Automatic feeding device for digit wheel of counter of gas meter

A technology of automatic feeding and gas metering, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of digital wheels taking a long time, small differences in appearance, easy to wrong installation, etc., to ensure assembly quality, reduce Manual workload, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

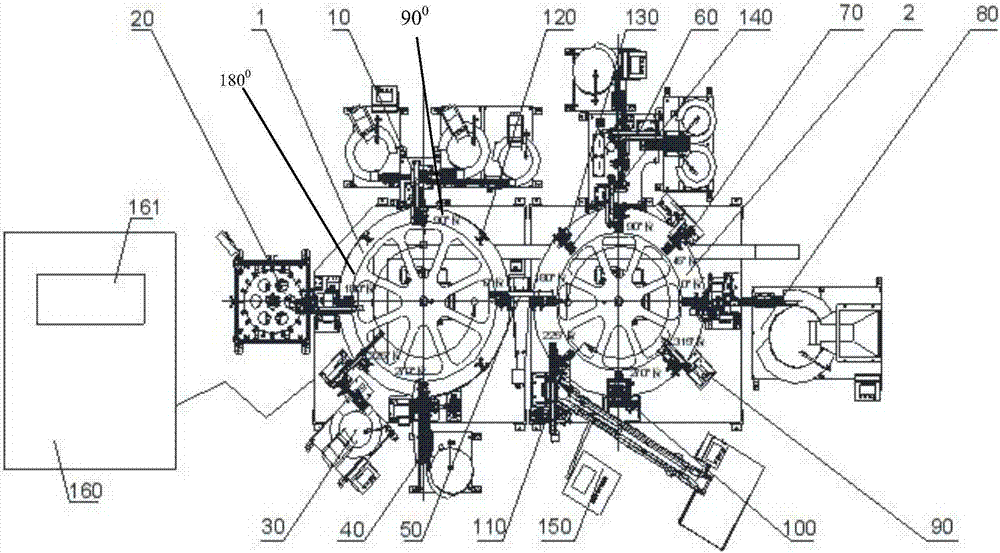

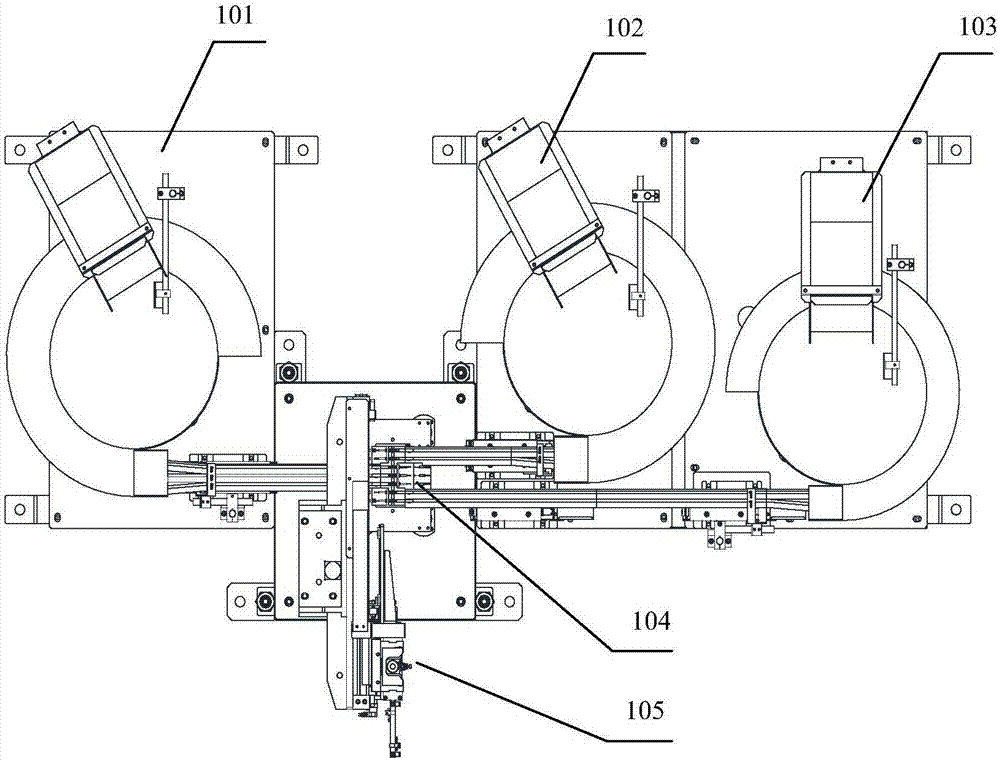

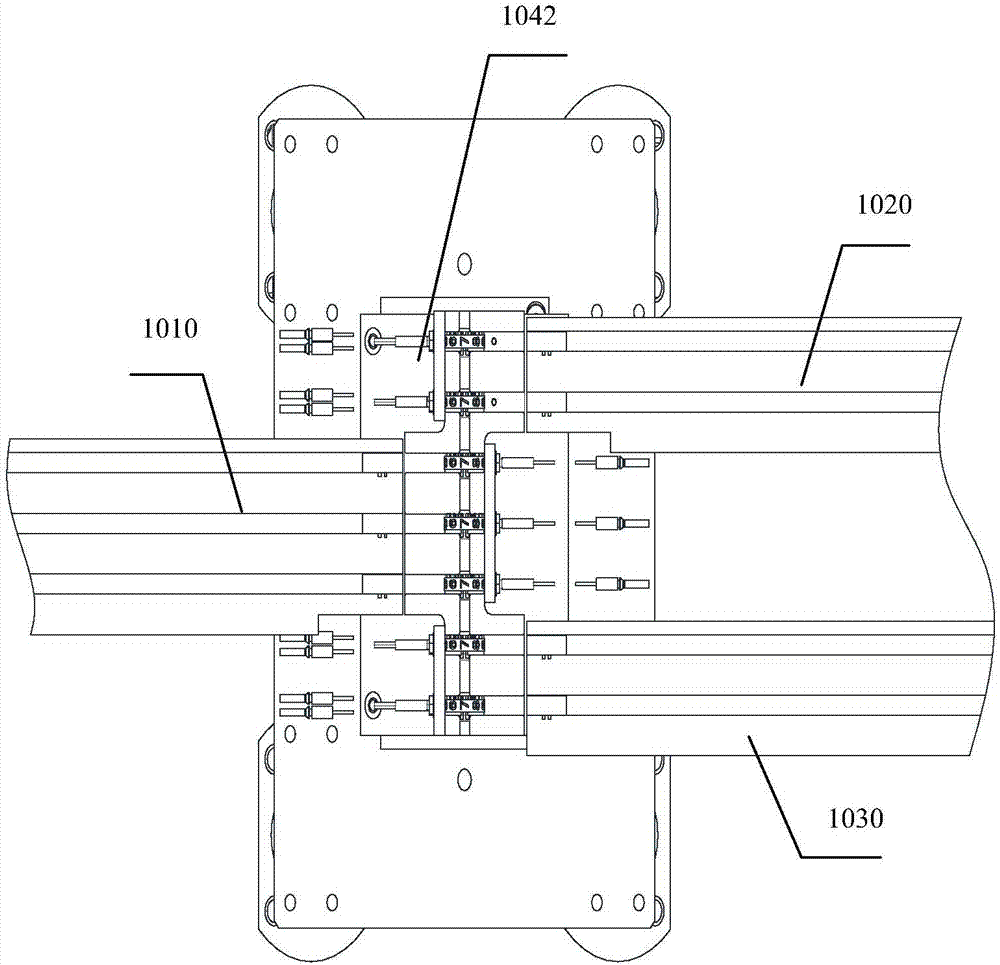

[0039] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0040] The present invention is used to produce a mechanical digital counter for a type gas meter, and its structure is as follows Figure 19 As shown, it is mainly composed of five black number wheels 004, two red character wheels 005, a first character wheel 006, a number wheel shaft 007, a switch wheel shaft 001, seven switch wheels 002 and a counter bracket 003. Each character wheel is evenly printed with numbers 0, 1, 2, 3, 4, 5, 6, 7, 8, 9. After the assembly is completed, the number 0 on the eight character wheels of the qualified counter is on a straight line. It coincides with the center line of the digital wheel shaft when viewed from above. When the digital wheel assembly 010 and the switch wheel assembly 008 are properly meshed, the switch wheel shaft 001 is parallel to the digital wheel shaft 007, and the counter bracket 003 is accurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com