A feeding mechanism for a composite machine

A compounding machine and feeding technology, applied in thin material processing, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems of reducing the yield, affecting the compounding effect, dislocation of the surface of the cloth, etc., to reduce the degree of deflection, Improve stability and avoid loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

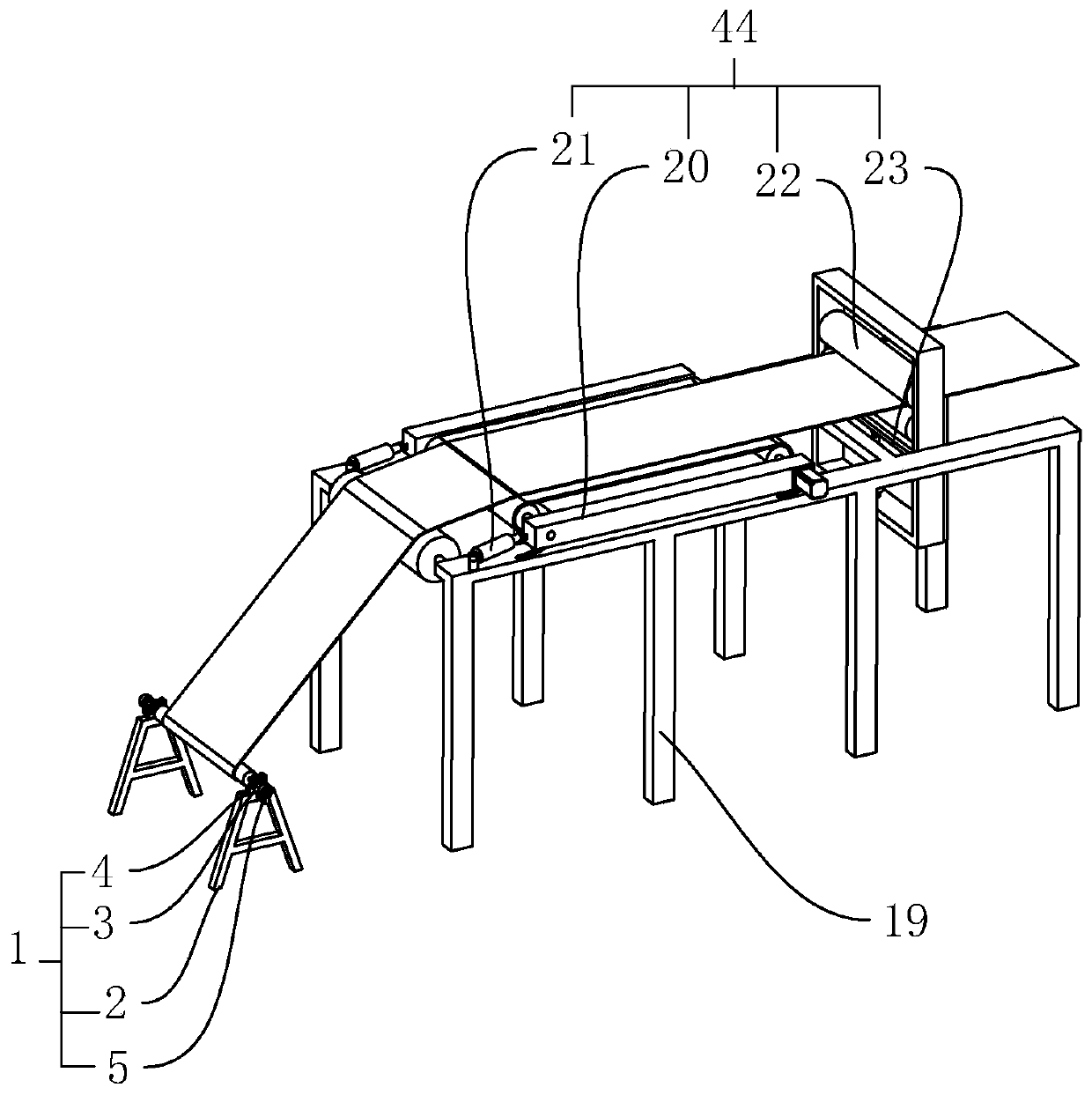

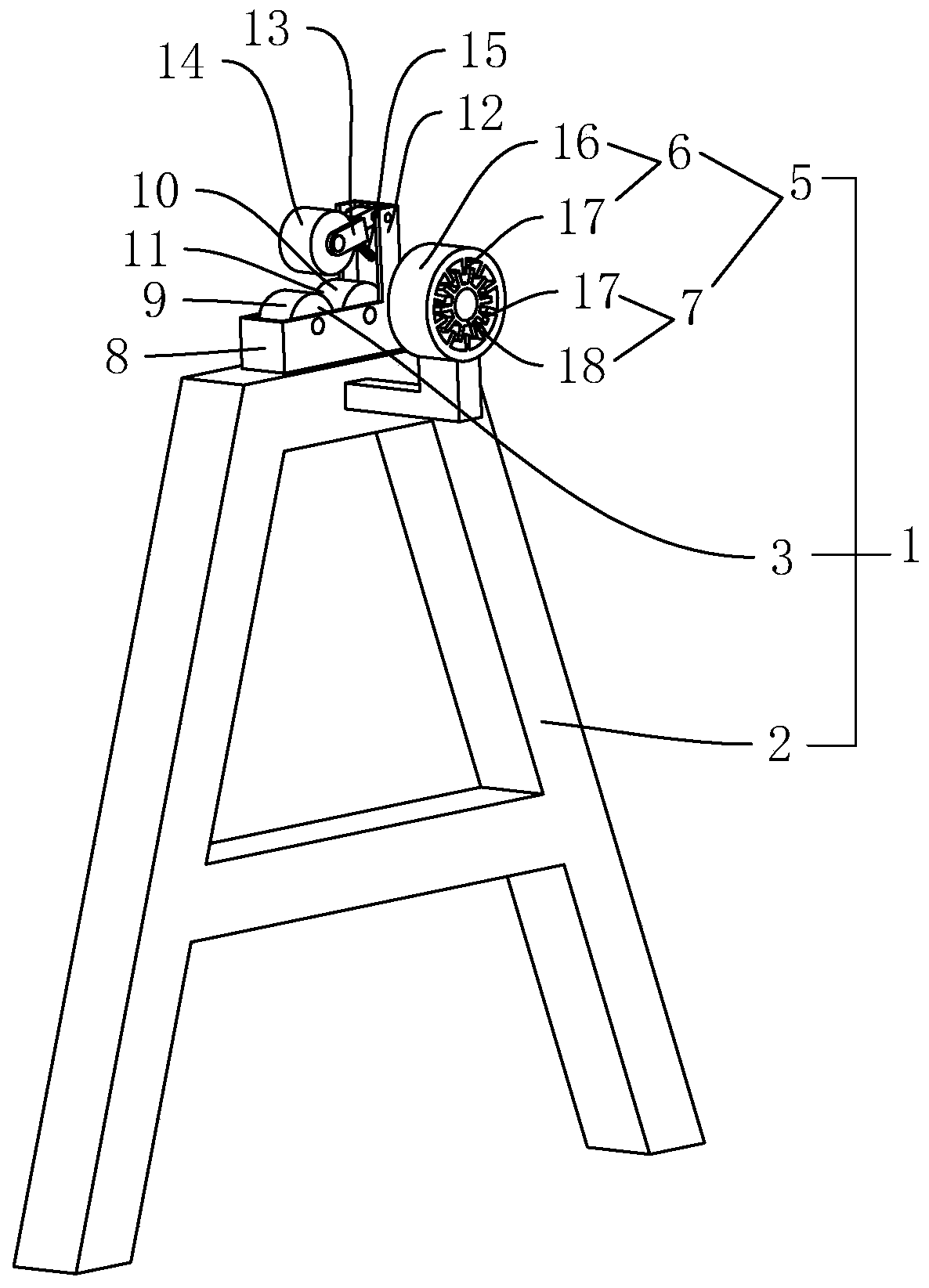

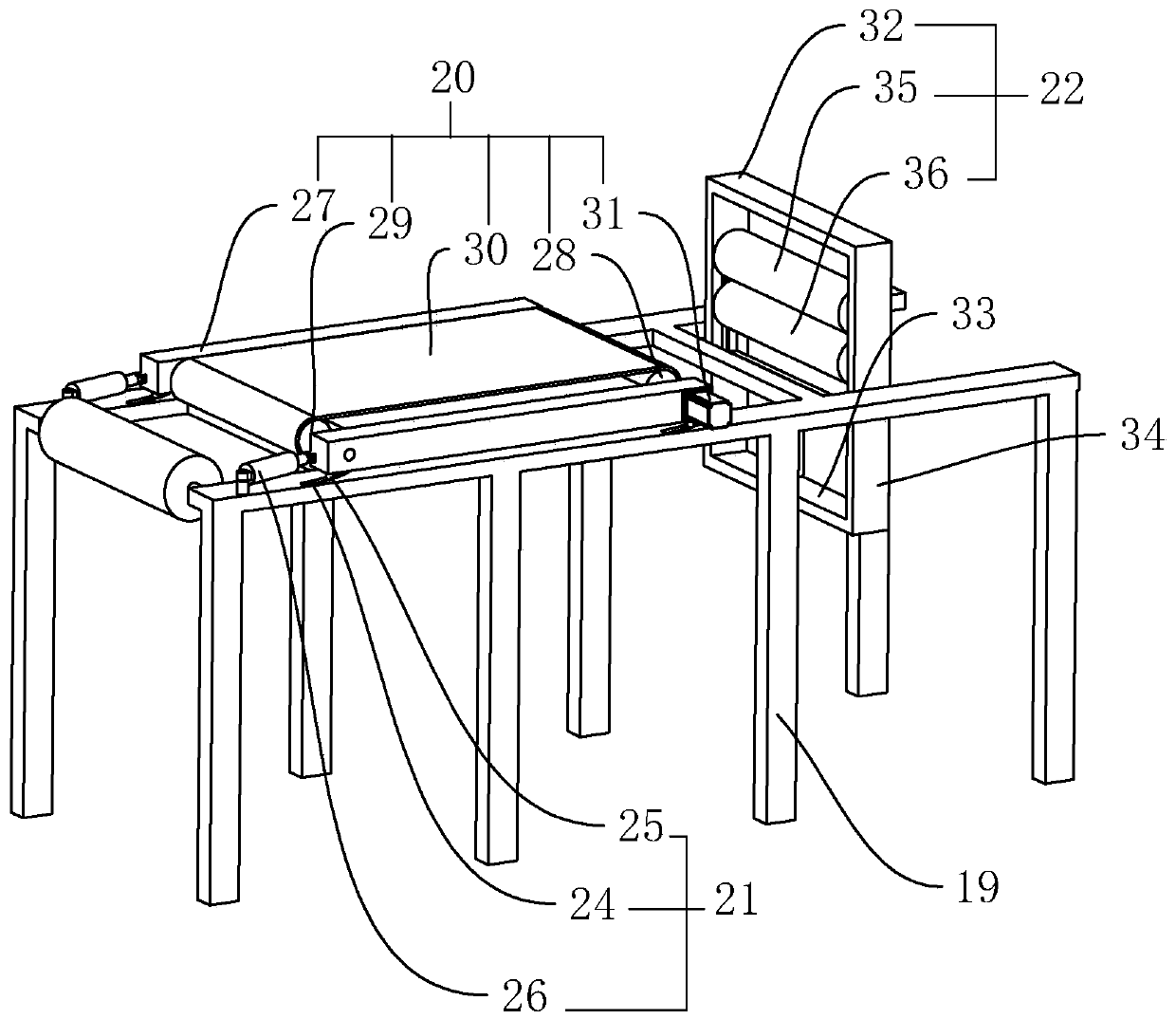

[0035] A feeding mechanism of a composite machine, such as figure 1 As shown, it includes a feeding device 1, the feeding device 1 includes a frame 2 placed on the ground, a support mechanism 3 is provided on the top of the frame 2, and the support mechanism 3 is equipped with a feeding rod 4 for sheathing a cloth roll. The two ends of the feeding rod 4 are built on the support mechanism 3 and can rotate freely. A brake mechanism 5 is arranged between the frame 2 and the feeding rod 4. The force end of the brake mechanism 5 acts on the two ends of the feeding rod 4. The brake mechanism 5 increases the resistance when the feeding rod 4 rotates, thereby effectively preventing the excessive rotation of the feeding rod 4 under the action of inertia; Higher than the feeding device 1, the cloth broken by the feeding device 1 is sent to the cloth guide fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com