Big grid pattern conveyer belt joint structure and method

A checkered pattern and conveyor belt technology, used in conveyors, transportation and packaging, belt fasteners, etc., can solve the problems of inability to obtain continuous and full patterns, uneven unevenness, and achieve convenient distinction, convenient cutting, Checkered pattern joins natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

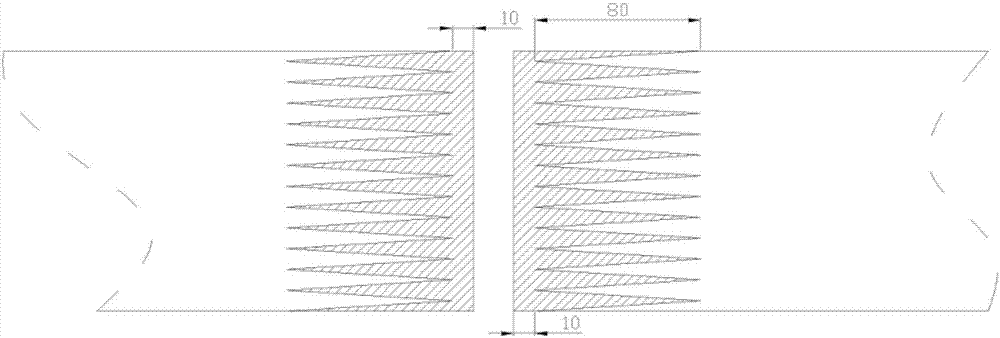

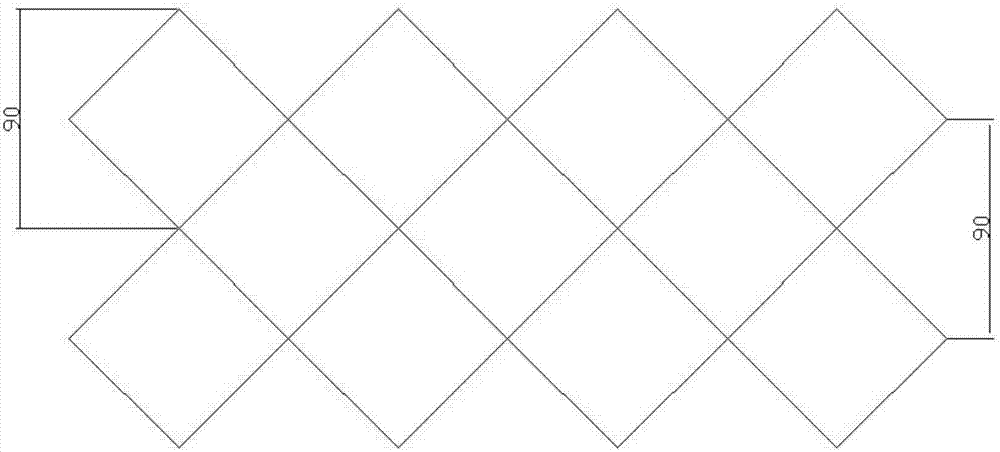

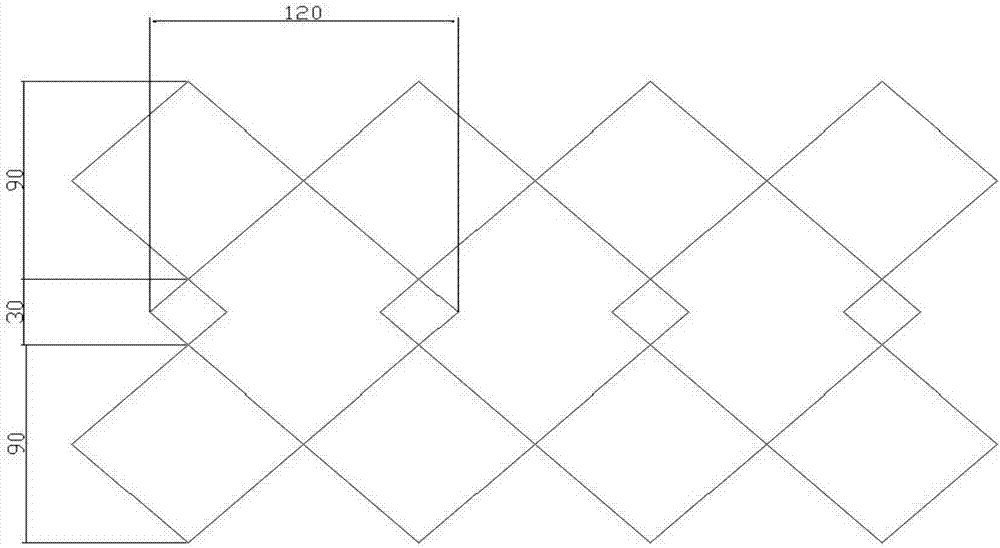

[0029] see figure 2 and 5 , the raised continuous large grid pattern on the conveyor belt, a pair of diagonal directions of the large grid are along the length and width of the conveyor belt, and the diagonal length of the large grid is 90mm; the conveyor belt is tiled, one end Cut along the diagonal of the large square; after the link size of the conveyor belt plus the joint allowance, divide by 90mm to produce a remainder ≤ 15, then the other end of the conveyor belt is also cut along the diagonal of the large square, that is, along the attached Figure 5 The line marked 4 is cut and looped to form figure 2 Joint Pattern Shown: Original large checkered pattern retained at the joint.

[0030] After the cutting is completed, the following process steps are sequentially included: layering, punching, positioning, and hot pressing.

Embodiment 2

[0032] see image 3 and 5 , if the link size of the conveyor belt is added to the joint allowance, the range of the remainder generated by dividing by 90mm is: 15 Figure 5 The line marked as 2 is cut and looped to form image 3 Joint pattern shown: A small 30mm checkered pattern is obtained at the joint site.

[0033] After the cutting is completed, the following process steps are sequentially included: layering, punching, positioning, and hot pressing.

Embodiment 3

[0035] see Figure 4 and 5 , if the link size of the conveyor belt is added to the joint allowance, the range of the remainder generated by dividing by 90mm is: 45 Figure 5 The line marked 3 is cut and looped to form Figure 4 Joint pattern shown: A small 60mm checkered pattern is obtained at the joint site.

[0036] After the cutting is completed, the following process steps are sequentially included: layering, punching, positioning, and hot pressing.

[0037] The invention avoids the phenomenon that the pattern on the surface of the conveyor belt is interrupted at the joint; avoids the situation that the pattern on the surface of the conveyor belt is uneven at the joint; All convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com