Vision-based full-closed-loop system of numerically-controlled machine tool

A CNC machine tool, full-closed-loop technology, applied in the direction of general control system, control/regulation system, digital control, etc., can solve the problems of no control of tool cutting results, no cutting process into control, etc., to improve processing quality and processing accuracy , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] For CNC milling machine, the present invention is implemented as follows:

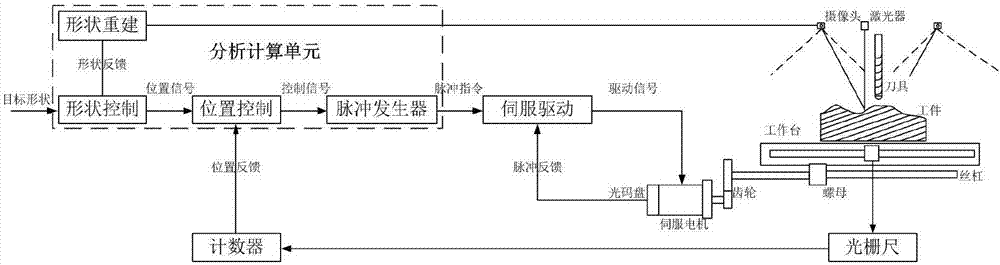

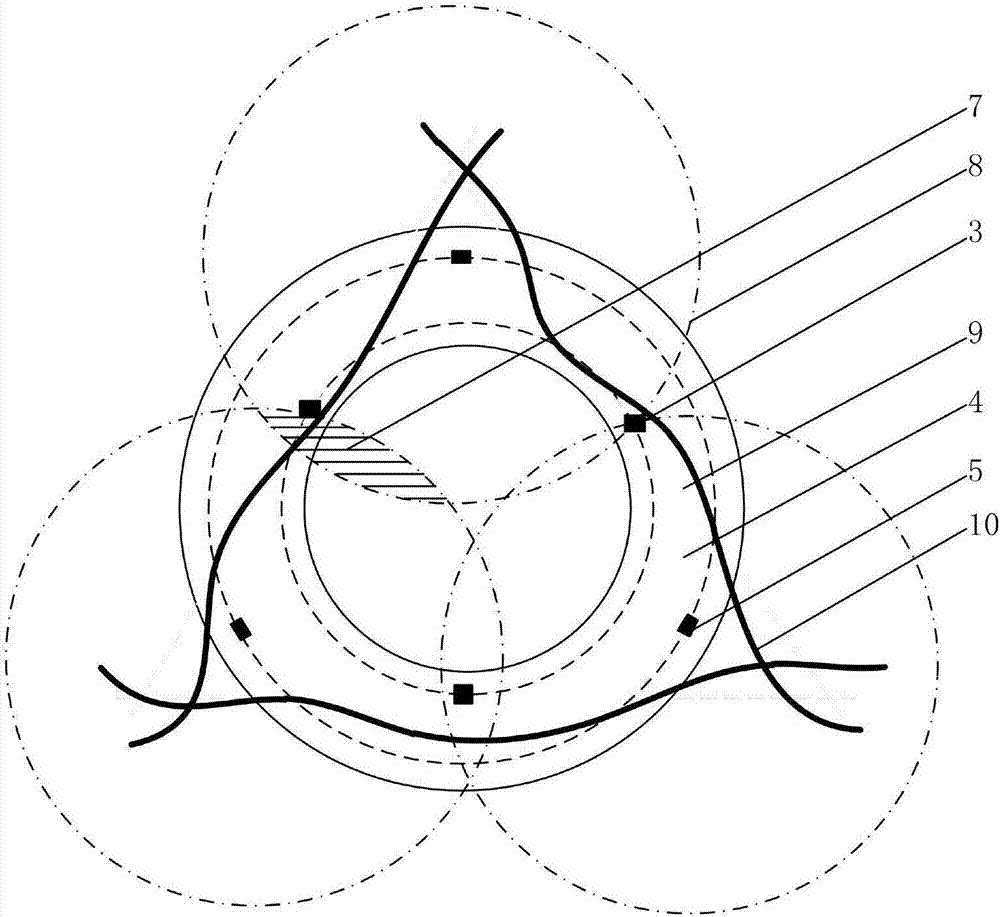

[0063] Such as Figure 1-5 As shown, a vision-based full-closed-loop system for CNC machine tools, the basic idea is to measure the three-dimensional shape of parts in real-time during the machining process to improve the machining accuracy, specifically including the semi-closed-loop controlled workbench and the full-closed-loop measurement unit , Analytical calculation unit, toolholders and tools for processing.

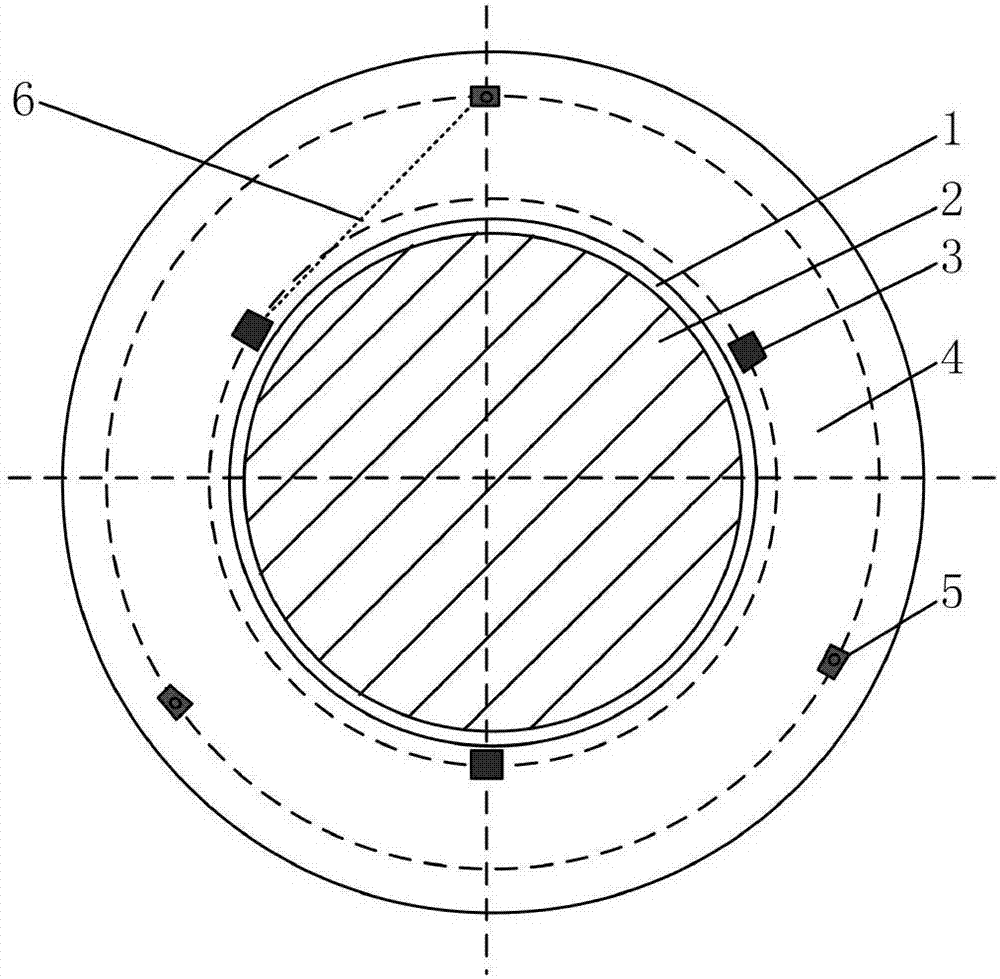

[0064] The measurement unit 4 is as attached figure 2 , in the shape of a flange, installed on the side of the tool holder 1 and on the handle of the tool with rolling bearings, does not rotate with the tool 2, but moves with the tool 2, and the measuring unit 4 is equipped with several pairs of laser emitters 3 and cameras 5 at equal radial intervals , the camera 5 is located on the outer large ring, and the laser transmitter 3 is located on the inner small ring. In order to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com