Single-pointer meter reading method based on machine vision

A technology of instrument reading and machine vision, which is applied in the field of computer image processing, can solve problems such as broken pointers, unapplicable occasions with limited inspection time, slow SIFT feature detection speed, etc., and achieve accurate reading results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

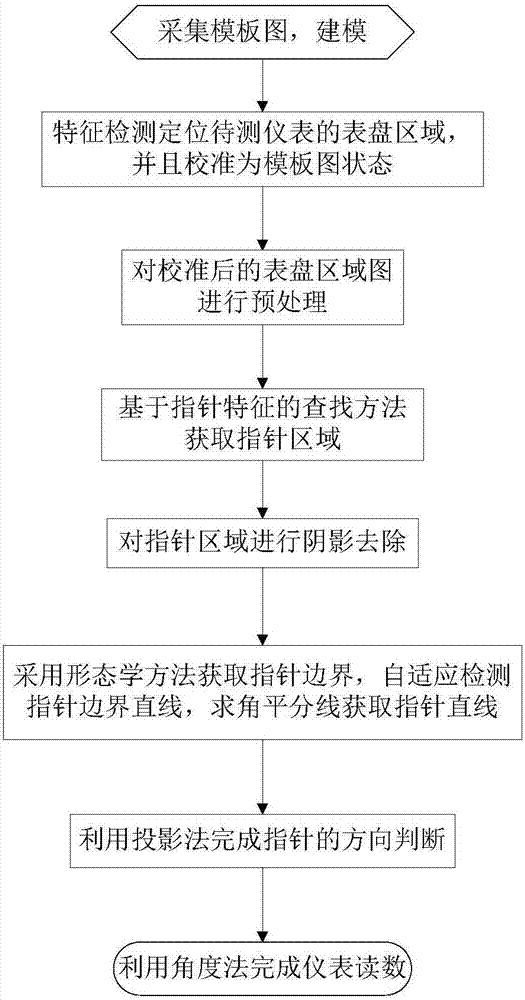

[0041] A machine vision-based single-pointer instrument reading method proposed by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] A machine vision-based single-pointer instrument reading method proposed by the present invention, the flow chart of which is shown in Figure 1, includes the following steps:

[0043] Step 1: Collect the template image, take the front view of the instrument as the template image, model the template image, perform feature detection on the dial area of the template image, and save the modeling information and feature information.

[0044]Modeling includes selecting the dial area, selecting the exclusion area, selecting the scale points and the center of revolution of the instrument. The selected dial area is to select a rectangular area that can contain the outline of the dial and does not contain redundant information, which can reduce the interference of irrele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com