Finishing method and finishing tool for base paper of printing paper

A paper base paper and tool technology, which is applied in the field of printing paper base paper finishing and finishing tools, can solve problems such as multi-process, production delay, breakage, etc., and achieve the effect of not delaying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

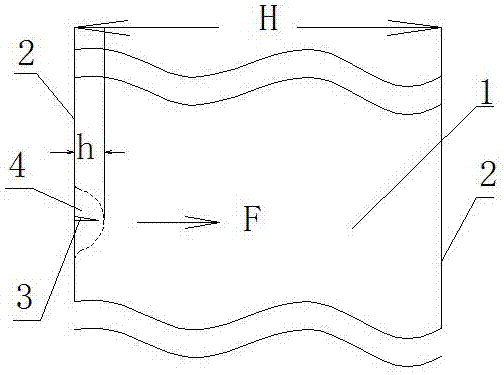

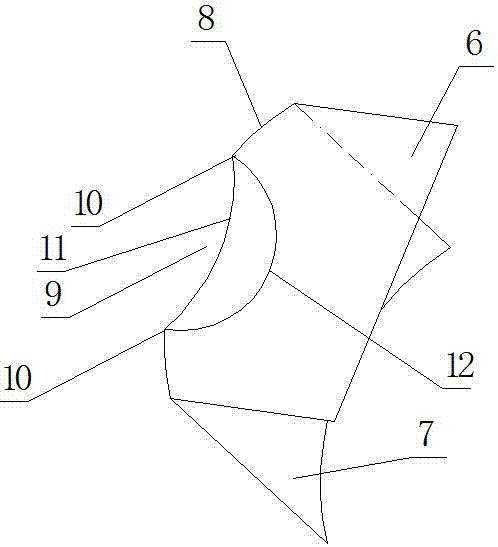

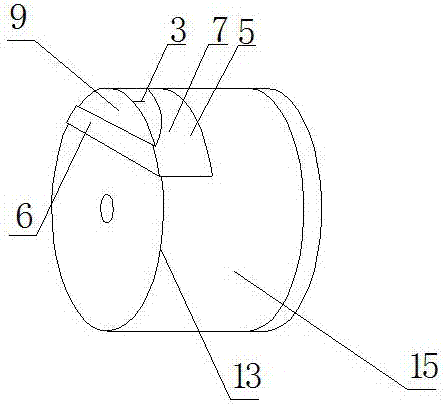

[0023] As shown in the figure, a printing paper base paper finishing method, the printing paper base paper is a cylindrical structural base paper, and the printing paper base paper is a long strip of paper after unfolding. figure 1 1 in it is the unrolled printing paper base paper, the printing paper base paper has two side parts 2, and the side part has a tear 3, and the method of finishing the base paper is to cut the tear part into a notch 4 with an arc-shaped structure. figure 1 The dotted line in is the cutting part, that is, the edge of the notch. 3 in the figure is the tearing part. If the tearing part is not processed, during the printing process, the tearing part will be damaged due to the pulling force of the printing roller. Continue to extend inward, that is, along the figure 1 The direction of the middle arrow F continues to tear, causing the base paper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com