Appearance inspection apparatus for semiconductor assembly, and optical path structure thereof

A technology of appearance inspection and optical path, which is applied in the direction of optical testing for flaws/defects, material analysis through optical means, scientific instruments, etc., and can solve problems such as increasing equipment installation and calibration time, and increasing manufacturers' troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings and reference numerals, so that those who understand the art can implement it after studying this specification.

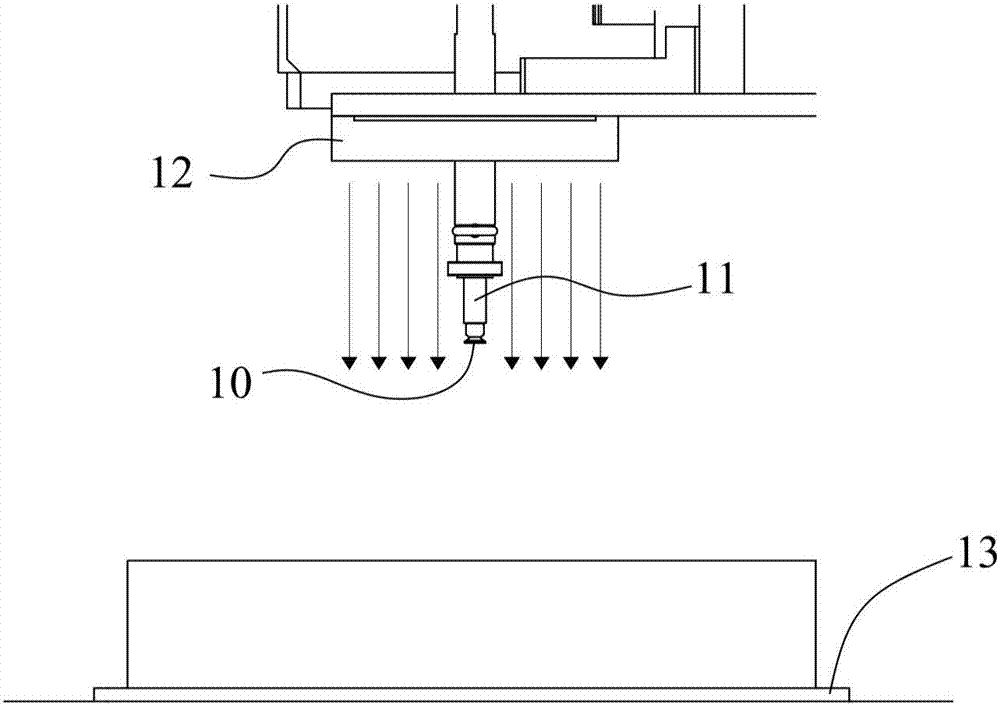

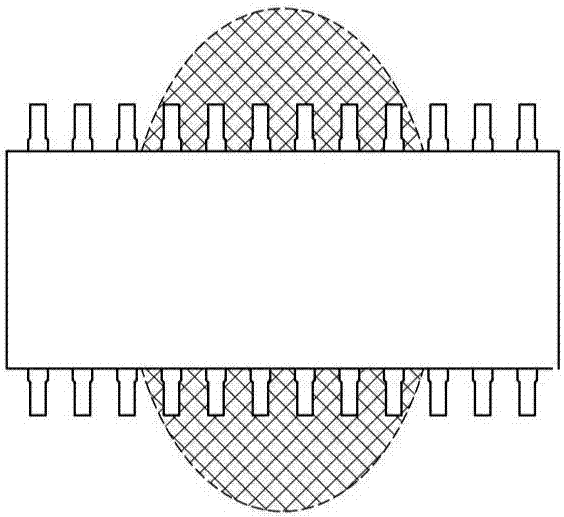

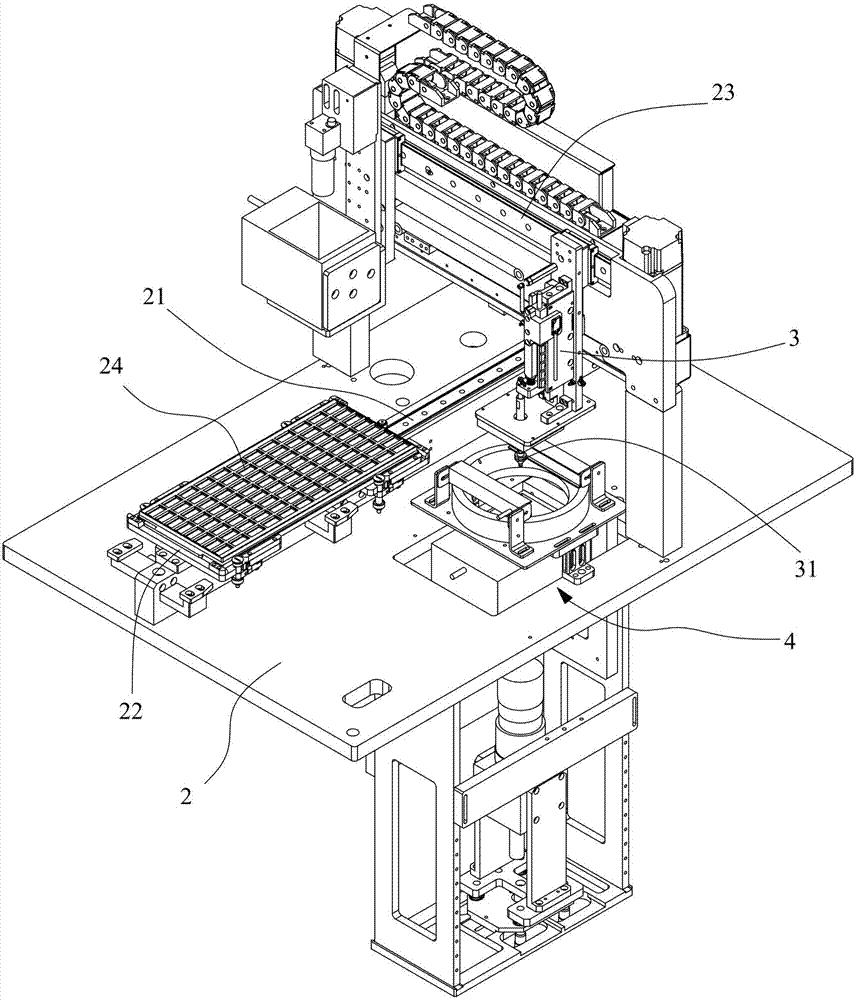

[0037] Such as image 3 Shown is a perspective view of the semiconductor component appearance inspection equipment of the present invention. The appearance inspection equipment of the semiconductor component of the present invention is that a transfer track 21, a carrier 22, a traverse track 23, a pick-and-place mechanism 3 and an appearance inspection area 4 are installed on the base 2, and the carrier 22 is installed on the mobile On the loading track 21, a carrier plate 24 can be carried for linear movement in the first direction, wherein the carrier plate 24 is used to place the semiconductor components to be tested; , the pick-and-place mechanism 3 is installed on the traversing track 23 and can move in a second direction, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com