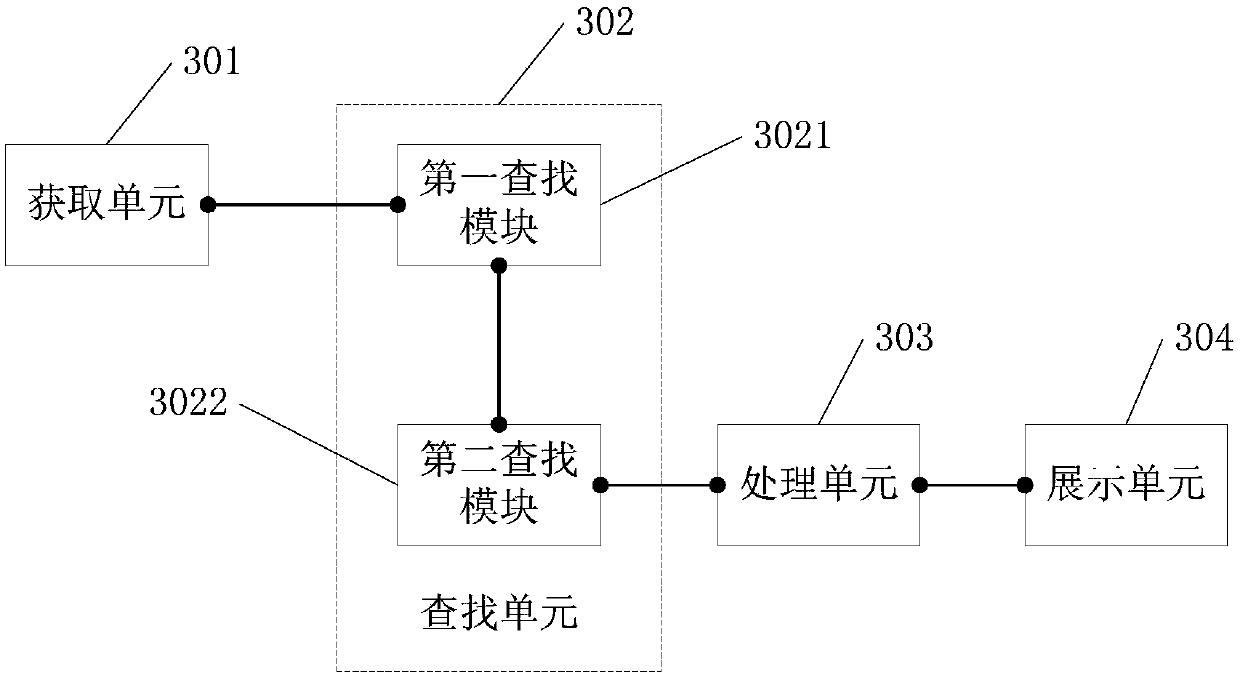

Media regional information determination method and related equipment

The embodiment of the invention provides a media regional information determination method and related equipment, which are used for reducing the workload and delivery error rate of media advertisement delivery personnel. The method comprises the steps of acquiring attribute information of target media information , wherein the target media information is media information is to be delivered, andthe attribute information of the target media information comprises a target media type and a target delivery region; and searching a target media region corresponding to the target media type and a target delivery region from a media mapping table to enable the target media information to be delivered to the target media region through the target media type, withthe media mapping table comprising a standard region, a media type and a mapping relationship between media regions.

Owner:BEIJING GRIDSUM TECH CO LTD

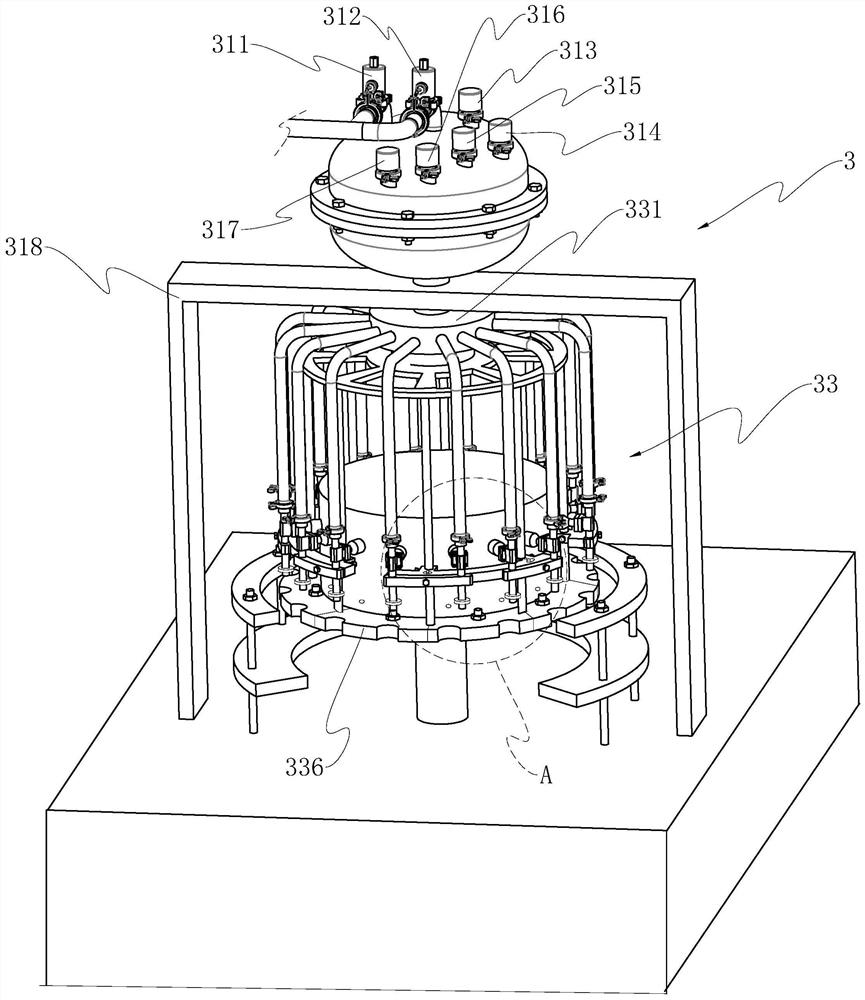

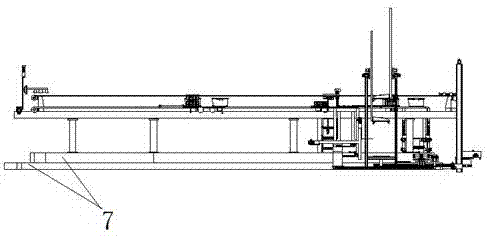

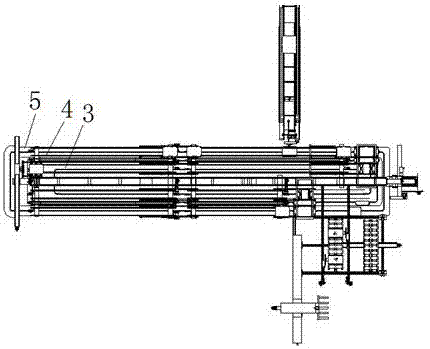

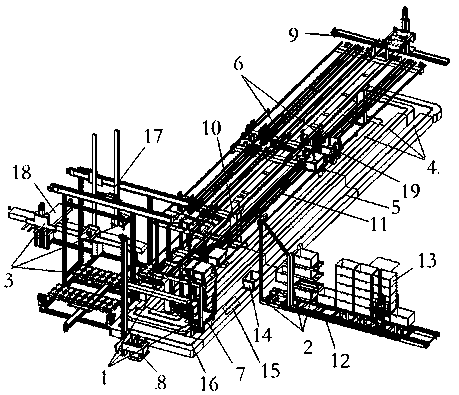

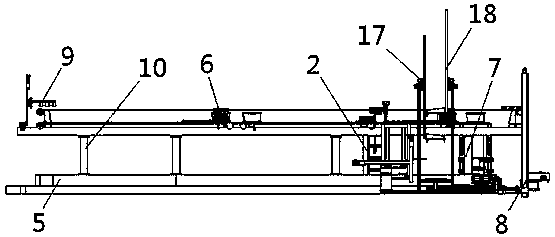

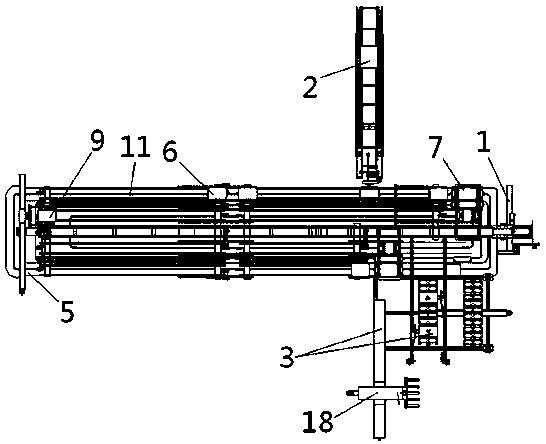

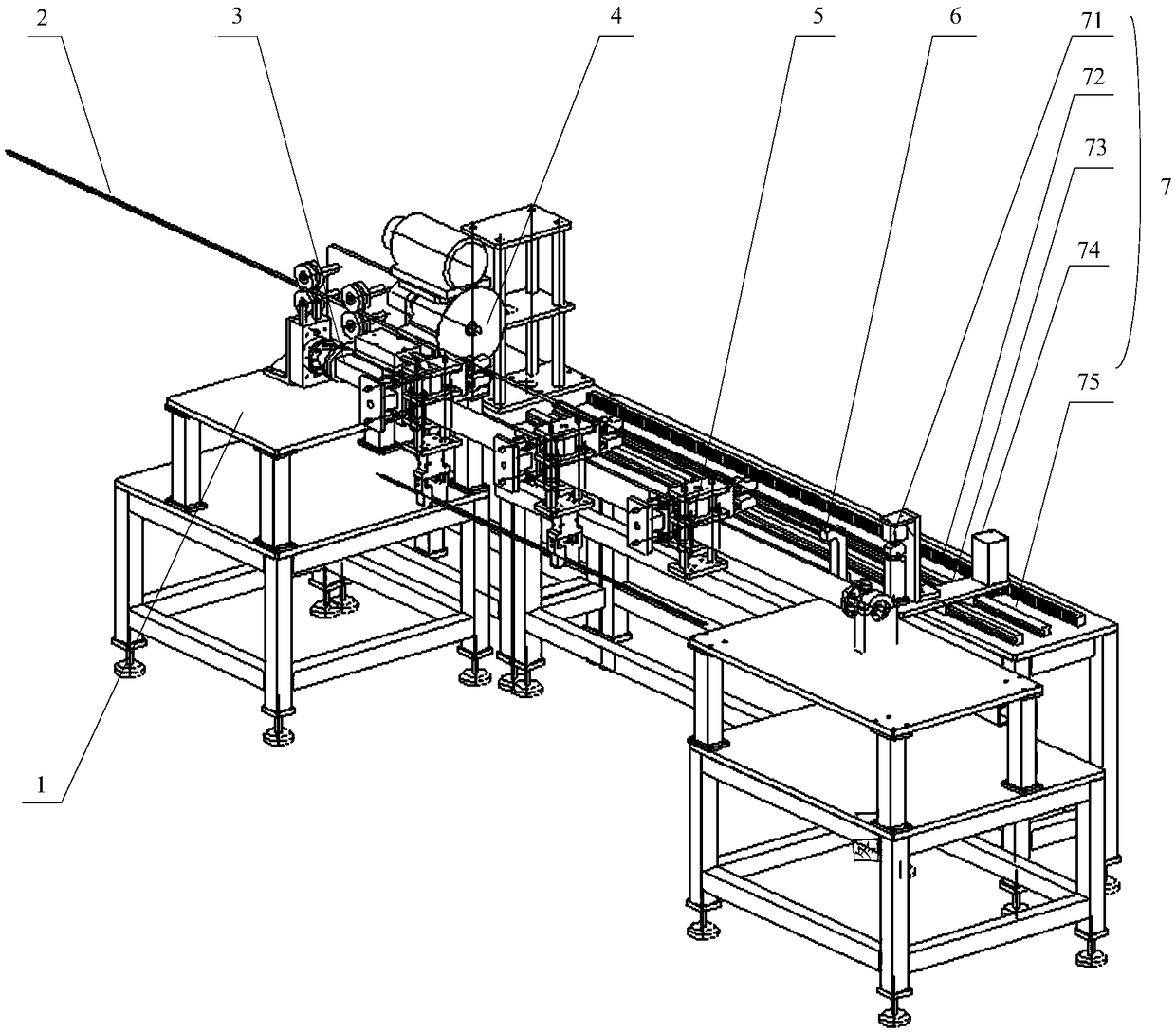

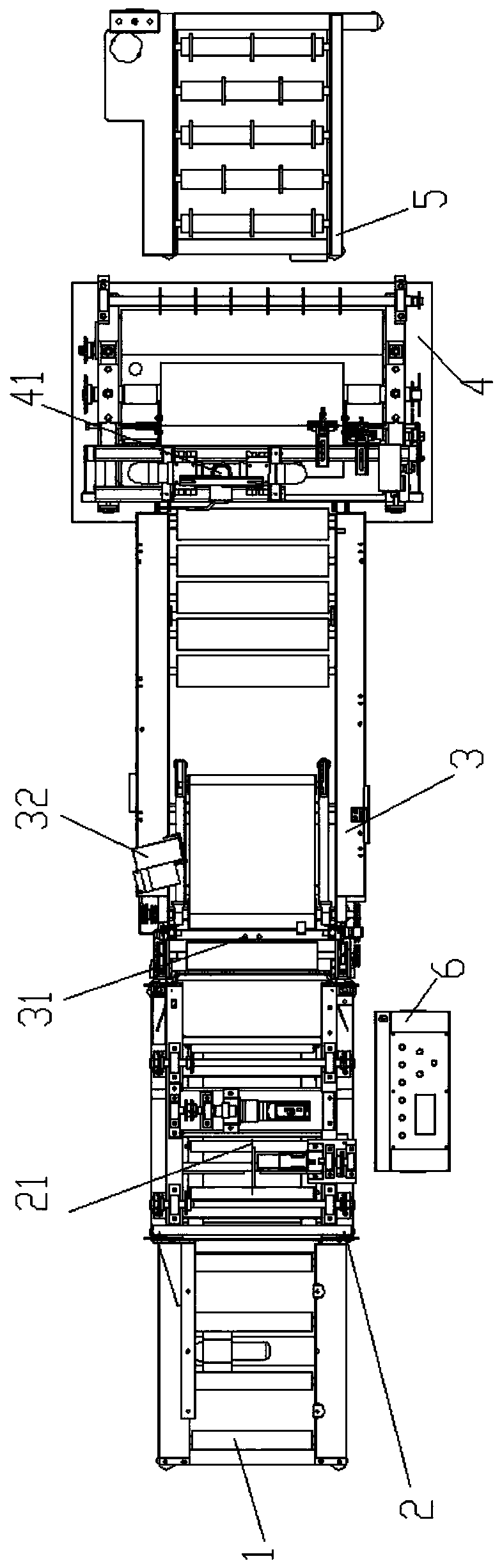

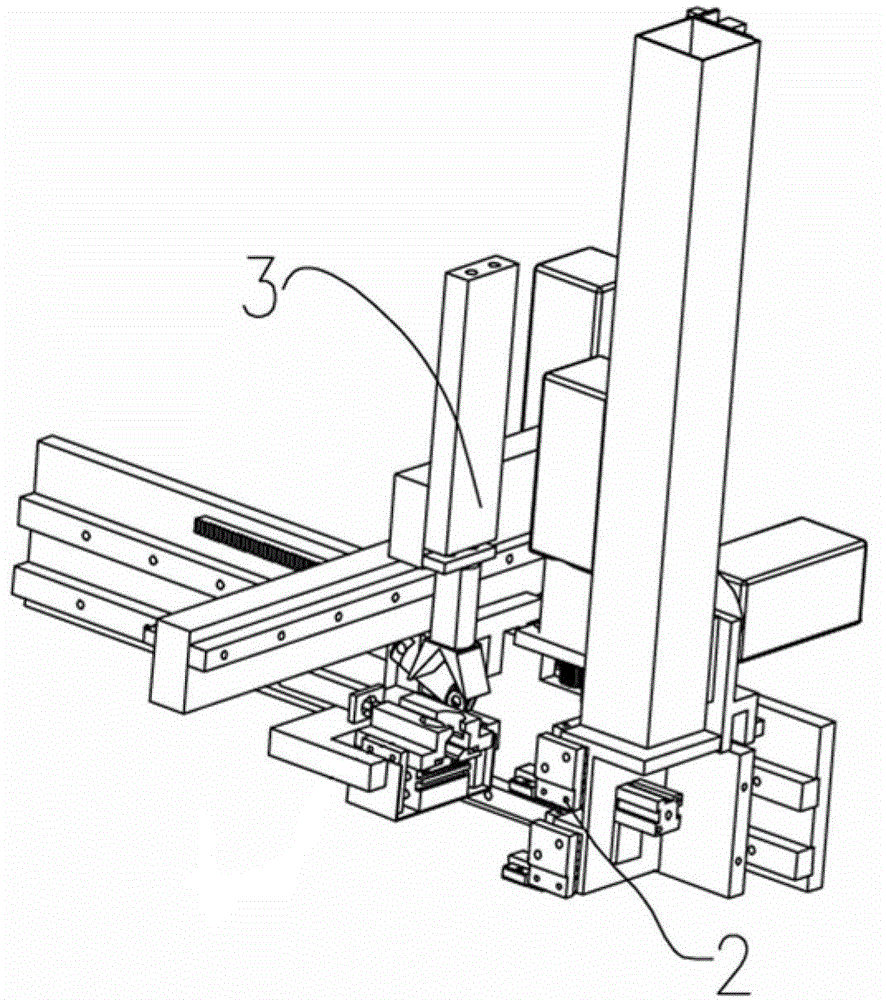

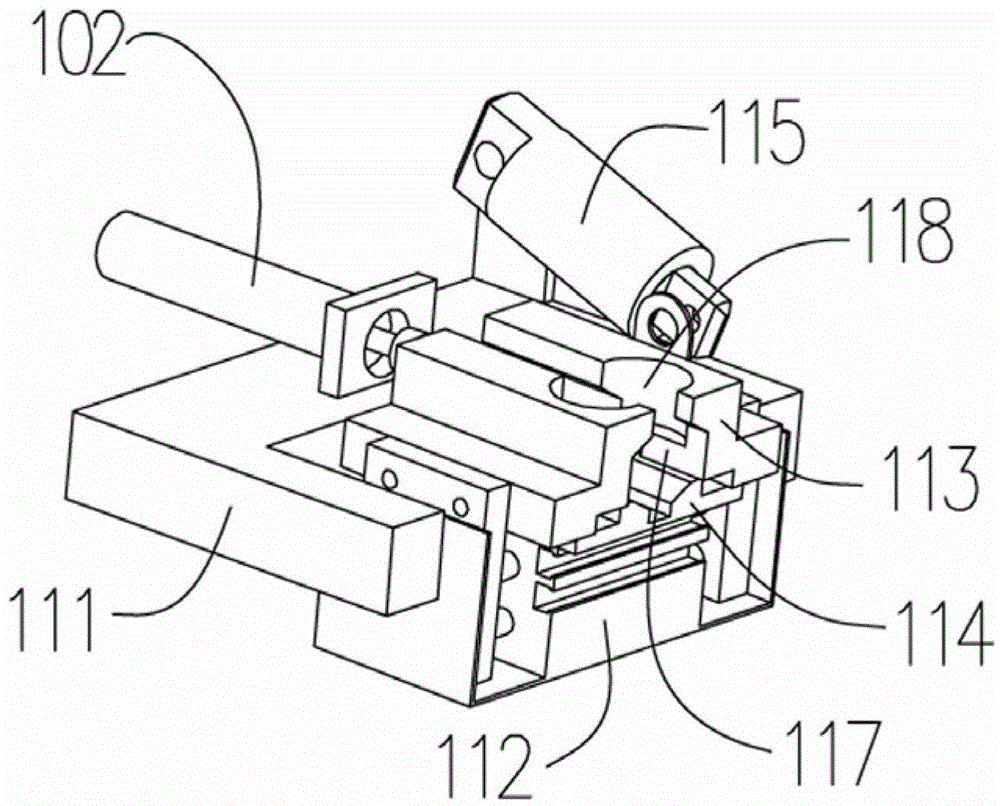

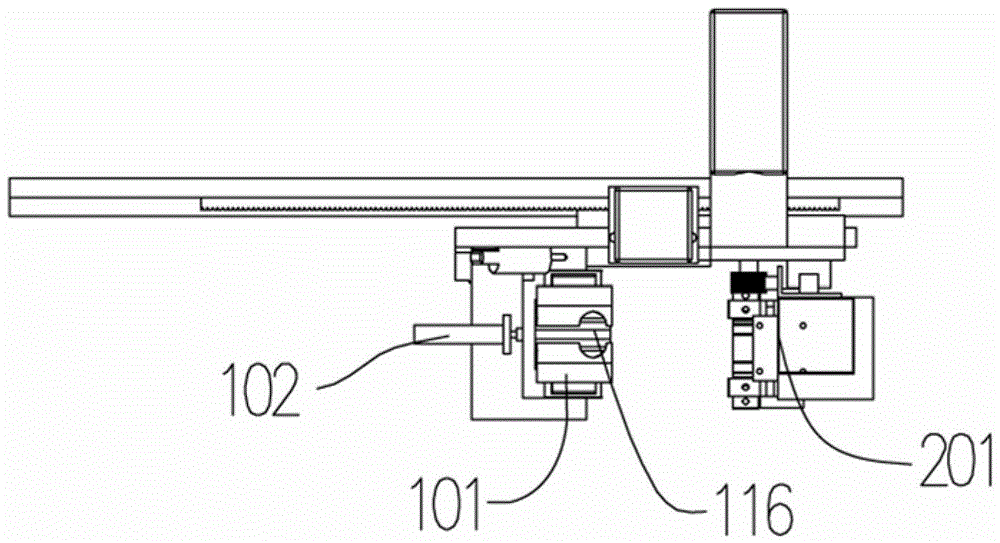

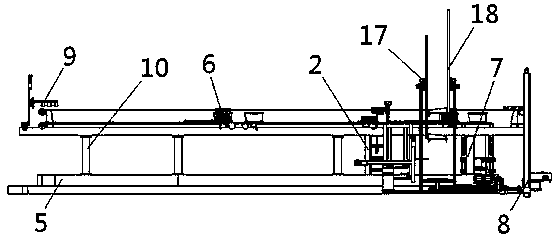

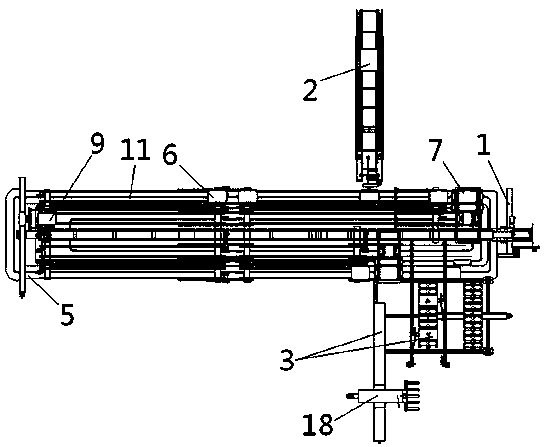

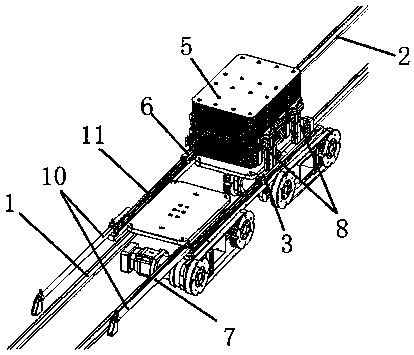

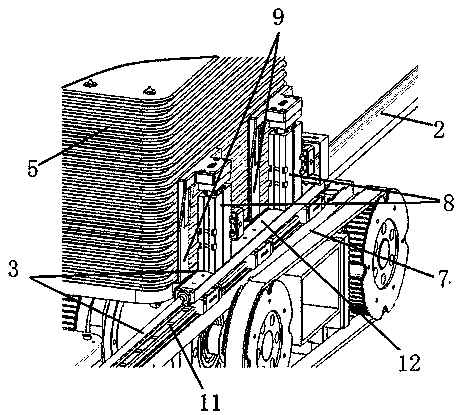

Pulling cable protective casing discharging device

PendingCN109079898AImprove cutting accuracyGuarantee product qualityMetal working apparatusEngineeringMechanical engineering

The invention provides a pulling cable protective casing discharging device. The pulling cable protective casing discharging device includes a worktable (1), a cutting unit (4), a conveying unit (7) and a supplying unit (3), wherein the cutting unit (4) is arranged on the worktable (1) for cutting a pulling cable protective casing raw material (2), the conveying unit (7) is arranged on the worktable (1) for grabbing and conveying the feeding end of the pulling cable protective casing raw material (2), the conveying unit (7) can convey the feeding end of the pulling cable protective casing rawmaterial (2) to a preset position for positioning, and the supplying unit (3) is arranged on the worktable (1) for conveying the feeding end of the pulling cable protective casing raw material (2) tothe conveying unit (7). According to the pulling cable protective casing discharging device, conveying errors are effectively lowered, the cutting precision is improved, the product quality of a pulling cable protective casing is ensured, operation of selecting the pulling cable protective casing after cutting is avoided, and the production efficiency is improved.

Owner:LIUZHOU WULING MOTORS +1

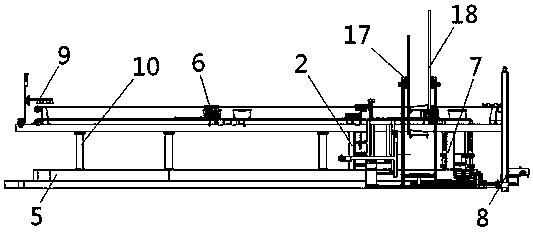

Intelligent material cargo allocation and boxing line production method and system

ActiveCN107826789AReduce errorsFast Wholesale and DistributionStorage devicesPackaging machinesTruckManipulator

The invention discloses an intelligent material cargo allocation and boxing line production method and system. Bulk materials are stored in a storage container in a classified manner according to goods property and size, meanwhile, cargo delivery frames are conveyed to an intelligent flow production line to be stacked according to the size classifying, during cargo allocation and boxing, the intelligent flow production line carries out cargo delivery frame selecting according to logistics information, frame dividing is carried out, the divided cargo delivery frames are put on a flow productionline conveying device, and multi-station conveying is carried out; every time the cargo delivery frames are moved to one station, cargos needed by the cargo delivery frames are taken out of the storage container, and put in the designed cargo delivery frame on the flow production line, after the cargos of the cargo delivery frame are fully loaded, a mechanical arm orderly stacks the cargo delivery frames according to the cargo delivery information, truck loading is carried out through a truck loading device, the complete cargo allocation, boxing and truck loading work is finished, a deliveryman delivers distribution materials needed by a customer to the different user designated positions according to the material distribution information.

Owner:LILING LVYUAN COMML & TRADING CO LTD

Ordering system with mobile phone as carrier

InactiveCN103489142AEasy to recordReduce delivery errorsData processing applicationsCo-operative working arrangementsEmbedded systemMobile phone

The invention relates to the technical field of systems for ordering, in particular to an ordering system with a mobile phone as the carrier. The ordering system is easy to operate and meal delivery errors are reduced. The ordering system comprises an operation module, an ordering menu and a working table, wherein the operation module and the ordering menu are installed in the mobile phone, and the working table is located in a restaurant; the operation module comprises a two-dimensional code scanning selection module, an account processing module, an editing module and a first transmission module; the working table comprises a first display module, a first receiving module and a processing module; a plurality of dishes names are arranged on the ordering menu, and dishes price information and a two-dimensional information scanning module are arranged below each dishes name.

Owner:ZHANGJIAGANG QIFEI SOFTWARE SCI & TECH

Wafer batch dispatching method and system under machine group based on real-time dispatching system

ActiveCN104977903BIncrease productivityAvoid the situation where the same batch of wafers are ordered at the same timeTotal factory controlProgramme total factory controlEngineeringGroup based

Owner:SEMICON MFG INT (SHANGHAI) CORP

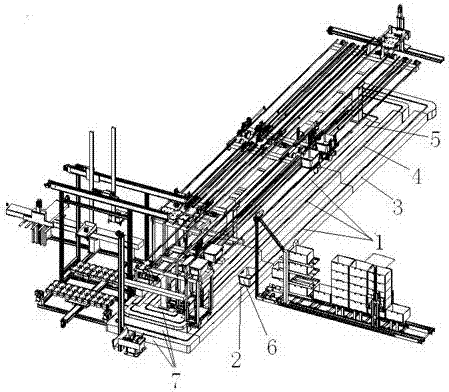

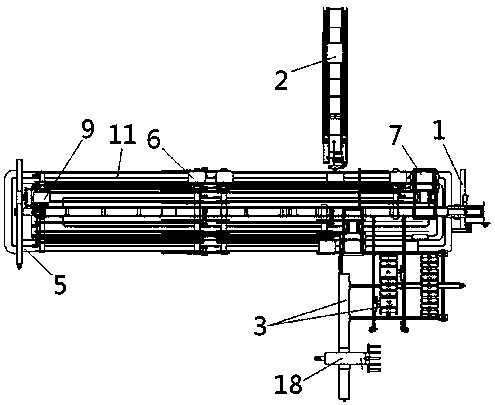

Equipment for automatically separating plywood veneers and screening and gluing single veneers

InactiveCN110722648AImprove delivery accuracyReduce delivery errorsLiquid surface applicatorsCoatingsMaterials preparationSingle plate

The invention discloses equipment for automatically separating plywood veneers and screening and gluing single veneers. A material preparation mechanism is connected and fixed to one end of a conveying mechanism, the other end of the conveying mechanism is fixedly connected with a screening mechanism, the conveying mechanism is correspondingly provided with a conveying platform, a scraper combination is arranged at the rear end of the conveying platform, the scraper combination is fixed on a conveying rack through screws, the screening mechanism is equipped with a number detection system and an impurity removal device, the gluing mechanism is fixed to the screening mechanism through connection, an automatic glue adding system is installed above the interior of the gluing mechanism, an electric control cabinet is arranged on the side edge of the conveying mechanism, and electric accessories and the electric control cabinet are correspondingly and electrically connected through a wire with an aviation plug. By means of the equipment, veneer main driving is more efficient, the scraper combination rotates intermittently, both main drive and main constraint are achieved. The conveying accuracy is improved. System delivery errors caused by excessive friction in older versions are reduced.

Owner:XIAMEN ZHONGSAI ELECTROMECHANICAL TECH

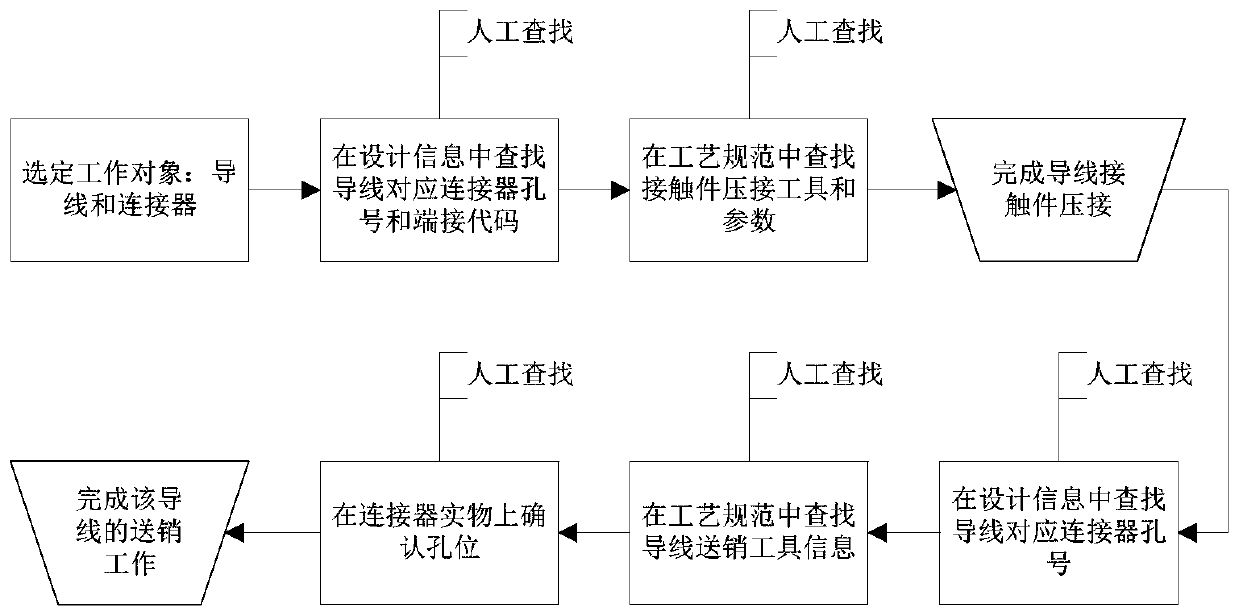

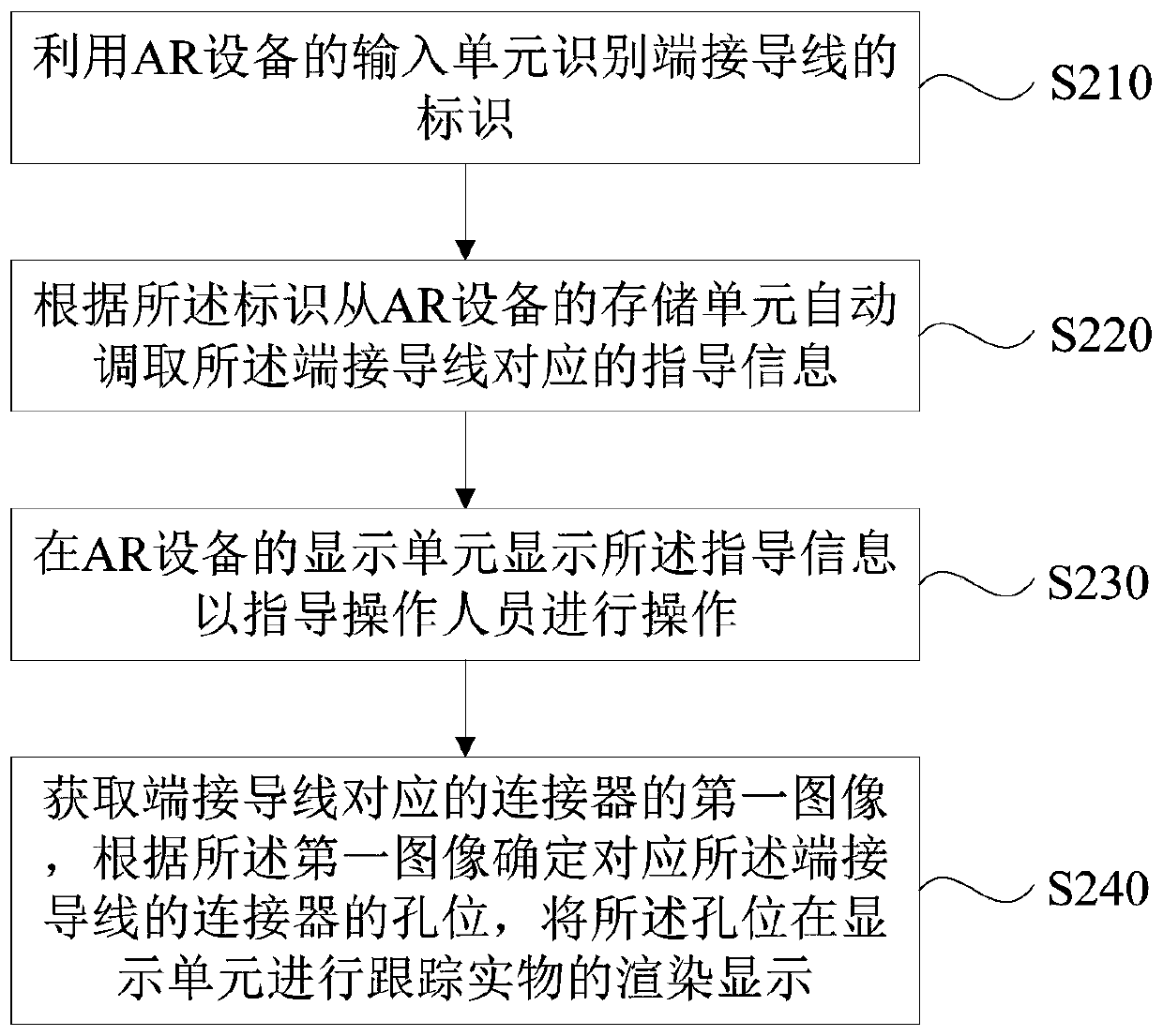

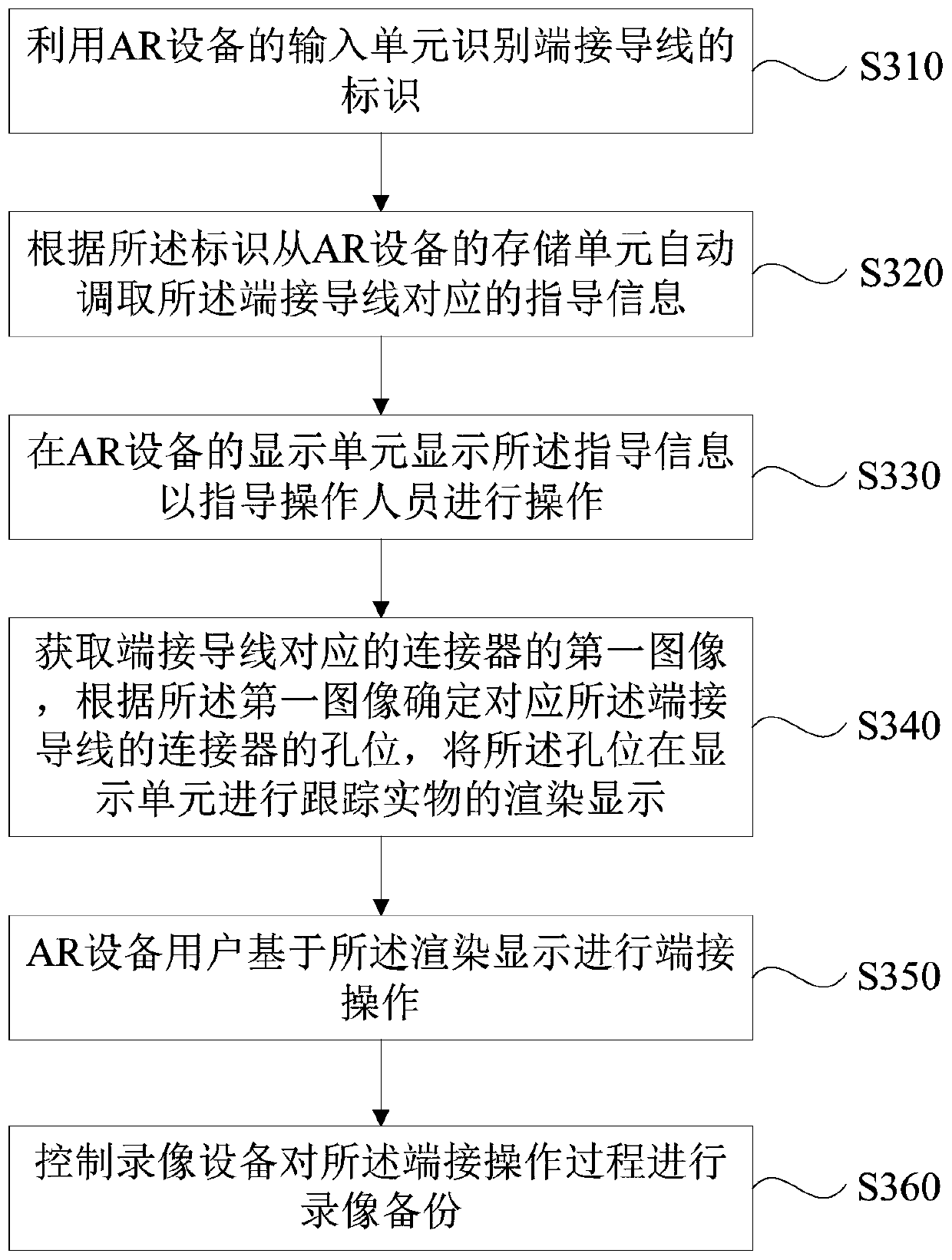

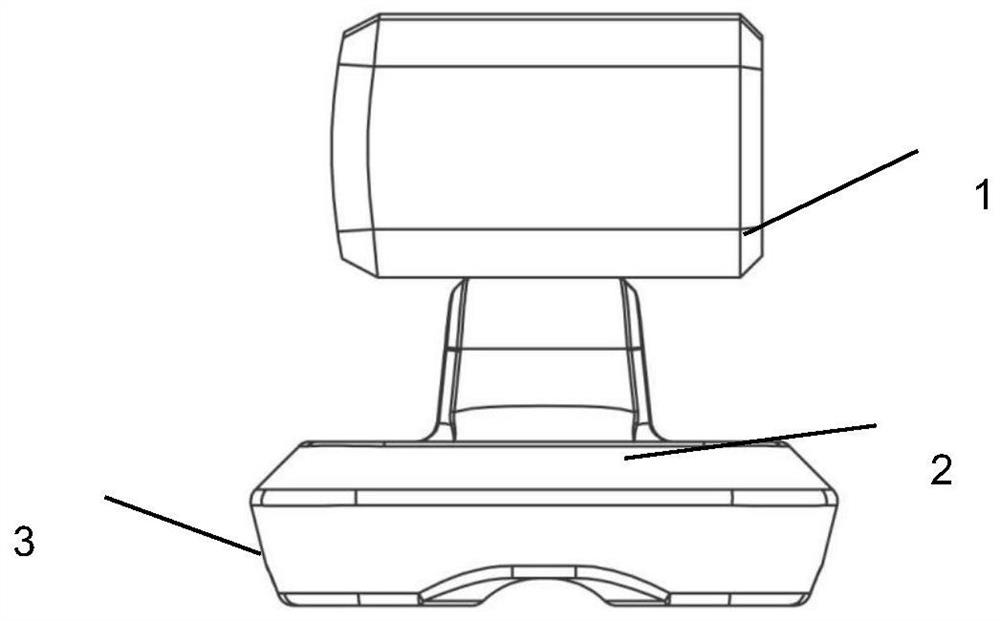

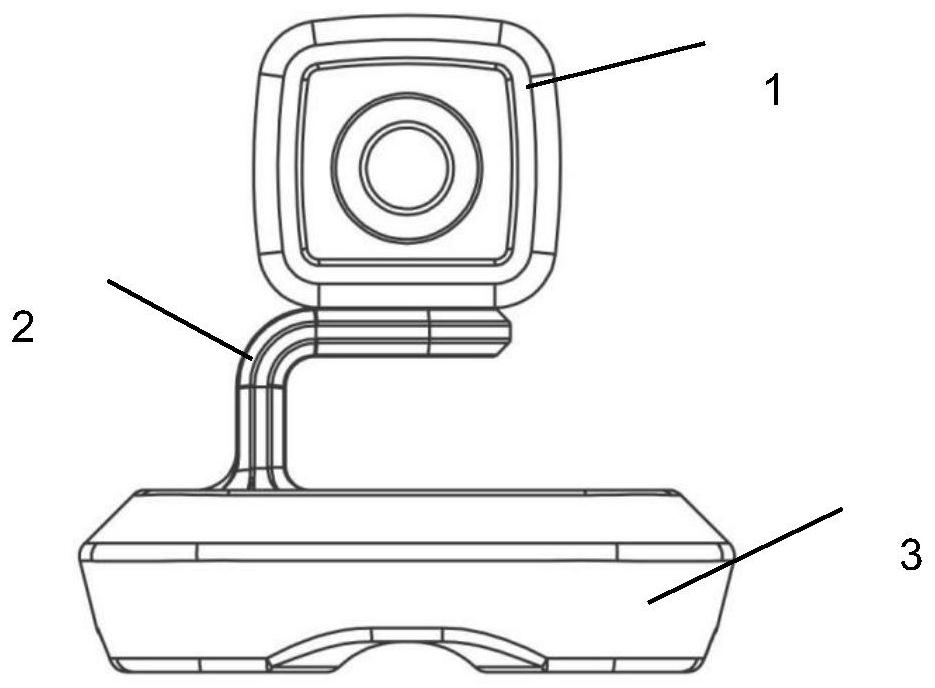

Connector pin sending method and device based on AR equipment, AR equipment and storage medium

PendingCN111273762AReduce delivery errorsReduced risk of errorInput/output for user-computer interactionData processing applicationsEmbedded systemStorage cell

The embodiment of the invention discloses a connector pin sending method and device based on AR equipment, the AR equipment and a storage medium. The method comprises the steps that an input unit of AR equipment is used for identifying an identifier of a terminating wire; calling guidance information corresponding to the terminating wire from a storage unit of AR equipment according to the identifier; displaying the guidance information on a display unit of the AR equipment so as to guide a user of the AR equipment to operate; and acquiring a first image of a connector corresponding to the terminating wire, determining a hole site of the connector corresponding to the terminating wire according to the first image, and rendering and displaying the hole site in a display unit for tracking areal object. According to the technical scheme provided by the embodiment of the invention, the AR equipment user is guided to operate by displaying the guidance information, so that the terminating and selling operation errors are reduced, and the error risk caused by manually searching the selling information is reduced.

Owner:SHANGHAI AIRCRAFT MFG

Logistics information collection terminal based on video identification

PendingCN113554367AReduce delivery errorsSave human effortCharacter and pattern recognitionDigital data authenticationCollection systemEngineering

The invention discloses a logistics information collection terminal based on video recognition, and belongs to the field of logistics delivery. A logistics information collection system comprises logistics information collection, face recognition and data management service. A logistics information acquisition terminal is used for recording a sent article, monitoring the trend of the article in real time and acquiring detailed information, including names, addresses, pictures and the like, of senders and addressees; and the information is sent to the mobile phone client through the data management service terminal to ensure that a sender inquires the express condition in real time, when the sender picks up the express, identity verification of the sender is completed by comparing face recognition of the sender with recipient information in a database, and distribution errors and low efficiency of manual verification are avoided.

Owner:SINOCHEM INT CORP

Auxiliary manipulator used between manipulators to transmit products and correct positions

The invention discloses an auxiliary manipulator used between manipulators to transmit products and correct positions. The auxiliary manipulator used between manipulators to transmit products and correct positions comprises a transversal pushing air rod and a first movable pneumatic clamp, and the first pneumatic clamp comprises a first clamping block, a first clamping air cylinder, a rotating air cylinder and a transversal moving base. The first clamping block is provided with a left block and a right block which are respectively connected with a push rod of the first clamping air cylinder, the first clamping air cylinder is connected with the transversal moving base in rotating mode, the upper side of the first clamping air cylinder is provided with a base plate, and a first clamping opening is formed by the base plate, the first left clamping plate and the first right clamping block. The transversal pushing air cylinder is arranged on the transversal moving base, one end of the rotating air cylinder is connected with the transversal moving base in rotating mode, and the other end of the rotating air cylinder is connected with the first clamping air cylinder in rotating mode. The manipulator device can be suitable for clamping and state correction of regular straight type products and irregular-shaped products, improves accuracy of the products on manipulator clamps, and improves working efficiency.

Owner:余姚汉卓力克管件有限公司

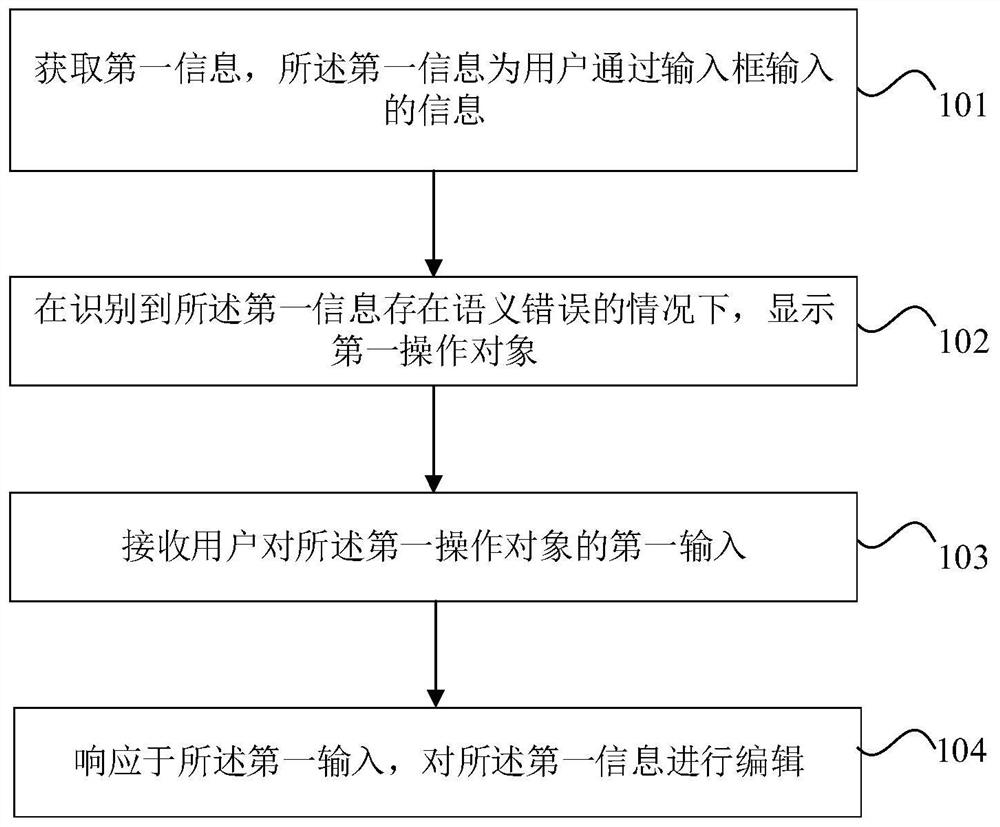

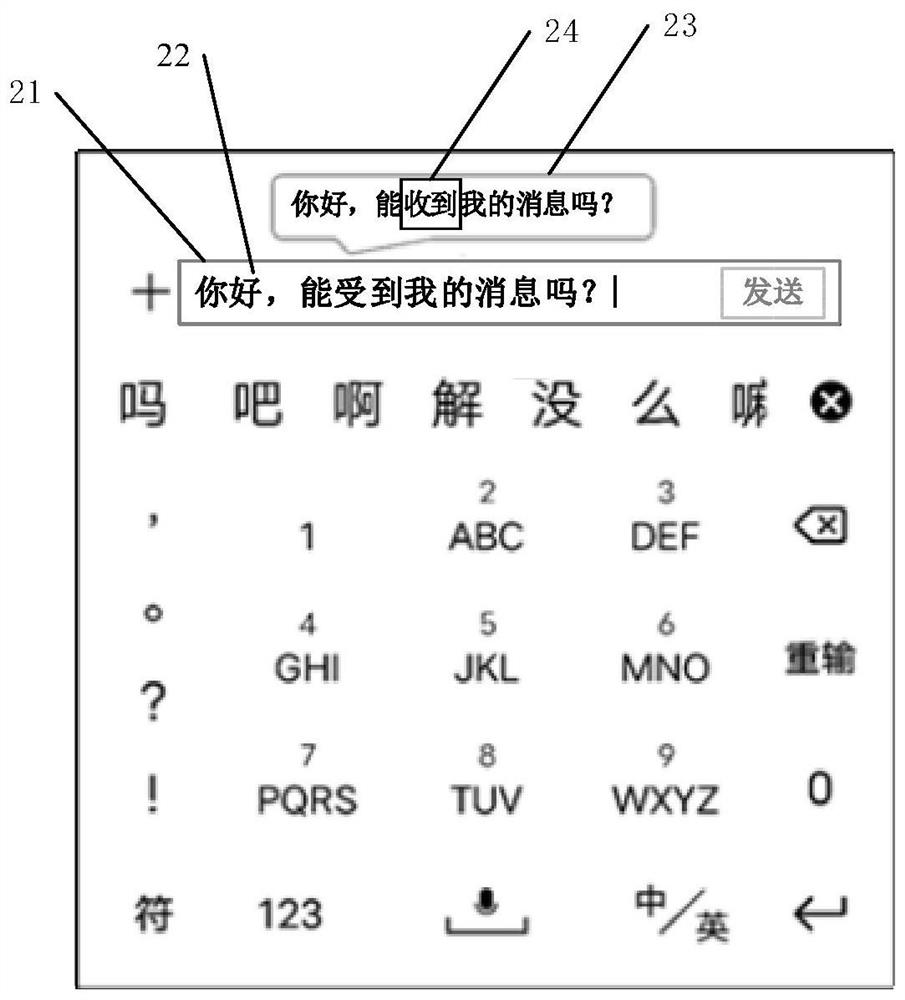

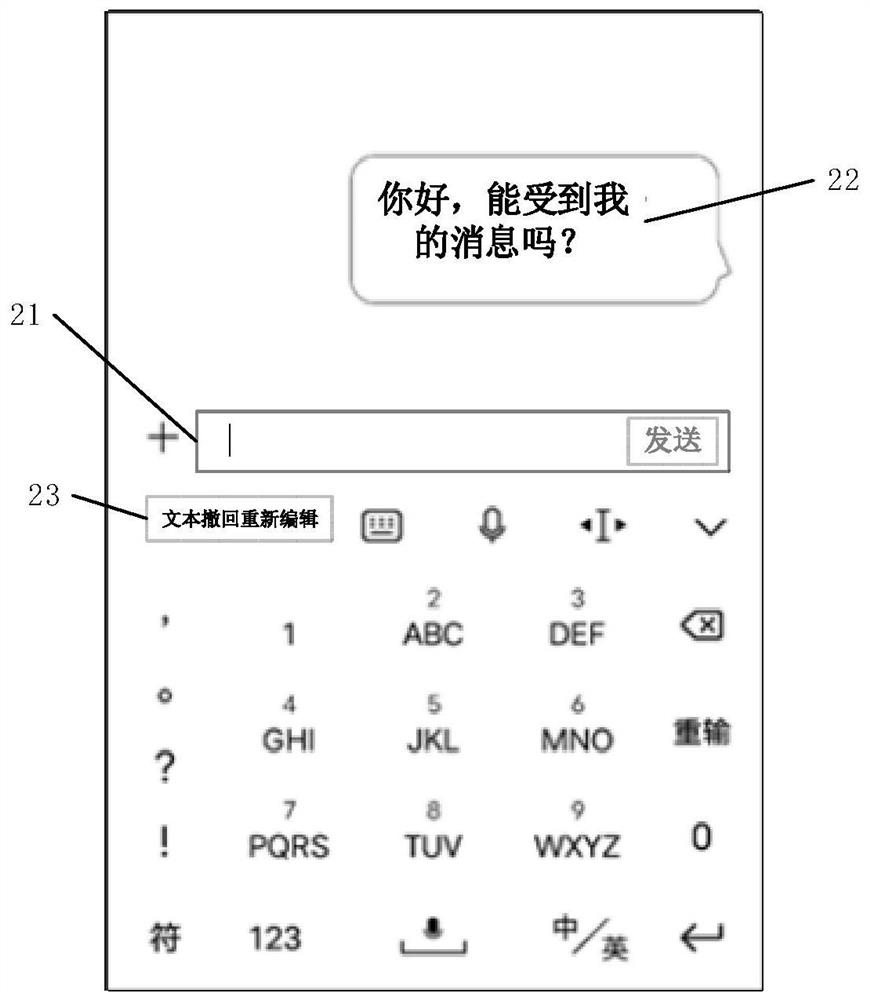

Information processing method and information processing device

The invention discloses an information processing method and an information processing device, and belongs to the technical field of communication. The method comprises the steps of acquiring first information, wherein the first information is information input by a user through an input box; displaying a first operation object under the condition of identifying that the semantic error exists in the first information; receiving a first input of a user on the first operation object; and editing the first information in response to the first input. According to the information processing method and device, errors occurring in the information input process of the user can be detected in time by conducting semantic recognition on the information, the user can be reminded of the errors in time by displaying the first operation object, the error information can be re-edited, output of the error information can be reduced, and therefore information transmission errors can be reduced.

Owner:南京维沃软件技术有限公司

A method and device for intelligent material distribution and packing "u"-shaped assembly line

ActiveCN107902310BRealize the operation method of "smart manufacturing"Reduce delivery errorsPackaging automatic controlStacking articlesLogistics managementRobot hand

The invention relates to an intelligent material allocation and binning U-shaped assembly line operation method and device. Bulk materials are contained into a storing container in a classified manneraccording to the object properties and sizes, and meanwhile, cargo delivering frames are classified and fed to an annular or U-shaped intelligent assembly operation line to be stacked; when allocation and binning are carried out, the cargo delivering frames are selected from the cargo delivering frame stacking position through the annular or U-shaped intelligent assembly operation line accordingto the logistics information, frame dividing is carried out, the divided cargo delivering frames are placed on a conveying device of the annular or U-shaped intelligent assembly operation line, and multi-station movement is carried out; cargoes needed by the cargo delivering frames are taken out from the storing container when movement is carried out by one station and are placed into specific cargo delivering frames of the annular or U-shaped intelligent assembly operation line, after all the cargoes of the cargo delivering frames are loaded, a mechanical arm is used for orderly stacking thecargo delivering frames to a tray according to cargo delivering information, then loading is carried out through a loading device, and the whole cargo allocation, binning and loading operation is completed.

Owner:LILING LVYUAN COMML & TRADING CO LTD

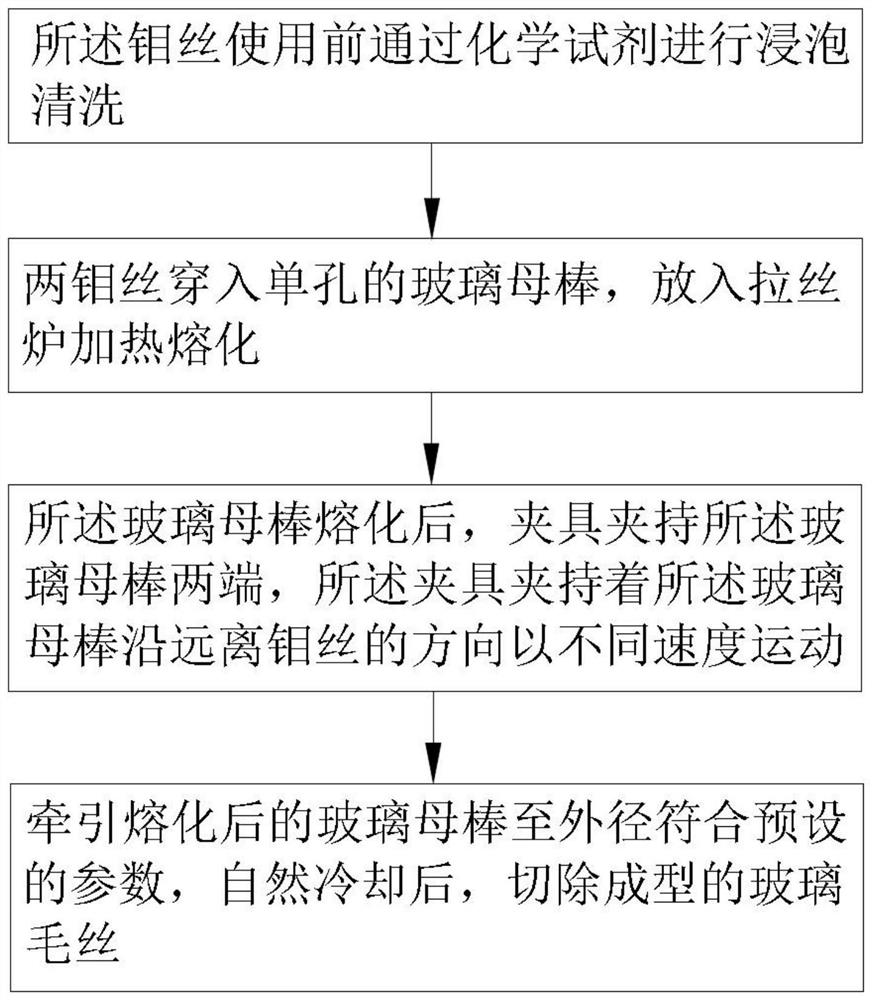

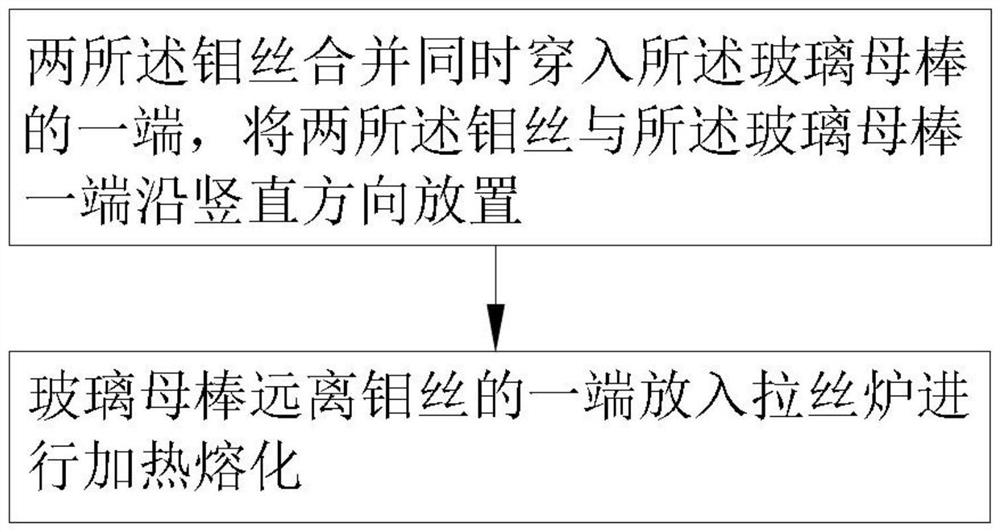

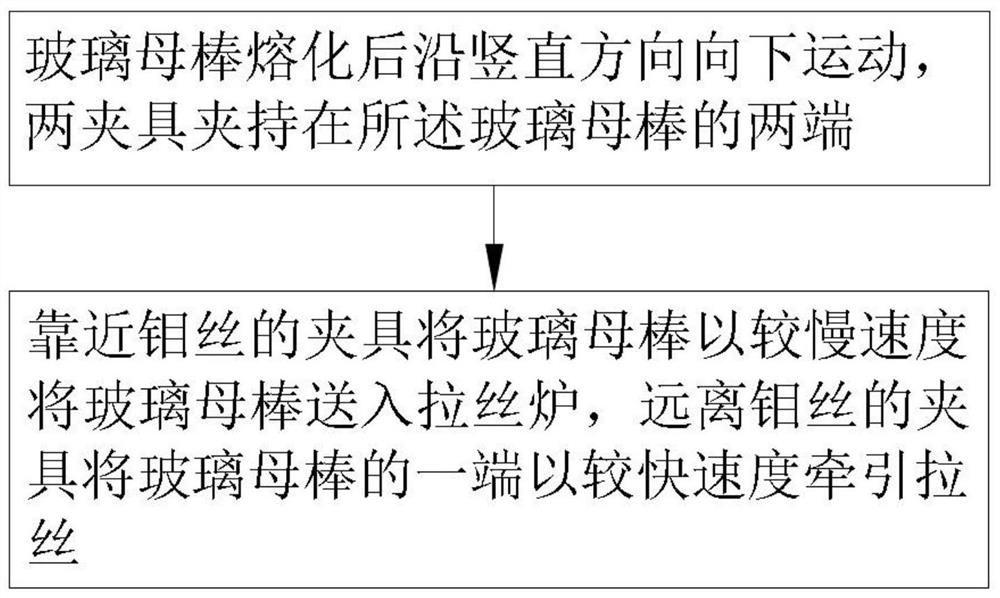

Double-fiber capillary tube and preparation method thereof

PendingCN113716863AReduce internal stressPrevent problems such as cracksGlass making apparatusCoupling light guidesCapillary TubingFiber drawing

The invention provides a preparation method of a double-fiber capillary tube, wherein the preparation method comprises the following steps: penetrating two molybdenum wires into a single-hole glass mother rod, putting in a fiber drawing furnace, heating and melting; after the glass mother rod is melted, clamping the two ends of the glass mother rod with a clamp, and clamping the glass mother rod by the clamp to move at different speeds in the direction away from the molybdenum wires; and pulling the molten glass mother rod until the outer diameter accords with a preset parameter, naturally cooling, and cutting off the formed glass broken filaments. The two molybdenum wires penetrate into the glass mother rod, the glass mother rod is put into the wire drawing furnace to be heated and melted, the hot-melted glass mother rod is clamped by the clamp to be subjected to traction wire drawing, the outer diameter of the glass broken filaments is adjusted to meet preset parameters, the formed glass broken filaments are cut off after natural cooling, through natural cooling, the internal stress of a product can be reduced, and the problems of cracks and the like on the product can be prevented. The invention further provides the double-fiber capillary tube which is suitable for the preparation method of the double-fiber capillary tube.

Owner:深圳市比洋互联科技有限公司

Transfer feeding method and device of two material intelligent delivery conveyer lines

ActiveCN107963412ARealize the operation method of "smart manufacturing"Avoid chaotic logisticsMechanical conveyorsEngineering

Owner:LILING LVYUAN COMML & TRADING CO LTD

A method and device for transferring and feeding materials between two sections of a material intelligent distribution conveyor line

ActiveCN107963412BRealize the operation method of "smart manufacturing"Avoid chaotic logisticsMechanical conveyorsProcess engineeringMaterial distribution

Owner:LILING LVYUAN COMML & TRADING CO LTD

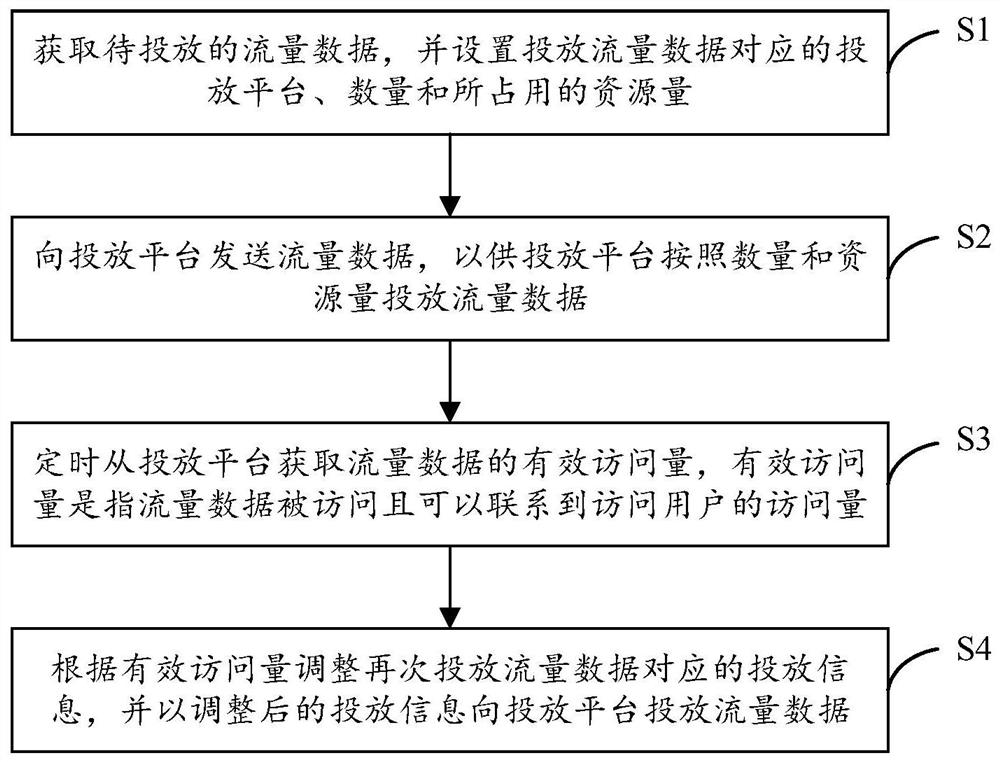

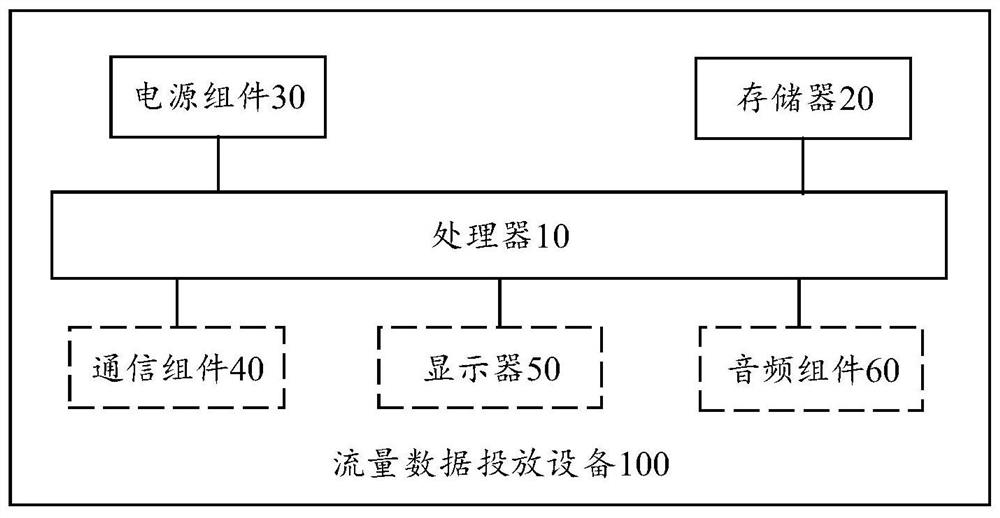

Traffic data delivery method, device and system and medium

PendingCN112036925ARealize standardized operationReduce delivery errorsMarket data gatheringDistributed computingReal-time computing

The embodiment of the invention provides a traffic data delivery method, device and system and a computer storage medium. According to the embodiment of the invention, standardized operation of delivery information can be realized by setting the delivery information of to-be-delivered flow data, and delivery error rate is reduced. Furthermore, the condition that the delivered flow data is accessedcan be judged according to the effective page view of the flow data obtained from the delivery platform at regular time, so that the scheme of delivering the flow data again can be adjusted in time,the timeliness is improved, a closed-loop mode is formed in the whole flow data delivery scheme, and loss stopping and income increasing in time are facilitated.

Owner:长沙市到家悠享网络科技有限公司

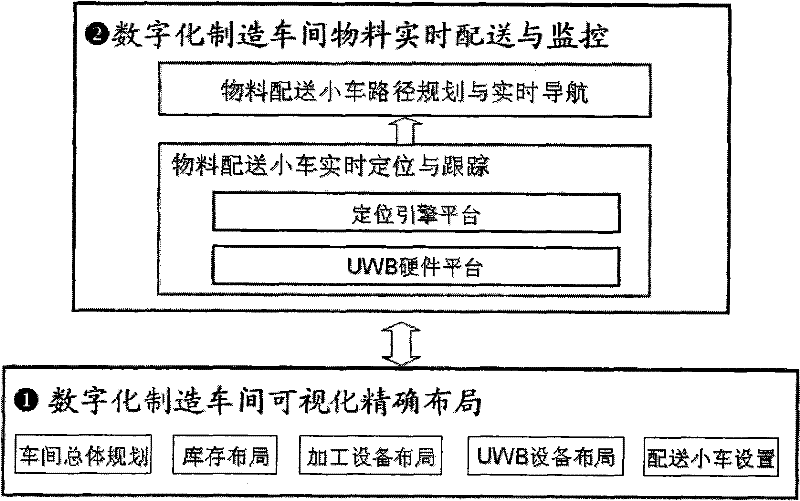

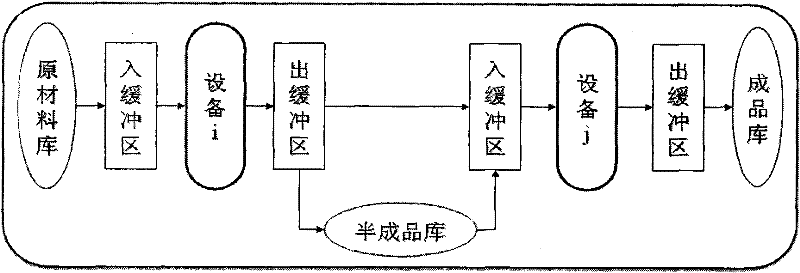

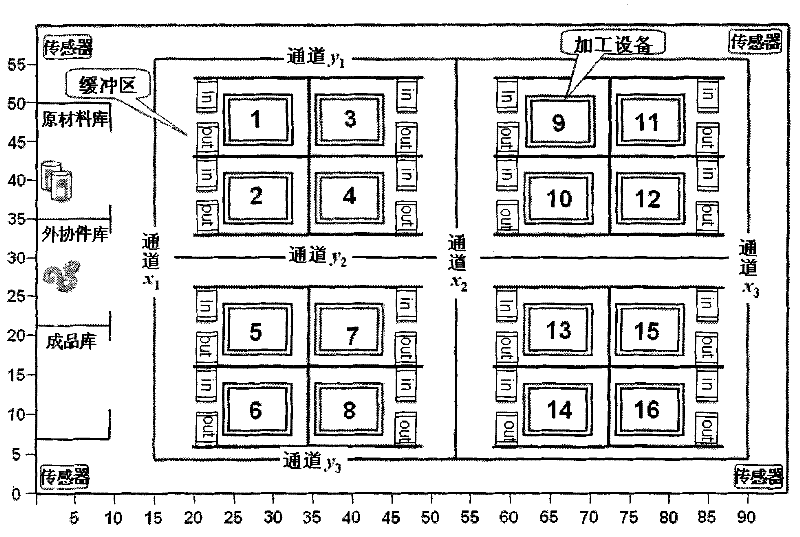

Digitalized manufacture workshop material real-time distributing system based on Ultra Wideband (UWB)

InactiveCN101782767BReach monitoringMonitor the delivery processTotal factory controlProgramme total factory controlUltra-widebandEngineering

The invention discloses a digitalized manufacture workshop material real-time distributing system based on an Ultra Wideband (UWB), comprising a digitalized manufacture workshop visualized precise laying module and a digitalized manufacture workshop material real-time distributing and monitoring module, wherein the digitalized manufacture workshop visualized precise laying module maps a relevant manufacture resource of a digitalized manufacture workshop to a computer in a uniform coordinate system and realizes the digitalization and the visualization of physical manufacture workshop layout; the digitalized manufacture workshop material real-time distributing and monitoring module comprises a material distributing trolley path planning and navigating submodule and a material distributing trolley real-time positioning and tracing submodule; the material distributing trolley path planning and navigating submodule plans a material distributing path of a digitalized manufacture workshop and carries out path navigation on the workshop material distributing process on the basis; and the material distributing trolley real-time positioning and tracing submodule realizes the real-time positioning and tracing on a material distributing trolley by applying a UWB wireless positioning technology. The digitalized manufacture workshop material real-time distributing system can effectively reduce the semifinished product stock, improve the instantaneity and the accuracy of material distribution and the production quality of a workshop and provide reference for realizing on-time production of the digitalized manufacture workshop.

Owner:XI AN JIAOTONG UNIV

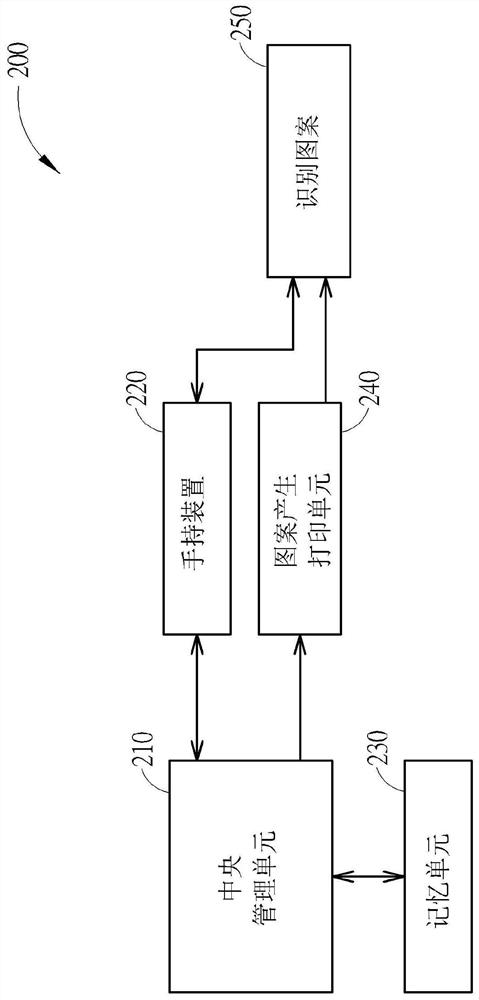

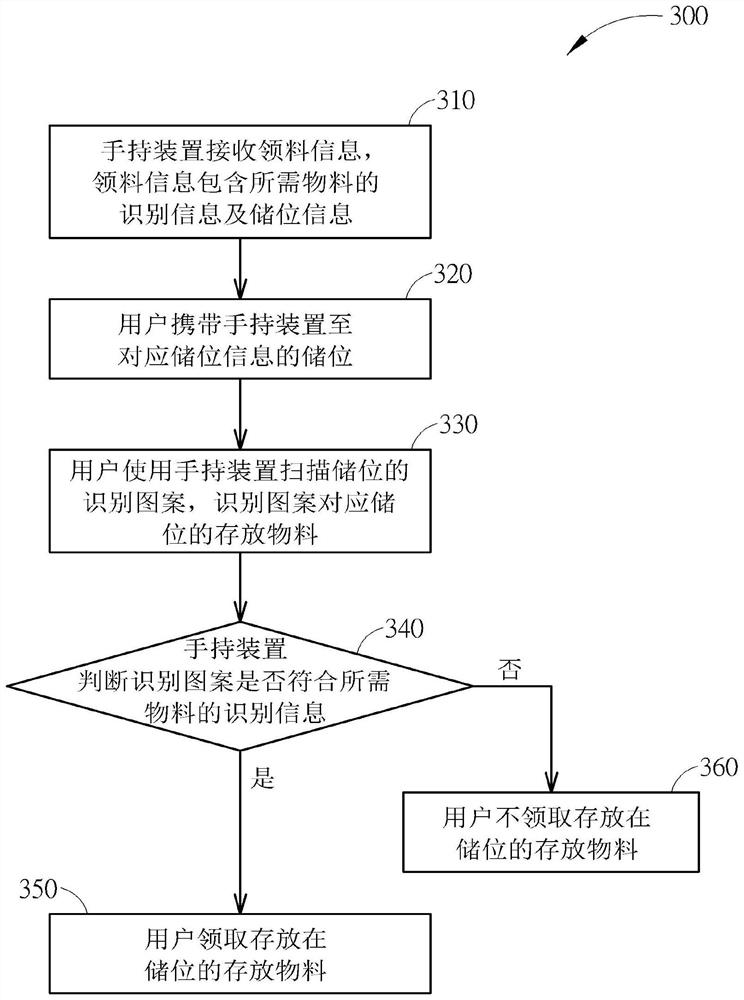

Material control method and material control system

PendingCN112070424AReduce picking timeRaise the sending rateLogisticsManufacturing computing systemsComputer hardwareControl system

The invention discloses a material control method and a material control system. The material control method and the material control system are used for distributing required materials stored in a warehouse. The material control method comprises the following steps that a handheld device receives material receiving information, wherein the material receiving information comprises identification information and storage position information of required materials; the user carries the handheld device to the storage position corresponding to the storage position information; the user uses the handheld device to scan the identification pattern of the storage position, wherein the identification pattern corresponds to the storage materials of the storage position; the handheld device judges whether the identification pattern conforms to the identification information of the required materials or not; and when the identification pattern conforms to the identification information of the required materials, the user gets the stored materials stored in the storage position.

Owner:ATAI FUJI MOTOR

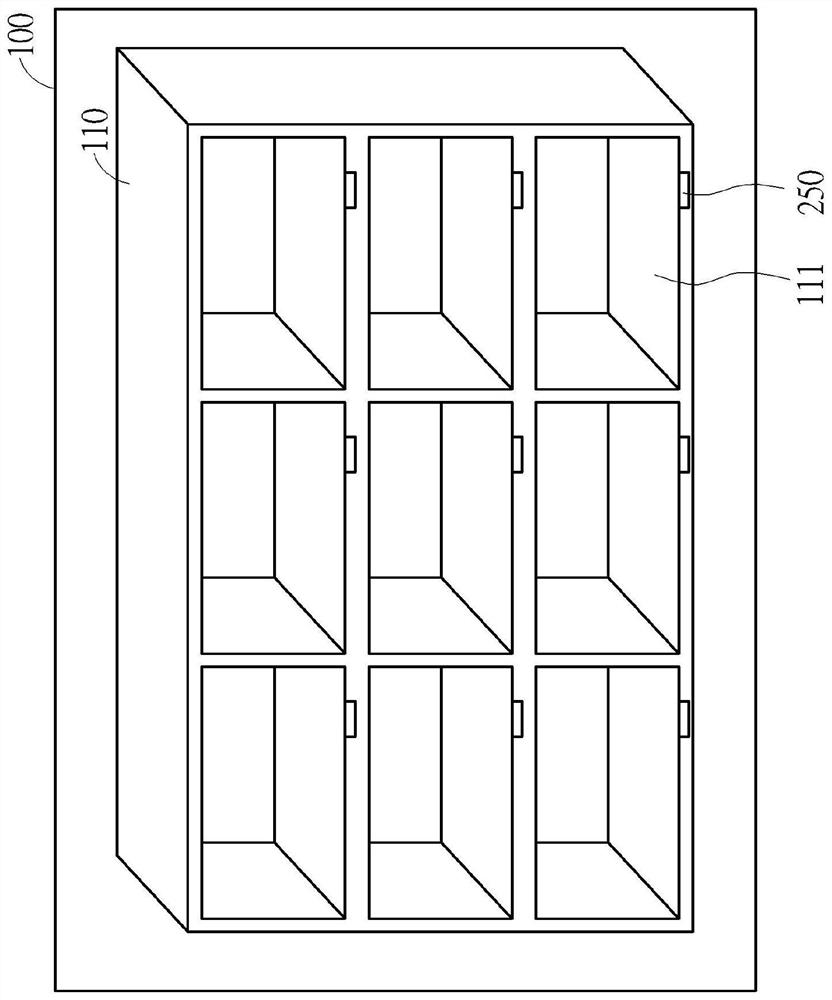

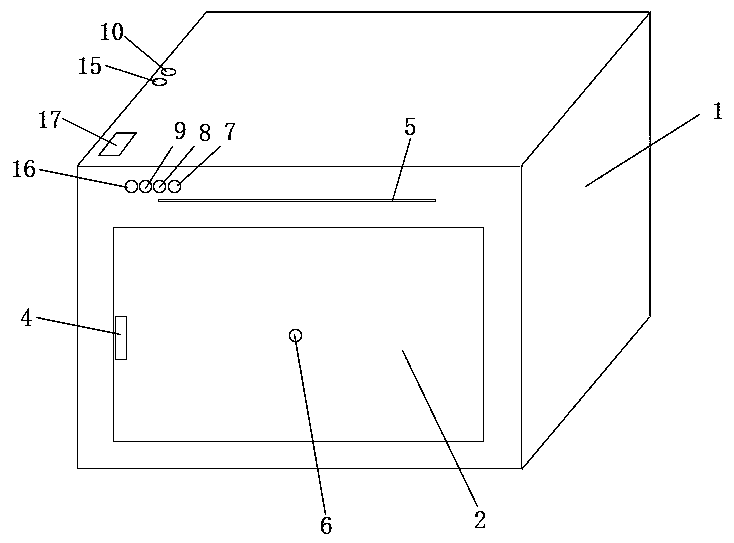

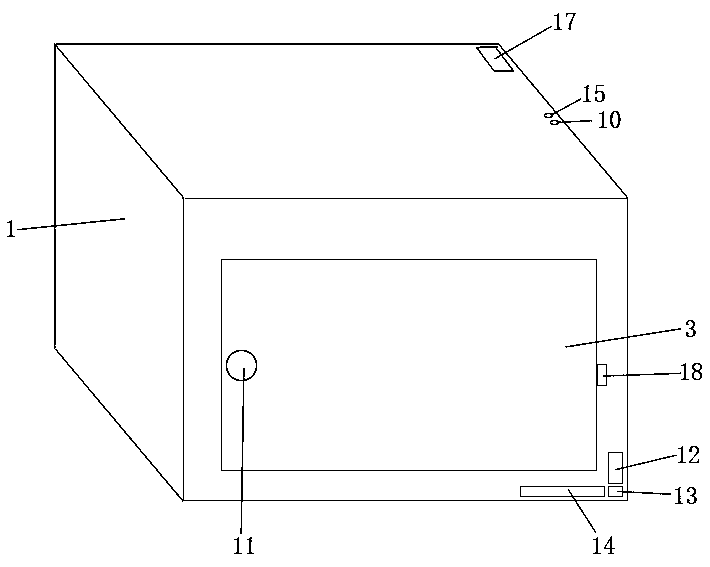

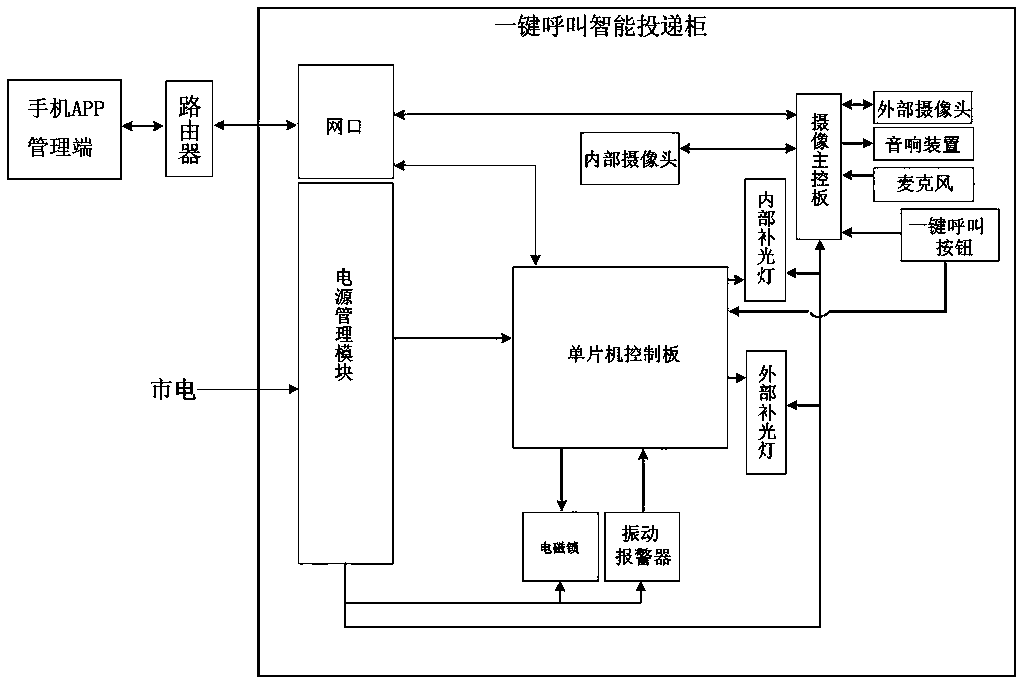

One-key calling intelligent delivery cabinet

PendingCN110719427AFull delivery monitoringHigh transparencyTelevision system detailsColor television detailsLogistics managementElectromagnetic lock

The invention provides a one-key calling intelligent delivery cabinet which comprises a cabinet body, a delivery door, a pickup door and a one-key video calling device; an electromagnetic lock is arranged on the delivery door, and a letter delivery port is formed in the cabinet body on the outer side; the one-key video calling device comprises a one-key calling button, an external camera, a sounddevice, a microphone and an internal camera; a mechanical lock is arranged on the pick-up door; and a power panel, a network interface and a single chip microcomputer control panel are arranged on thecabinet body below the pickup door. According to the invention, the recipient is notified in a one-key calling mode, real-time video intercom between the postman and the recipient is realized, the recipient can monitor delivery in the whole process, the transparency of the express delivery process is improved, and delivery errors are reduced. The one-key calling intelligent delivery cabinet has the advantages of being high in delivery efficiency, low in logistics cost, safe, reliable and convenient to use.

Owner:HEBEI HUPAI GRP AODI CABINET IND

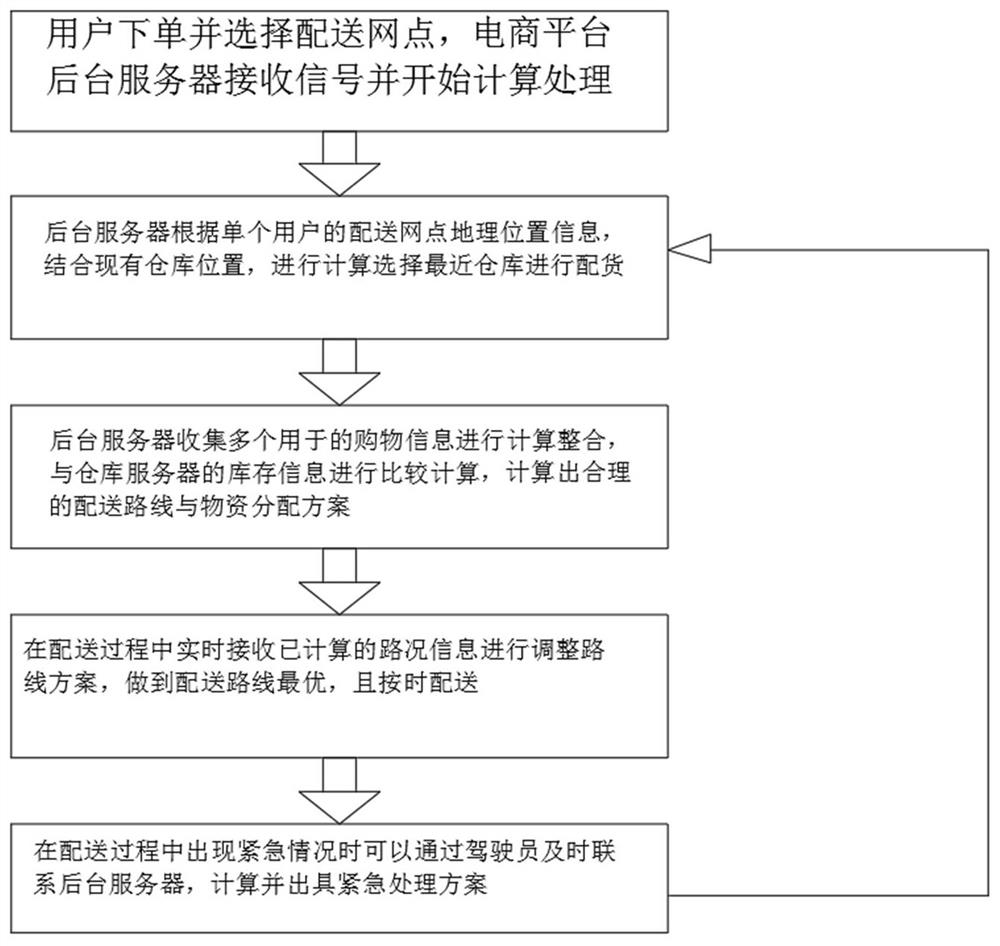

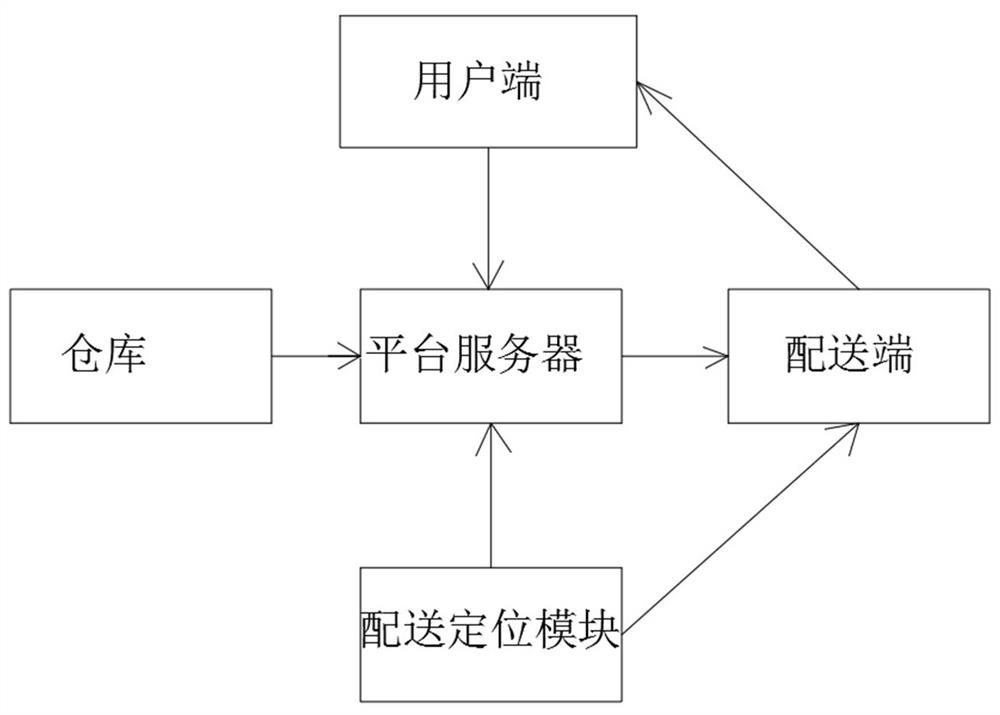

Community vegetable buying distribution method and distribution verification device based on data processing

PendingCN113034086AEasy to transportFeatures real-time deep learningLogisticsCommerceDistribution methodData mining

The invention relates to a community vegetable buying distribution method based on data processing and a distribution verification device. A check meter is adopted to conveniently check goods of a distribution network, a community vegetable buying distribution method is optimized by adopting a method based on data processing, and according to ordering preferences of users in different regions in different seasons, the goods of customer preference types are stored in a prospective manner in an amount-increasing manner, goods with poor sales volume are promoted and discounted on an e-commerce platform in real time, inventory in a warehouse is reduced, and meanwhile, distribution personnel can check and verify the goods when arriving at each distribution point through a calibrator, so the conditions of less delivery, missing delivery and wrong delivery are avoided, the delivery error rate is better reduced, the delivery service quality is improved, the verification workload of delivery personnel is effectively reduced, the manual verification intensity is reduced, the delivery efficiency is effectively improved, and the delivery error rate is reduced.

Owner:中科海拓(无锡)科技有限公司

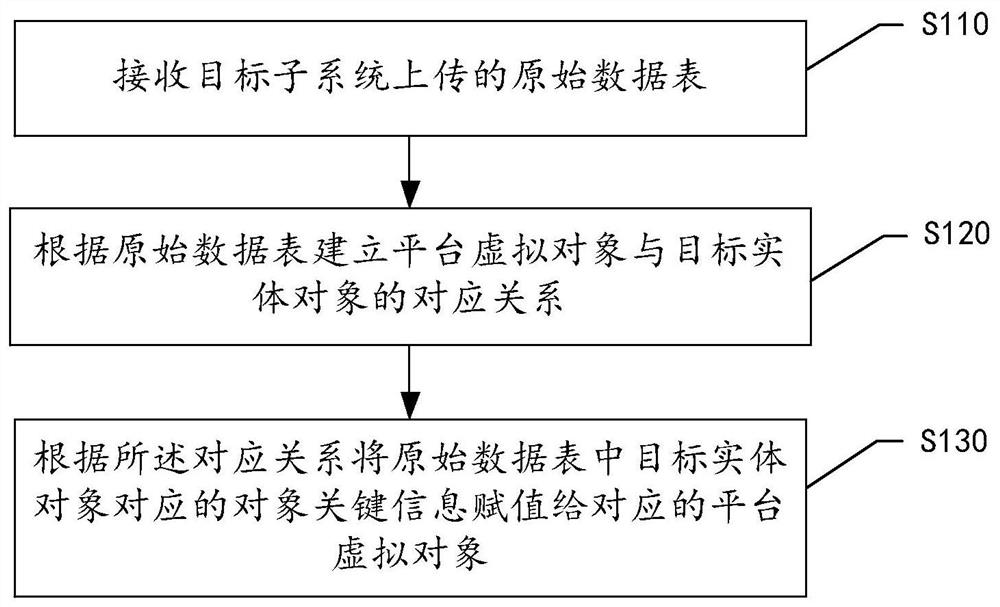

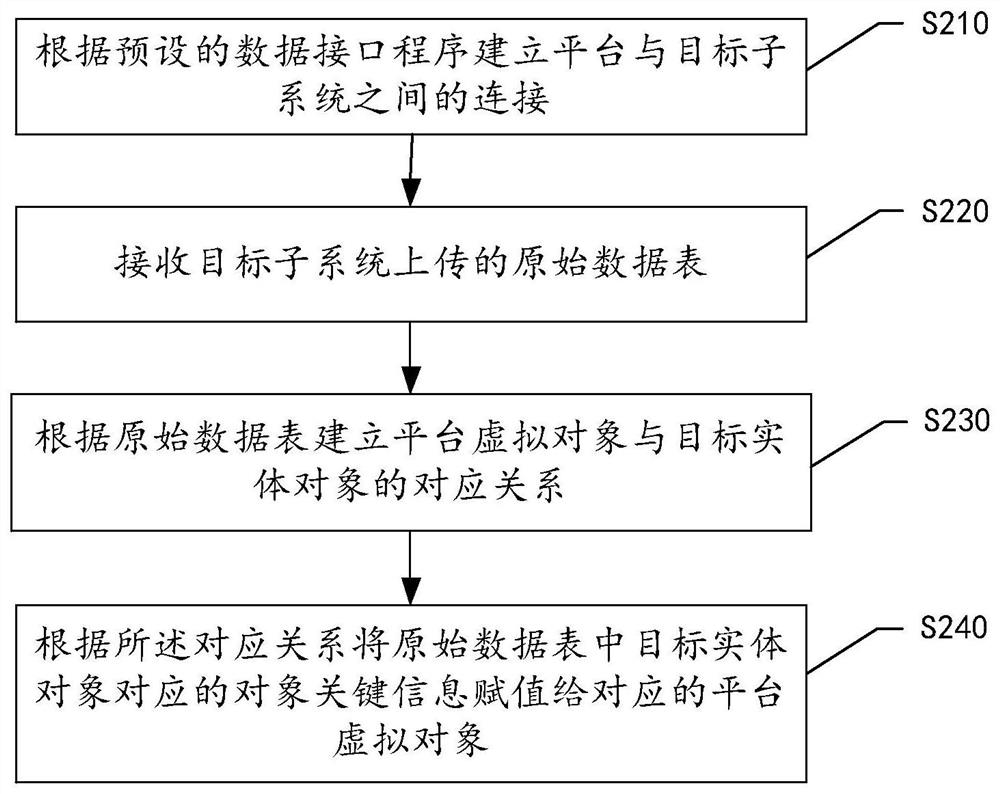

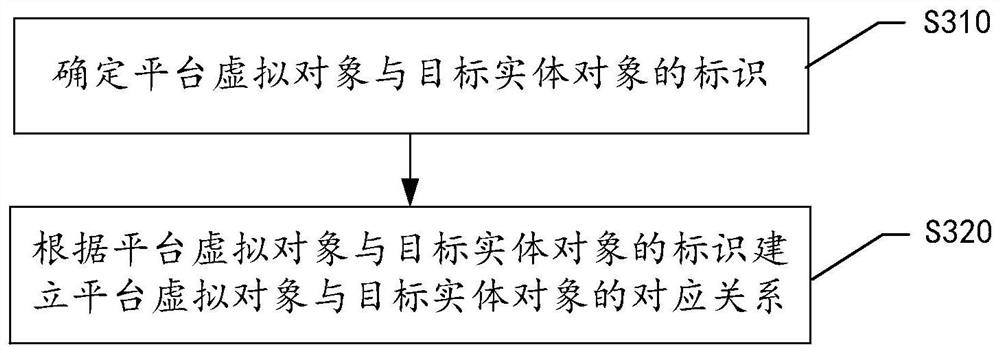

Data processing method and device, electronic equipment and readable storage medium

PendingCN114020740ASave time organizingImprove data delivery efficiencyDatabase management systemsRelational databasesOriginal dataSoftware engineering

The embodiment of the invention provides a data processing method and device, electronic equipment and a readable storage medium, and the method comprises the steps: receiving an original data table uploaded by a target subsystem, building a corresponding relation between a platform virtual object and a target entity object according to the original data table, and according to the corresponding relationship, assigning the attribute key information corresponding to the target entity object in the original data table to the corresponding platform virtual object, so that automatic and batch data processing is realized, the data delivery efficiency during data delivery can be improved, and the error rate is reduced.

Owner:BEIJING PERSAGY ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com