A high-power blue LED multi-layer packaging structure

A packaging structure, high-power technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of decreased quantum efficiency of phosphor powder, affecting packaging lumen efficiency, reducing packaging light extraction efficiency, etc., to solve the problem of quantum efficiency decline, improve The effect of light source utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

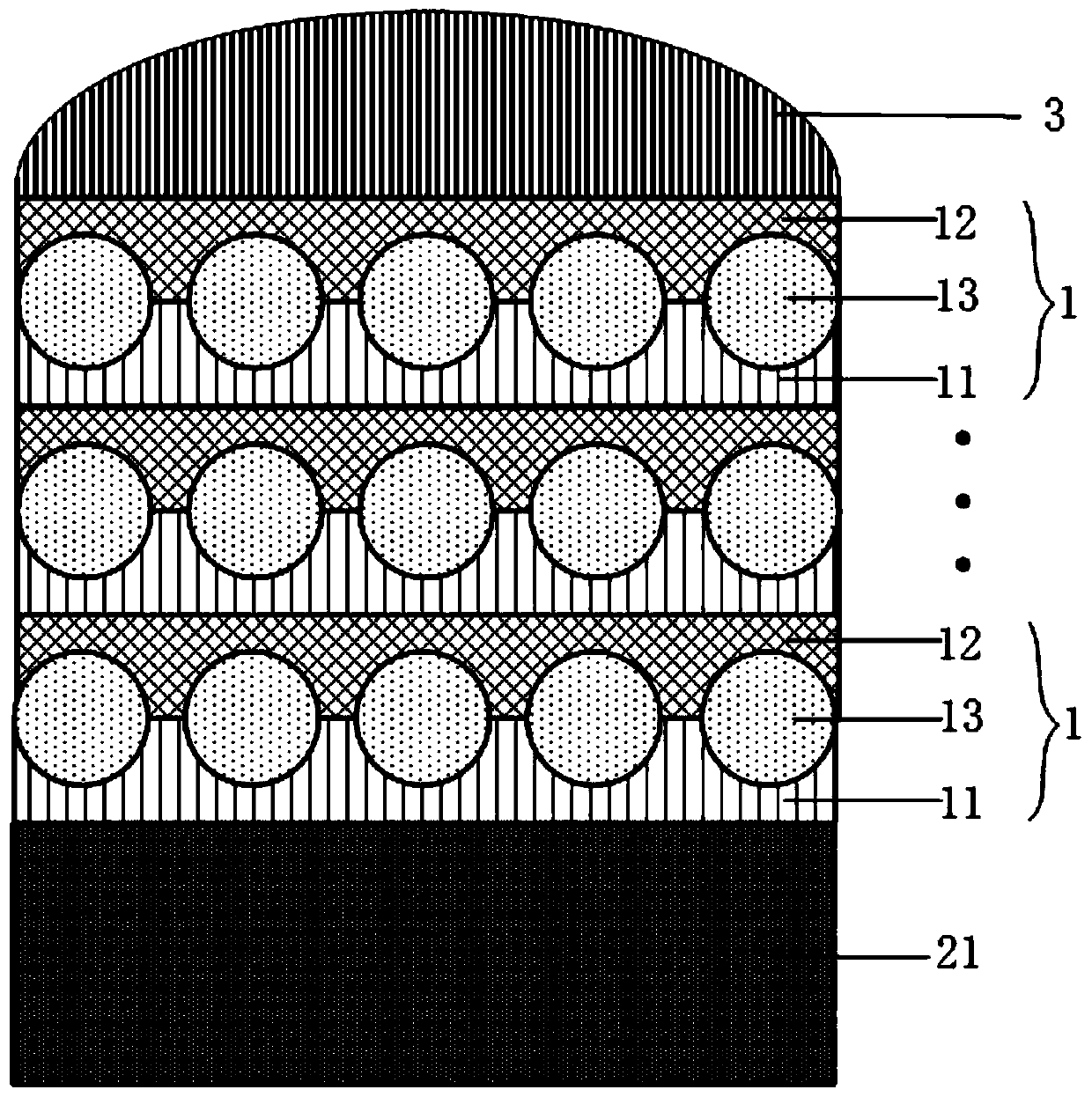

[0031] figure 1 A schematic diagram of a high-power blue LED multi-layer packaging structure provided by an embodiment of the present invention, including: multiple sets of lens layers 1, a heat dissipation substrate 21, and an outer packaging layer 3;

[0032] The lens layer 1 is arranged on the heat dissipation substrate 21, and an outer encapsulation layer 3 is arranged on the top of the multiple sets of lens layers 1; wherein, each set of lens layers includes a lower encapsulation layer 11, an upper encapsulation layer 12, a spherical lens 13;

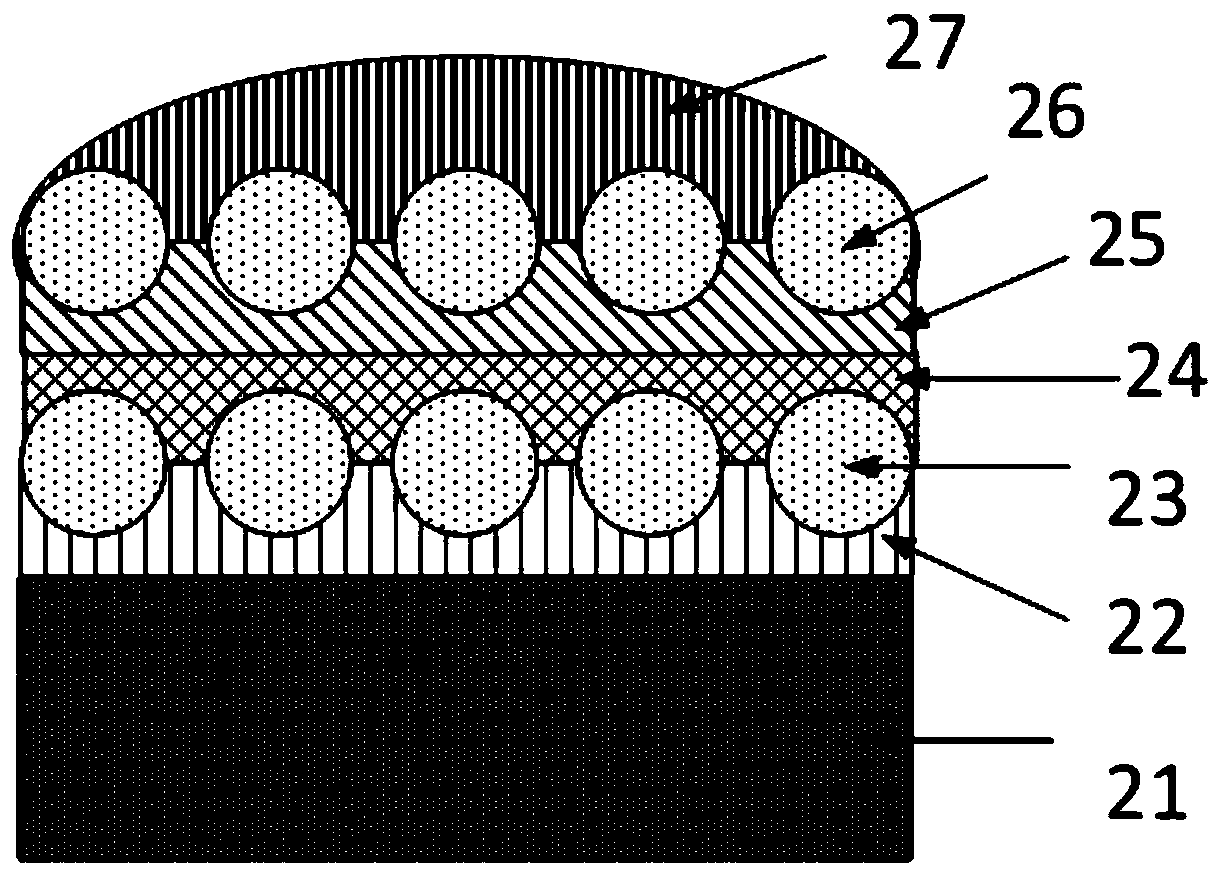

[0033] At least a part of the spherical lens 23 is embedded in the lower encapsulation layer 22 , and the upper encapsulation layer 24 is located on the non-embedded portion of the spherical lens 23 and the lower encapsulation layer 22 .

[0034] The lower encapsulation layer 11, the upper encapsulation layer 12, and the spherical lens 13 are all made of silica gel. The outer packaging layer 3 is a convex structure. Specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com