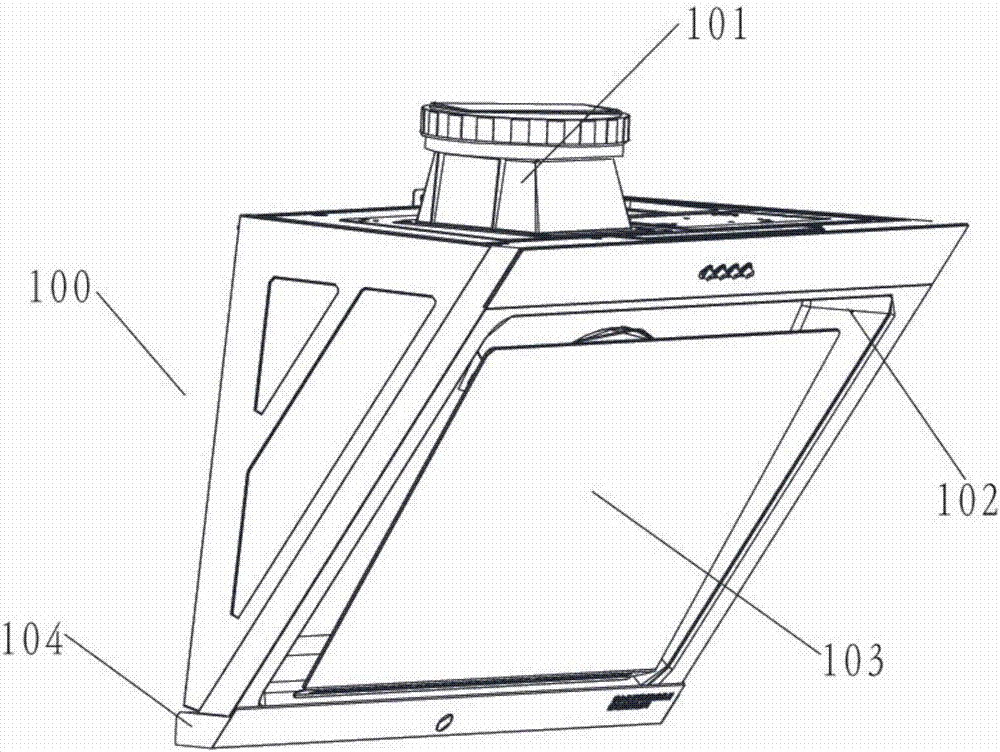

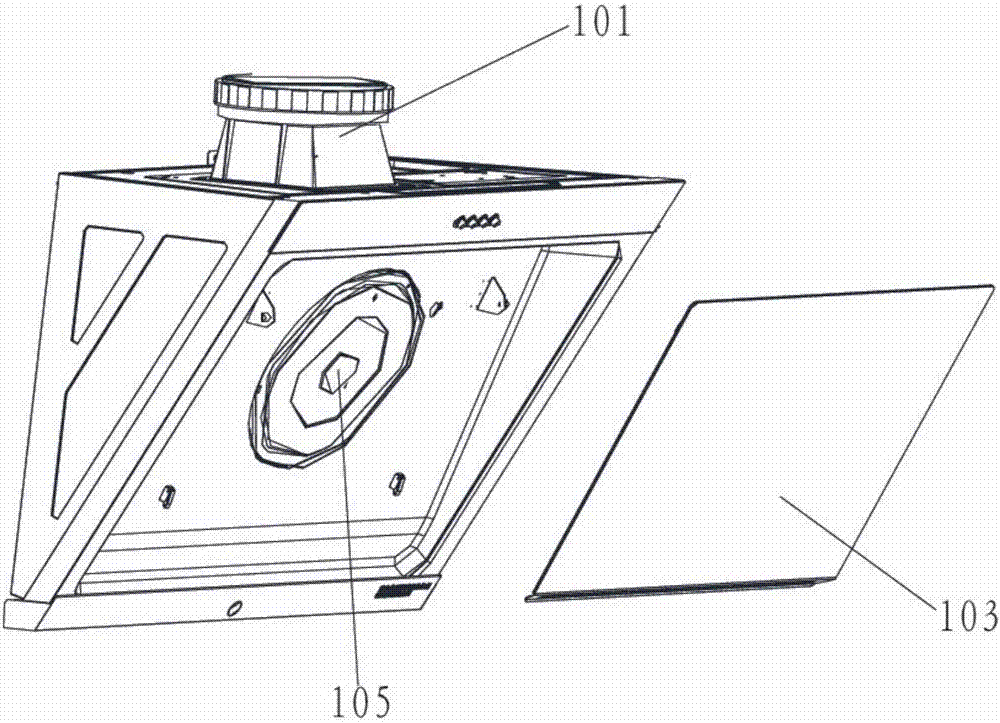

Range hood

A range hood and air intake technology, which is applied in the field of kitchen utensils, can solve the problems of air volume loss, low air intake efficiency, and poor smoking effect, and achieve the effects of increasing the smoke collection area, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

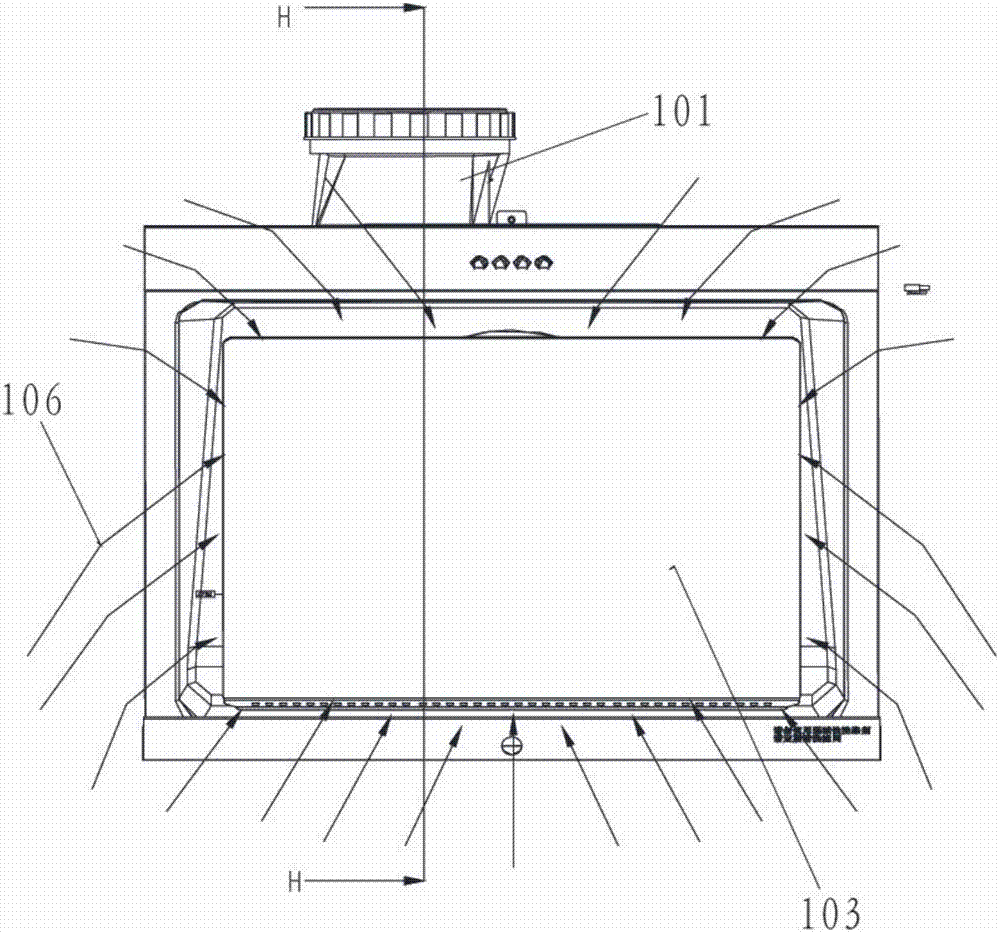

[0040] Such as Figure 5 to Figure 10 As shown, the embodiment of the present invention provides a range hood 200, including a box body and an air inlet front assembly, the air inlet front assembly includes a deflector 221, and the deflector 221 is installed on the cabinet; The left side is provided with a first air inlet cavity 2211 protruding toward the direction of the box body, and the right side of the deflector 221 is provided with a second air inlet cavity 2212 protruding toward the direction of the box body, and the first air inlet cavity Both 2211 and the second air inlet cavity 2212 are provided with at least one air inlet.

[0041] Preferably, in this embodiment, the box body includes a casing 212 and a frame 211 connected to the casing 212 and positioned above the casing 212, and the volute 231 is arranged in the installation space jointly formed by the casing 212 and the frame 211 Inside.

[0042] In the range hood 200 provided by the present invention, the firs...

Embodiment 2

[0073] The difference with the technical solution of Embodiment 1 is:

[0074] Such as Figure 11 to Figure 12 As shown, in this embodiment, the longitudinal section shapes of the first air inlet cavity 2211 and the second air inlet cavity 2212 are both triangular, and the air inlet includes four cavity surfaces arranged on the first air inlet cavity 2211 One or more of the air inlets on one or more of the four cavity surfaces of the second air inlet cavity 2212.

[0075] Both the first air inlet cavity 2211 and the second air inlet cavity 2212 on the deflector 221 preferably adopt the structure of a triangular cavity, and the first air inlet cavity 2211 and the second air inlet cavity 2212 are all provided with inlets. breath. Wherein, each triangular cavity includes four cavity surfaces, one or more of the four cavity surfaces of the first air inlet cavity 2211 and one of the four cavity surfaces of the second air inlet cavity 2212 There are air inlets on one or more of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com