LED light and LED packaging method

A technology of LED packaging and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of quantum efficiency reduction, affecting the lumen efficiency of LED light sources, and reducing light intensity, and achieve the effect of improving luminous dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

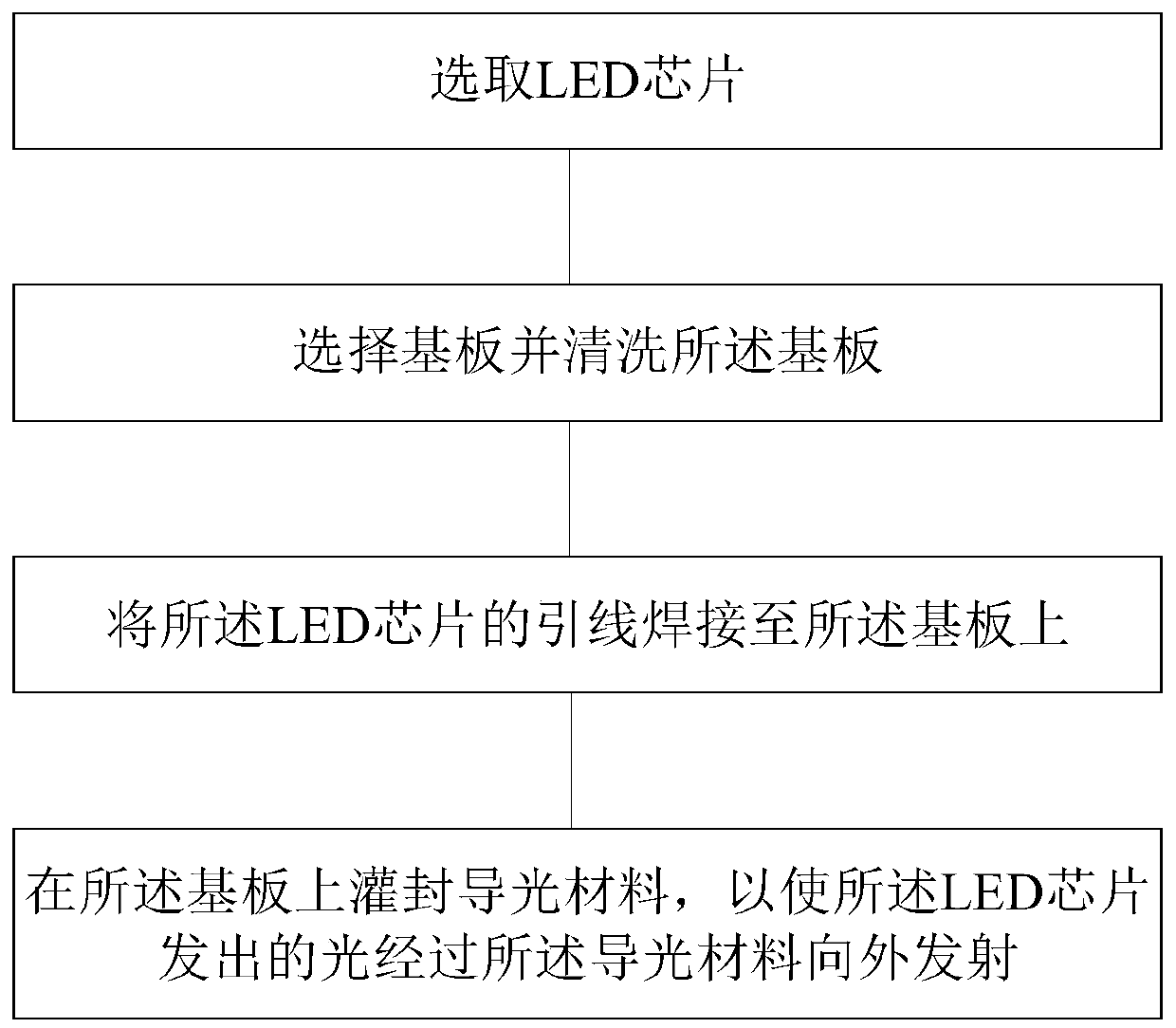

[0043] See figure 1 , figure 1 A schematic flow chart of an LED packaging method provided by an embodiment of the present invention, the method includes:

[0044] Select the LED chip;

[0045] selecting a heat sink and cleaning said heat sink;

[0046] Welding the leads of the LED chip to the heat sink;

[0047] A light guide material is potted on the heat sink, so that the light emitted by the LED chip is emitted outward through the light guide material.

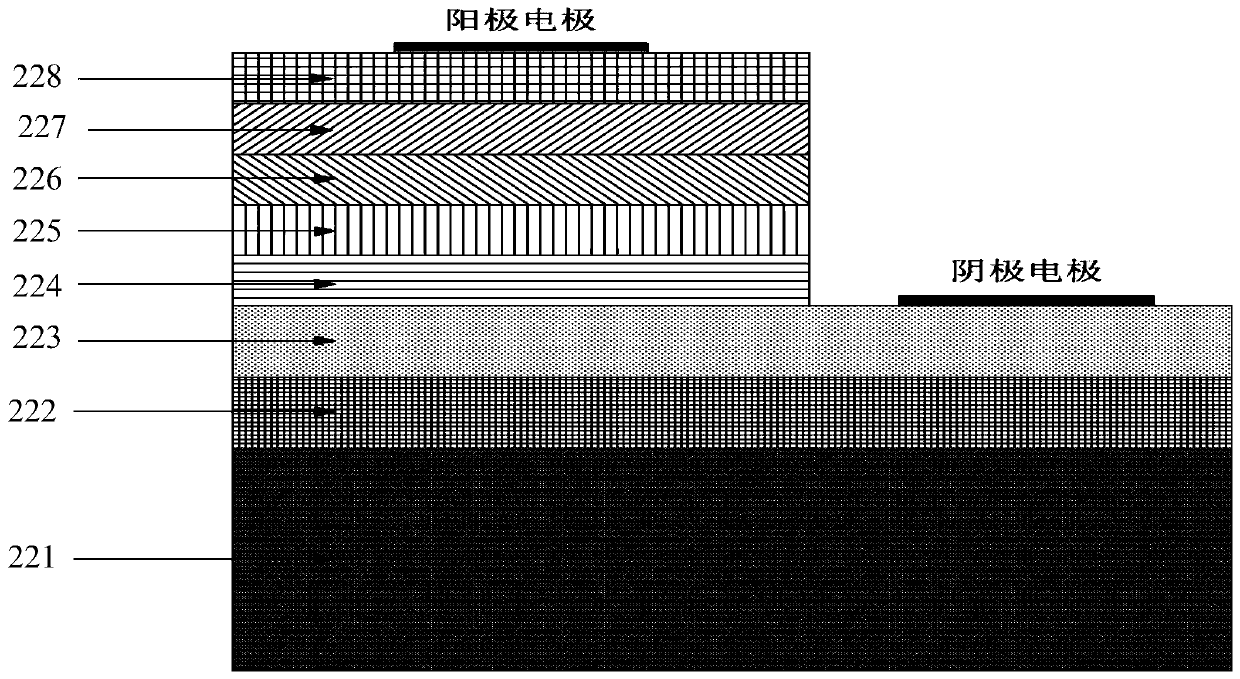

[0048] Further, on the basis of the above implementation manner, please refer to figure 2 , figure 2 A structural schematic diagram of an LED chip provided by an embodiment of the present invention, the LED chip sequentially includes a substrate layer (221), a GaN buffer layer (222), an N-type GaN layer (223), a first P-type GaN quantum well wide bandgap layer (224), InGaN layer (225), second P-type GaN quantum well wide bandgap layer (226), AlGaN barrier layer (227), P-type GaN layer (228) and electrodes.

[0049]...

Embodiment 2

[0078] This embodiment further illustrates the packaging method of the LED chip provided by the present invention.

[0079] see again image 3 ,exist image 3 In the shown heat sink, the width W of the heat sink is 0.5 mm to 10 mm, the diameter R of the circular groove is 0.2 mm to 1 mm, the distance L2 between two connected circular grooves is 0.5 mm to 10 mm, and the thickness of the heat sink is D and the length L, the distance L1 between the initial circular groove and the heat sink wall can be determined according to the process conditions, and the present invention is not limited here.

[0080] Preferably, the thickness of the heat sink used in this embodiment is relatively thick, so the heat sink will not affect the heat dissipation effect due to the reduction of the degree of fit between the heat sink and the peripheral heat dissipation device due to high temperature deformation.

[0081] please refer again Figure 4 ,exist Figure 4 Among them, the first silica ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com