A noodle extruding device capable of excluding air

A technology for extrusion molding and noodles, which is applied in the direction of dough extruders, etc., and can solve problems such as pressure plate and dough accumulating large air, affecting dough extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

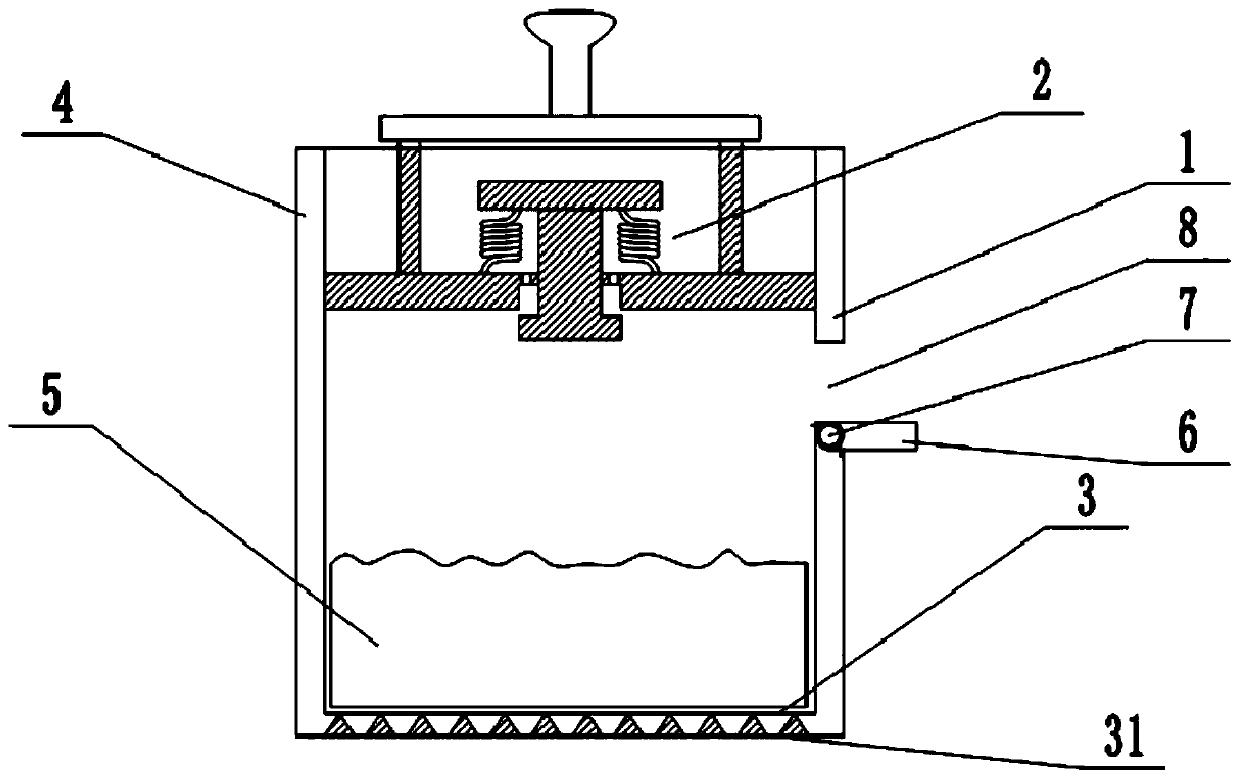

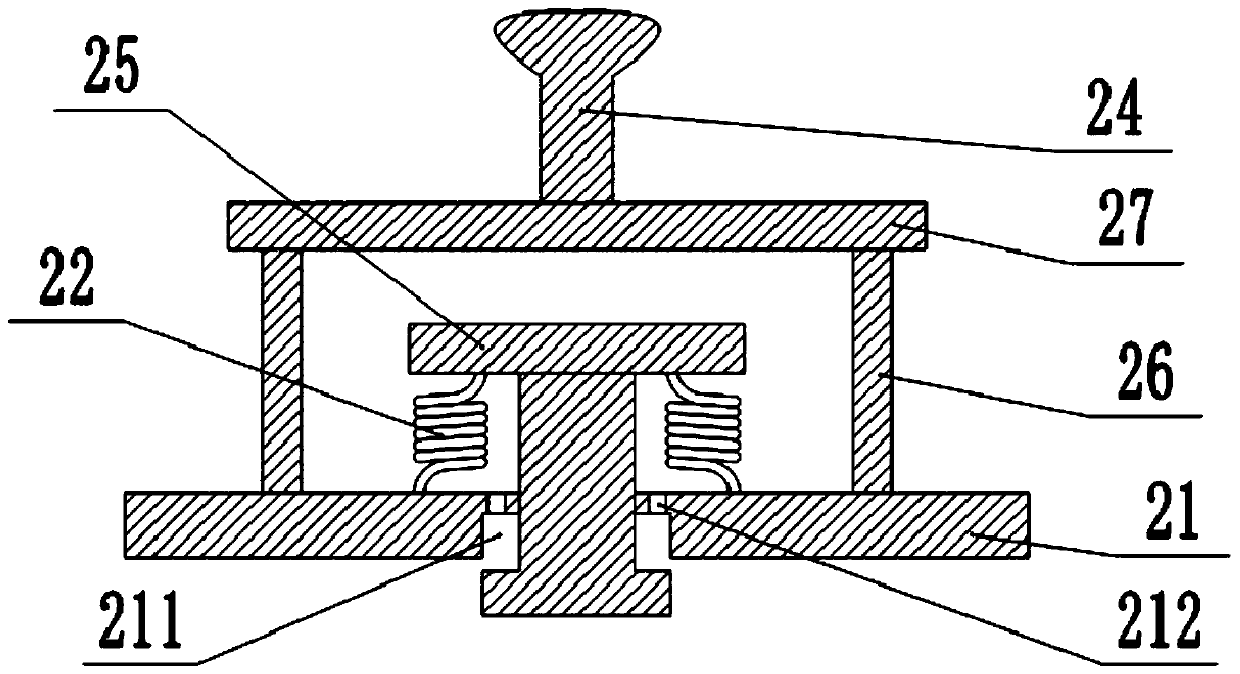

[0021] The reference signs in the accompanying drawings of the description include: forming cylinder 1, pressing plate 2, pushing plate 21, stepped hole 211, hole 212, spring 22, fixing plate 23, pushing rod 24, plunger 25, connecting rod 26, long plate 27 , forming plate 3, forming hole 31, feed inlet 4, dough 5, movable plate 6, torsion spring 7, feed inlet 8.

[0022] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a kind of noodle extruding molding device that can exclude air, comprises forming tube 1, and the bottom end of described forming tube 1 is provided with forming plate 3, and described forming plate 3 is provided with several forming holes 31, and described A pressing plate 2 is slidably connected to the inside of the forming cylinder 1, and the pressing plate 2 includes a pushing plate 21 that fits with the wall of the forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com