Textile defect detection method based on peak coverage value and mixed features

A technology of mixing features and textiles, applied in image data processing, instruments, calculations, etc., can solve problems such as reducing the degree of automation of machine identification of textile defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

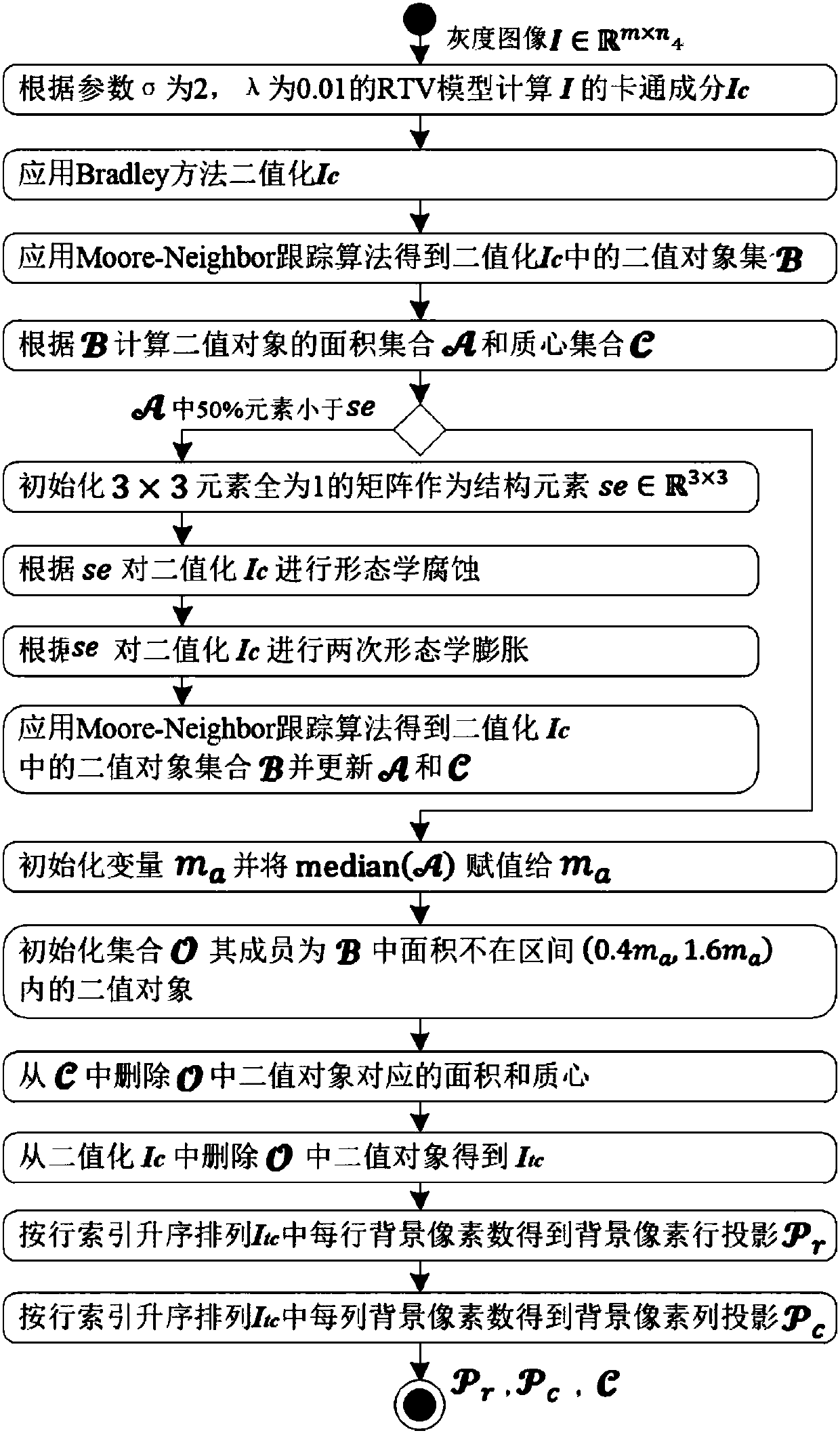

[0106] The implementation of the calculation method of the present invention is completed by writing computer programs, and the self-defined algorithms involved in the specific implementation process are described by pseudocodes. The program input is a grayscale textile image, and the program output is a collection of tiles with defects. The embodiment of the present invention includes five steps, the first three steps are the training phase, and the last two steps are the testing phase.

[0107] The training phase includes the following steps:

[0108] Step 1: Calculate the parameters required for grid segmentation based on a series of flawless images to determine the ideal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com