A combination layout method of pile plate retaining wall and culvert

An arrangement method and culvert technology, applied in the field of geotechnical engineering, can solve the problems of difficult sliding force of gravity retaining wall, deterioration of roadbed stability, and long-term stability safety hazards of the project, and achieve economical cost, good implementation effect, and avoidance of connection. Effects of Difficulty and Conflict Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with specific examples.

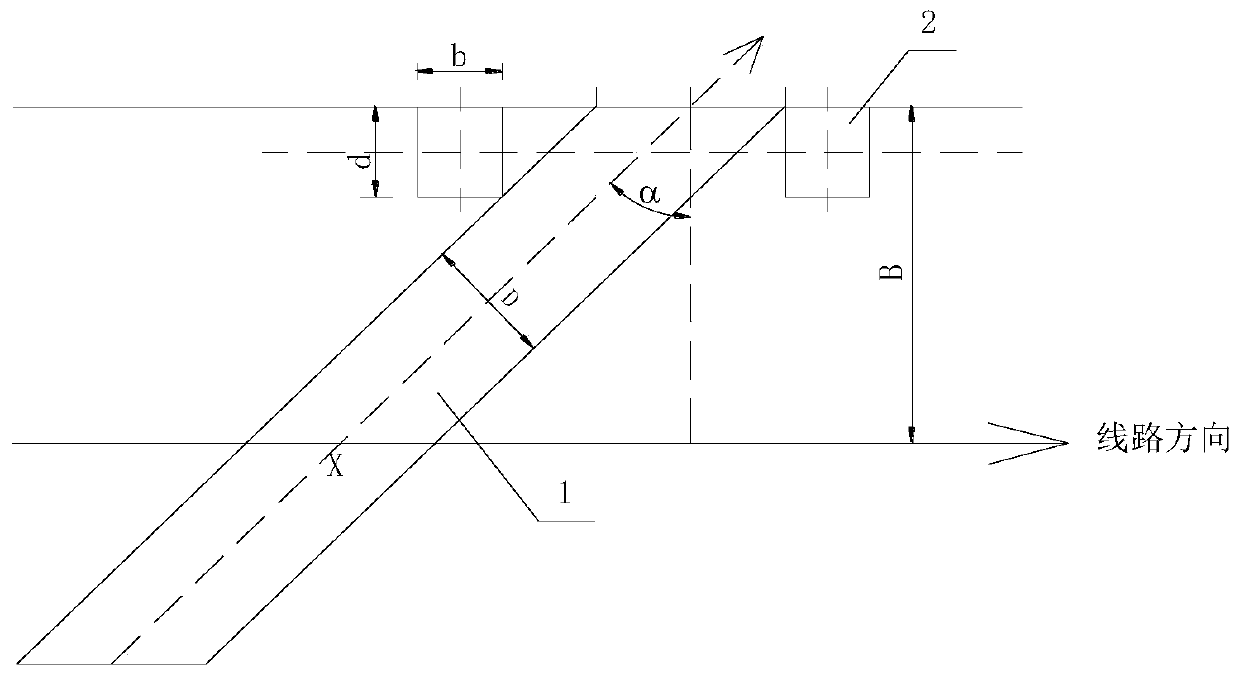

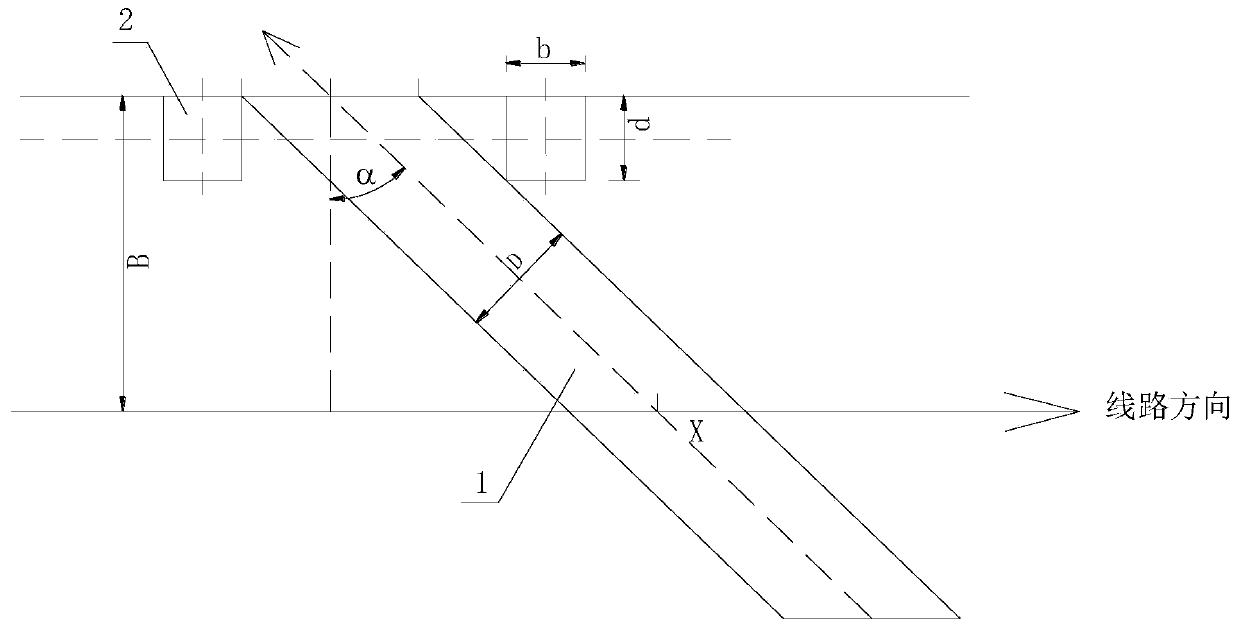

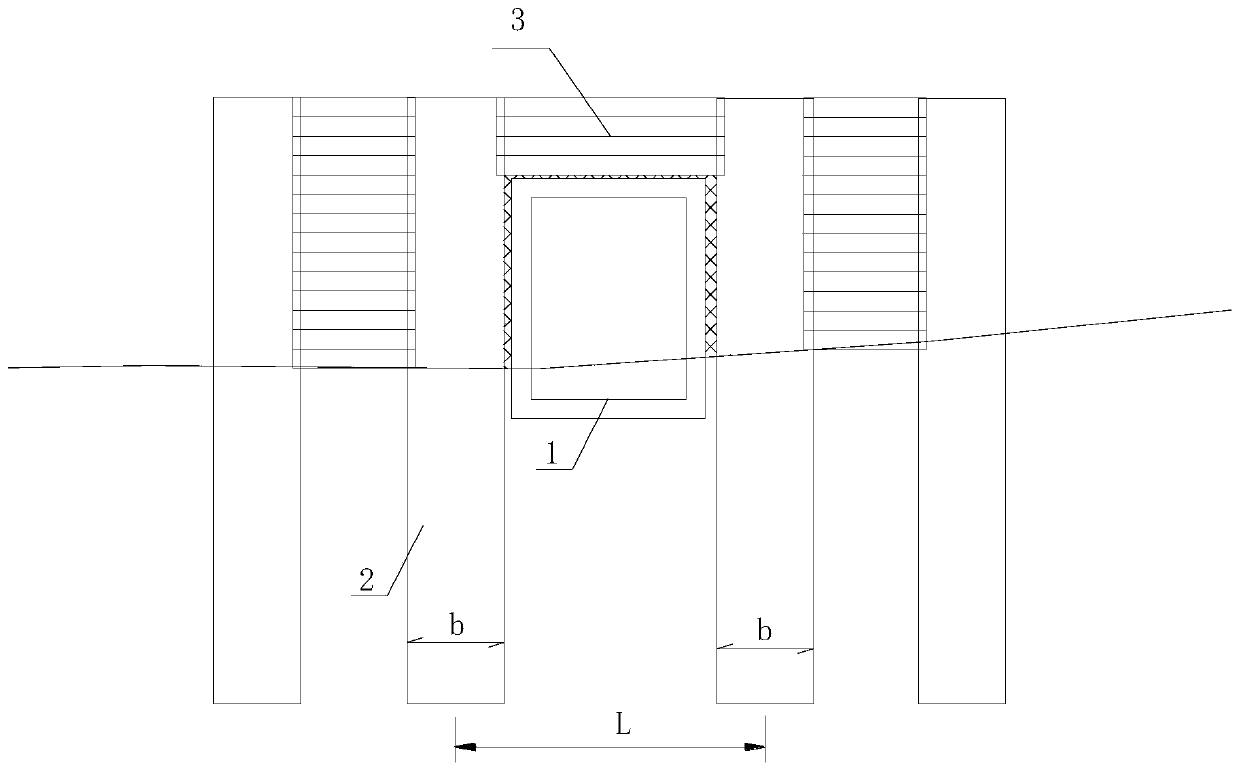

[0048] as above Figure 1~3 Shown is a layout method for the combination of a pile-slab retaining wall and a culvert, including the following steps:

[0049] 1) Carry out culvert engineering: determine the culvert center mileage X, culvert width D, and culvert angle α according to flood drainage, irrigation, traffic and terrain conditions, and do culvert engineering according to the design, and the relevant requirements for culvert construction must meet the technical requirements of culvert design , the culvert structure needs to meet the additional load requirements of the retaining slab;

[0050] 2) Carry out the anchor pile pile body construction of the pile-slab retaining wall: according to step 1) culvert center mileage X, culvert width D, and culvert angle α determine the small mileage direction pile center mileage K of the anchor pile 1 , Center mileage K o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com