Auxiliary manipulator used between manipulators to transmit products and correct positions

A technology for manipulators and products, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of inability to transmit special-shaped structures, low functionality, and reduced work efficiency, so as to reduce product transmission errors, enhance functionality, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

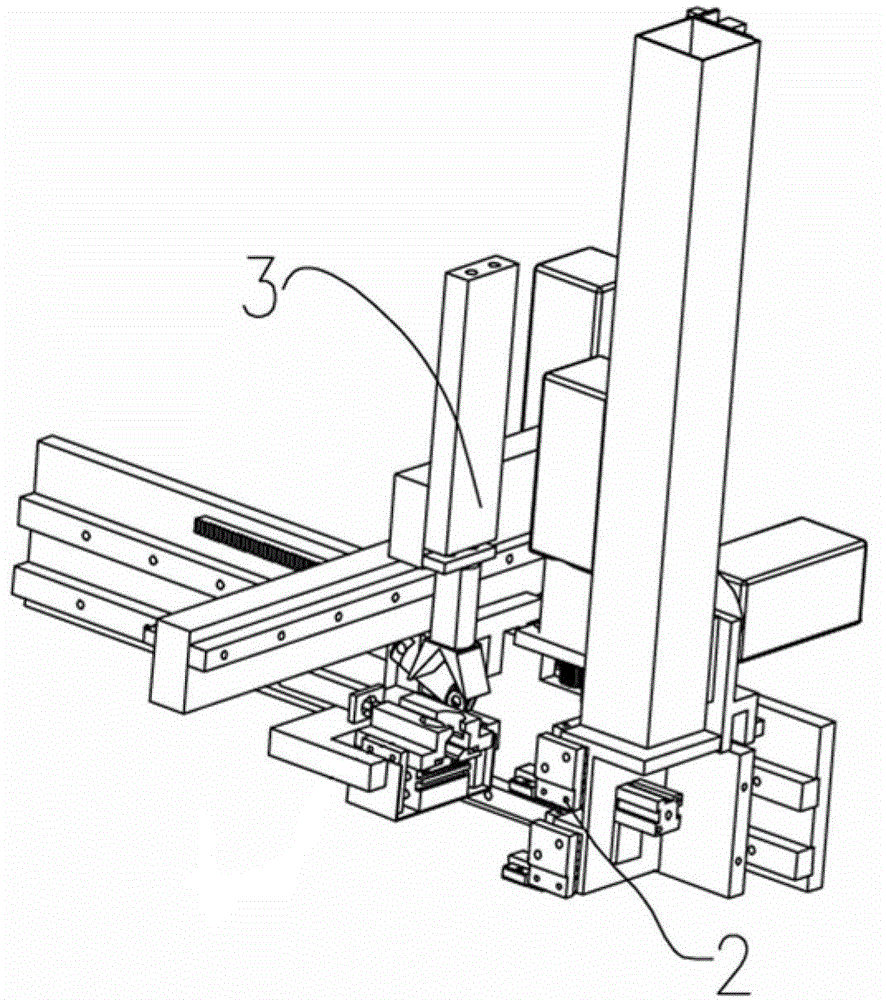

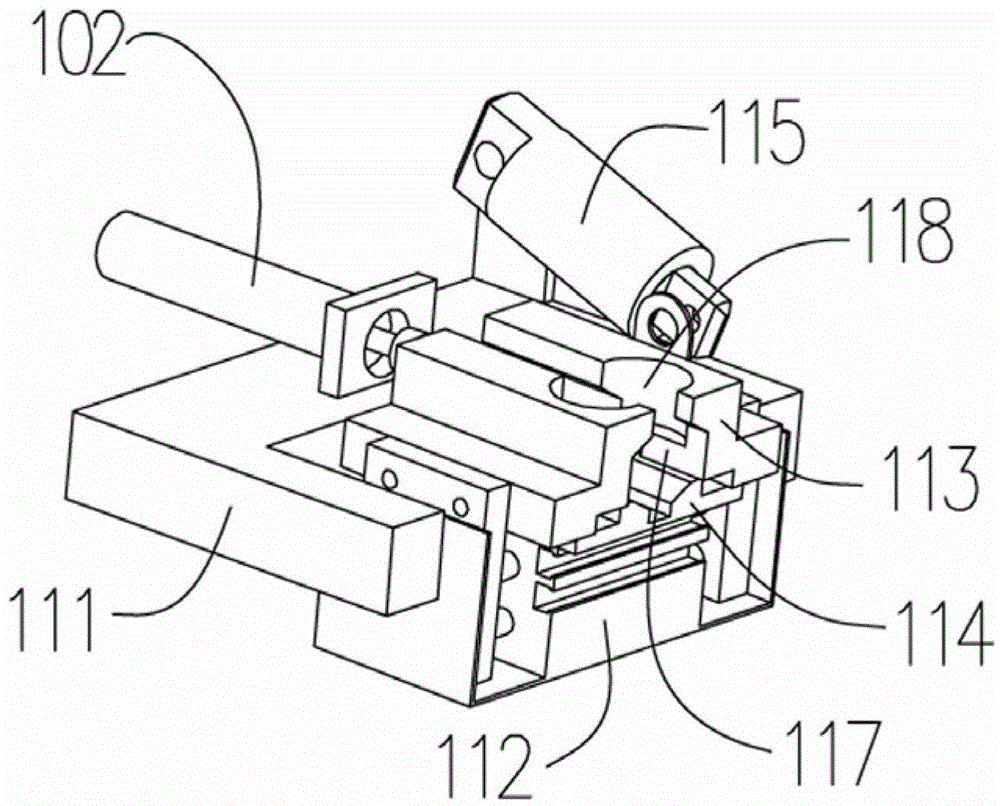

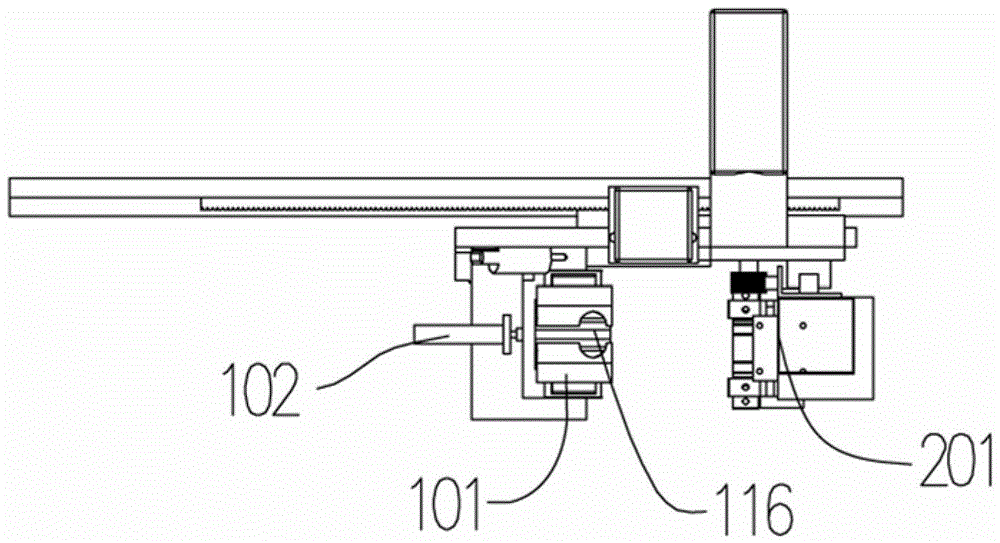

[0028] Embodiment 1: When the conventional straight joint 4 is transferred and processed, the entire processing equipment includes the picking manipulator 3, the auxiliary manipulator and the product to the machine tool manipulator device 2 such as figure 1 with Figure 5 Shown. The first clamping cylinder 112 is pushed clockwise by the rotating cylinder 115 to rotate 90°, the pick-up manipulator 3 is loosened so that the joint 4 is put into the lateral clamping opening 117 and the product entering the end gap, the rotating cylinder 115 is reversed The hour hand is pushed and rotated by 90°, and the product is sent to the manipulator device 2 of the machine tool through the laterally moving base 111. The laterally pushing air rod 102 pushes the connector 4 slowly forward from the product entry gap of the lateral clamp 117. The connector The position is slowly corrected due to the change of the gap, and finally the product is pushed into the fixture in the manipulator device 2 of...

Embodiment 2

[0029] Embodiment 2: When transferring the angle-pass joint 4 for processing, the entire processing equipment includes the picking manipulator 3, the auxiliary manipulator and the product delivery to the machine tool manipulator device 2. The picking manipulator 3 moves downward to place the joint 4 in the first clamping opening 116 of the angle pass, and the left and right first clamping blocks 113 are slowly clamped so that the joint 4 is automatically corrected according to the position of the first clamping opening 116 , The clamping joint 4 moves forward to the manipulator device 2 where the product is sent to the machine tool through the lateral movement base 111, the left and right first clamping blocks 113 are loosened, and the lateral pushing air rod 102 clamps the joint 4 from the lateral direction. The rear end of the port 117 is pushed forward, and the manipulator device 2 sent to the machine tool clamps the joint 4, and then sent to the machine tool for processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com