High-efficiency compactor for waste cotton pads for medical gynecology

A high-efficiency, compactor technology, applied to presses, manufacturing tools, etc., can solve problems such as slow compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

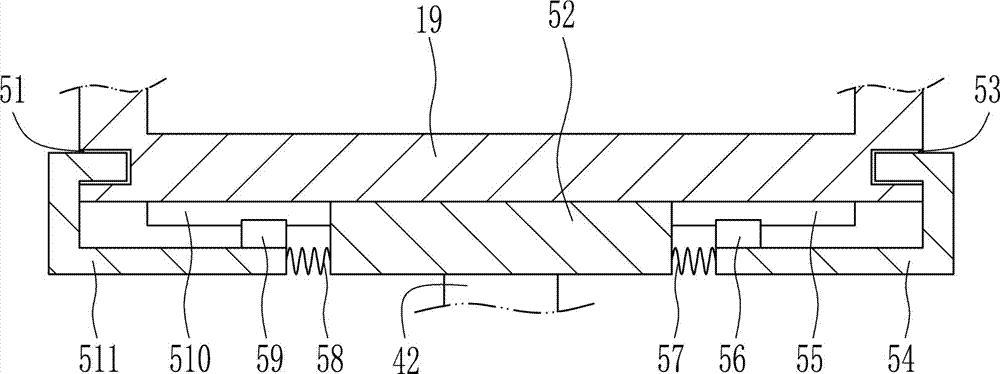

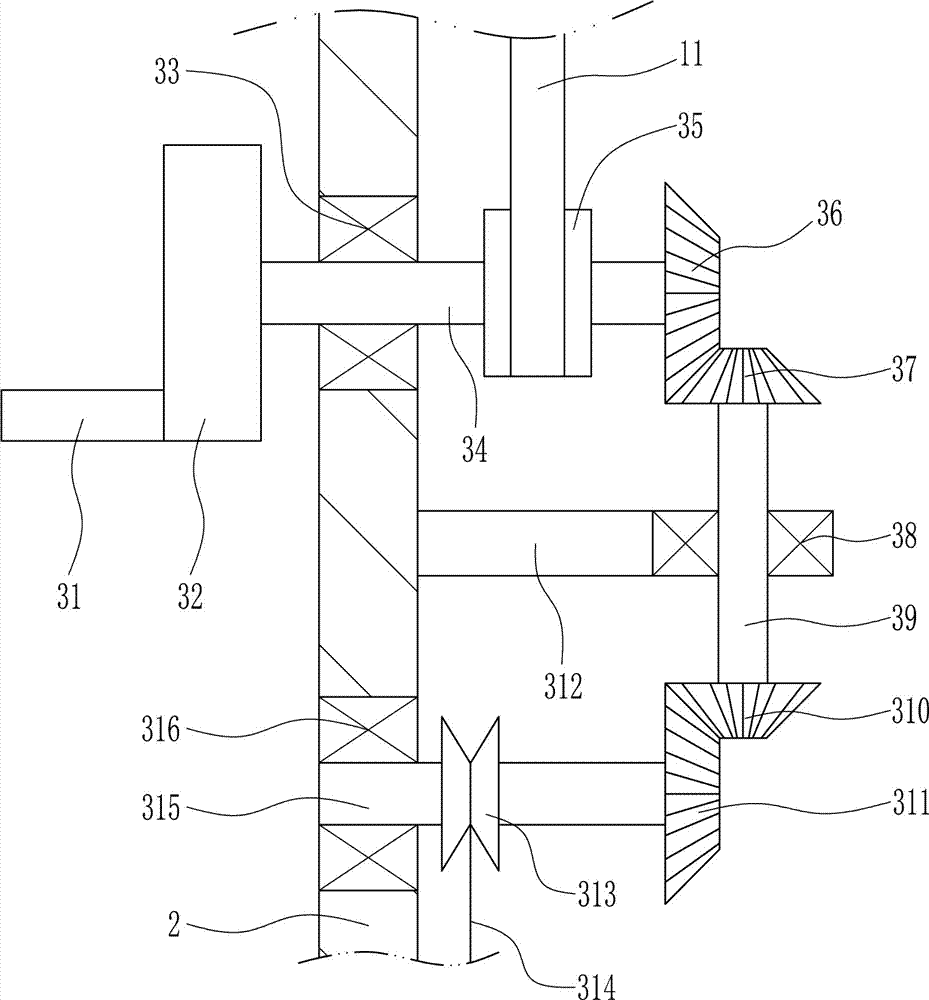

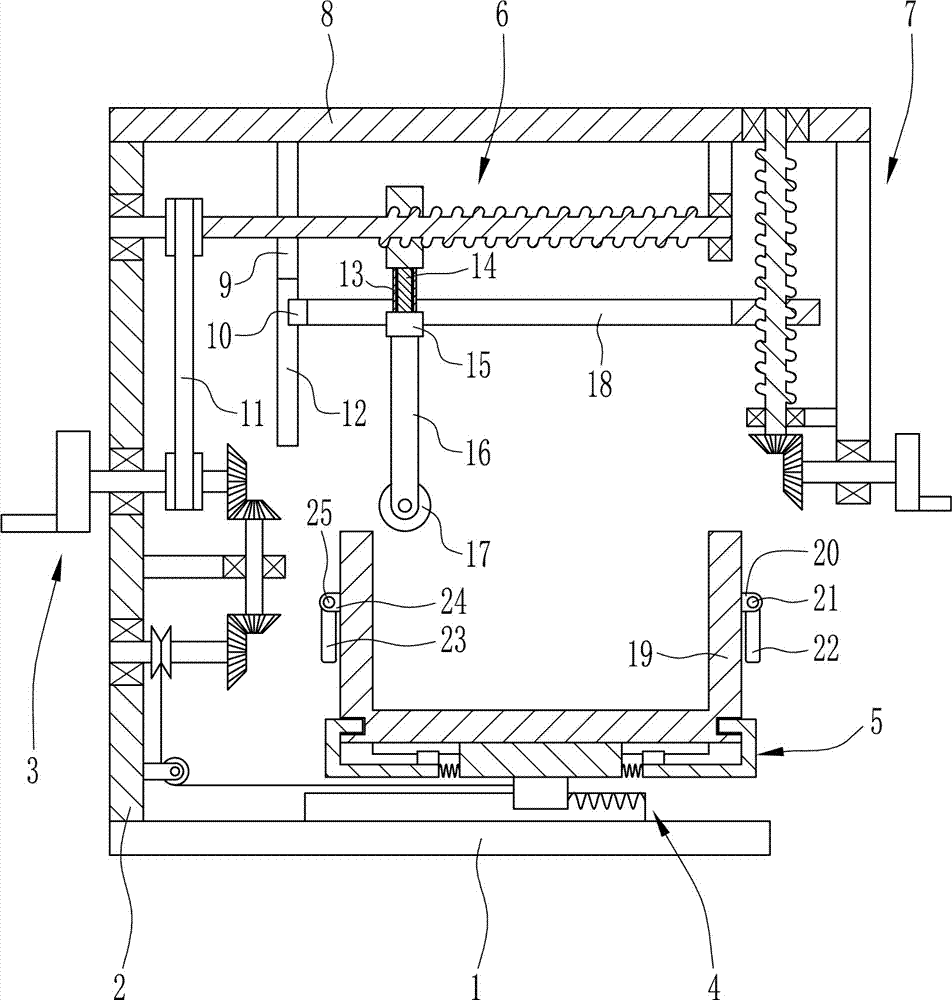

[0033] A high-efficiency compactor for medical and gynecological waste cotton pads, such as Figure 1-7 As shown, it includes a first mounting plate 1, a second mounting plate 2, a driving mechanism 3, a first moving mechanism 4, a fixing mechanism 5, a second moving mechanism 6, a height adjustment mechanism 7, a third mounting plate 8, a first Fixed bar 9, first slide block 10, flat belt 11, first slide rail 12, round pipe 13, slide bar 14, second slide block 15, second fixed bar 16, roller 17, second slide rail 18 and lay Box 19; the second mounting plate 2 is fixed to the end of the first mounting plate 1 along the vertical direction, the third mounting plate 8 is fixed to the top of the second mounting plate 2 along the horizontal direction, and the driving mechanism 3 is fixed to the second mounting plate 2 On the plate 2, the first moving mechanism 4 is affixed to the top of the first mounting plate 1, the driving mechanism 3 is connected to the first moving mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com