Special extrusion device matched with pipe fitting

A technology for extrusion devices and pipe fittings, which is applied to metal extrusion dies and other directions, can solve the problems of affecting the quality of the acoustic tube, inconvenient use, insufficient drawing force, etc., and achieves reliable connection of pipe fittings, easy replacement, and good water-stopping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

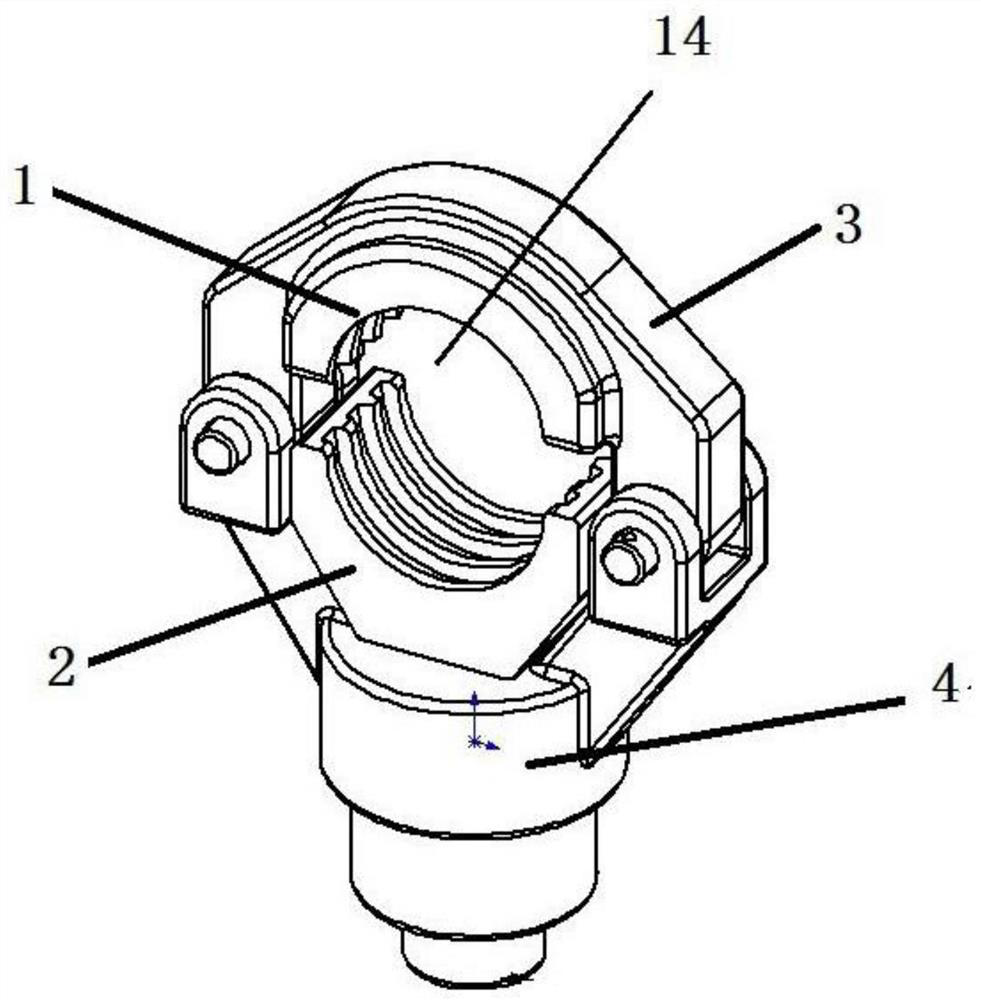

[0027] figure 1 It is a schematic diagram of the structure of two grinding heads when they are docked in the embodiment of the present invention, by figure 1 It can be seen that a special extruding device for pipe fittings in the present invention includes an upper grinding head 1, a lower grinding head 2, an upper grinding head seat 3, a base 4 and a power unit. The upper grinding head 1 and the lower grinding head 2 are both semi-cylindrical, and there are N convex ribs 10 protruding on the inner wall. The inner walls of the two grinding heads form a cylindrical tube receiving area 14 .

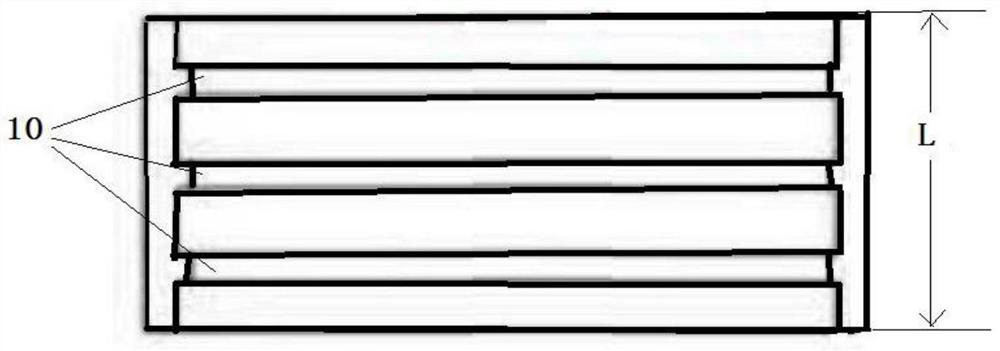

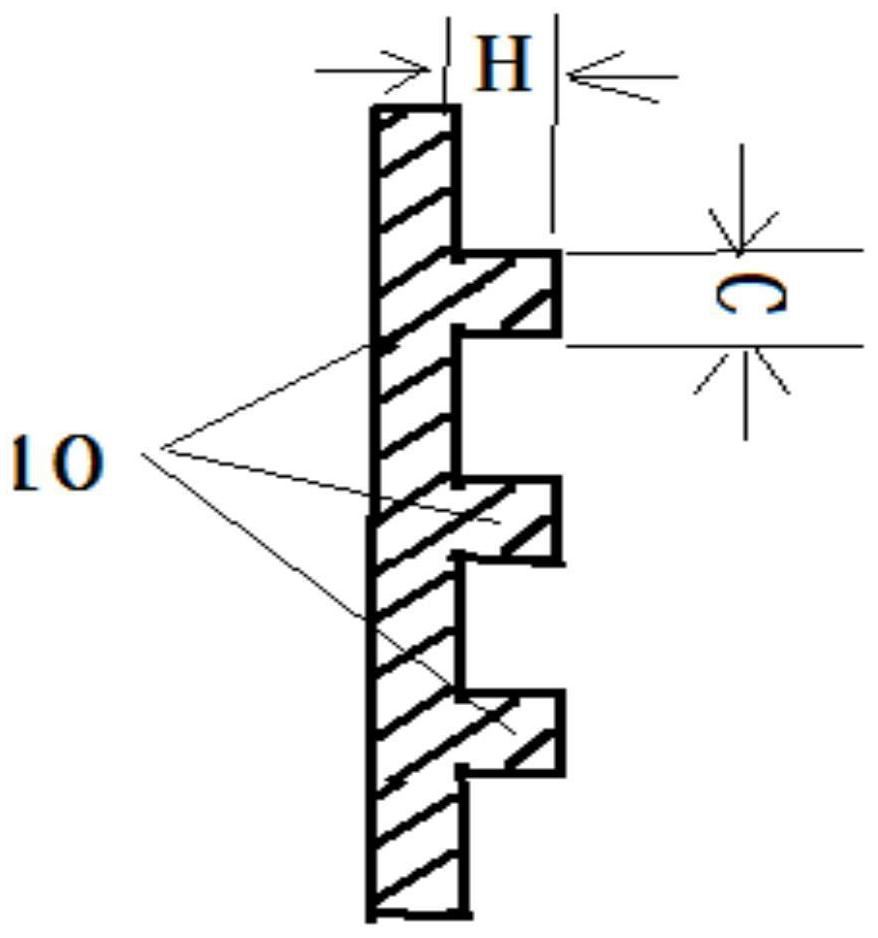

[0028] The number of the ribs 10 is 2-4, and the width and height of each rib 10 are both 1mm-4mm. figure 2 It is a schematic diagram of the structure of the grinding head in the embodiment of the present invention, image 3 for figure 2 The left view of , showing the depth and width of the rib. Depend on figure 2 and image 3 It can be seen that in this embodiment, the number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com