Coffee machine service life tester

A technology of coffee machine and tester, applied in the direction of machine/structural component testing, instruments, measuring devices, etc., can solve the problems of increasing long-term cost, not directly generating benefits, loss, etc., to achieve cost saving, far-reaching application prospects and economical Prospects, the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

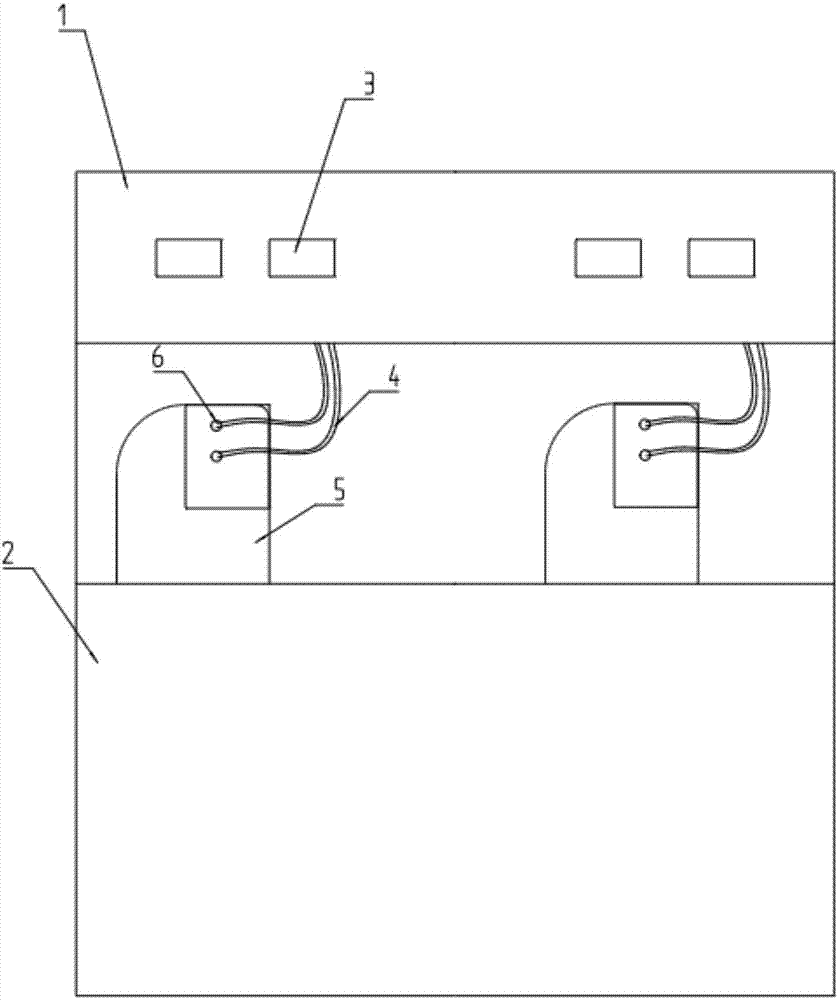

[0014] Such as Figure 1-2 Shown is an embodiment of the coffee machine life tester according to the present invention.

[0015] The coffee machine life tester includes a test machine 1, a base 2, an instrument 3, and a test air pipe 4, wherein the test machine 1 is set on the base 2, and the test machine 1 is provided with at least one instrument 3, and the base 2 has an outwardly extending top surface for placing the coffee machine 5 to be tested. At least one test air delivery pipe 4 is provided at the bottom of the test machine 1, and the test air delivery pipe 4 is connected to the coffee machine 5 via the coffee machine gas guide port 6 , for delivering high-pressure steam to the coffee machine 5 .

[0016] When in use, the built-in controller is used to replace the built-in controller of the coffee machine 5 to fully control the coffee machine 5, specifically, to guide the external controlled steam into the coffee machine 5 to test various functions in a repeated cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com