Anti-blocking dust filtering equipment

An anti-clogging and dust-filtering technology, applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of use cost, high maintenance cost, unsatisfactory improvement of dust removal effect, complicated structure of dust removal equipment, etc., and achieve simplification Structure, improvement of dust filtering effect, effect of improving dust filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

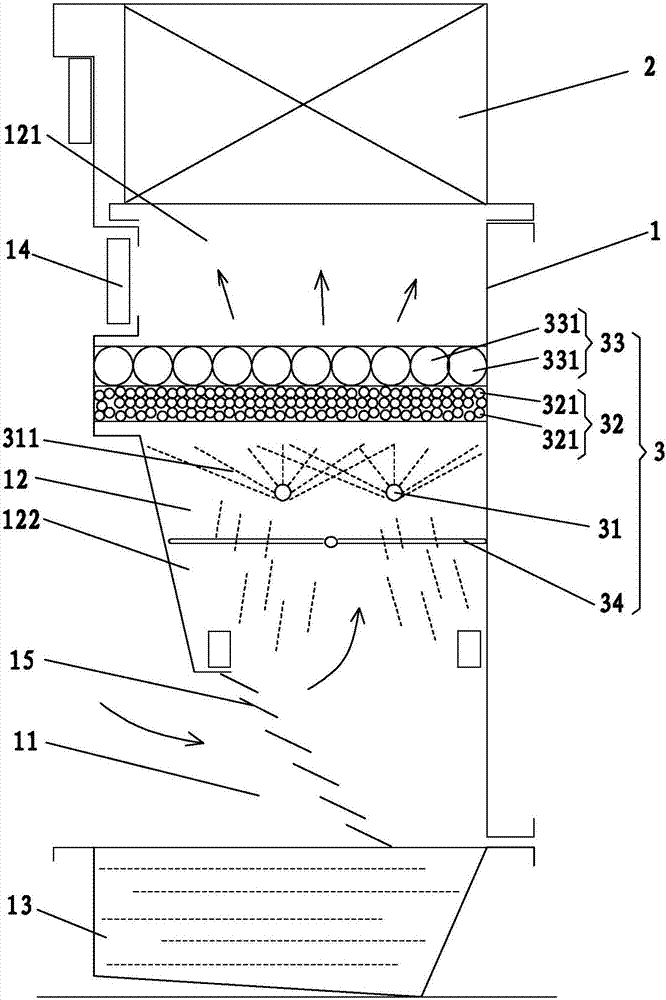

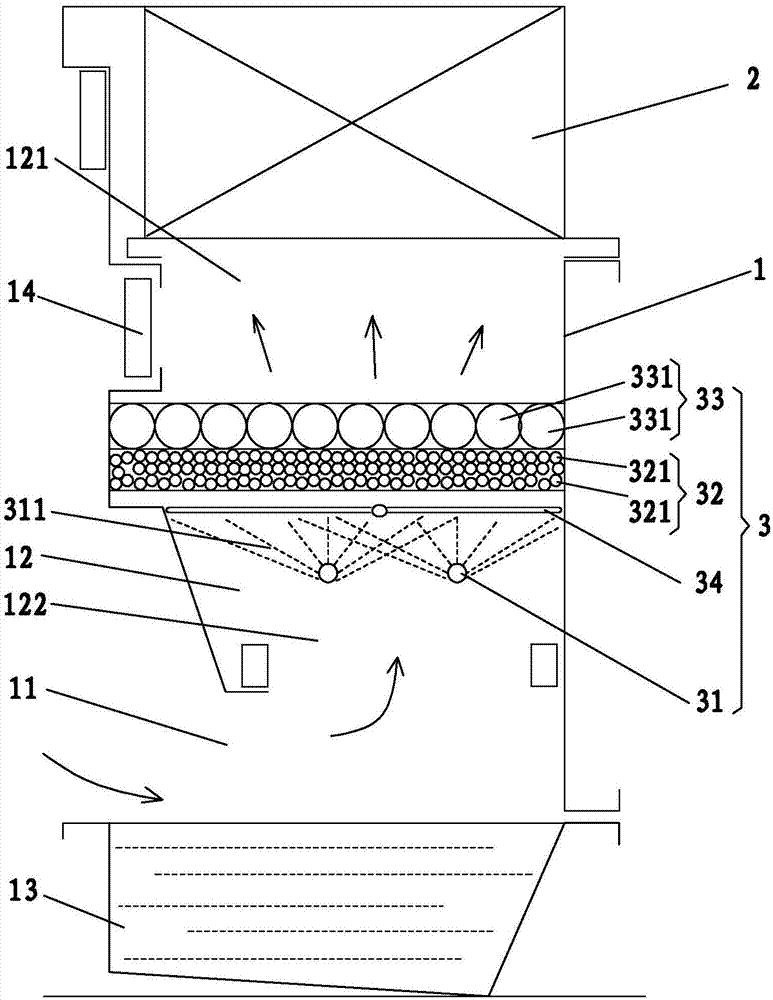

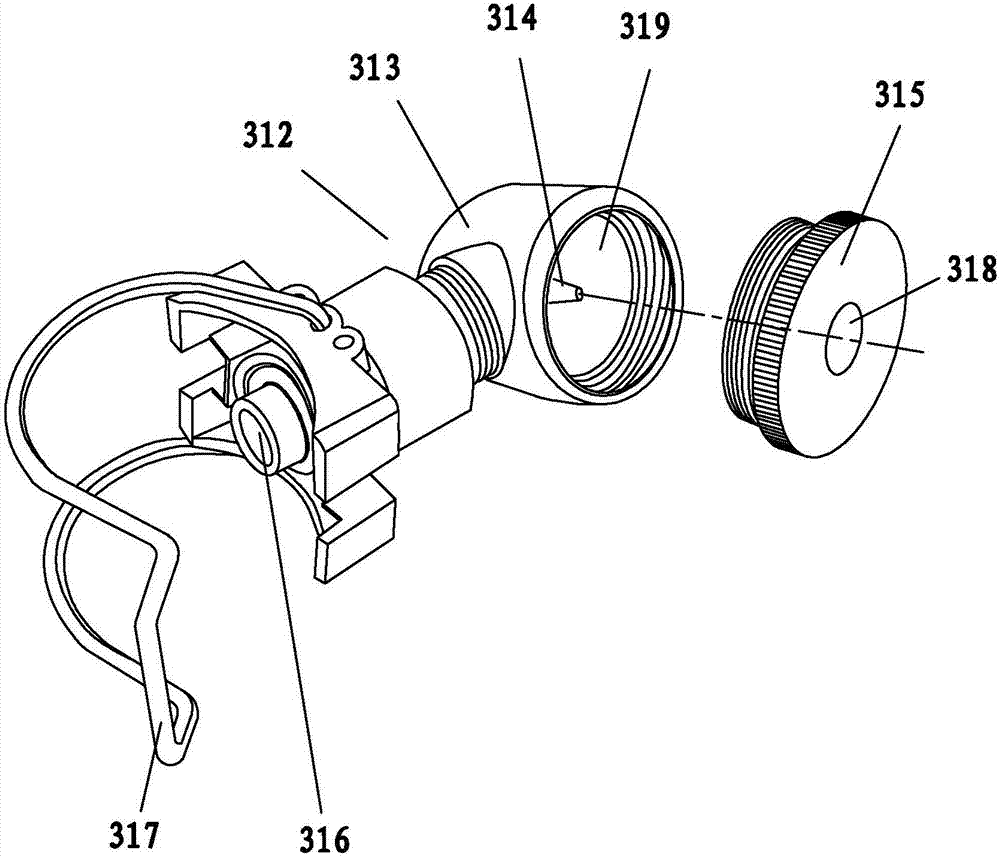

[0033] like Figure 1 to Figure 4 As shown, the anti-clogging dust filter device of the present invention mainly includes a casing 1 , a fan 2 and a dust filter group 3 .

[0034] Housing 1 adopts profiles such as plates and channel steels to make a semi-enclosed space. There is an air inlet 11 on the casing 1, and the inner cavity of the casing 1 forms a filter cavity 12, which is mainly used to accommodate the dust filter group 3, etc., and forms a passage for air flow, so that the gas and liquid can flow in the filter cavity 12 Dust suppression and filtration are completed inside. A liquid tank 13 is provided at the bottom of the filter chamber 12 , and a dust filter group 3 is provided in the filter chamber 12 and above the liquid tank 13 . The liquid tank 13 is used to receive the liquid and dust etc. d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com