Patents

Literature

31results about How to "Solve the drop in quantum efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

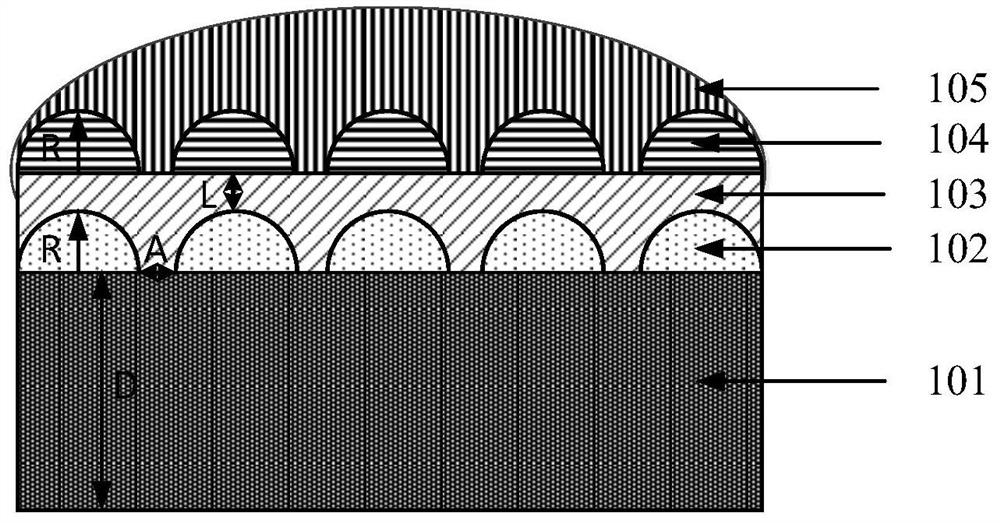

LED package structure

ActiveCN108011011AImprove cooling effectLarge heat capacitySemiconductor devicesTransmittanceCooling effect

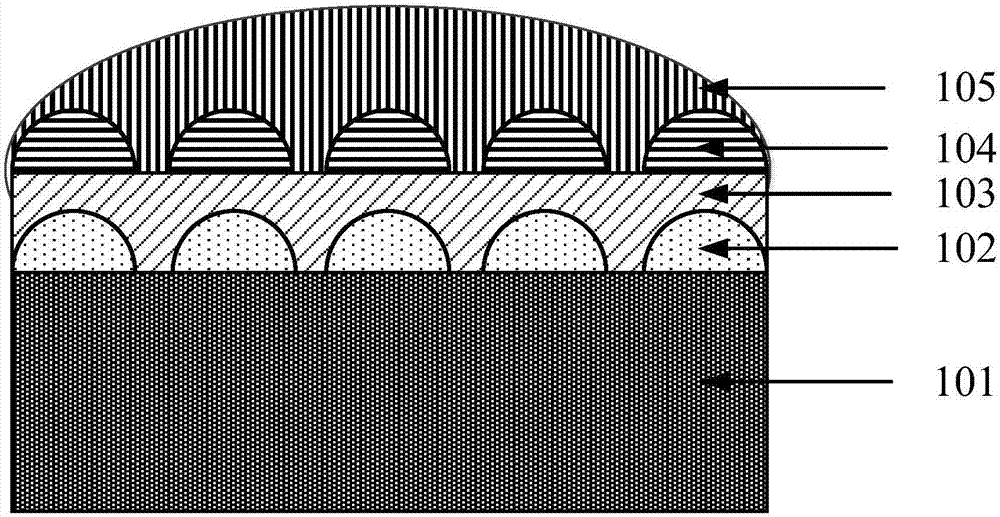

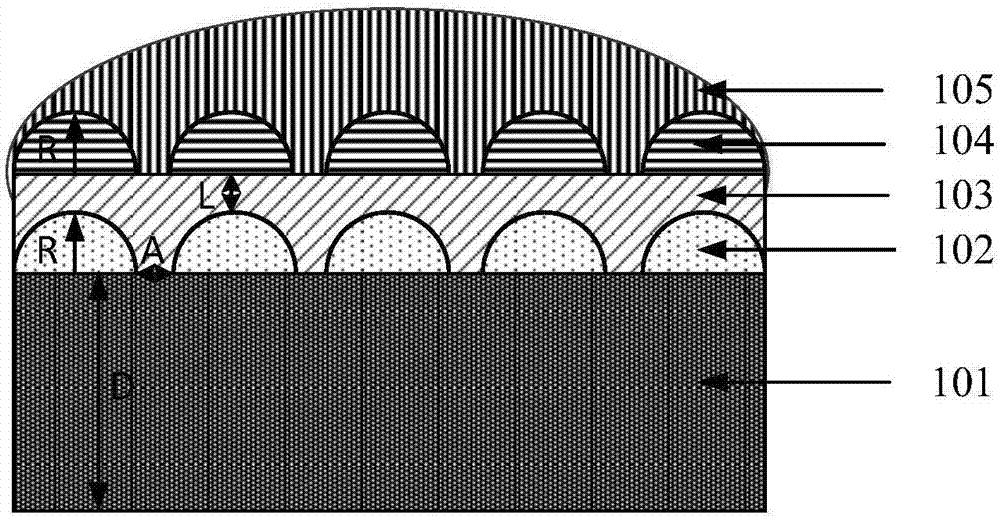

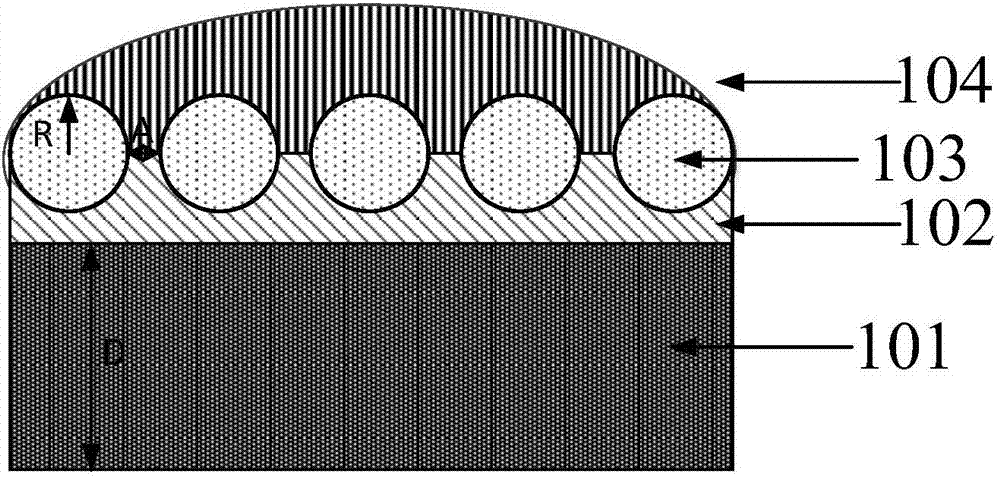

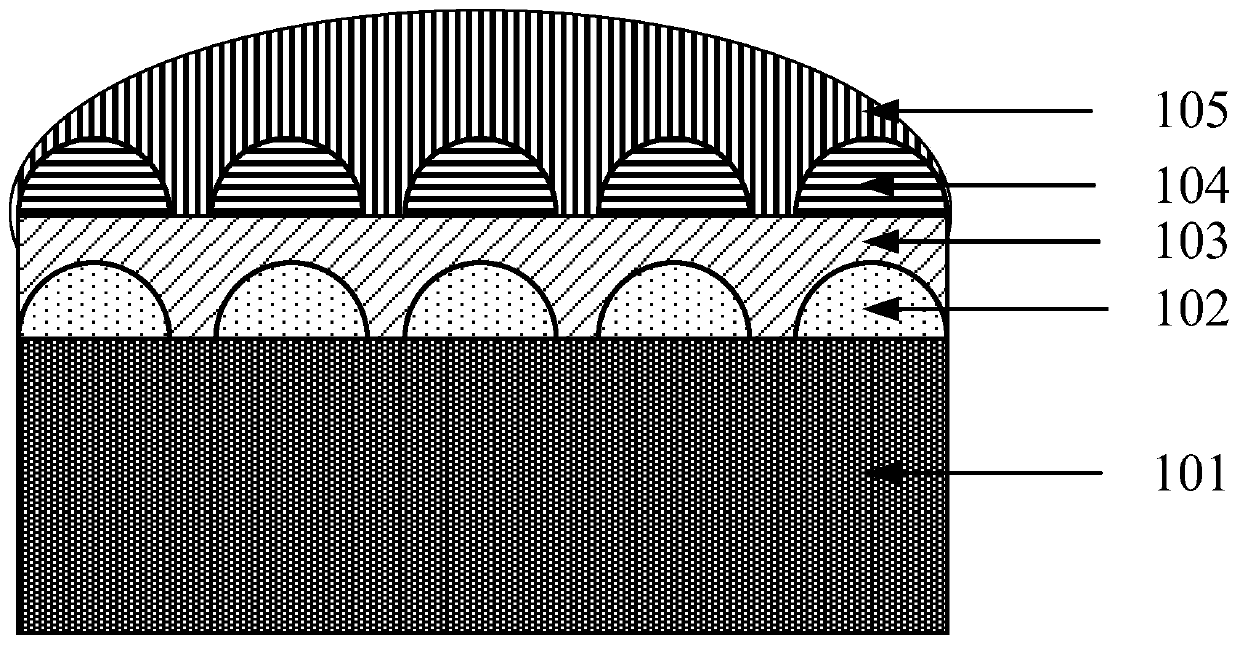

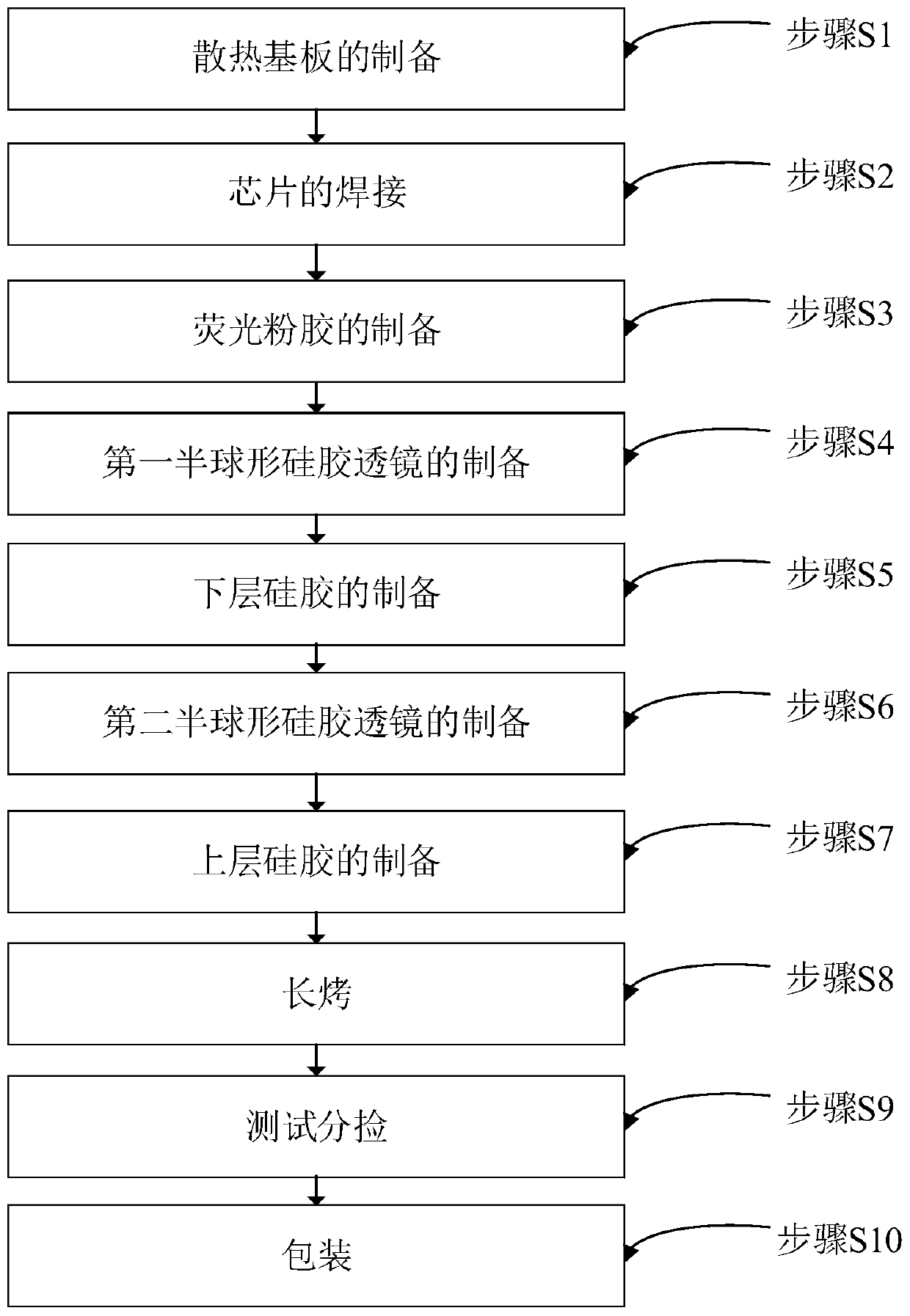

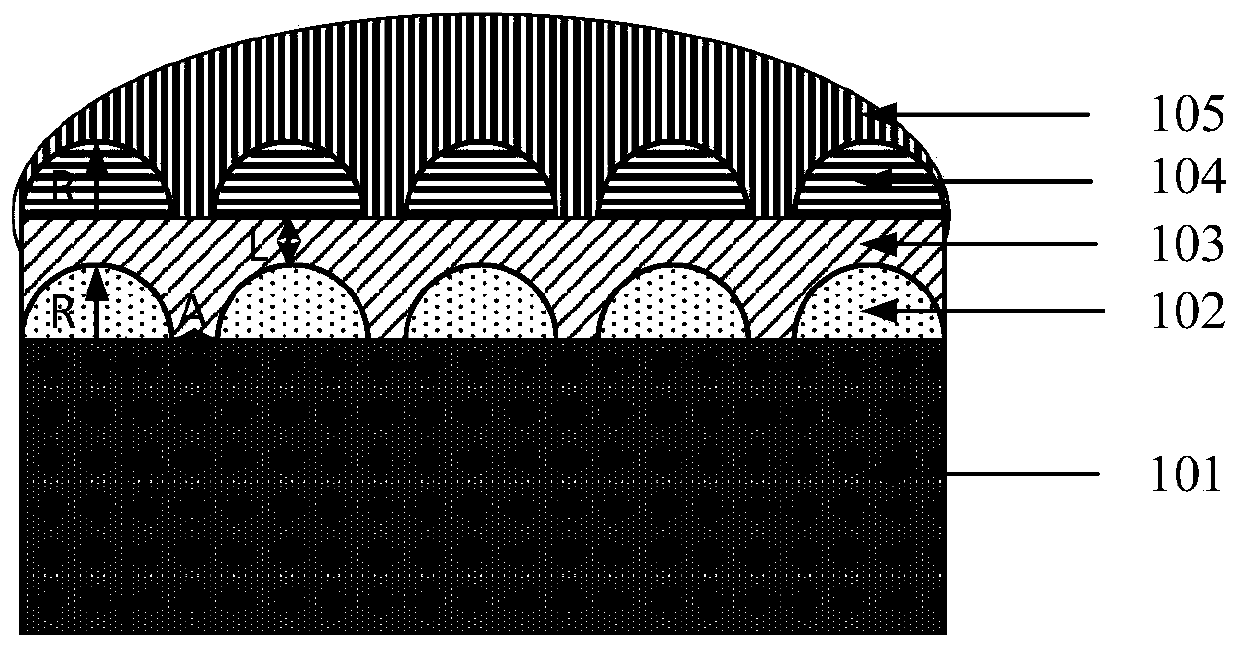

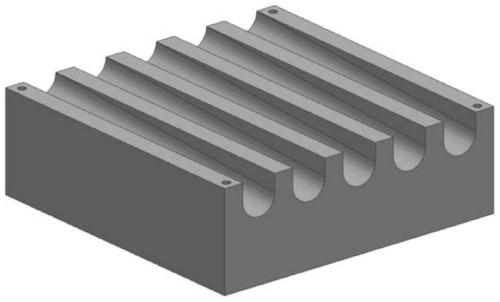

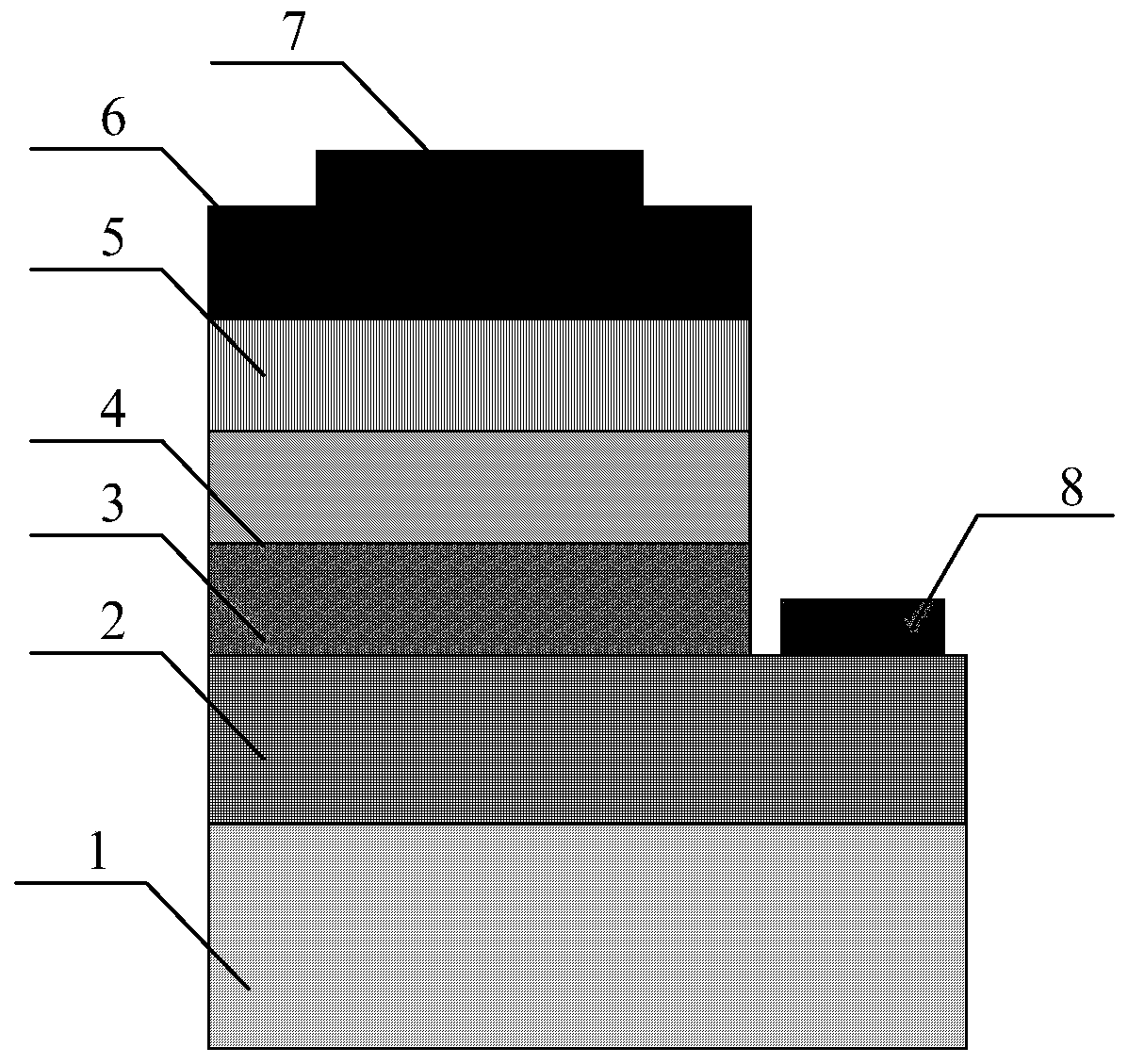

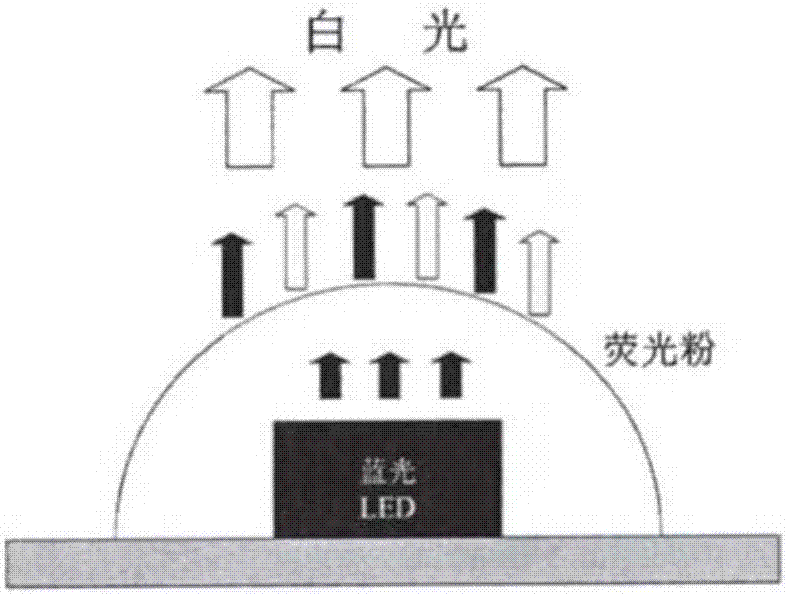

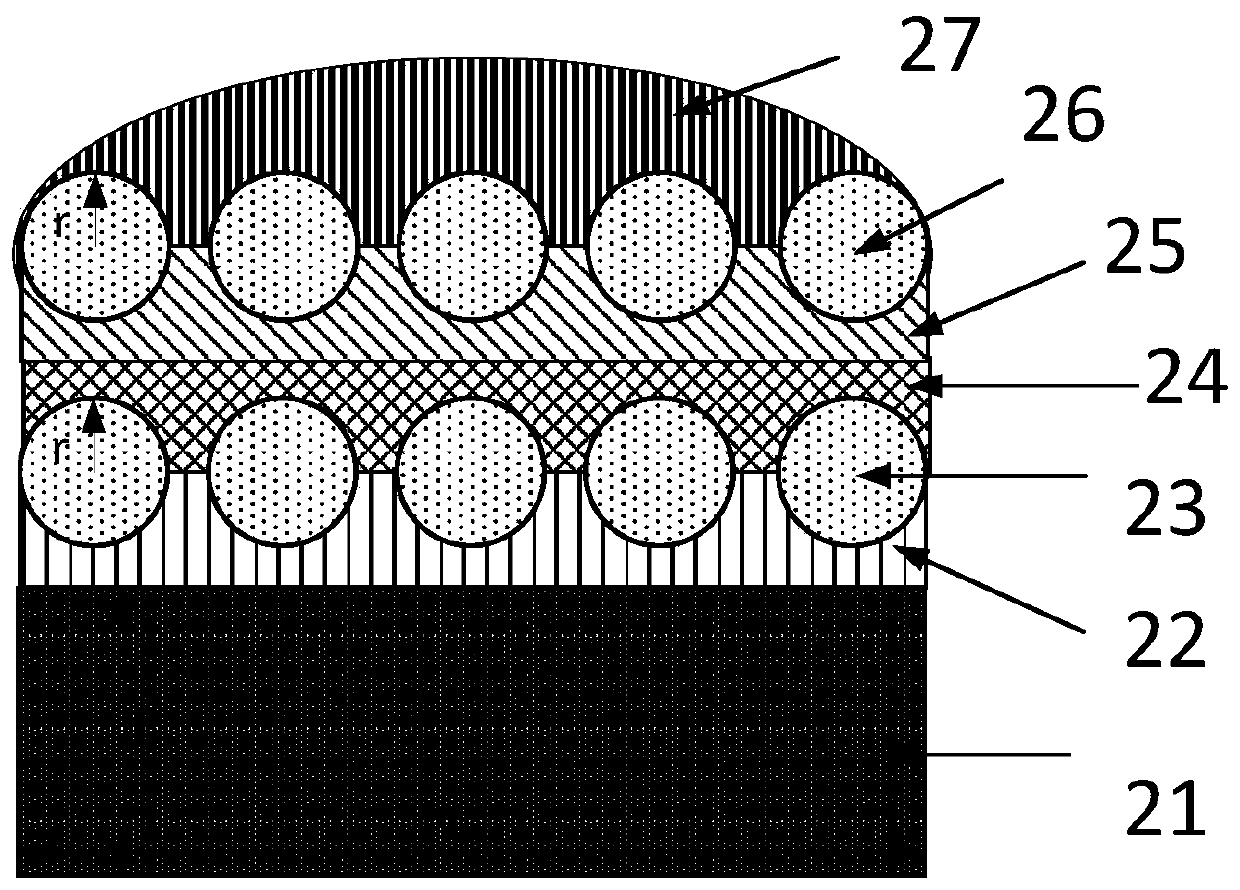

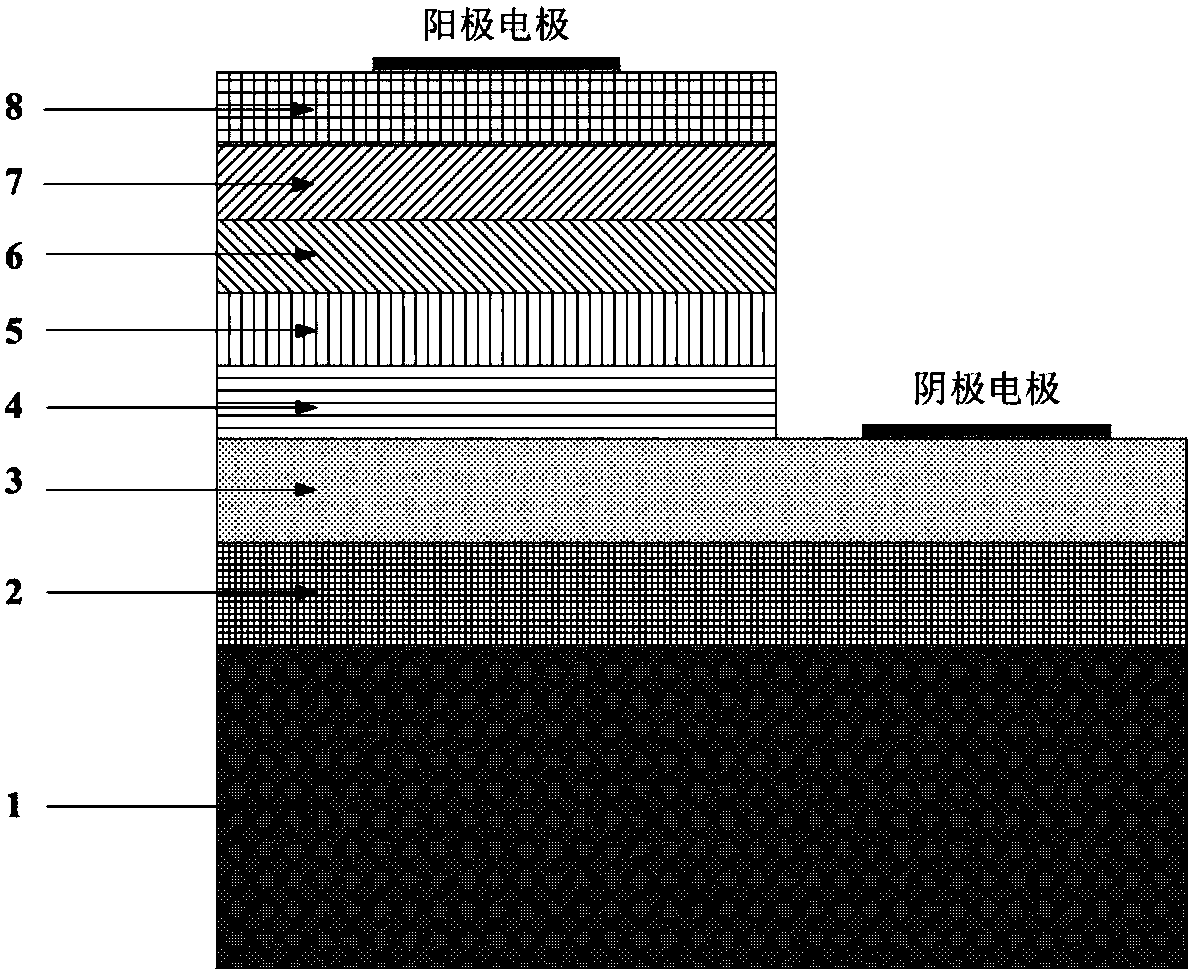

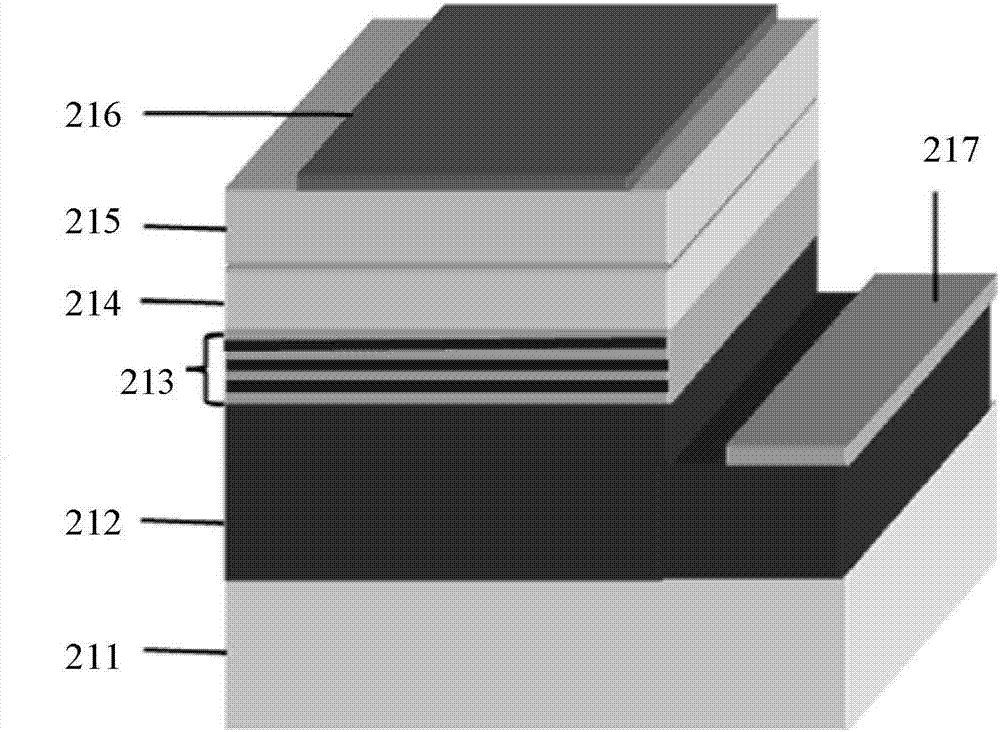

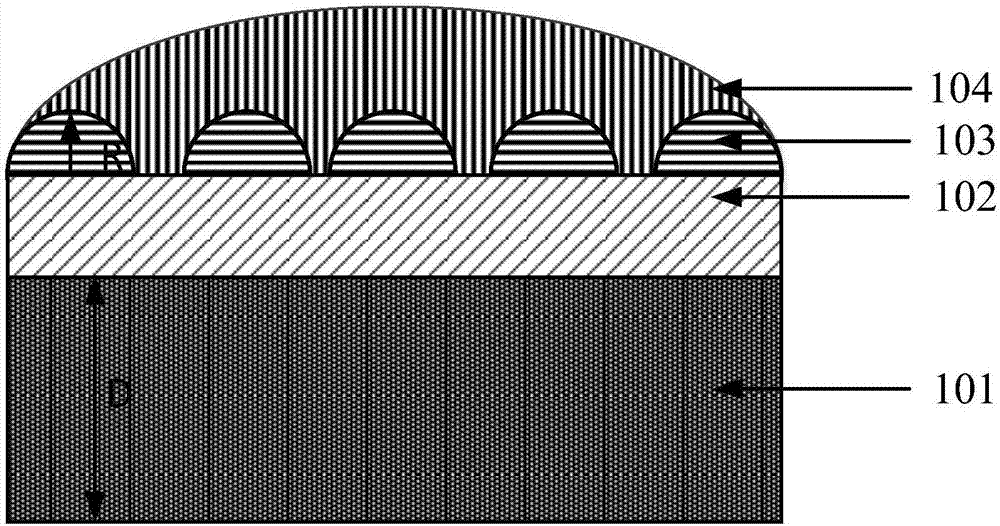

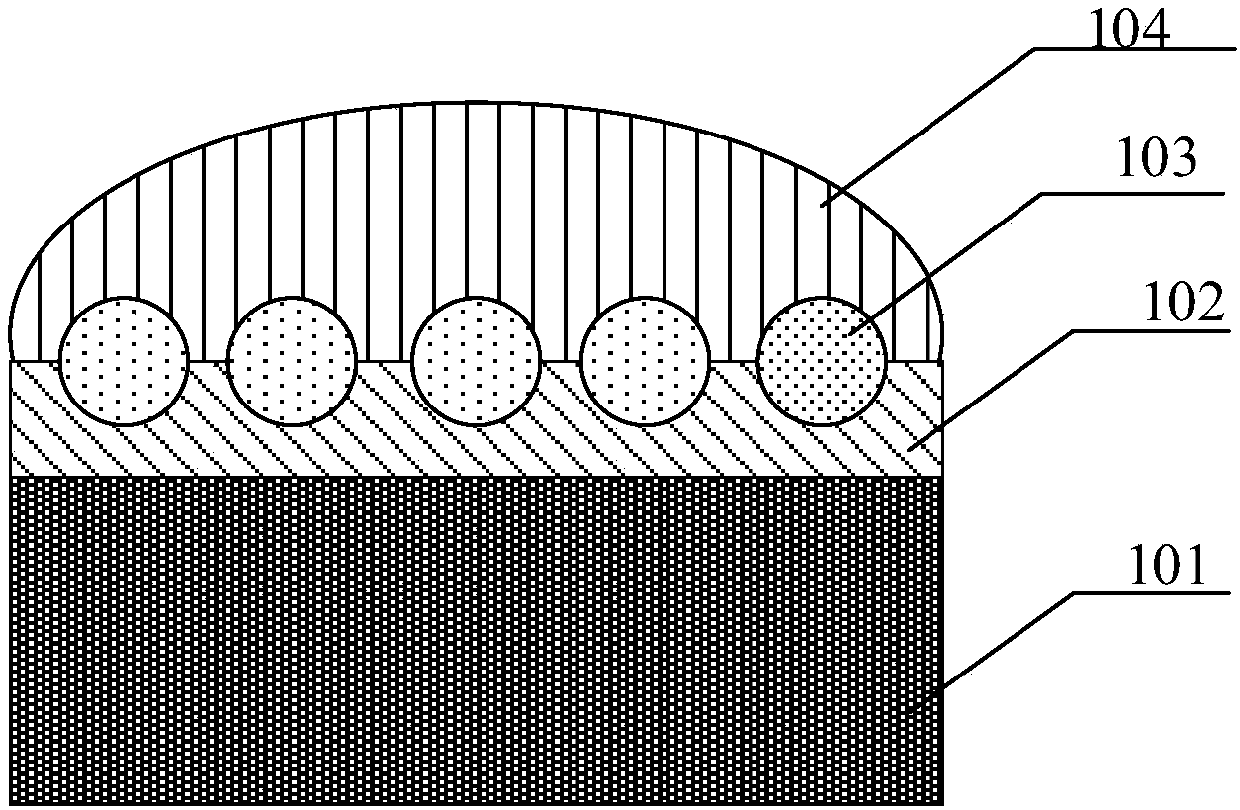

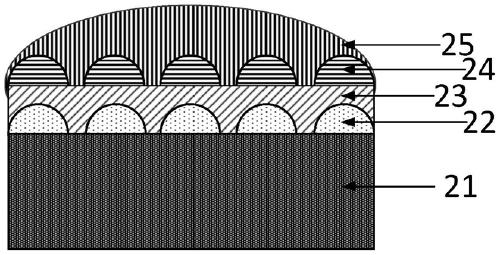

The invention relates to an LED package structure. The structure comprises a cooling substrate 101, a blue-light lamp wick chip, first semi-spherical silica gel lenses 102, lower-layer silica gel 103,second semi-spherical silica gel lenses 104 and upper-layer silica gel 105, wherein the blue-light lamp wick chip is arranged on an upper surface of the cooling substrate 101, the first semi-spherical silica gel lenses 102 are arranged on upper surfaces of the blue-light lamp wick chip and the cooling substrate 101 at intervals, the lower-layer silica gel 103 is arranged on upper surfaces of theblue-light lamp wick chip and the first semi-spherical silica gel lenses, the second semi-spherical silica gel lenses 104 are arranged on an upper surface of the lower-layer silica gel 103 at intervals, and the upper-layer silica gel 105 is arranged on upper surfaces of the lower-layer silica gel 103 and the second semi-spherical silica gel lenses 104. In the LED package structure, the cooling effect of an LED is improved by employing an iron cooling substrate with an oblique through hole structure; with the adoption of the two-layer semi-spherical silica gel lens structure, the light from anLED chip can be enabled to penetrate through a package material very well to irradiate, and the light transmittance is improved.

Owner:SHENZHEN SUIJING OPTOELECTRONICS CO LTD

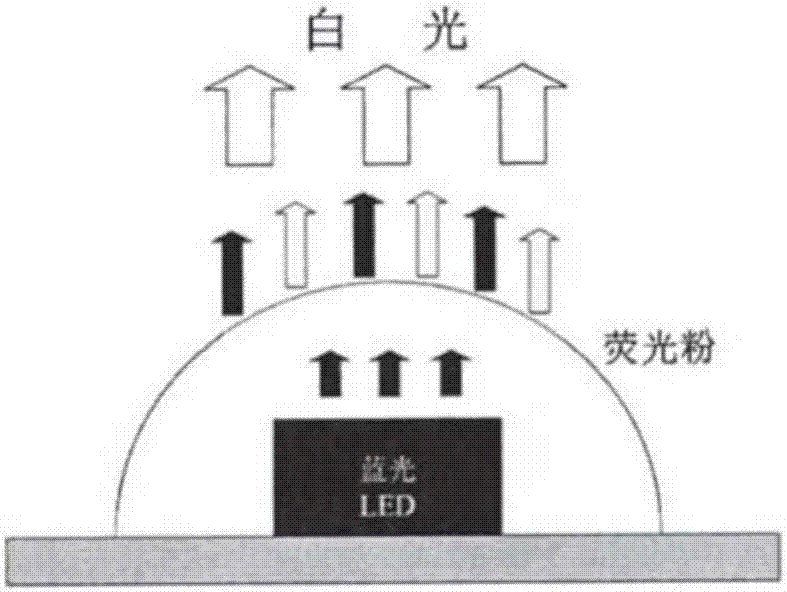

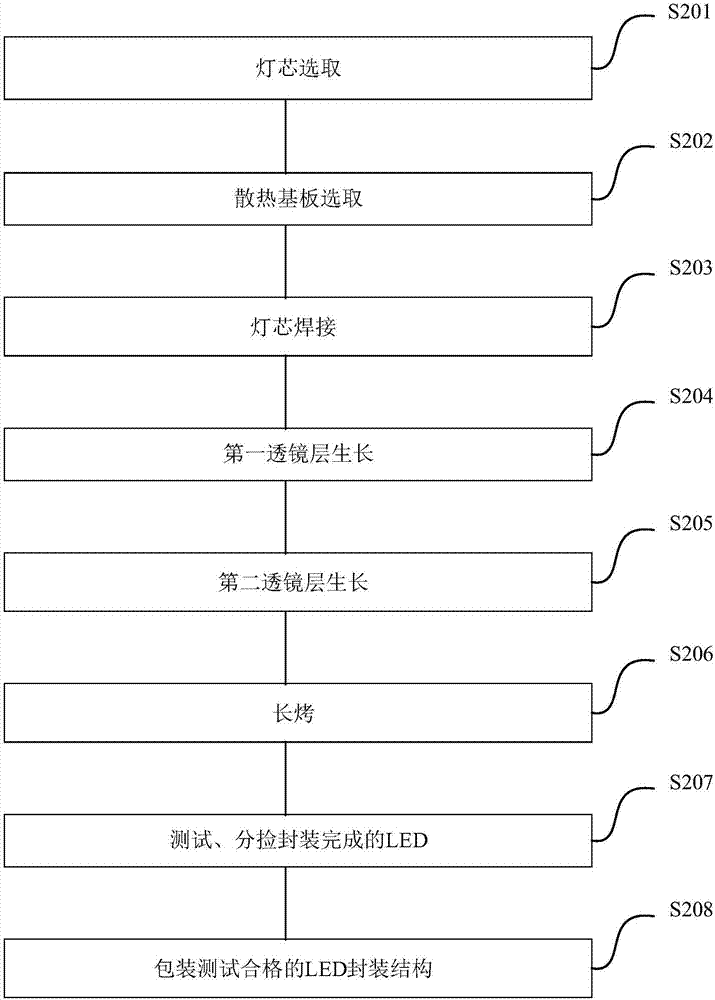

LED lamp and LED packaging method

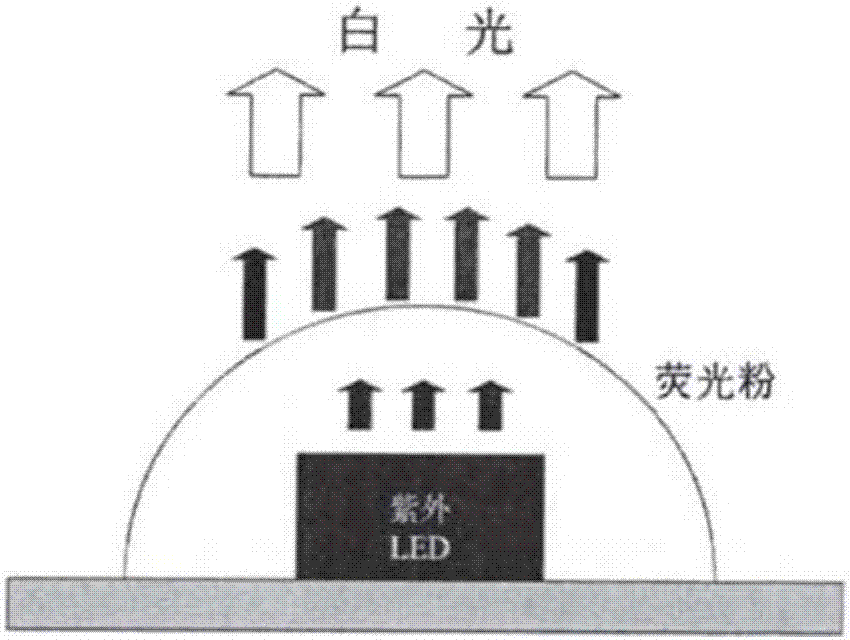

ActiveCN108011022AImproved luminous dispersionSolve the drop in quantum efficiencySemiconductor devicesLed packagingHeat sink

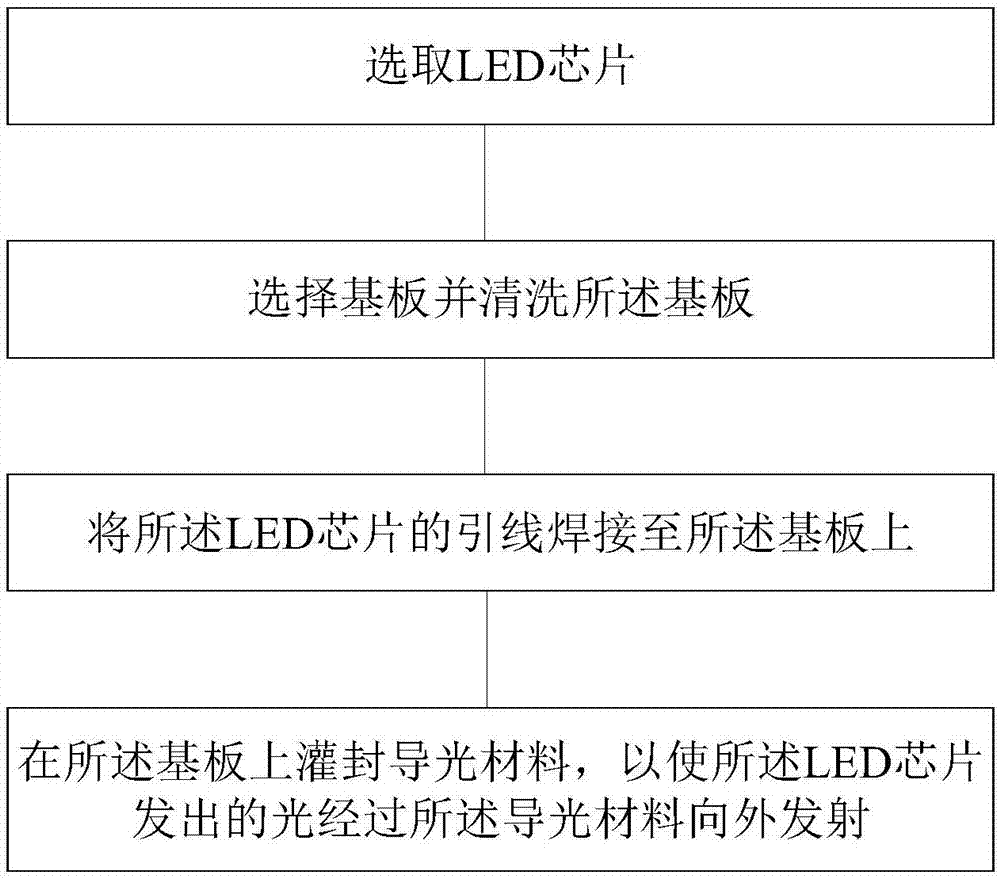

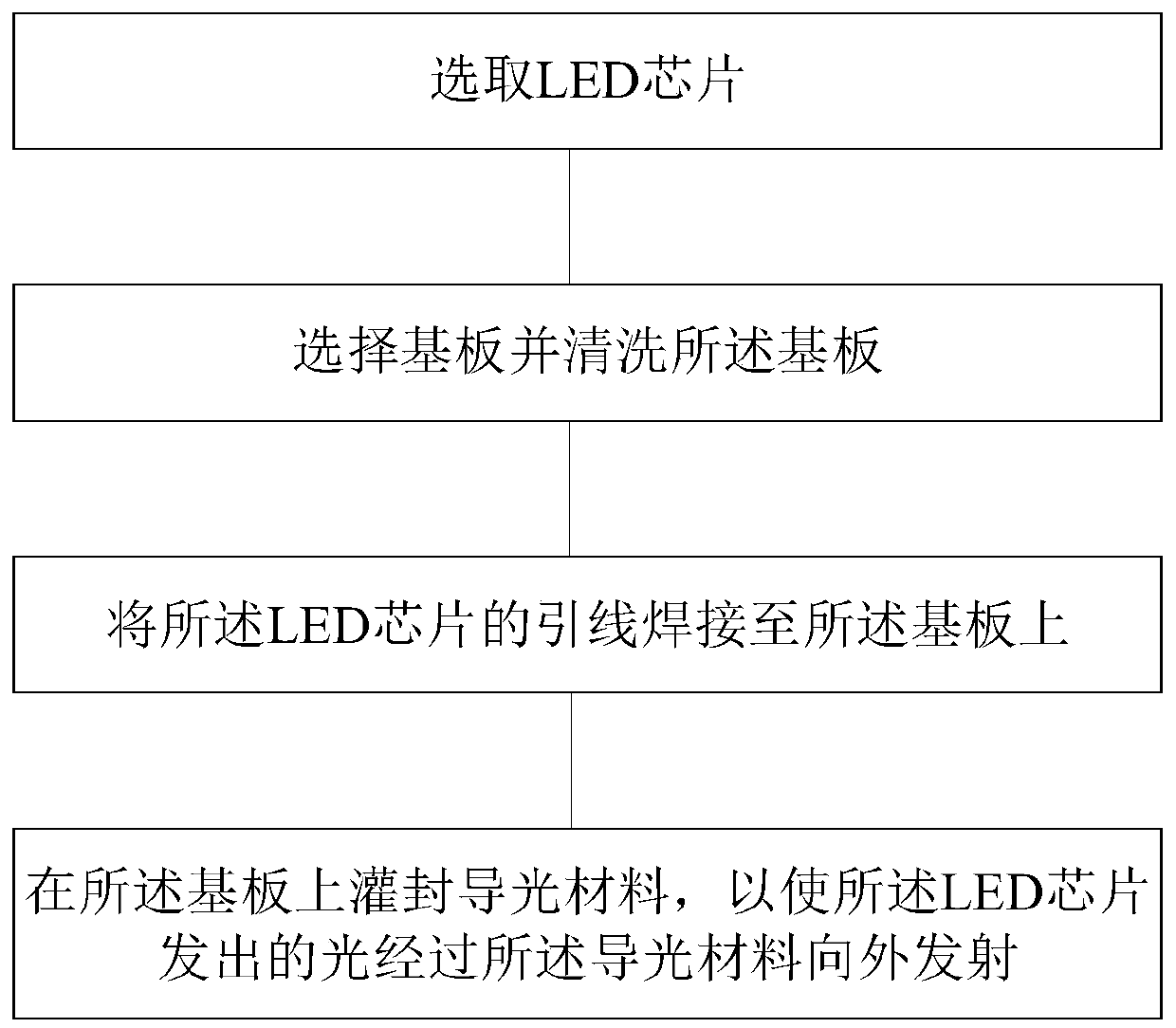

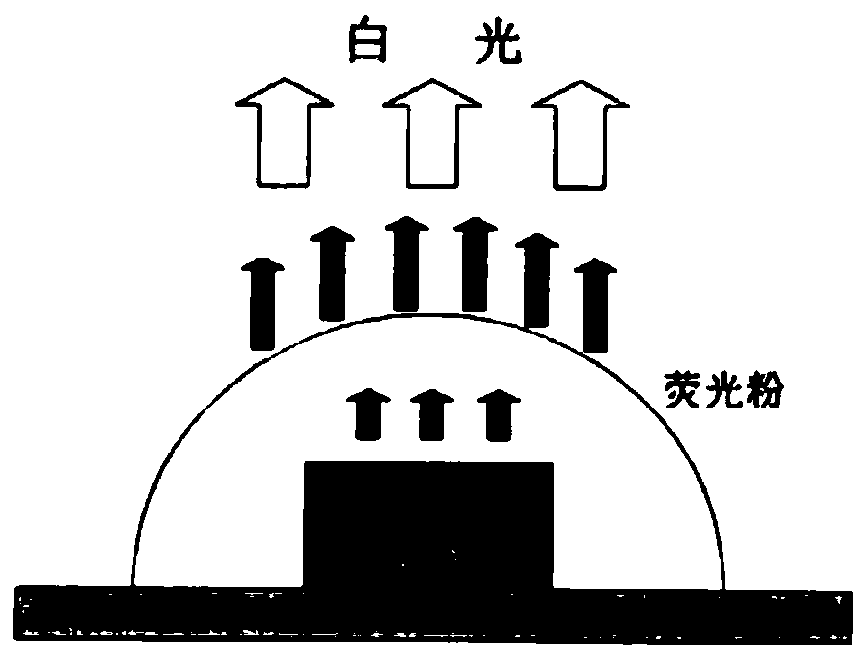

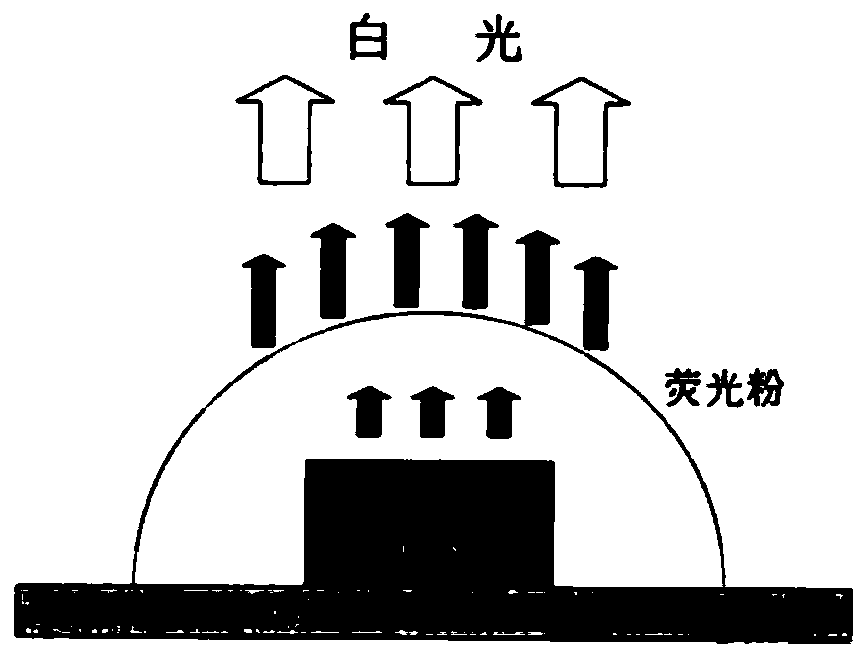

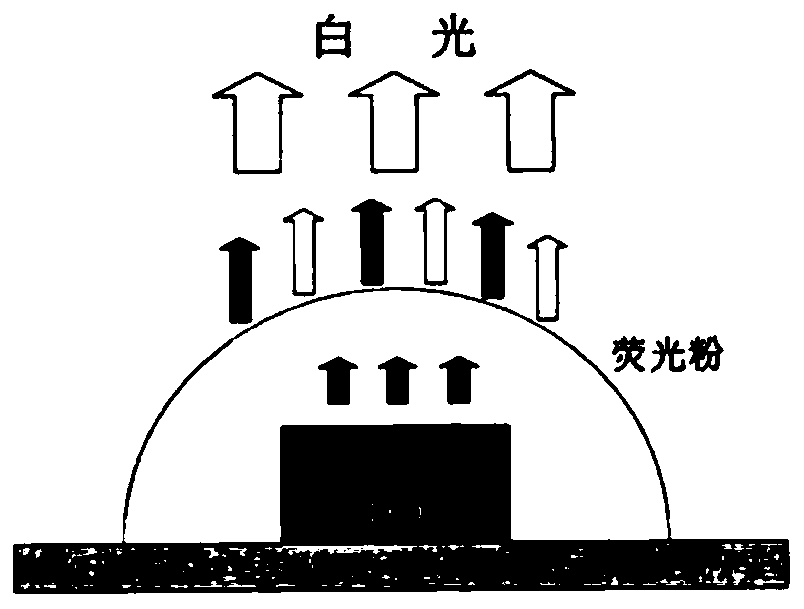

The invention relates to an LED lamp and an LED packaging method. The packaging method comprises the steps of selecting an LED chip; selecting heat sink and cleaning the heat sink; welding a lead of the LED chip on the heat sink; and potting a light guide material on the heat sink to make light emitted from the LED chip emit outwards through the light guide material. The LED lamp provided by the invention is packaged by adopting the method; and according to the packaging method, through separation of fluorescent powder from the LED chip, the problem that the quantum efficiency and the light transmittance of the fluorescent powder are reduced due to high temperature is solved.

Owner:杭州般若高科技有限公司

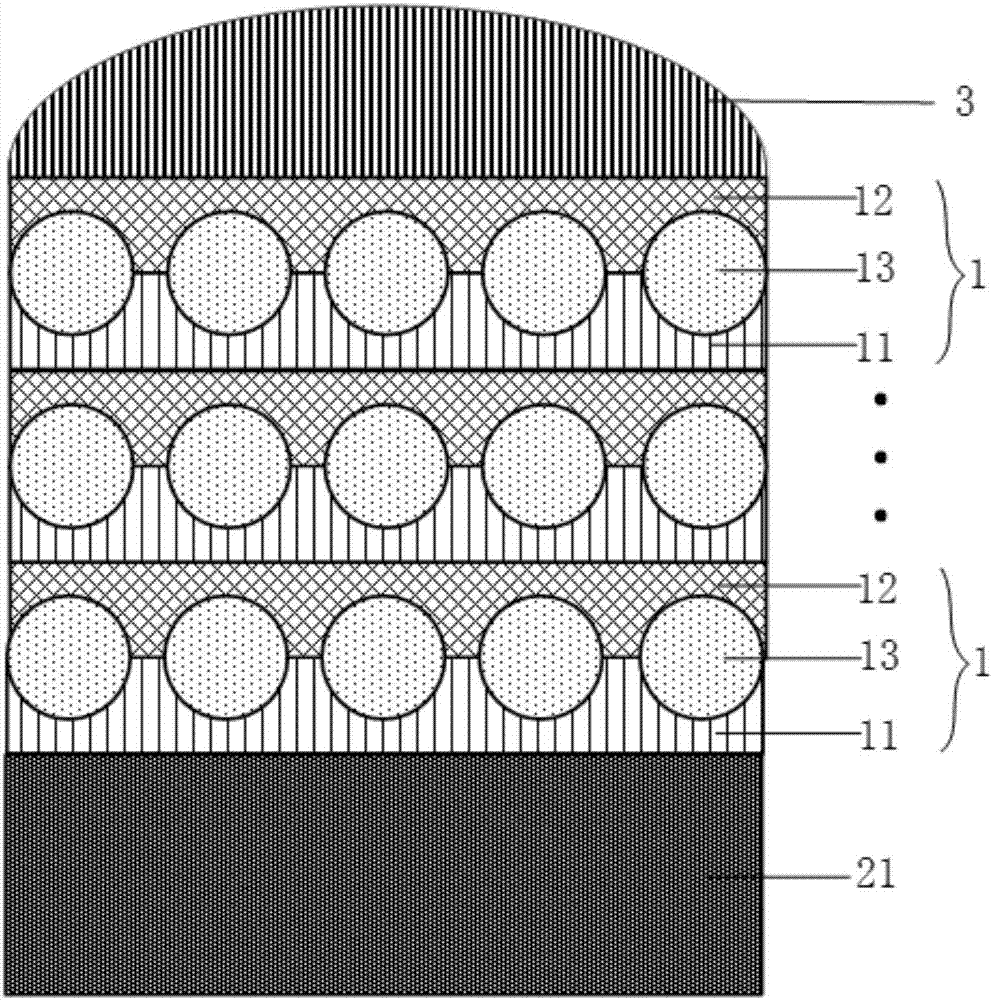

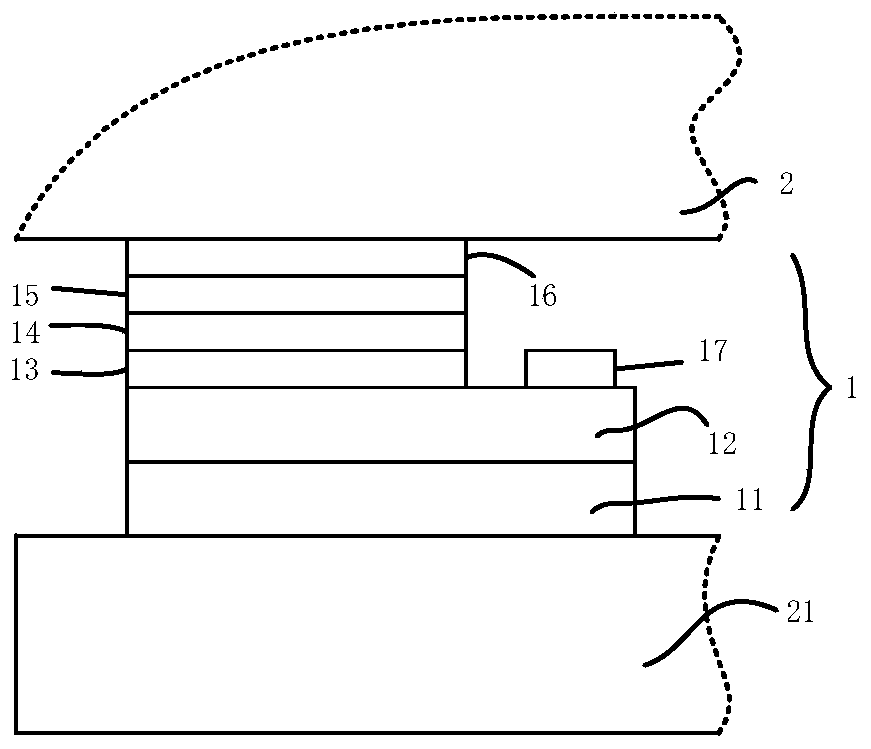

Multilayer packaging structure of high-power blue-light LED

ActiveCN107994113AFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesQuantum efficiencyEngineering

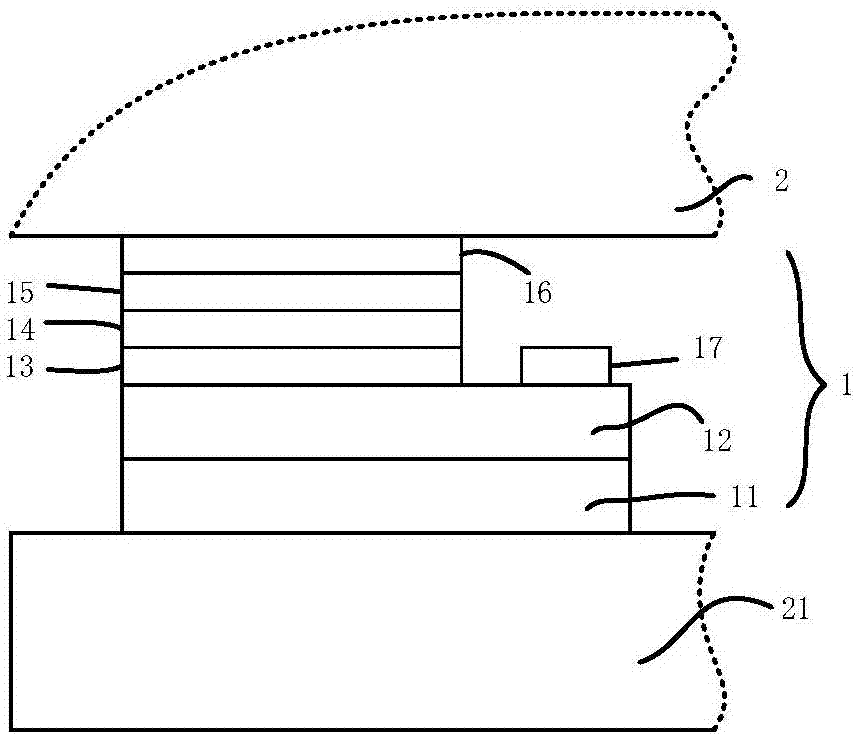

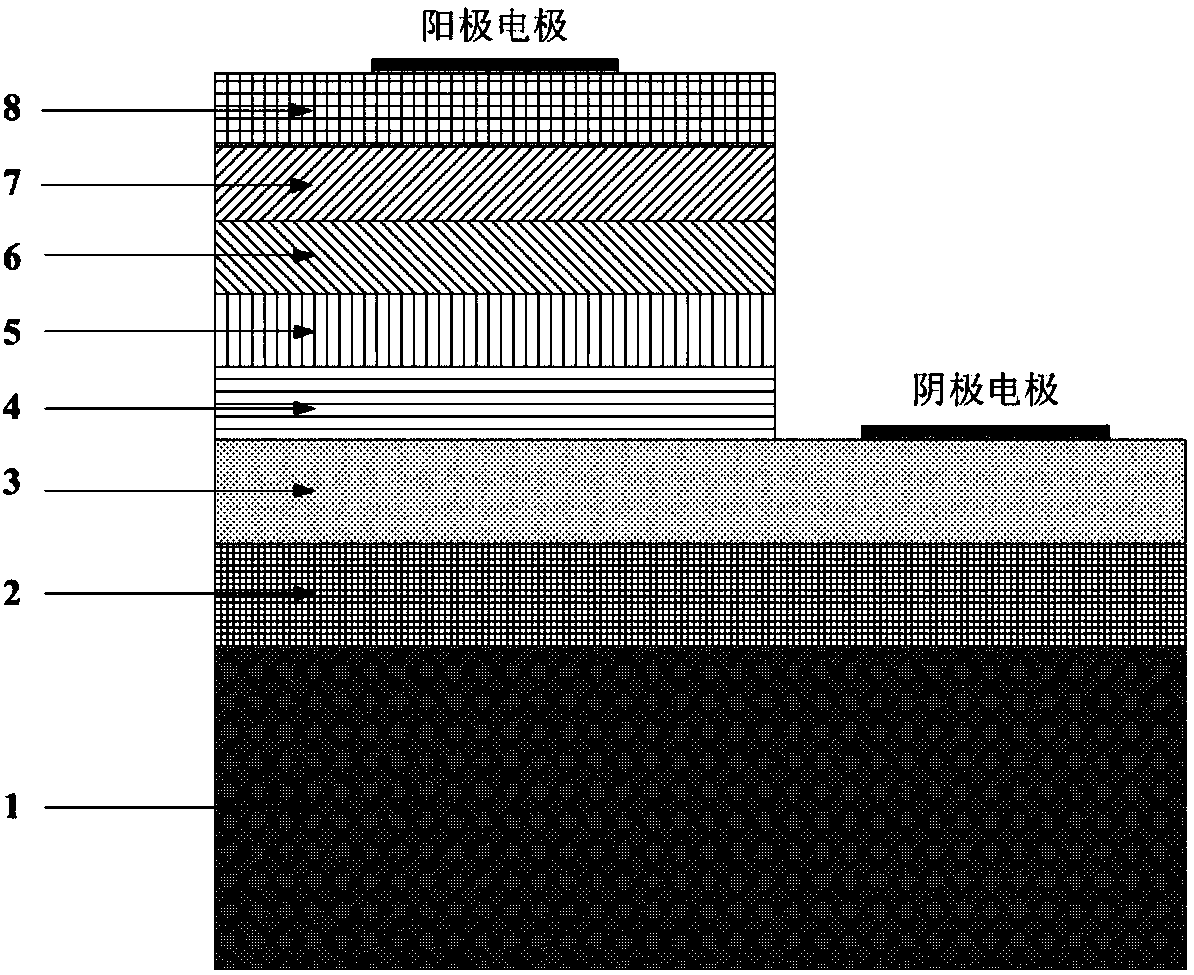

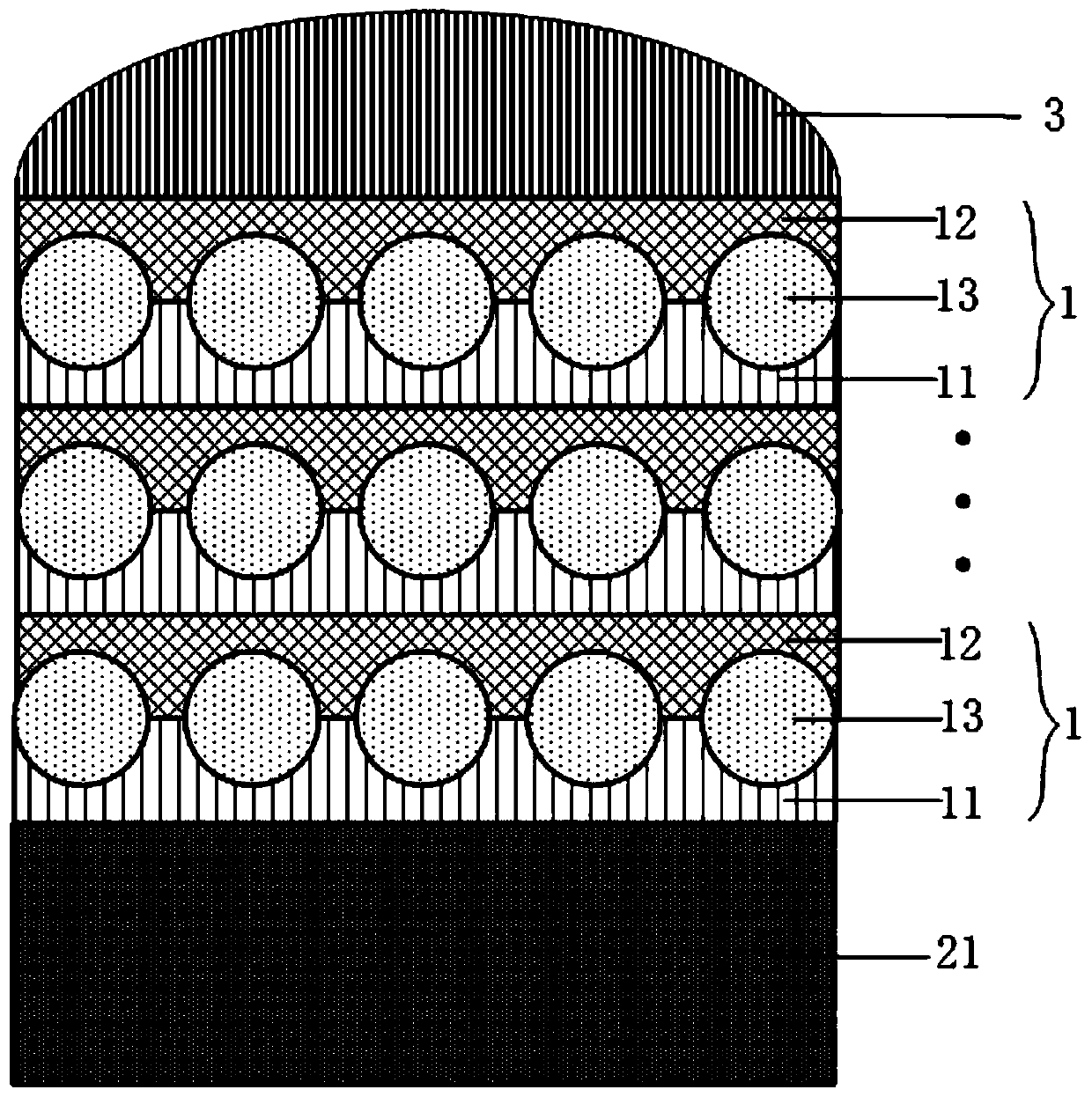

The invention discloses a multilayer packaging structure of a high-power blue-light LED. The structure comprises a plurality of groups of lens layers (1), a heat dissipation substrate (21) and an outer packaging layer (3). The lens layers (1) are arranged on the heat dissipation substrate (21). The outer packaging layer (3) is further arranged on the topmost part of the plurality of groups of lenslayers (1). Each group of the lens layers comprises a lower packaging layer (11), an upper packaging layer (12) and a spherical lens (13). At least a part of a spherical lens (23) is embedded into the lower packaging layer (22). The upper packaging layer (24) is located in the non-embedded part of the spherical lens (23) and is above the lower packaging layer (22). According to the multilayer packaging structure of the high-power blue-light LED provided in the invention, the spherical lens is adopted. Therefore, the technical problem that the illumination brightness of a light source is not centralized enough is solved. Meanwhile, the secondary shaping is not needed, so that the structure is simple. The production cost is reduced. In addition, compared with the prior art, fluorescent powders do not need to be coated on a chip. The problem that the brightness is reduced due to the fact that the quantum efficiency of fluorescent powders caused by high temperature is reduced is solved.

Owner:深圳市天瀛深源科技有限公司

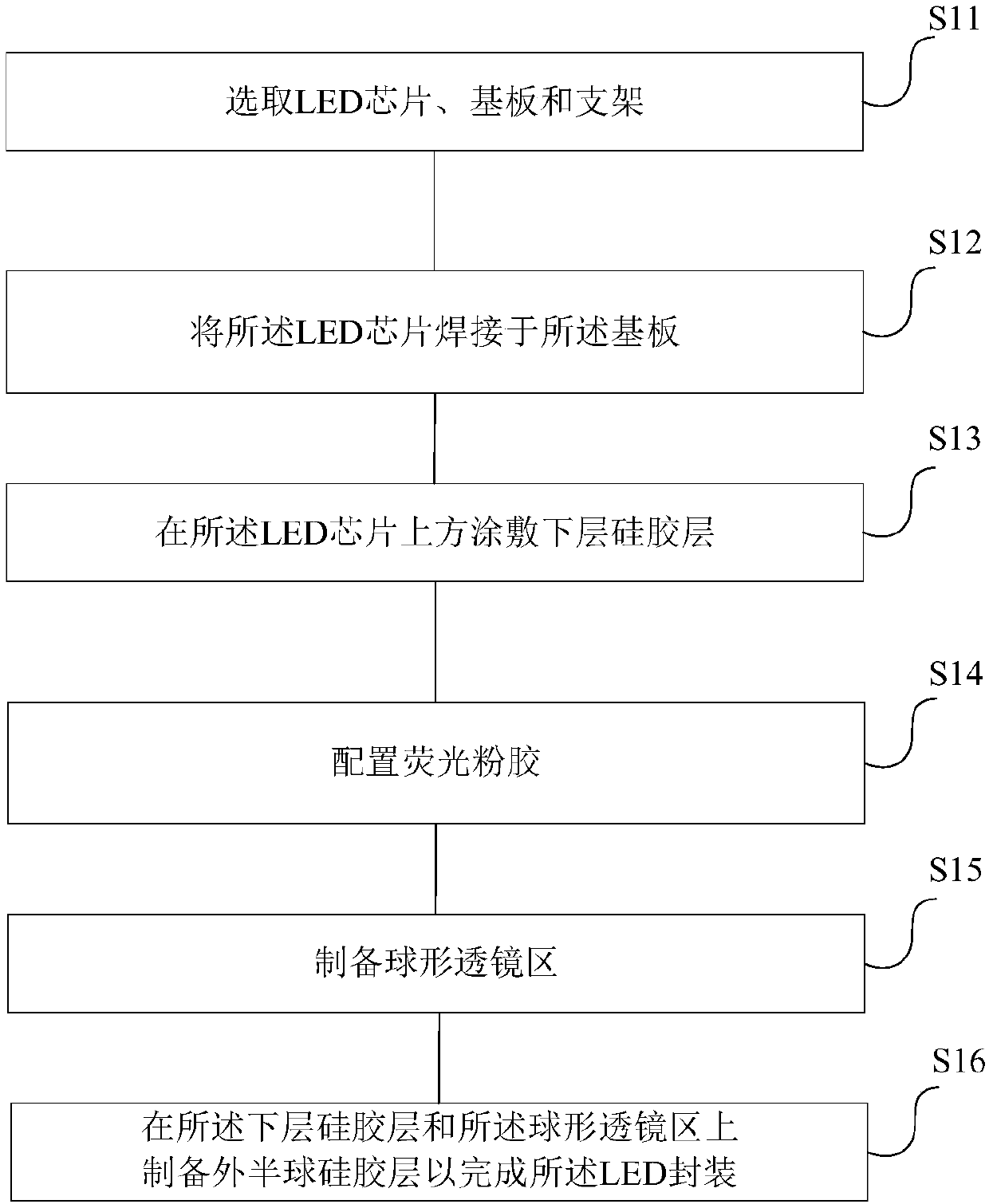

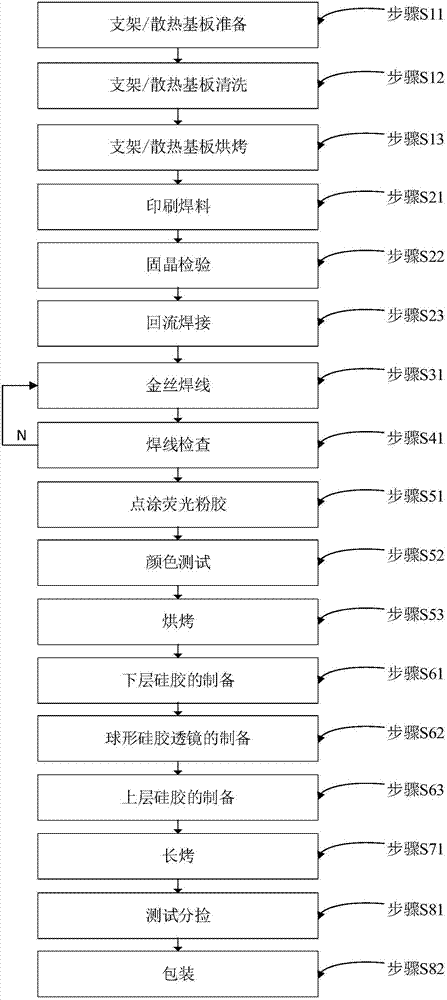

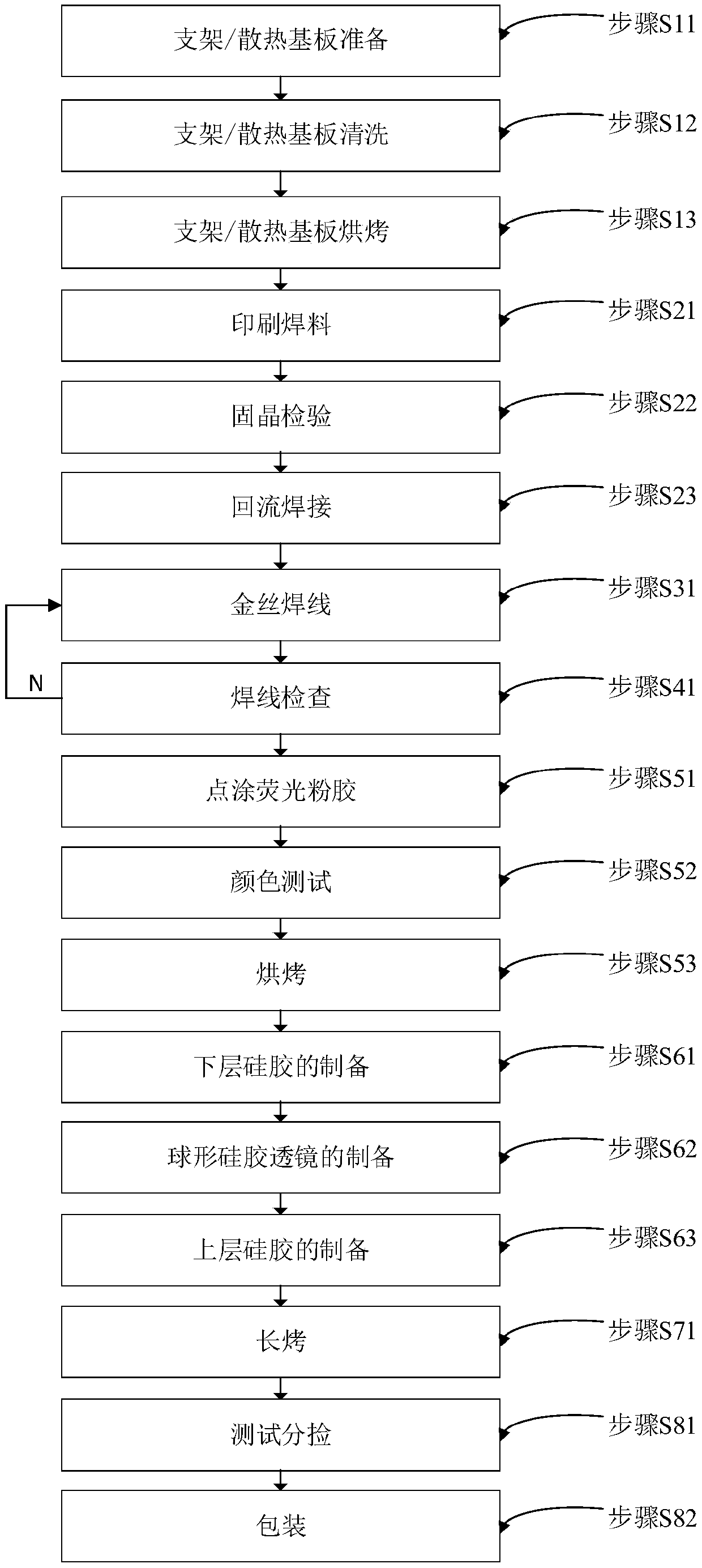

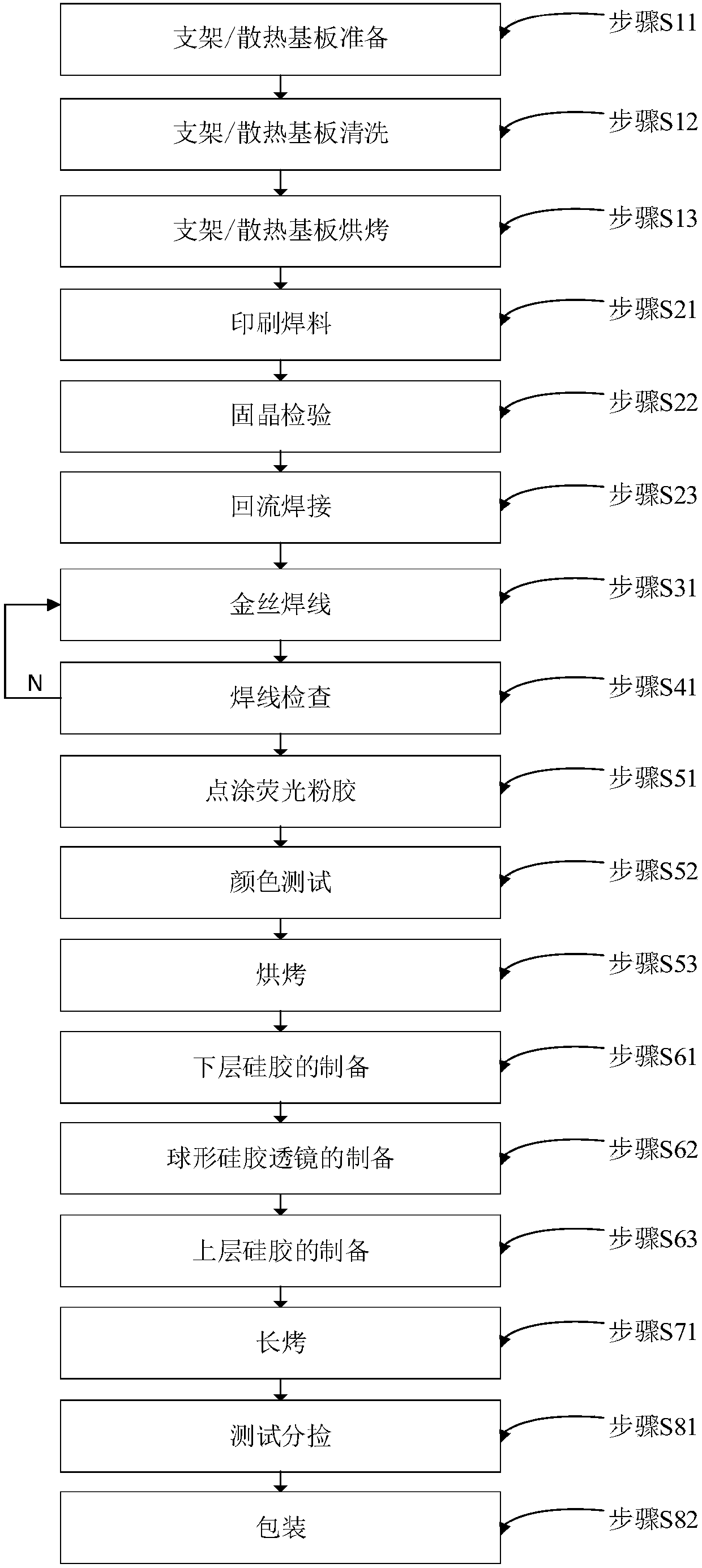

LED packaging structure and method thereof

InactiveCN107833948ASolve the decrease of light transmittanceImproved luminous dispersionSemiconductor devicesLed packagingTransmittance

The invention relates to an LED packaging structure and a method thereof. The method comprises steps: an LED chip, a cooling substrate and a bracket are selected; the LED chip is welded on the coolingsubstrate; a lower silica gel layer is applied above the LED chip; phosphor gel is prepared; a spherical lens area is manufactured; and an external hemisphere silica gel layer is prepared on the lower silica gel layer and the spherical lens area to complete LED packaging. The LED packaging method provided in the invention adopts a phosphor and LED chip separation process, and the problem that thequantum efficiency of the phosphor falls due to high temperature can be solved; the silica gel contacted with the LED chip is high temperature-resisting, and the problem that the transmittance fallsdue to aging and yellowing of the silica gel can be solved; and besides, silica gel balls are uniformly arranged in a rectangle or a diamond shape, and light of a light source can be ensured to be evenly distributed in a concentrated area.

Owner:XIAN CREATION KEJI CO LTD

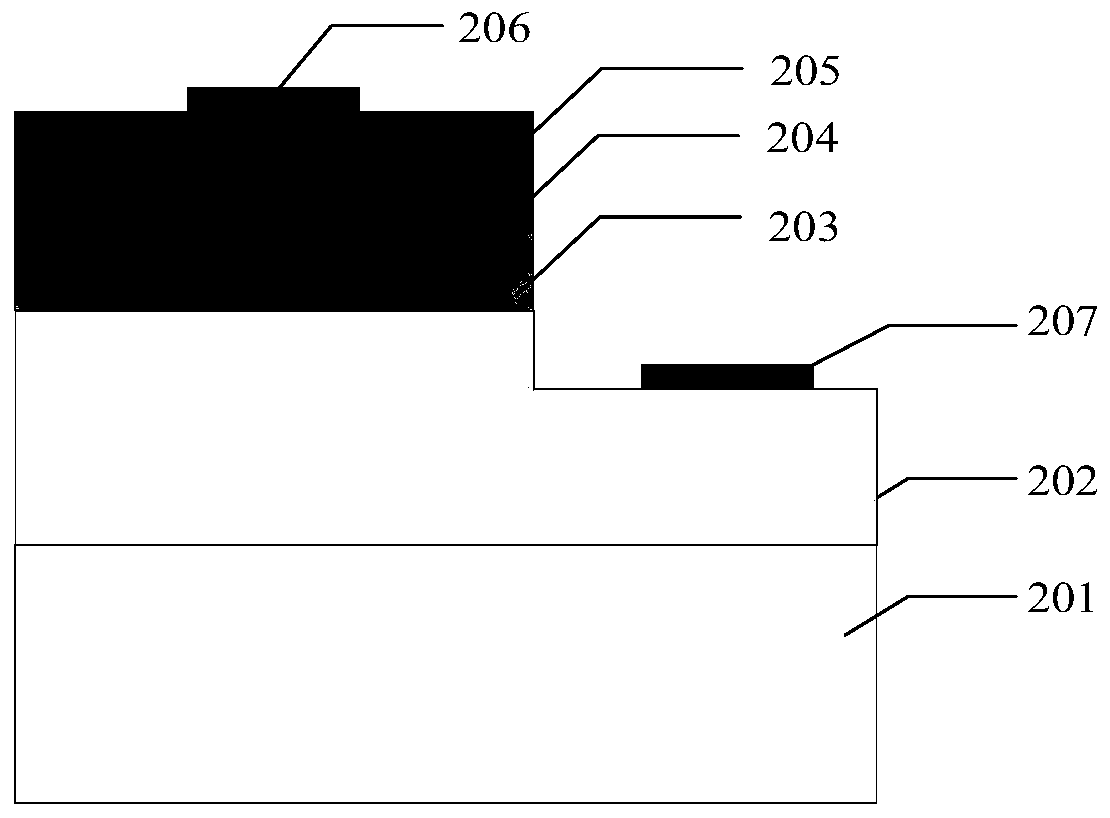

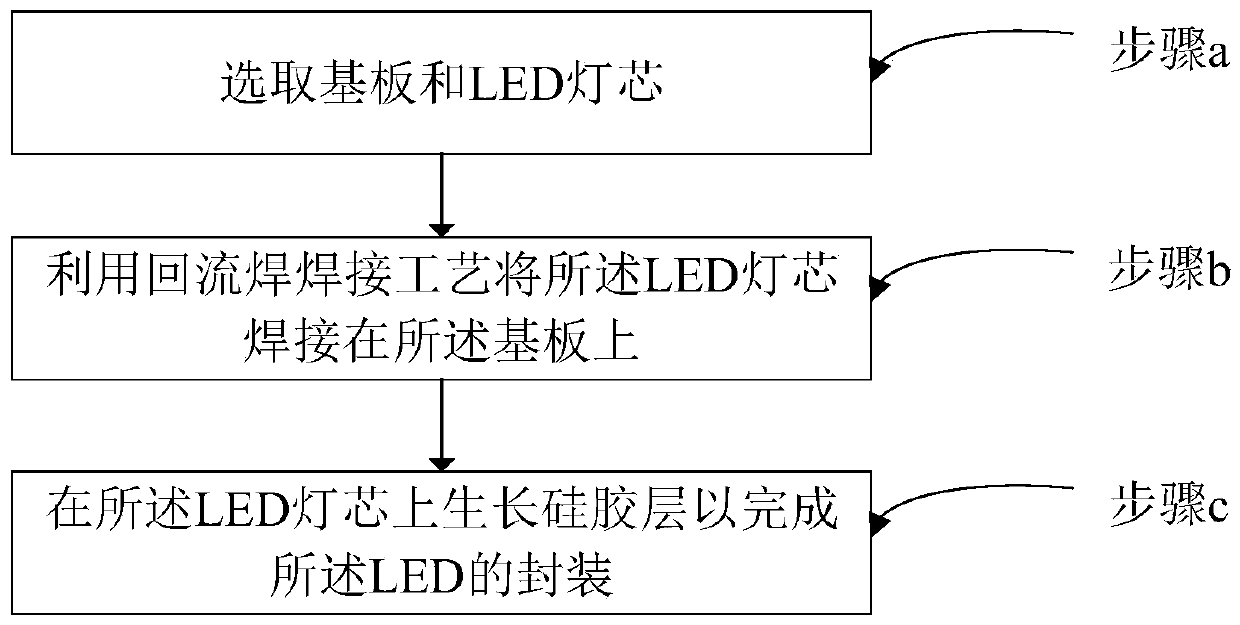

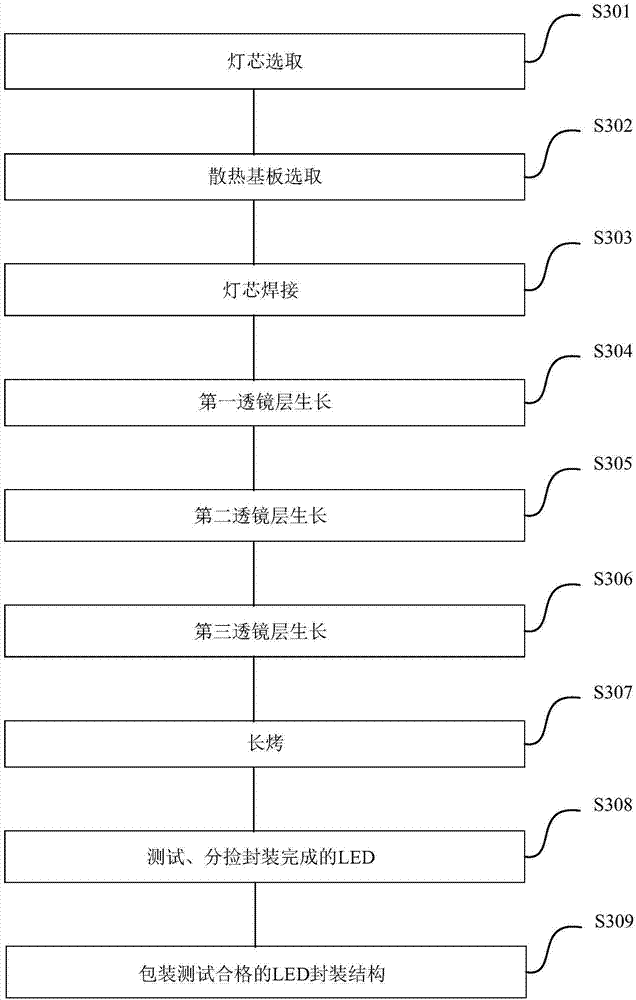

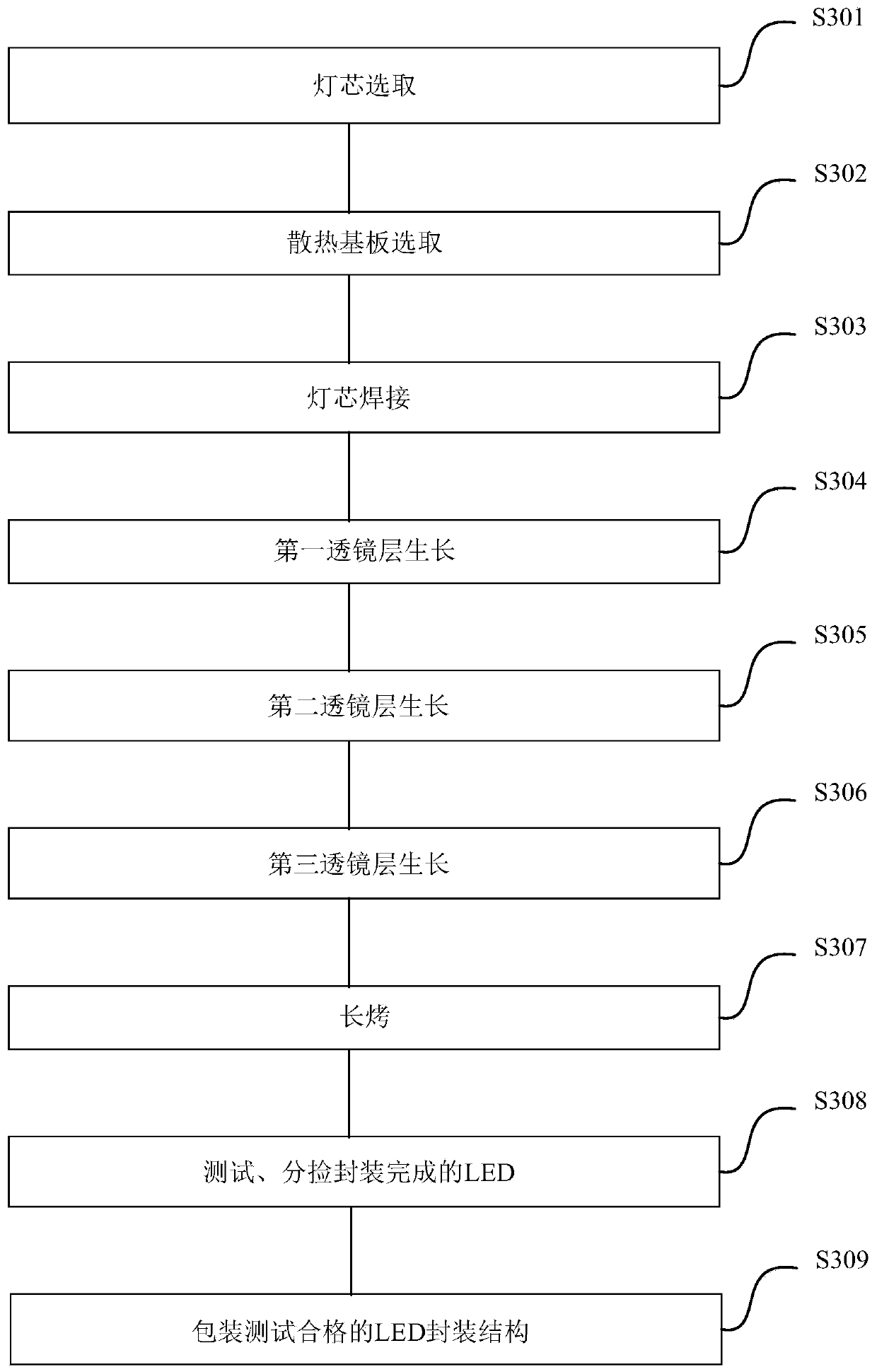

LED packaging method

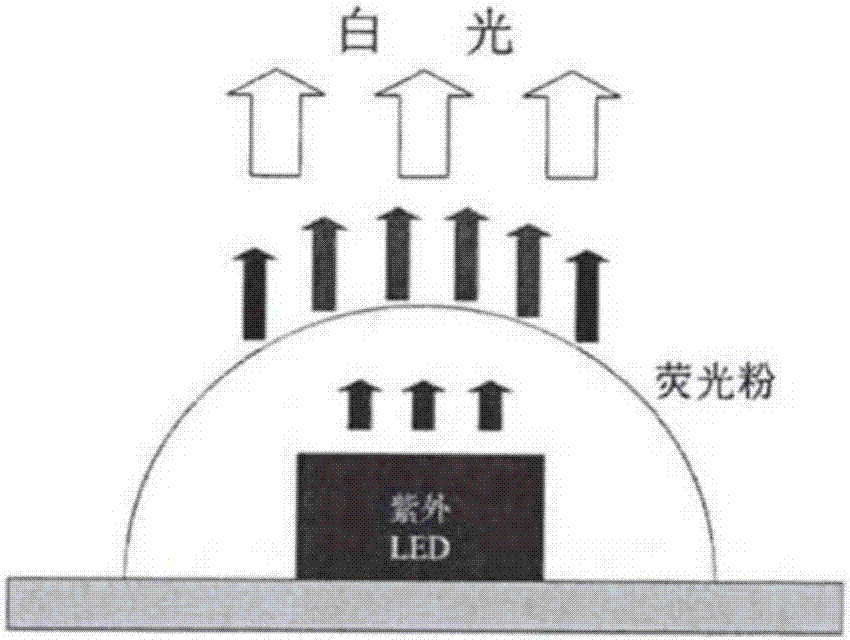

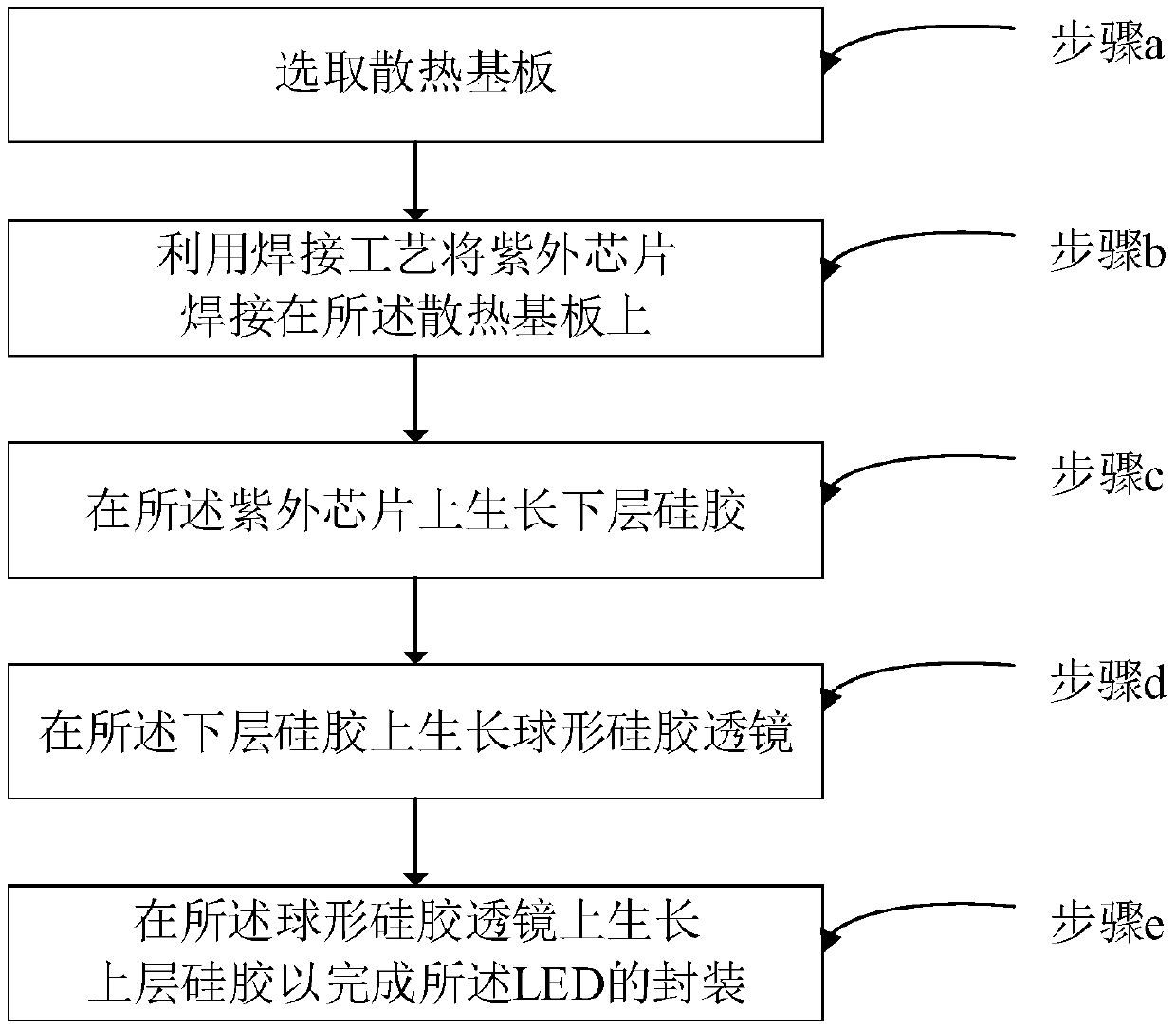

InactiveCN107833946ASolve the drop in quantum efficiencyContinuously adjust colorSemiconductor devicesTransmittanceRefractive index

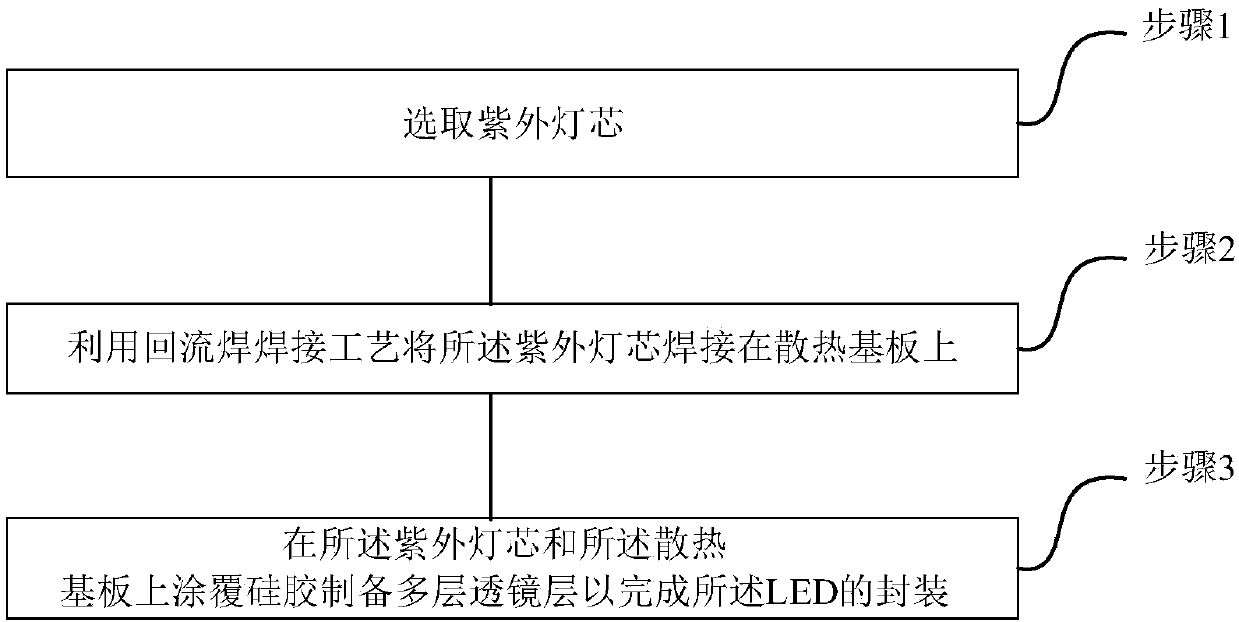

The invention relates to an LED packaging method. The method comprises the following steps of selecting an ultraviolet lamp wick; welding the ultraviolet lamp wick on a substrate through the reflow soldering process; coating silica gel on the ultraviolet lamp wick and the substrate to prepare a multilayer lens layer, and completing the LED packaging process. By adopting the LED packaging method, through preparing the multilayer lens layer, the refractive index is sequentially increased, so that the light transmittance of the LED lamp wick can be improved. Therefore, more light emitted by the LED lamp wick can be irradiated out through packaging materials.

Owner:XIAN CREATION KEJI CO LTD

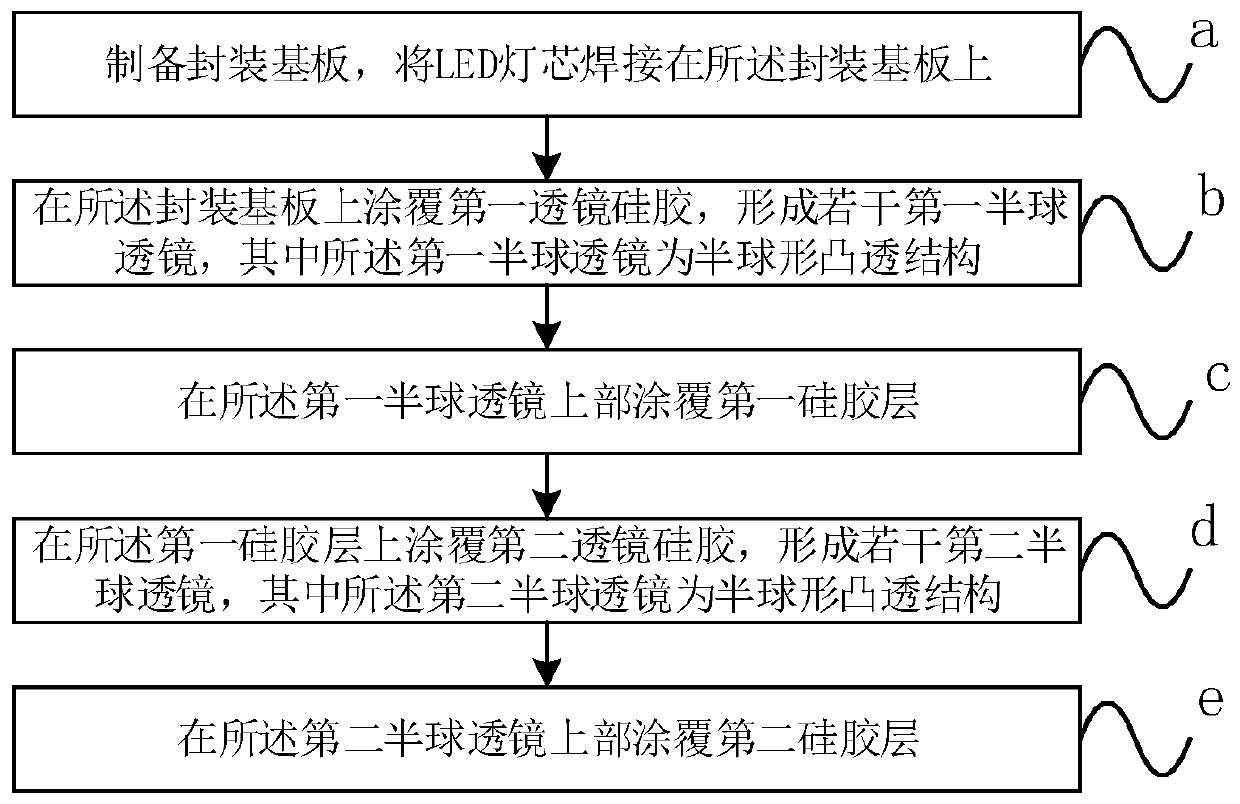

High-power LED double-layer hemispherical structure packaging technology

ActiveCN108011026AFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesSpherical shapedEngineering

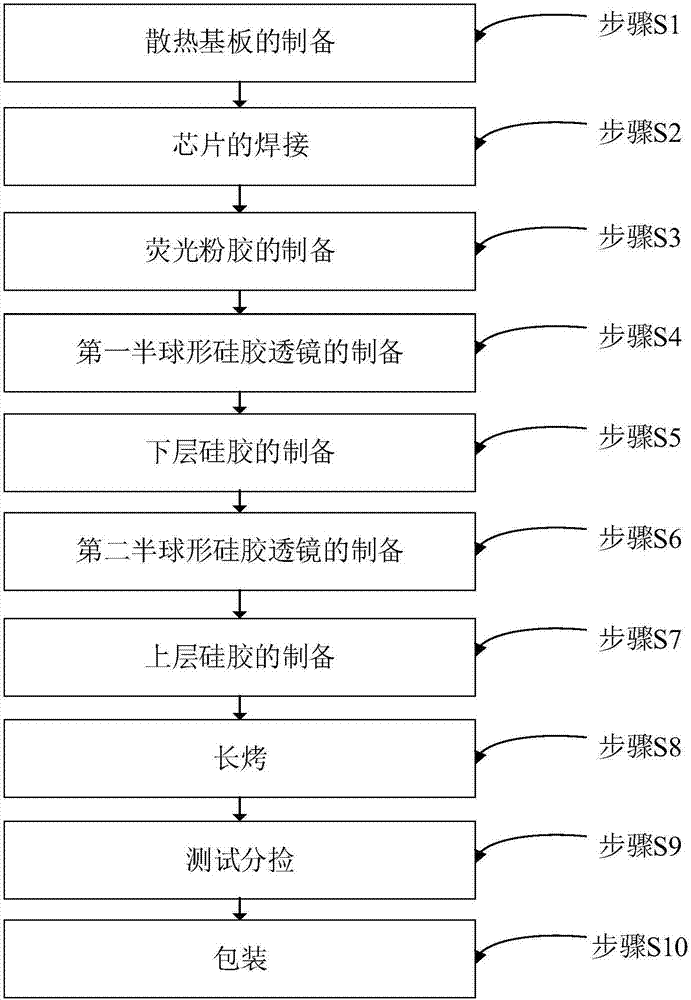

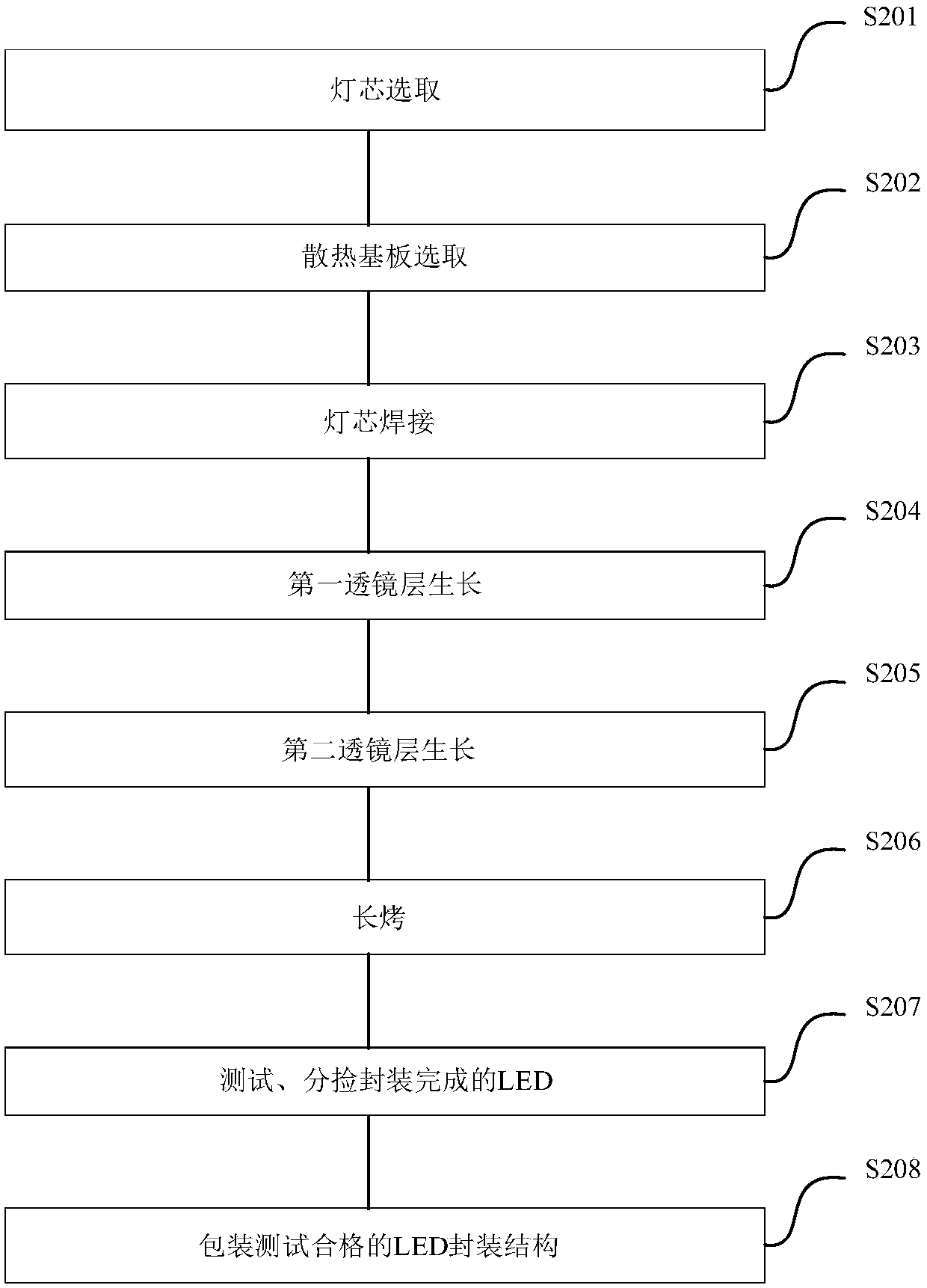

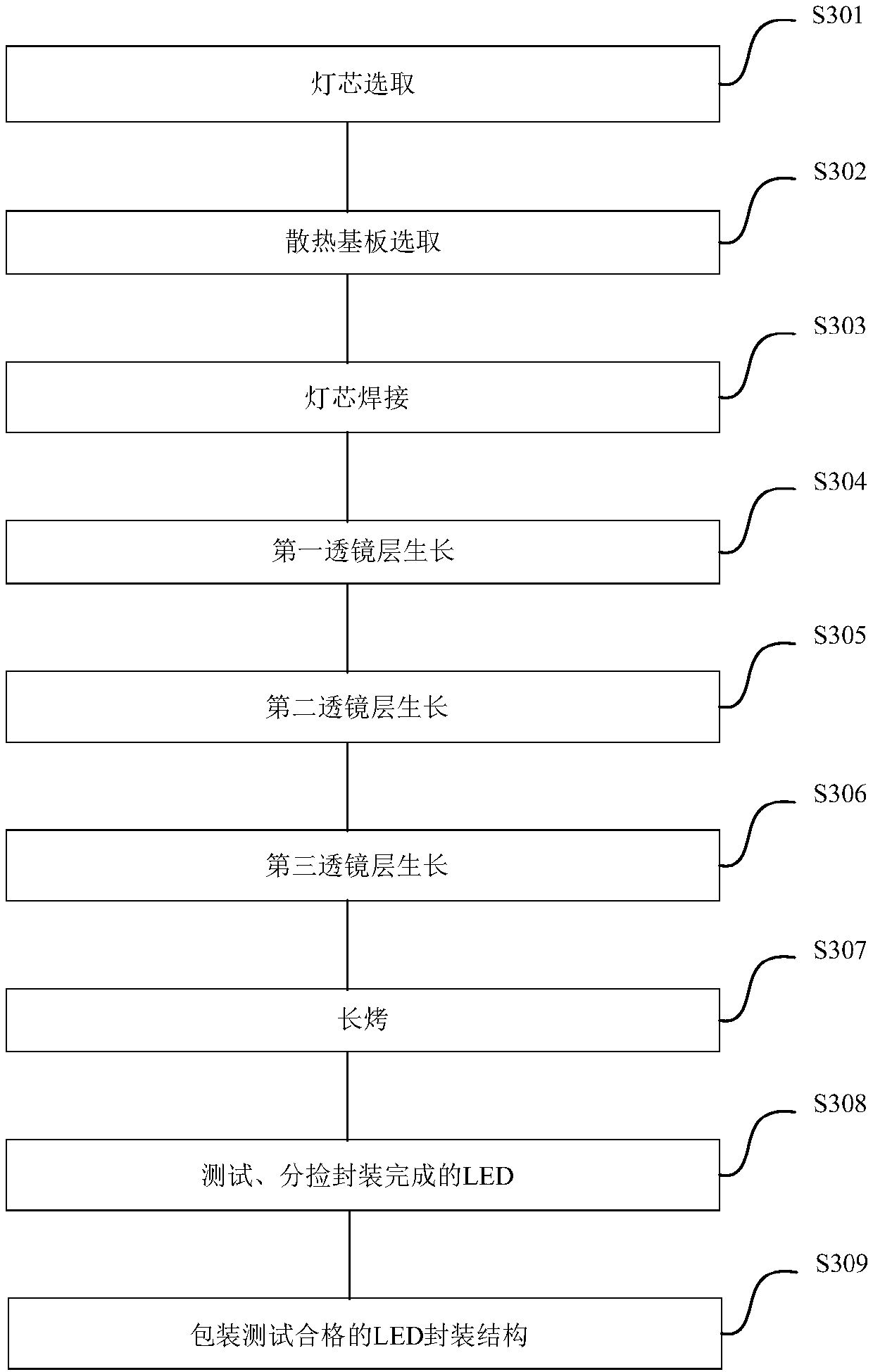

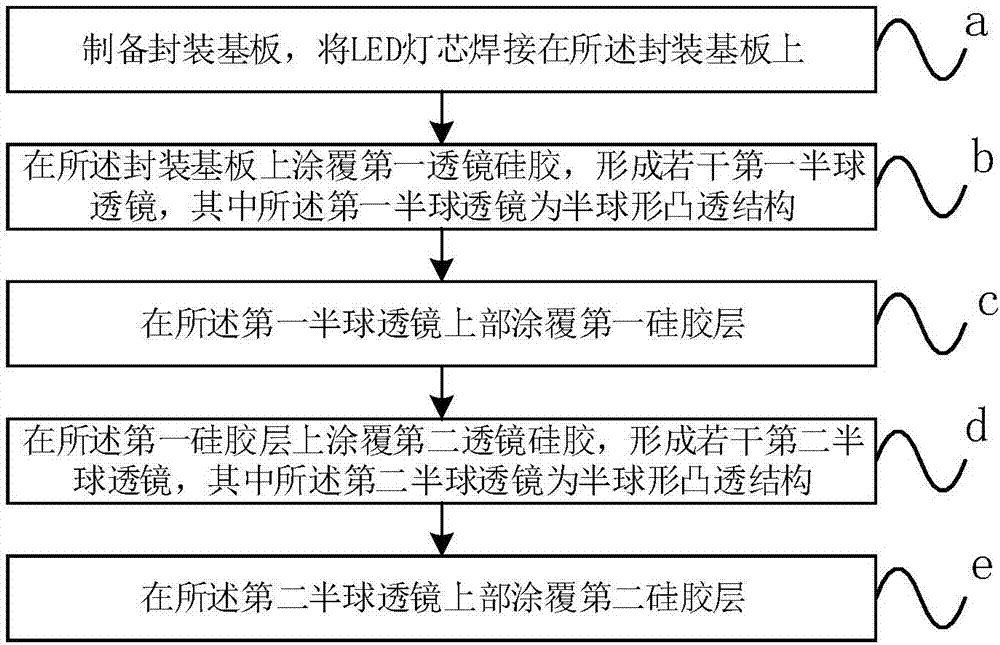

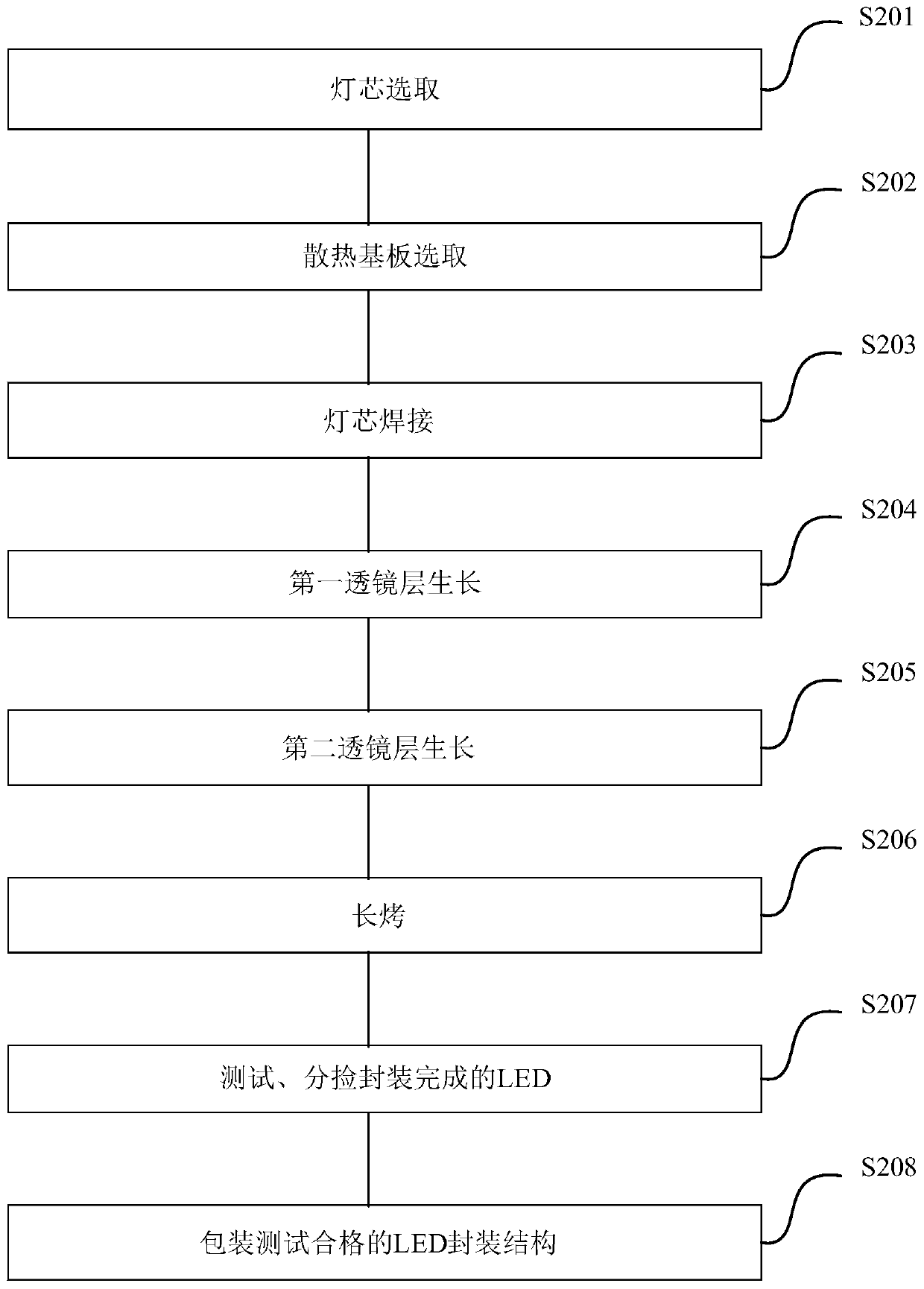

The invention relates to a high-power LED double-layer hemispherical structure packaging technology, which comprises the following steps of (a) preparing a packaging heat dissipation substrate and welding an LED lamp core on the packaging heat dissipation substrate; (b) coating the packaging heat dissipation substrate with first lens silica gel and forming a plurality of first hemispherical lenses, wherein the first hemispherical lenses are of a hemispherical convex lens structure; (c) coating the upper parts of the first hemispherical lenses with a first silica gel layer; (d) coating the first silica gel layer with second lens silica gel and forming a plurality of second hemispherical lenses, wherein the second hemispherical lenses are of a hemispherical convex lens structure; and (e) coating the upper parts of the second hemispherical lenses with a second silica gel layer, wherein at least one layer of the second hemispherical lenses and the second silica gel layer contains fluorescent powder and the LED lamp core is an ultraviolet lamp core. According to the high-power LED double-layer hemispherical structure packaging technology, secondary shaping is not needed, so that the technology is simple and the cost is low.

Owner:XIAN CREATION KEJI CO LTD

LED packaging method

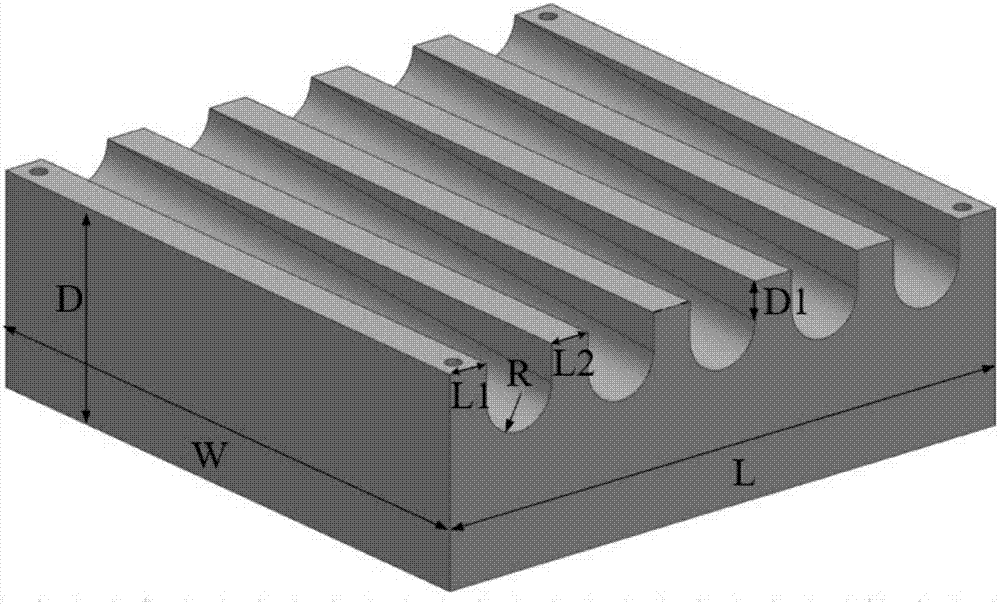

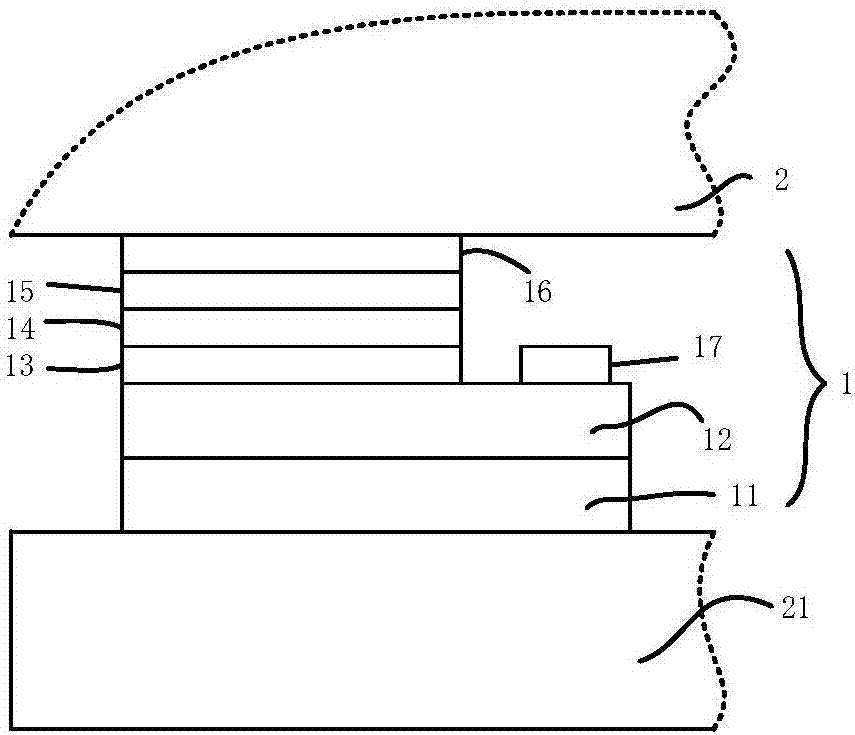

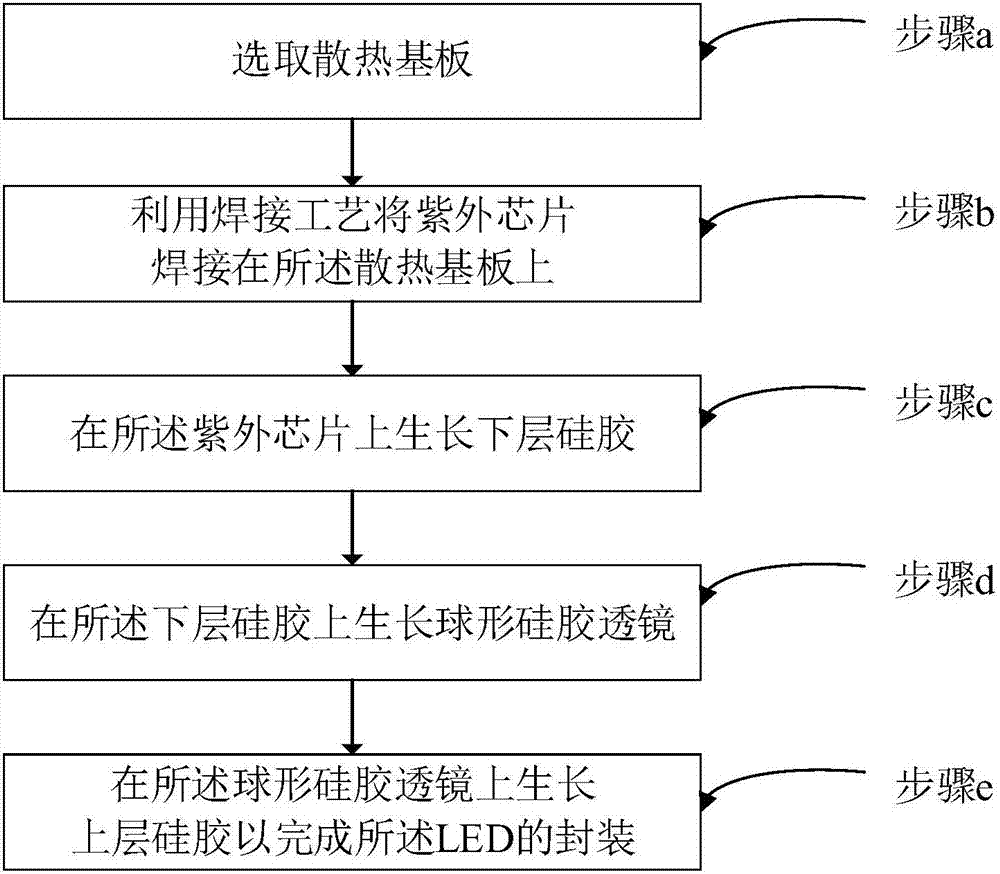

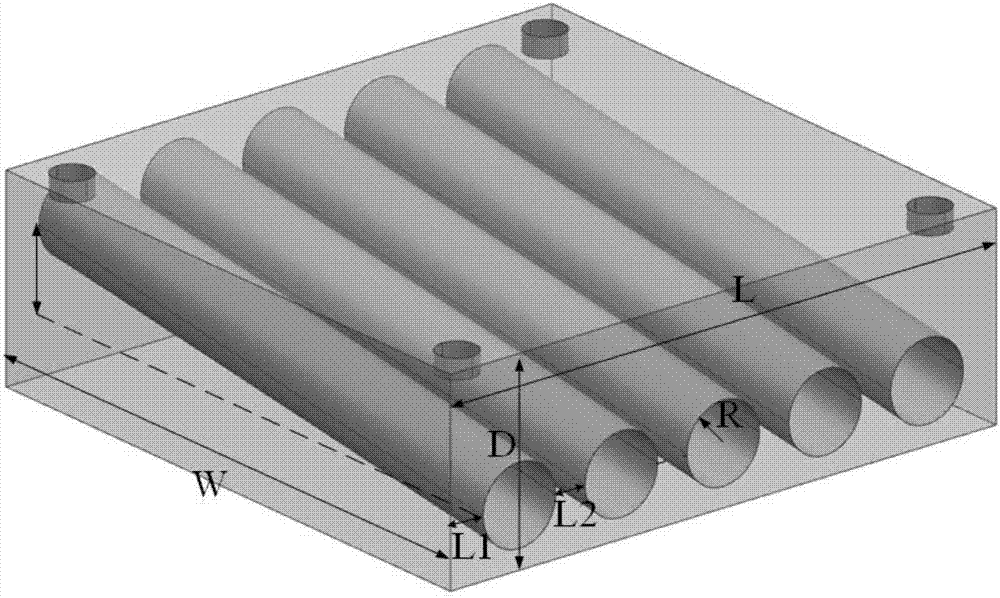

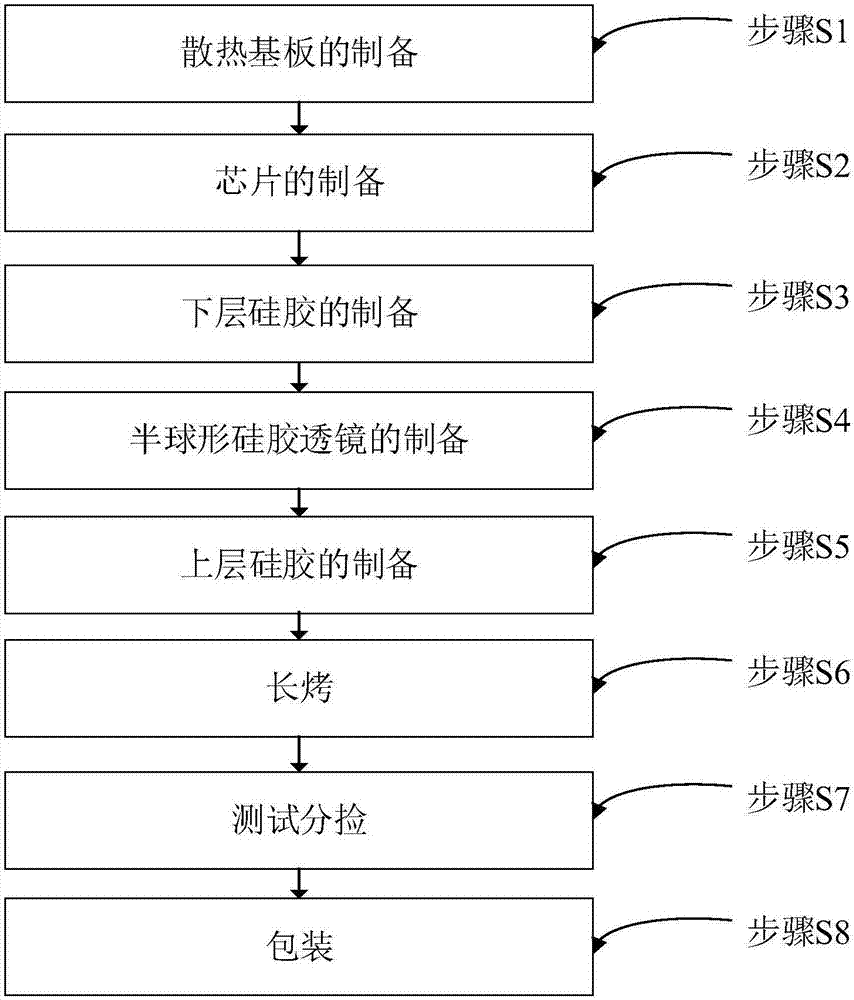

ActiveCN108011019ALarge heat capacityGood thermal conductivitySemiconductor devicesLed packagingTransmittance

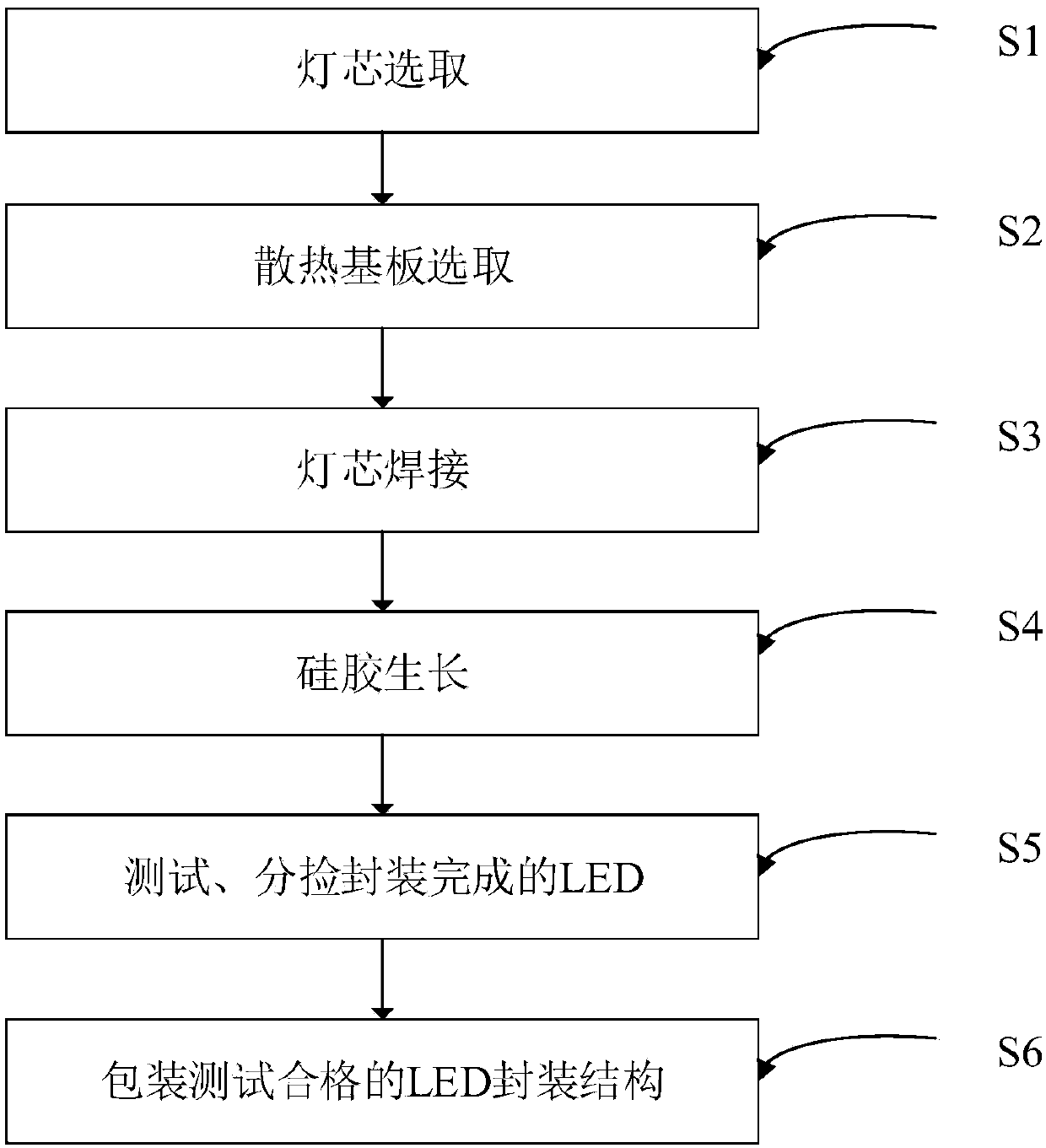

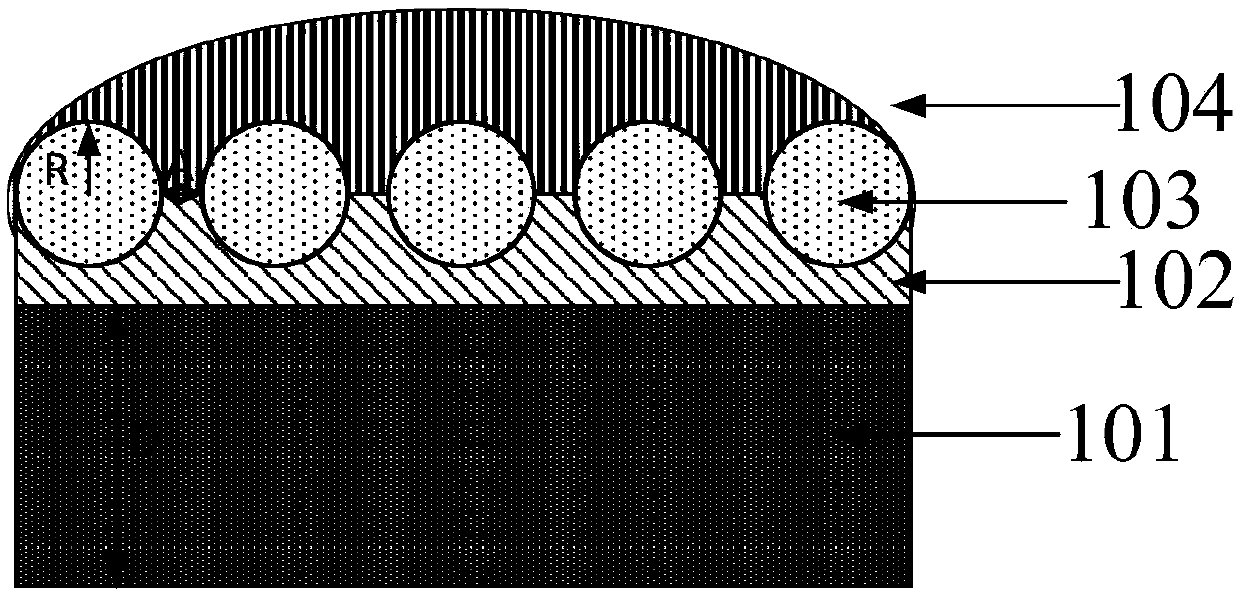

The invention relates to an LED packaging method, which comprises the steps of selecting a heat dissipation substrate; welding an ultraviolet chip on the heat dissipation substrate by using a weldingprocess; growing lower silica gel on the ultraviolet chip; growing a spherical silica gel lens on the lower silica gel; and growing upper silica gel on the spherical silica gel lens to complete packaging of an LED. According to an LED packaging structure, the heat dissipation effect of the LED is improved by adopting the iron heat dissipation substrate with a through hole structure; the conditionthat an LED chip can better irradiate outwards through a packaging material can be ensured by adopting a spherical silica gel lens structure; and the light transmittance is improved.

Owner:廊坊源驰科技有限公司

LED light and LED packaging method

ActiveCN108011022BSolve the drop in quantum efficiencyHigh light transmittanceSemiconductor devicesQuantum efficiencyLight guide

Owner:杭州般若高科技有限公司

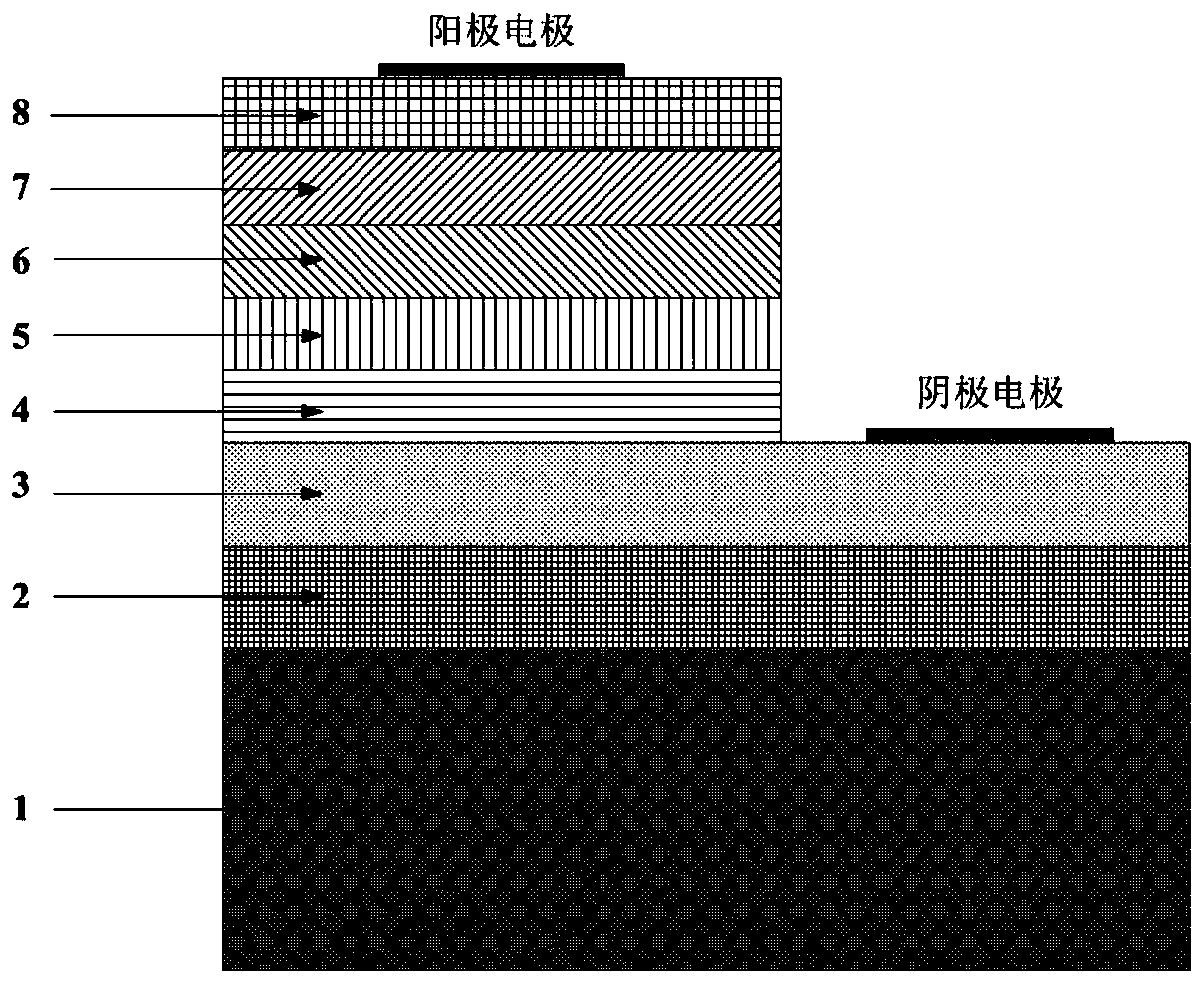

An LED packaging structure

ActiveCN108011011BImprove cooling effectLarge heat capacitySemiconductor devicesEngineeringSilica gel

The invention relates to an LED package structure. The structure comprises a cooling substrate 101, a blue-light lamp wick chip, first semi-spherical silica gel lenses 102, lower-layer silica gel 103,second semi-spherical silica gel lenses 104 and upper-layer silica gel 105, wherein the blue-light lamp wick chip is arranged on an upper surface of the cooling substrate 101, the first semi-spherical silica gel lenses 102 are arranged on upper surfaces of the blue-light lamp wick chip and the cooling substrate 101 at intervals, the lower-layer silica gel 103 is arranged on upper surfaces of theblue-light lamp wick chip and the first semi-spherical silica gel lenses, the second semi-spherical silica gel lenses 104 are arranged on an upper surface of the lower-layer silica gel 103 at intervals, and the upper-layer silica gel 105 is arranged on upper surfaces of the lower-layer silica gel 103 and the second semi-spherical silica gel lenses 104. In the LED package structure, the cooling effect of an LED is improved by employing an iron cooling substrate with an oblique through hole structure; with the adoption of the two-layer semi-spherical silica gel lens structure, the light from anLED chip can be enabled to penetrate through a package material very well to irradiate, and the light transmittance is improved.

Owner:SHENZHEN SUIJING OPTOELECTRONICS CO LTD

led package structure

ActiveCN108011008BSolve the drop in quantum efficiencyHigh light transmittanceSemiconductor devicesQuantum efficiencyEngineering

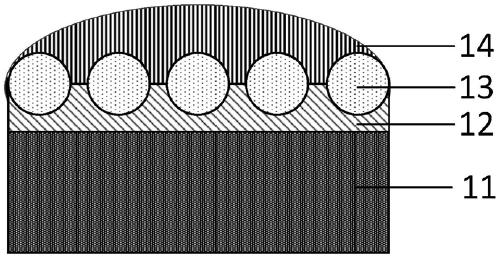

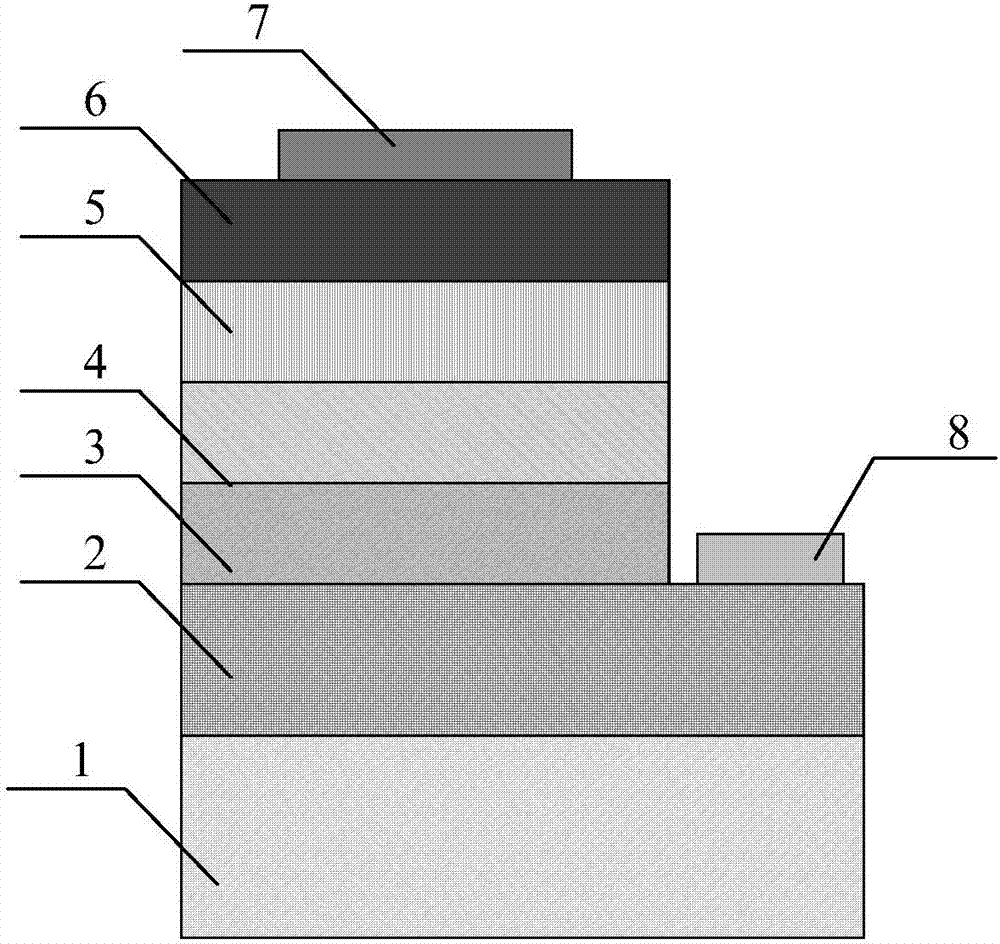

The invention relates to an LED packaging structure, which comprises an LED bottom plate (11), a first silica gel layer (12), a lens area (13) and a second silica gel layer (14), wherein the first silica gel layer (12) is arranged on the LED bottom plate (11); the lens area (13) is arranged on the first silica gel layer (12); and the second silica gel layer (14) is arranged on the first silica gellayer (12) and the lens area (13). According to the LED packaging structure provided by the invention, by adopting a technology for separating fluorescent powder from an LED chip, the problem that the quantum efficiency of the fluorescent powder is reduced due to high temperature is solved; and silica gel in contact with the LED chip is high temperature-resistant silica gel, so that the problem that the light transmittance is reduced due to ageing and yellowing of the silica gel is solved; and meanwhile, provided silica gel spheres are uniformly arranged in a rectangle or diamond manner, so that uniform distribution of light of a light source in a concentration area can be ensured.

Owner:张家界祯弘照明有限公司

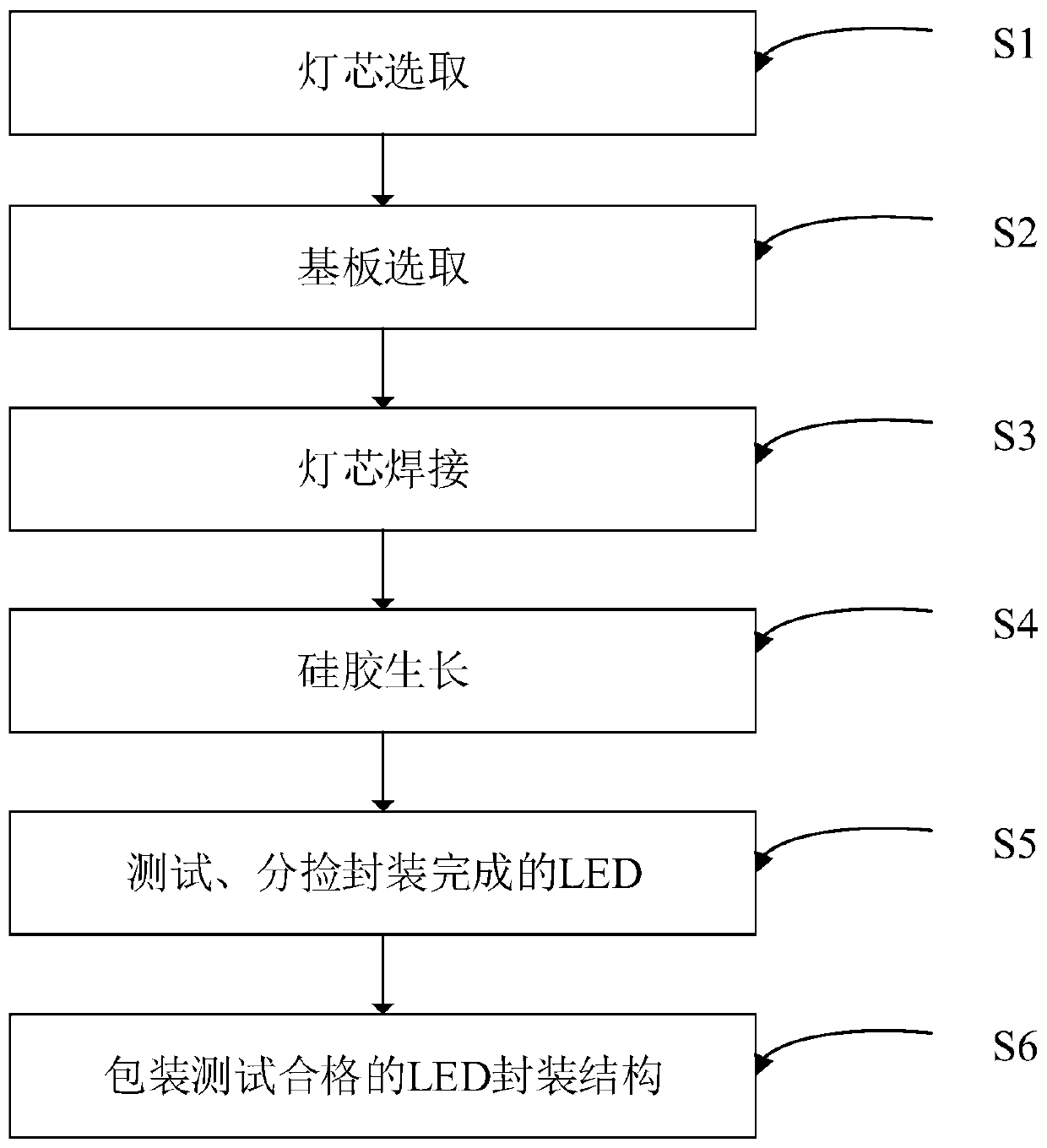

A kind of white light led packaging method

ActiveCN108011006BSolve the drop in quantum efficiencyContinuously adjust color temperatureSemiconductor devicesQuantum efficiencyPhysical chemistry

The invention relates to a white LED packaging method, which comprises the steps of selecting a substrate and an LED lamp core; welding the LED lamp core on the substrate by using a reflow soldering process; and growing silica gel layers on the LED lamp core to complete packaging of an LED. According to the white LED packaging method, the problem that the quantum efficiency of fluorescent powder is reduced due to high temperature is solved through separation of the fluorescent powder from the LED lamp core.

Owner:广州市安亿仕电子科技有限公司

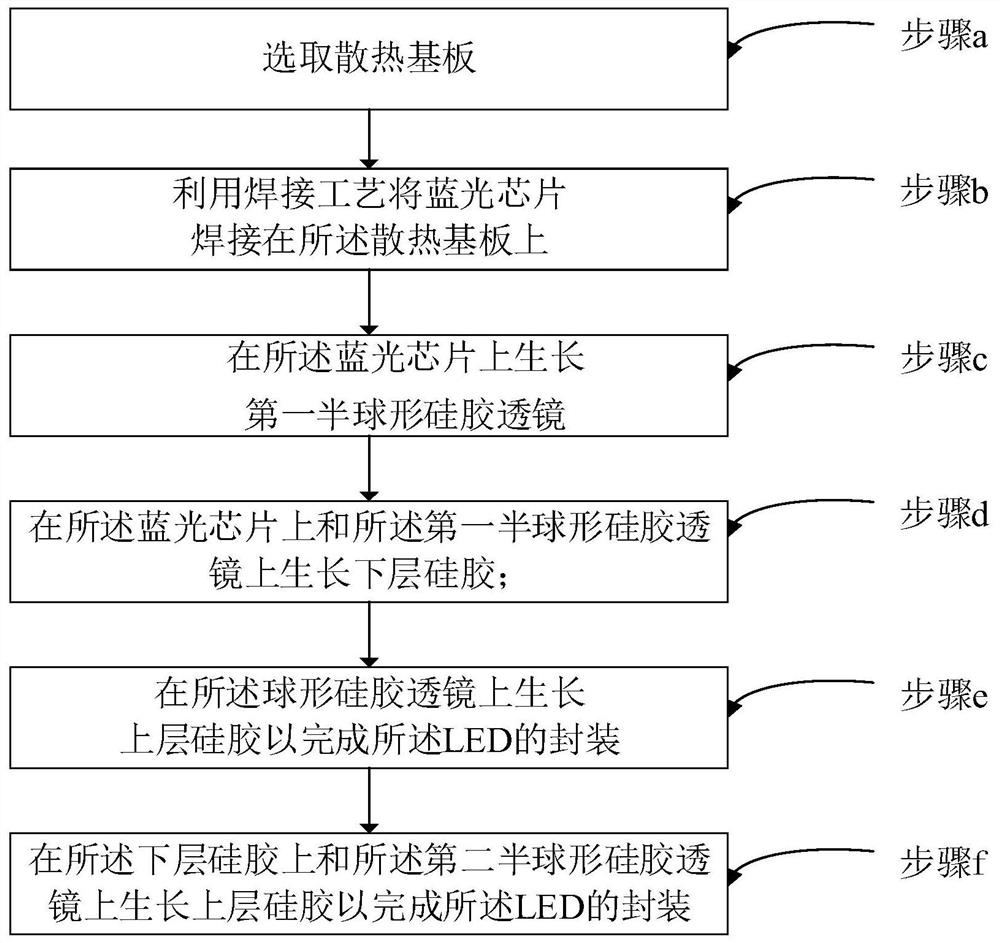

A kind of LED encapsulation method

ActiveCN107833951BImprove cooling effectLarge heat capacitySemiconductor devicesPhysical chemistryCooling effect

The invention relates to an LED packaging method. The method comprises steps: a cooling substrate is selected; a blue light chip is welded on the cooling substrate by using a welding technology; a first hemispherical silica gel lens grows on the blue light chip; a lower silica gel layer grows on the blue light chip and the first hemispherical silica gel lens; a second hemispherical silica gel lensgrows on the lower silica gel layer; and an upper silica gel layer grows on the lower silica gel layer and the second hemispherical silica gel lens to complete LED packaging. According to the LED packaging structure of the invention, through adopting the iron cooling substrate with an oblique through hole structure, the cooling effects of the LED are increased; through adopting the spherical silica gel lens structure, light of the LED chip can shine out better through the packaging material, and the light transmittance is improved.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG

A LED package structure

ActiveCN108011018BImproved luminous dispersionSolve the drop in quantum efficiencySemiconductor devicesLight beamEngineering

Owner:广东安林电子科技股份有限公司

Package process of large-power blue-light LED dual-layer structure

InactiveCN108011009AFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesEngineeringSilica gel

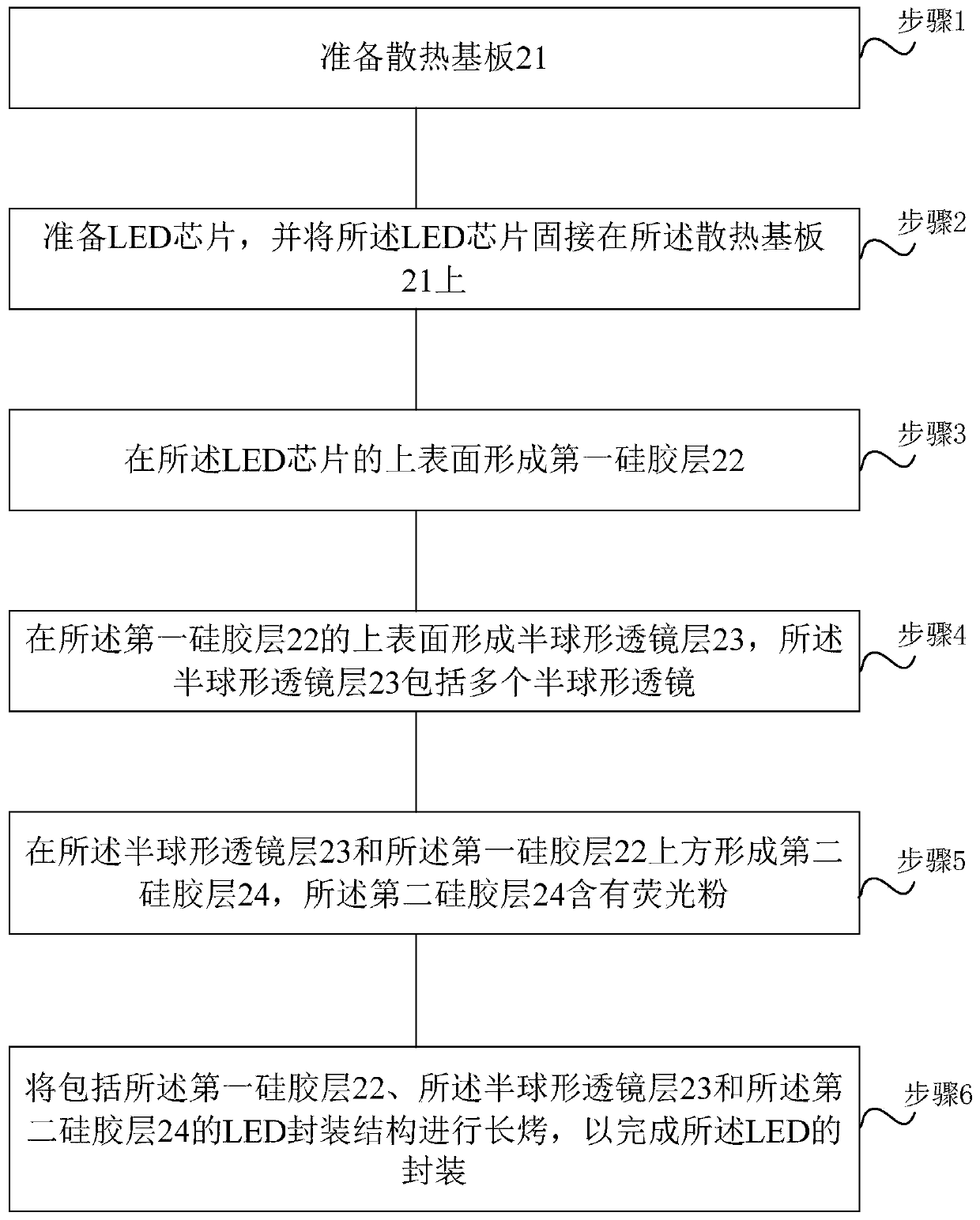

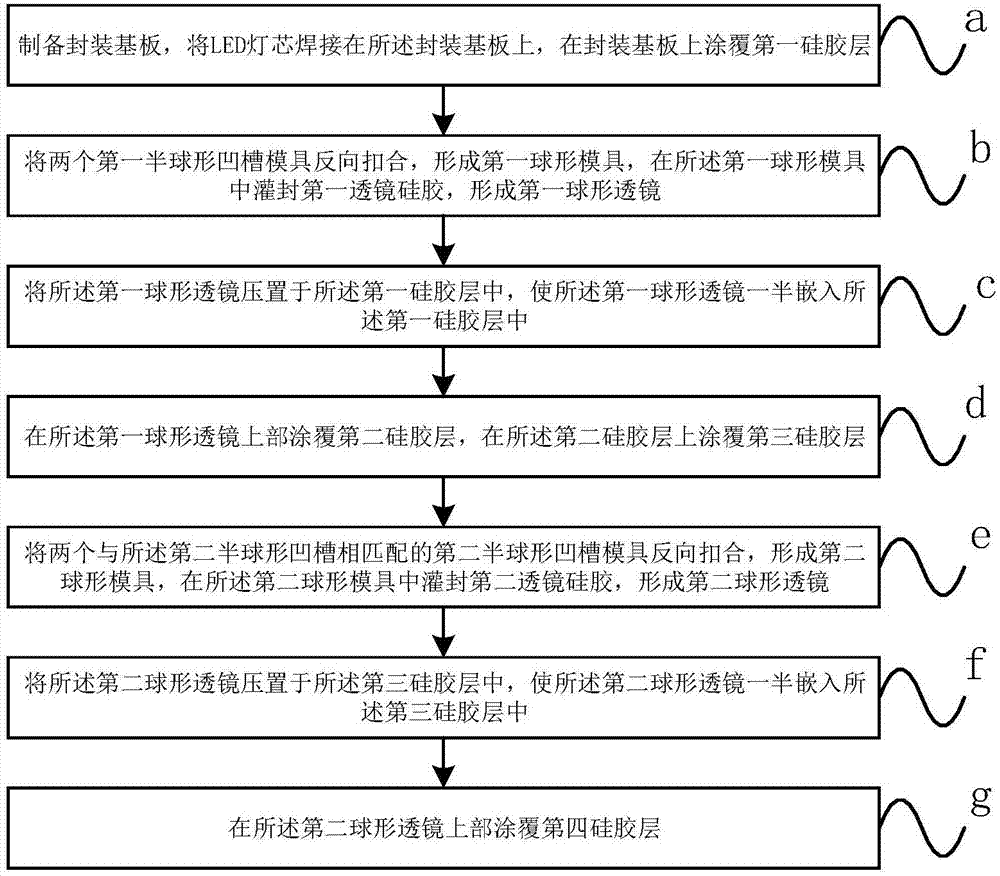

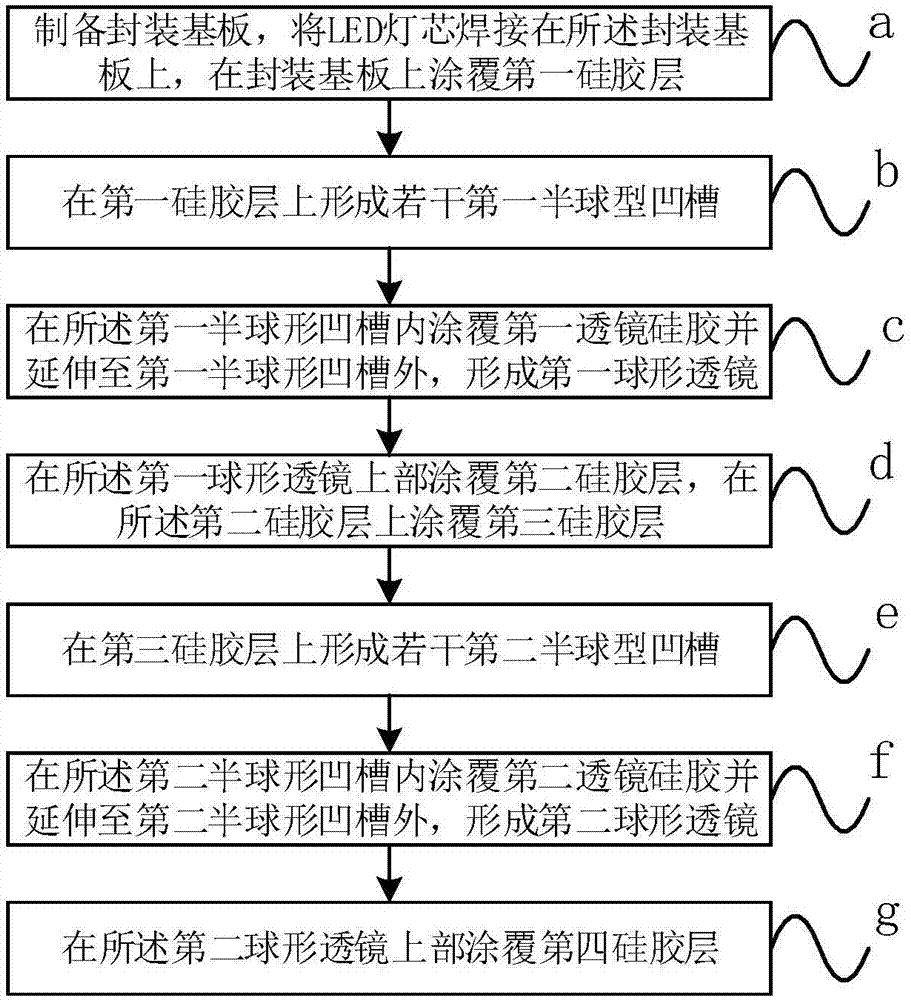

The invention relates to a package process of a large-power blue-light LED dual-layer structure. The package process comprises the following steps of (a) fabricating a package cooling substrate, welding an LED lamp core on the package cooling substrate, and coating a first silica gel layer on the package cooling substrate; (b) forming a first spherical lens; (c) laminating the first spherical lensin the first silica gel layer; (d) coating a second silica gel layer at an upper part of the first spherical lens, and coating a third silica gel layer on the second silica gel layer; (e) forming a second spherical lens; (f) laminating the first spherical lens in the first silica gel layer; and (g) coating a fourth silica gel layer at an upper part of the second spherical lens, wherein at least one of the second silica gel layer, the third silica gel layer and the fourth silica gel layer is provided with fluorescent power, and the LED lamp core is a ultraviolet lamp core. According to the package process of the large-power blue-light LED dual-layer structure, secondary shaping is not needed, and the process is simple and is low in cost.

Owner:XIAN CREATION KEJI CO LTD

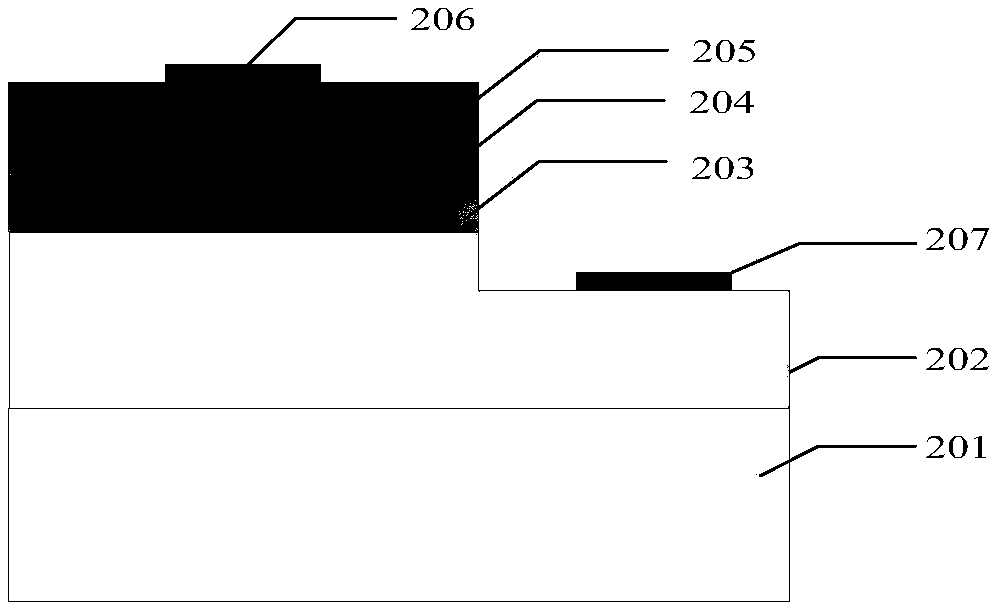

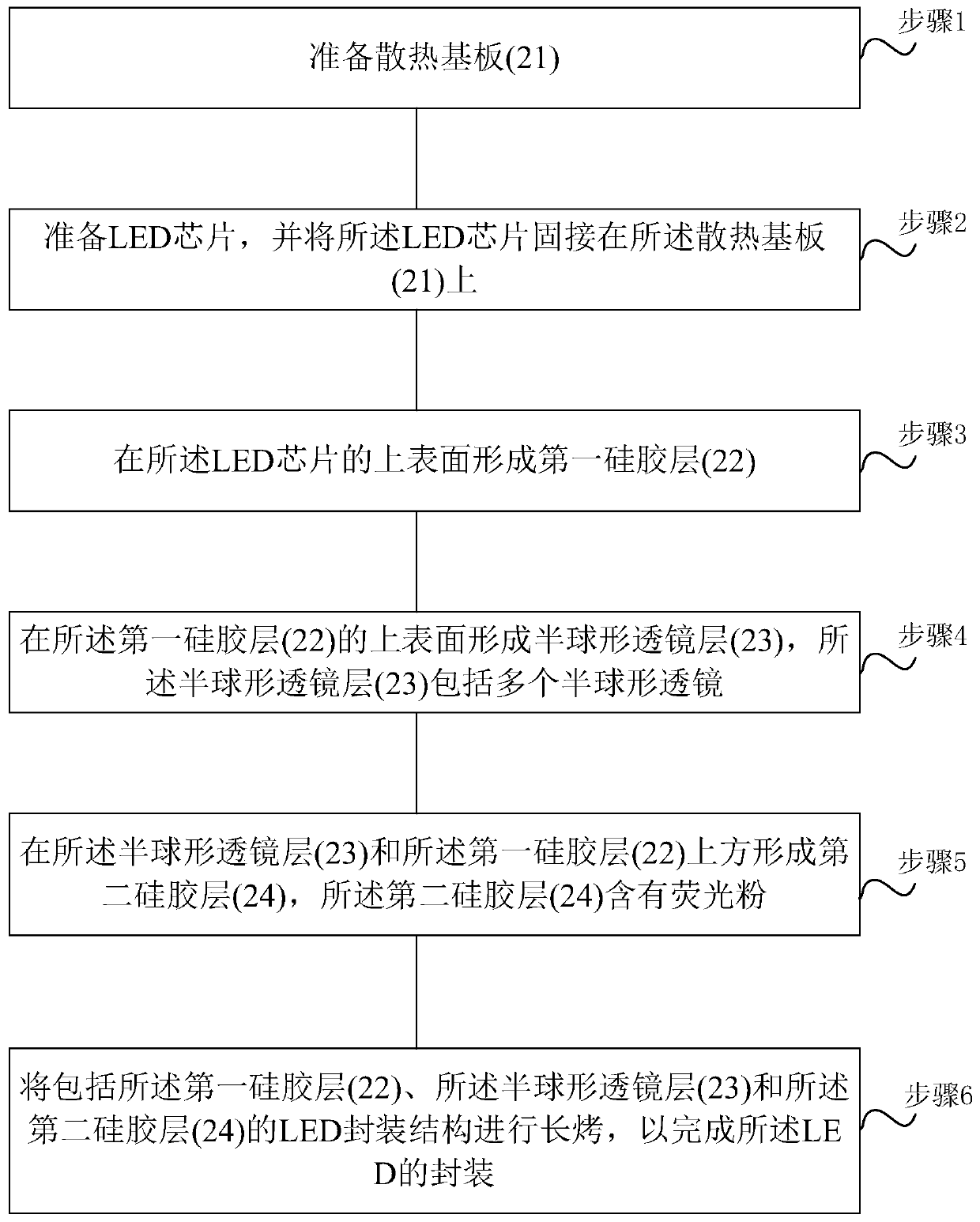

LED package method

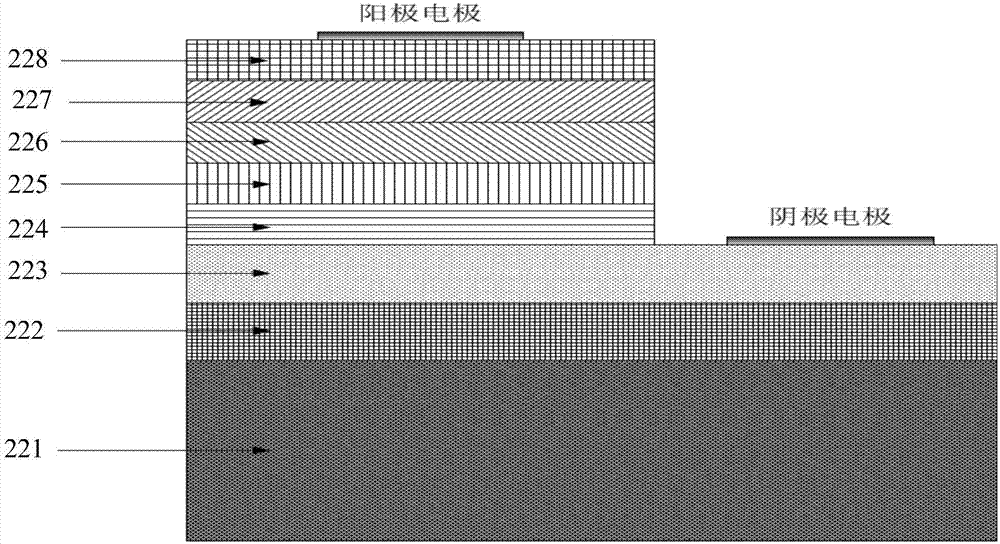

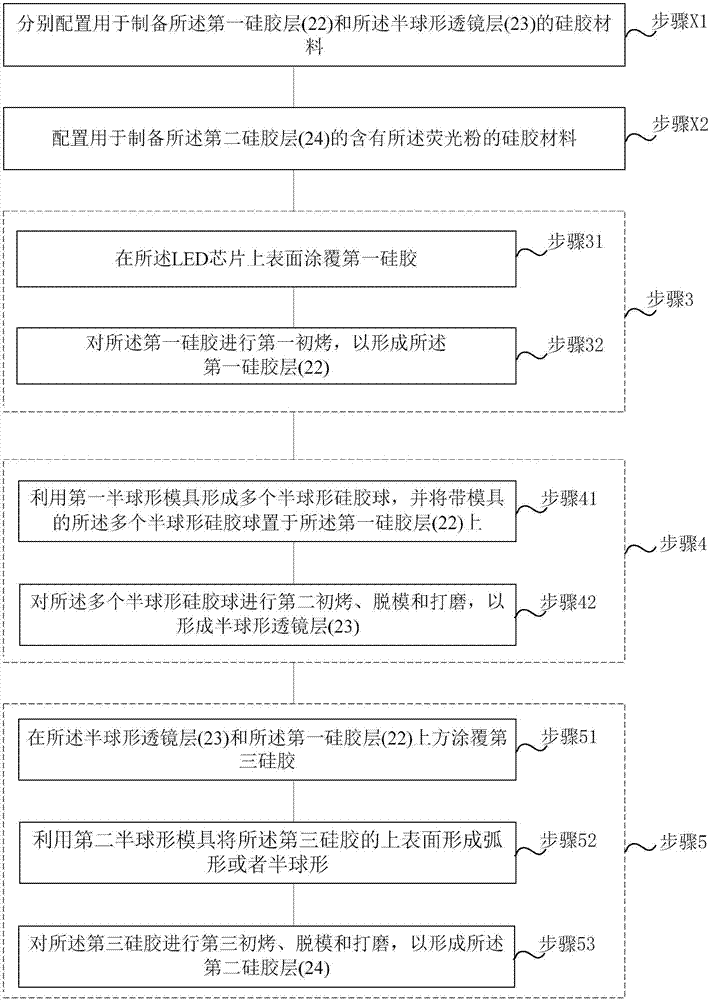

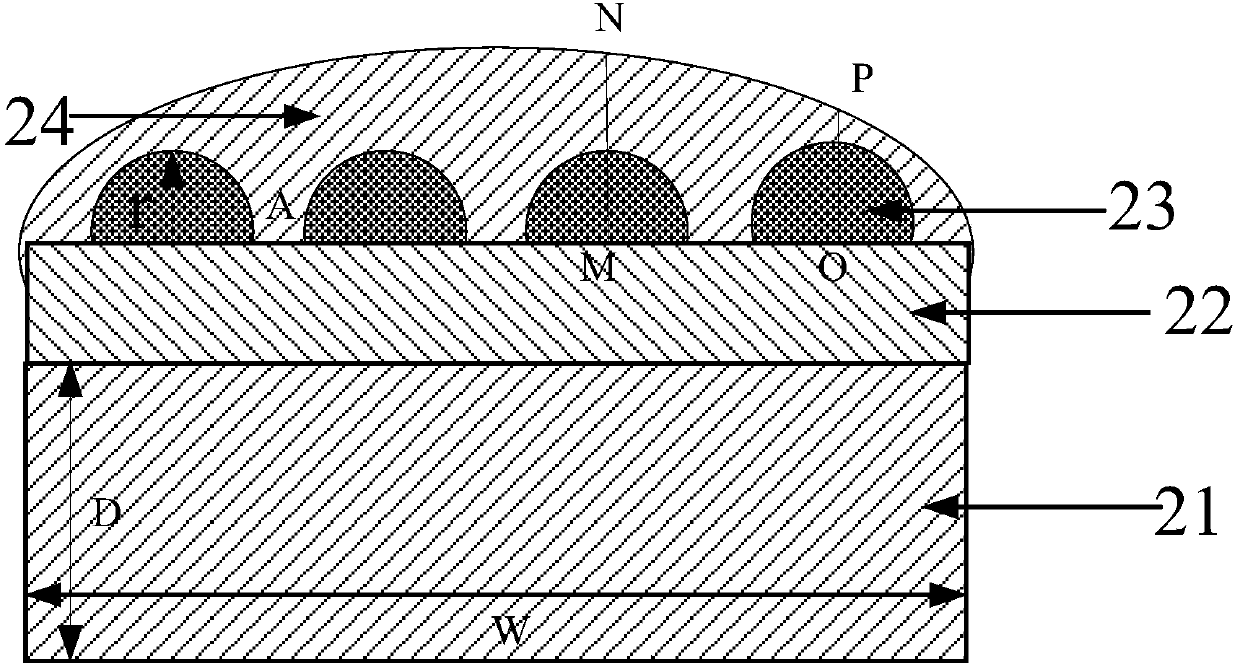

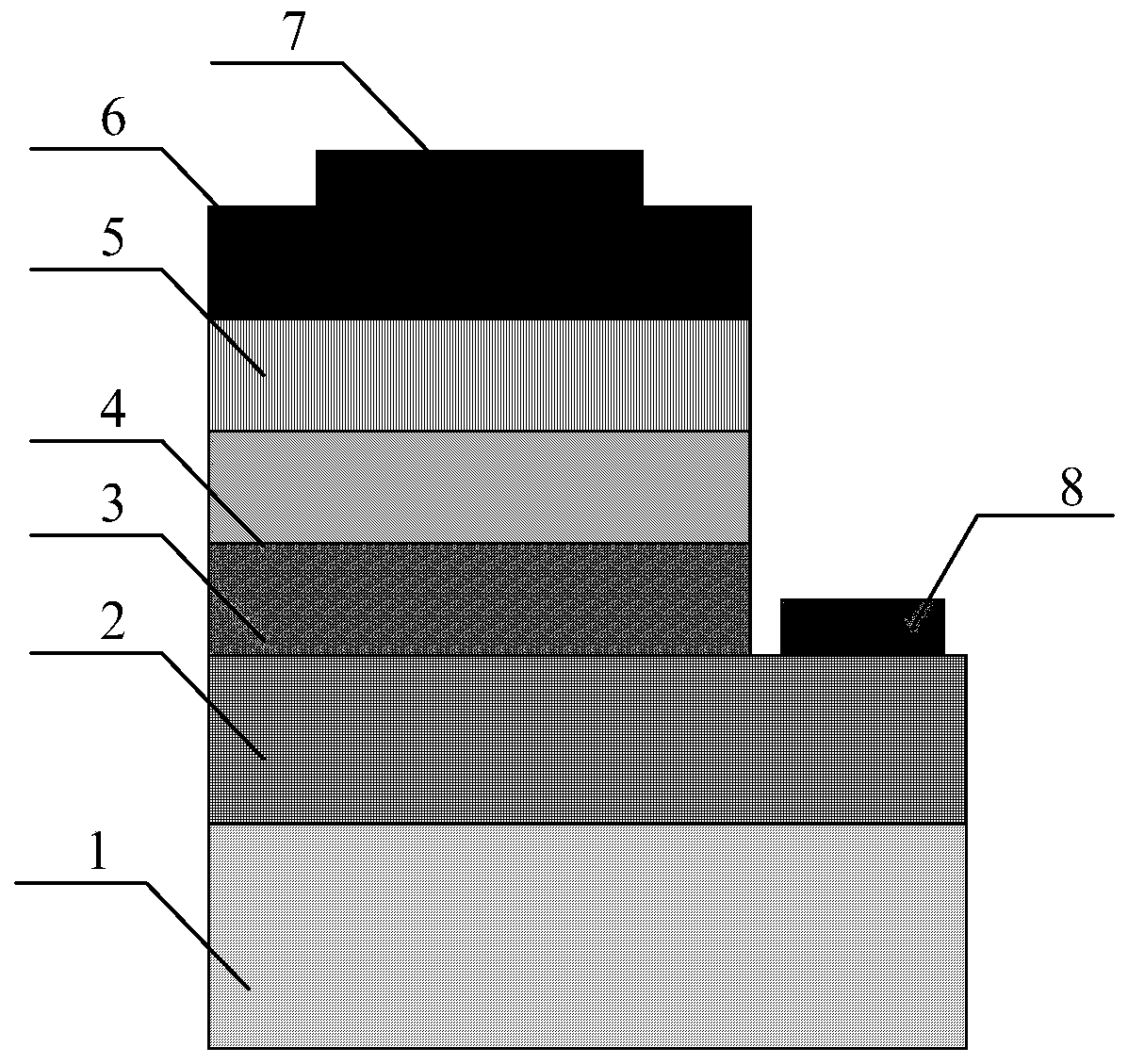

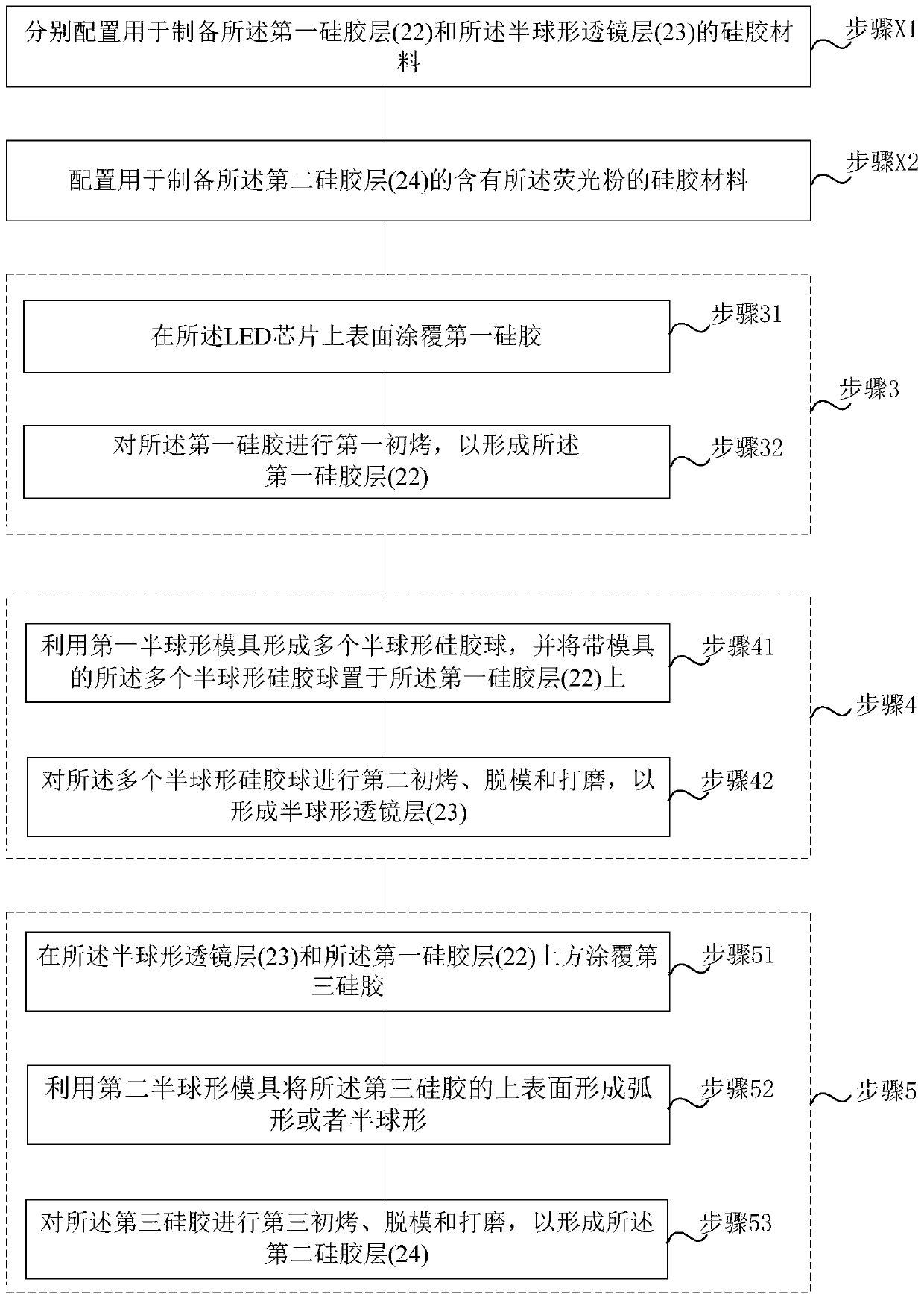

ActiveCN108011010AImproved luminous dispersionSolve the drop in quantum efficiencySemiconductor devicesEngineeringSilica gel

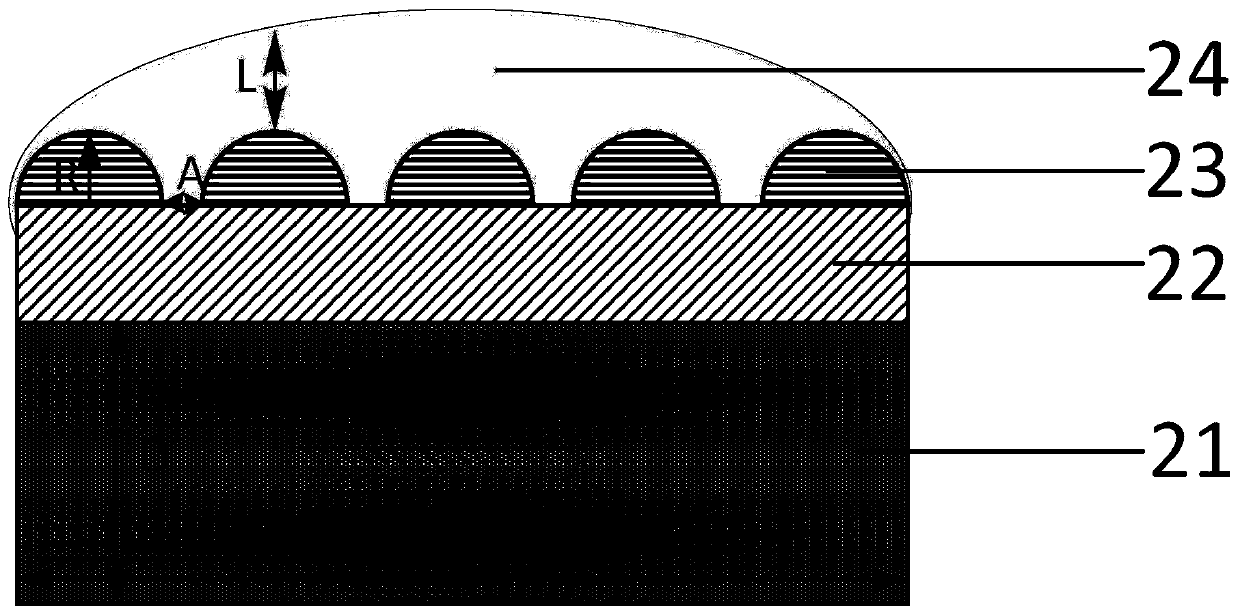

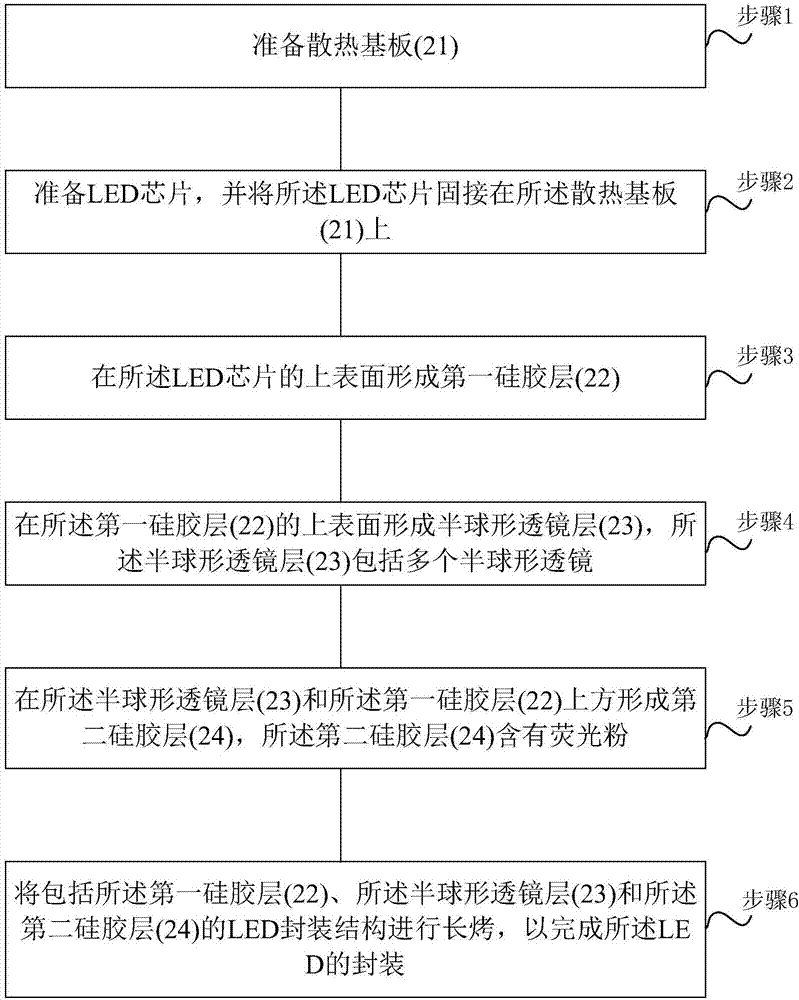

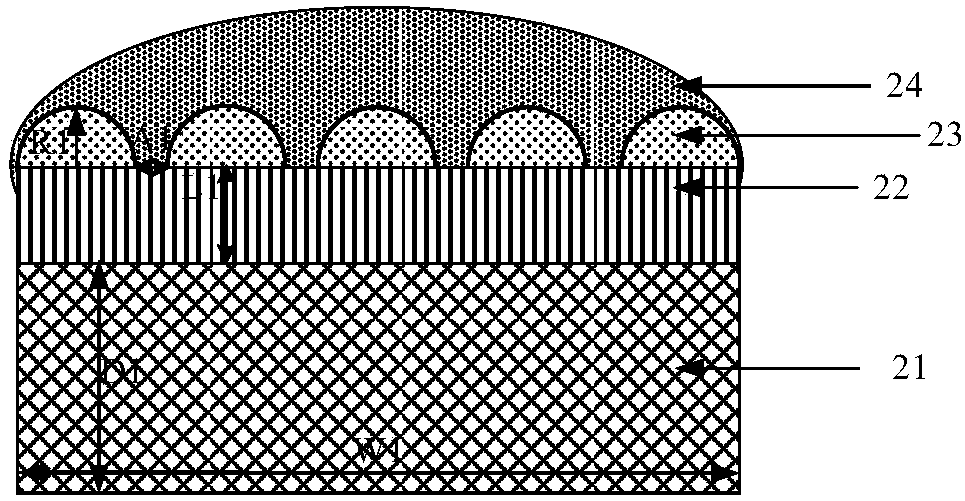

The invention relates to an LED package method. The LED package method comprises the steps of preparing a cooling substrate (21); preparing an LED chip, fixedly connecting the LED chip onto the cooling substrate (21); forming a first silica gel layer (22) on an upper surface of the LED chip; forming a semi-spherical lens layer (23) on an upper surface of the first silica gel layer (22), wherein the semi-spherical lens layer (23) comprises a plurality of semi-spherical lenses; forming a second silica gel layer (24) above the semi-spherical lens layer (23) and the first silica gel layer (22), wherein the second silica gel layer (24) contains fluorescent powder; and baking an LED package structure comprising the first silica gel layer (22), the semi-spherical lens layer (24) and the second silica gel layer (24) for a long time so as to complete package of an LED. According to the LED package method disclosed by the embodiment of the invention, the semi-spherical lens layer is arranged between the first silica gel layer and the second silica gel layer, the fluorescent powder is arranged in the second silica gel layer, so that light beams are more concentrated and uniformly irradiate, moreover, the fluorescent powder is prevented from being in direct contact with the LED chip, and the light extraction efficiency is improved.

Owner:YANGZHOU HUACAI OPTO ELECTRONICS

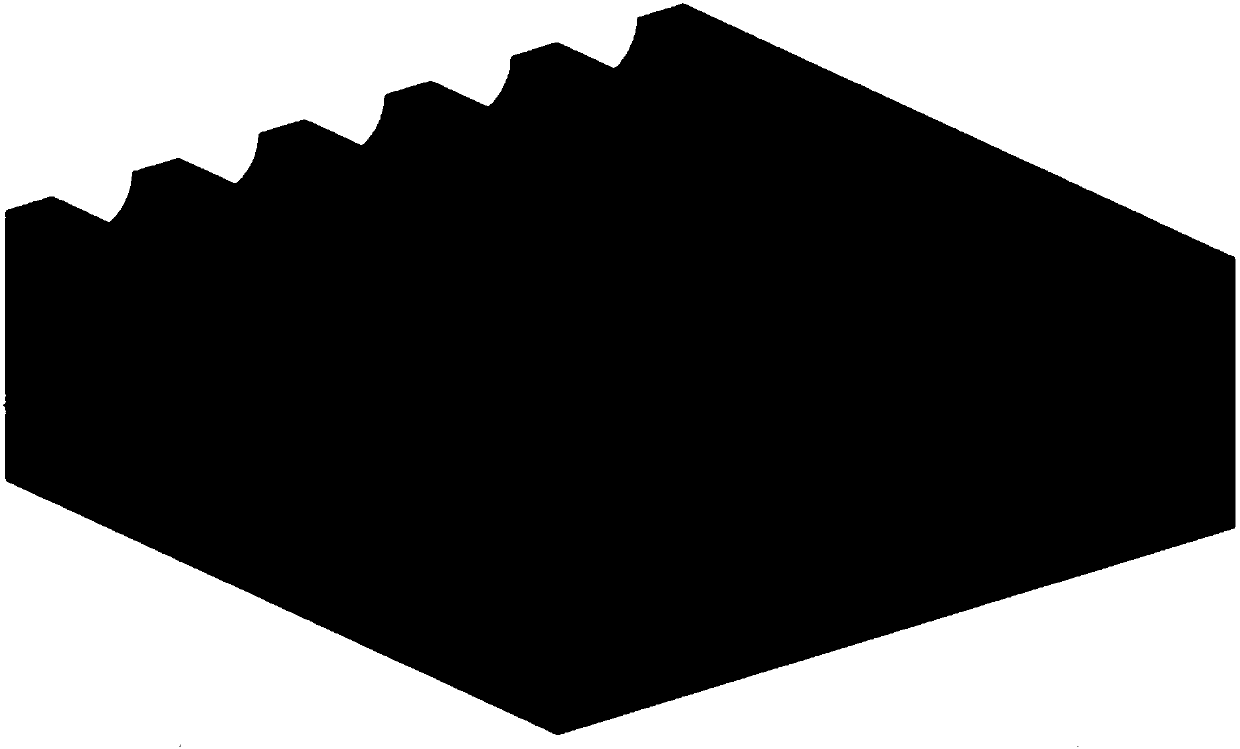

High-power LED double-layer structure packaging process

InactiveCN107994107AFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesEngineeringSilica gel

The invention relates to a high-power LED double-layer structure packaging process. The process comprises the following steps of a, preparing a packaging heat-dissipation substrate, welding an LED lamp core on the packaging heat-dissipation substrate, and coating a first silica gel layer on the packaging heat-dissipation substrate; b, forming a plurality of first semi-spherical grooves in the first silica gel layer; c, coating the first lens silica gel in the first semi-spherical grooves and extending the first lens silica gel out of the semi-spherical grooves to form a first spherical lens; d, coating a second silica gel layer on the upper portion of the first spherical lens, and coating a third silica gel layer on the second silica gel layer; e, forming a plurality of second semi-spherical grooves in the third silica gel layer; f, coating the second lens silica gel in the plurality of second semi-spherical grooves and extending the second lens silica gel out of the plurality of second semi-spherical grooves to form a second spherical lens; g, coating a fourth silica gel layer on the upper portion of the second spherical lens. According to the invention, the high-power LED double-layer structure packaging process does not need secondary shaping, and is simple in process and low in cost.

Owner:XIAN CREATION KEJI CO LTD

White-light LED package structure

ActiveCN107946436ASolve the drop in quantum efficiencyContinuously adjust color temperatureSemiconductor devicesQuantum efficiencyEngineering

The invention relates to a white-light LED package structure. The structure comprises a heat radiation substrate 21, an LED lamp chip arranged on the upper surface of the heat radiation substrate 21,a lower silica gel layer 22 arranged on the upper surface of the LED lamp chip, hemispherical silica gel balls 23 arranged on the upper surface of the lower silica gel layer 22, and an upper silica gel layer 24 arranged on the upper surfaces of the lower silica gel layer 22 and the hemispherical silica gel balls 23. The white-light LED package structure solves the problem of reduction of quantum efficiency of fluorescent powders due to high temperature by separating the fluorescent powders from the LED lamp chip.

Owner:广东安林电子科技股份有限公司

A kind of LED encapsulation method

ActiveCN108011019BImprove thermal conductivityImprove cooling effectSemiconductor devicesTransmittanceSilica gel

The invention relates to an LED packaging method, which comprises the steps of selecting a heat dissipation substrate; welding an ultraviolet chip on the heat dissipation substrate by using a weldingprocess; growing lower silica gel on the ultraviolet chip; growing a spherical silica gel lens on the lower silica gel; and growing upper silica gel on the spherical silica gel lens to complete packaging of an LED. According to an LED packaging structure, the heat dissipation effect of the LED is improved by adopting the iron heat dissipation substrate with a through hole structure; the conditionthat an LED chip can better irradiate outwards through a packaging material can be ensured by adopting a spherical silica gel lens structure; and the light transmittance is improved.

Owner:廊坊云航科技有限公司

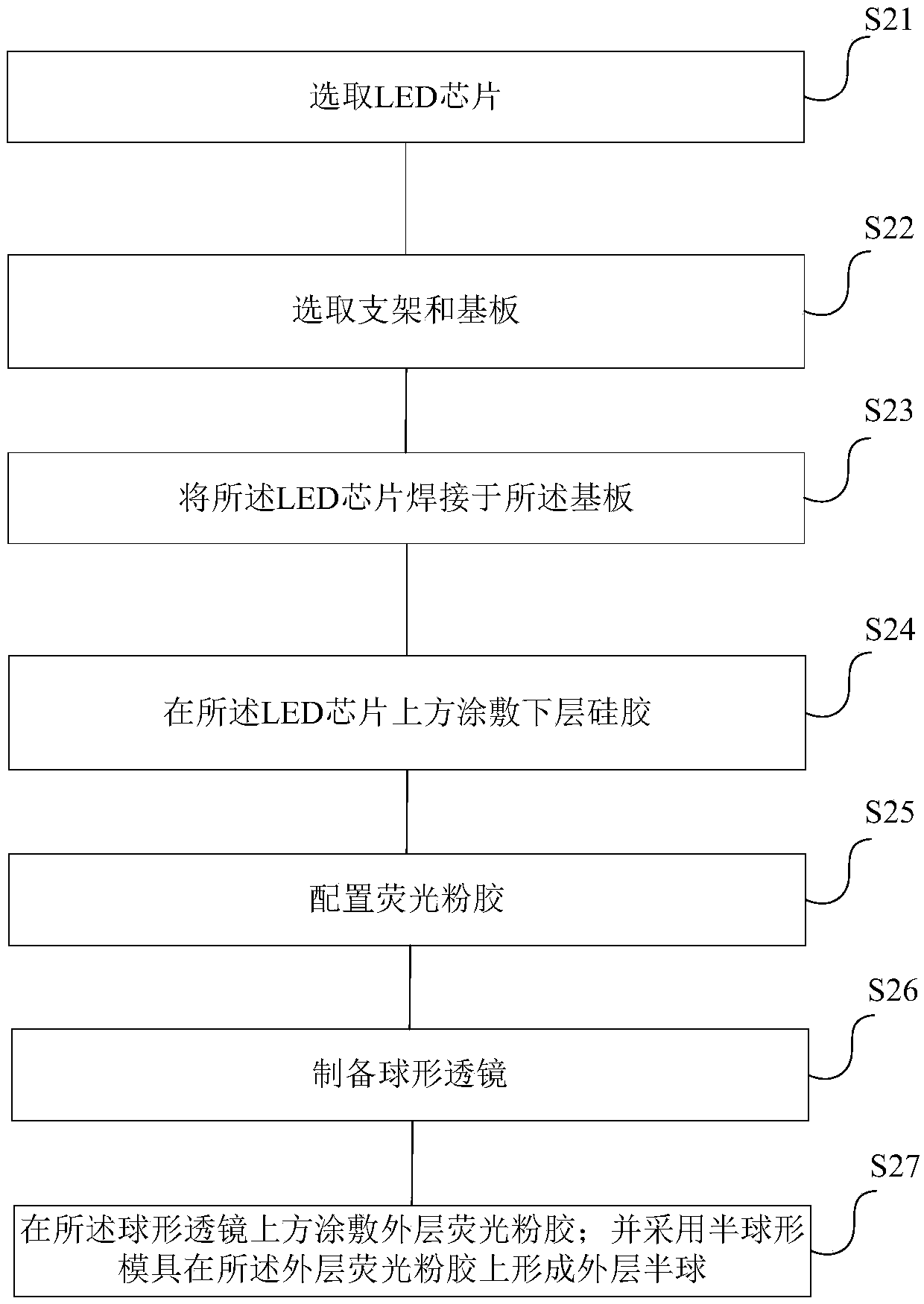

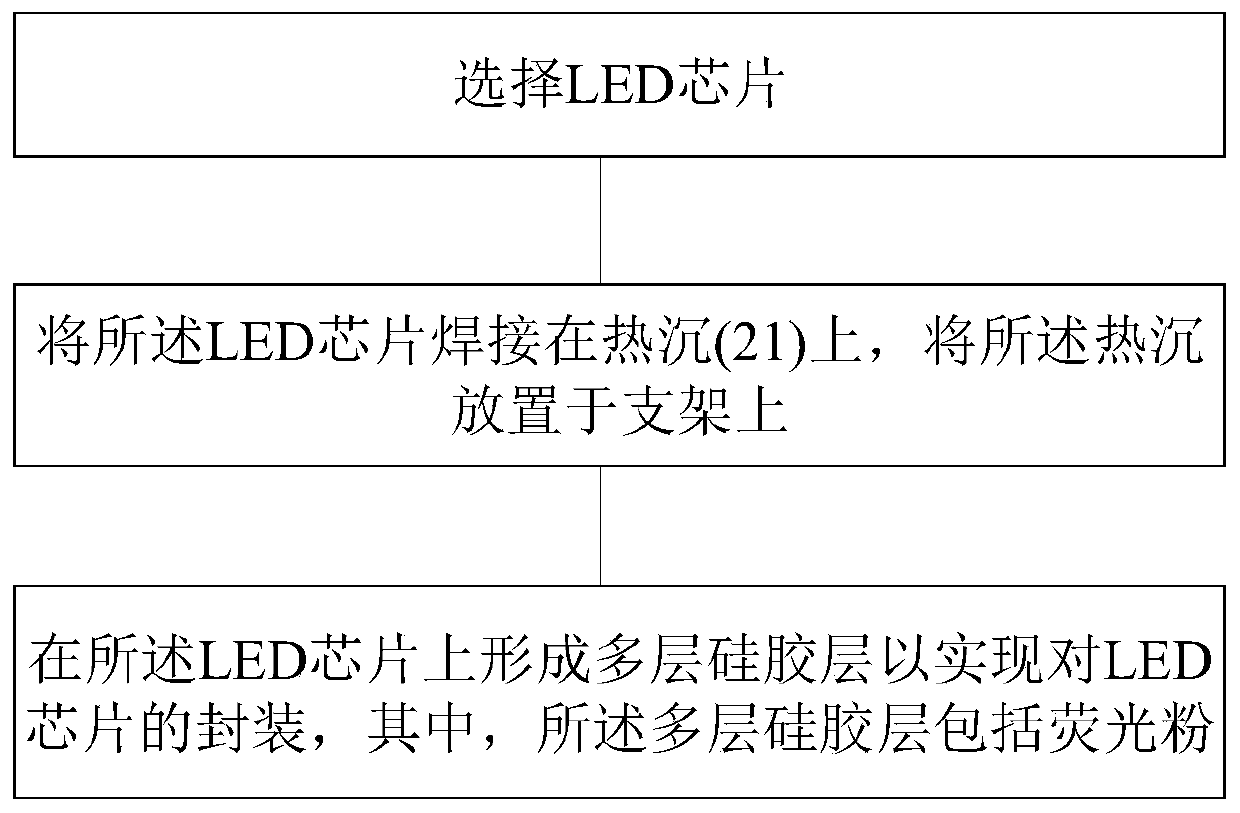

led light and led packaging process

ActiveCN108011024BSolve the drop in quantum efficiencyHigh light transmittanceSemiconductor devicesQuantum efficiencyTransmittance

The invention relates to an LED lamp and an LED packaging technology. The packaging technology comprises the steps of selecting an LED chip; welding the LED on heat sink (21) and arranging the heat sink (21) on a bracket; and forming multiple silica gel layers on the LED chip to achieve packaging of the LED chip, wherein the silica gel layer, in contact with the LED chip, in the multiple silica gel layers does not contain fluorescent powder. According to the LED packaging technology, the fluorescent powder is separated from the LED chip, so that the problem that the quantum efficiency of the fluorescent powder is reduced due to high temperature is solved; and silica gel in contact with the LED chip is high-temperature resistant silica gel, so that the problem that the light transmittance is reduced due to ageing and yellowing of the silica gel is solved.

Owner:广东安林电子科技股份有限公司

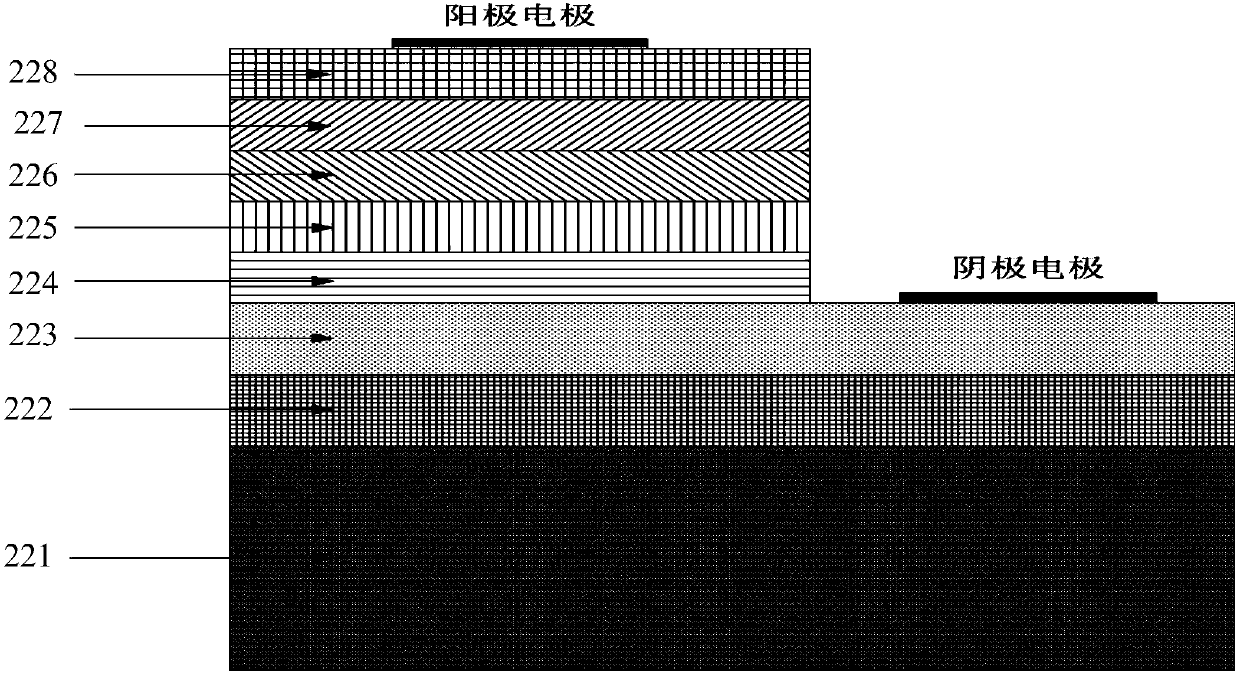

LED package body and high-light-transmittance LED lamp

InactiveCN107946442ASolve the drop in quantum efficiencyHigh light transmittanceSemiconductor devicesQuantum efficiencyOptical transmittance

The invention relates to an LED package body and a high-light-transmittance LED lamp. The LED package body comprises a heat sink (21), an LED chip arranged on the heat sink (21), a first silica gel layer (22) coated on the LED chip and the heat sink (21), a second silica gel layer (23) arranged on the first silica gel layer (22), and a third silica gel layer (24) arranged on the second silica gellayer (23). According to the LED package body, fluorescent powders thereof are separated from the LED chip, thereby solving the problems of reduction of quantum efficiency of the fluorescent powders due to high temperature and reduction of light transmittance.

Owner:XIAN CREATION KEJI CO LTD

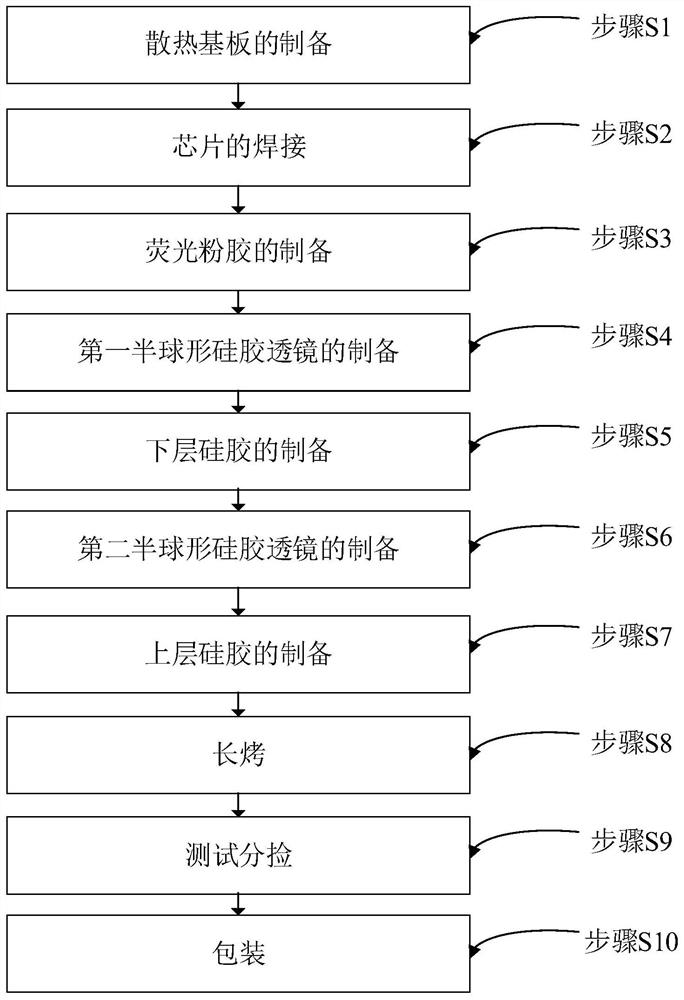

LED packaging method

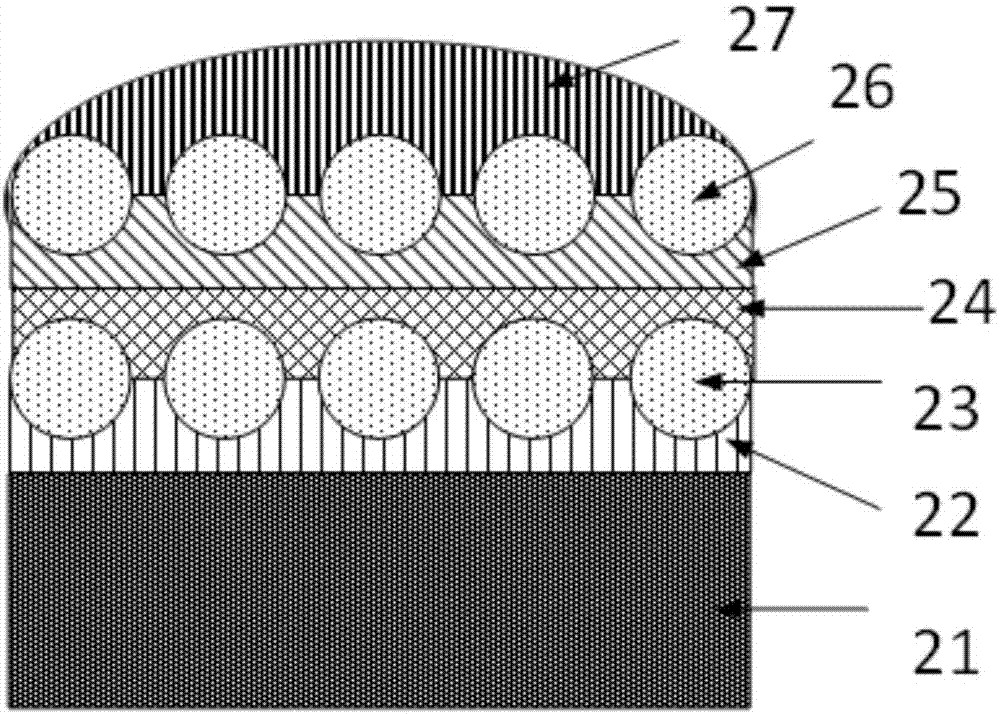

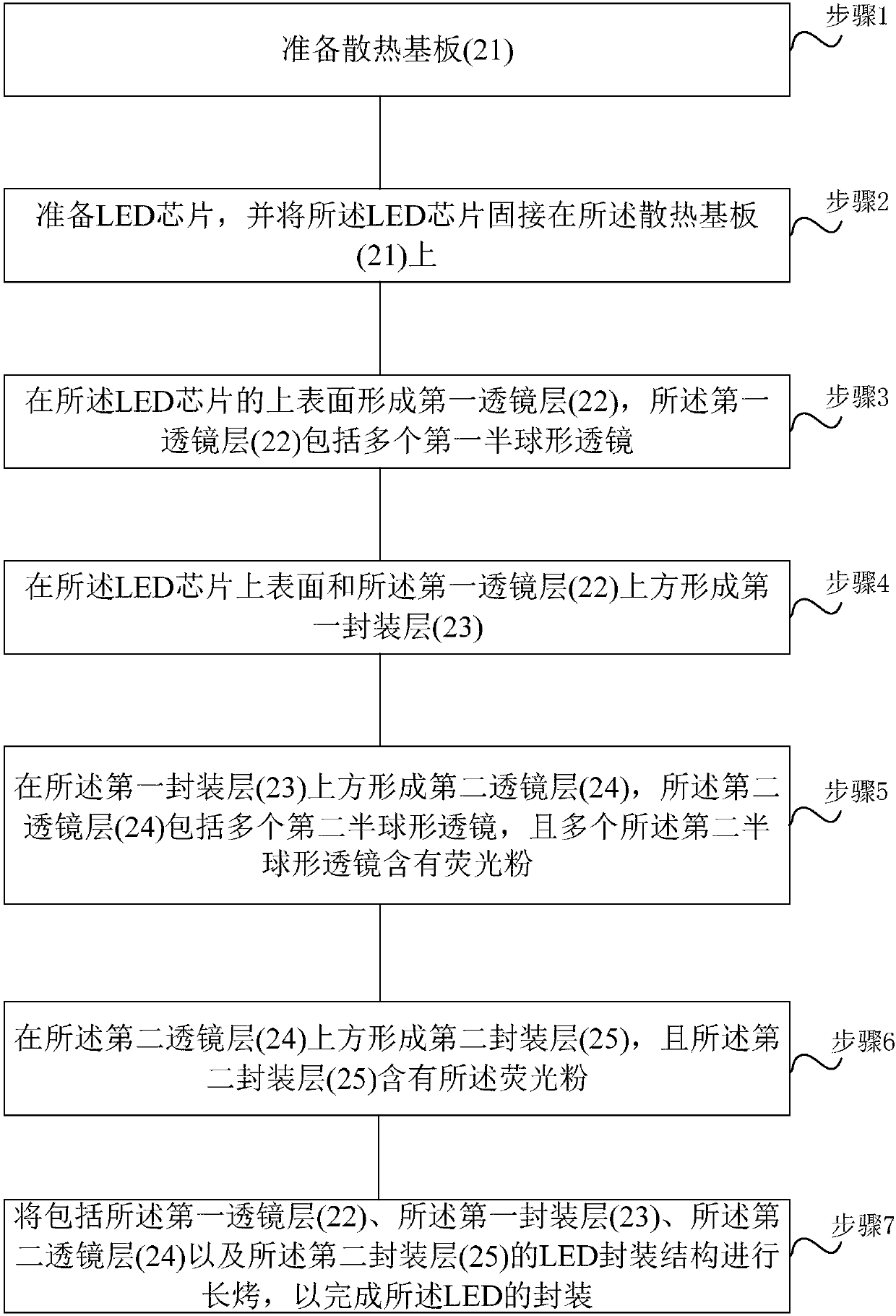

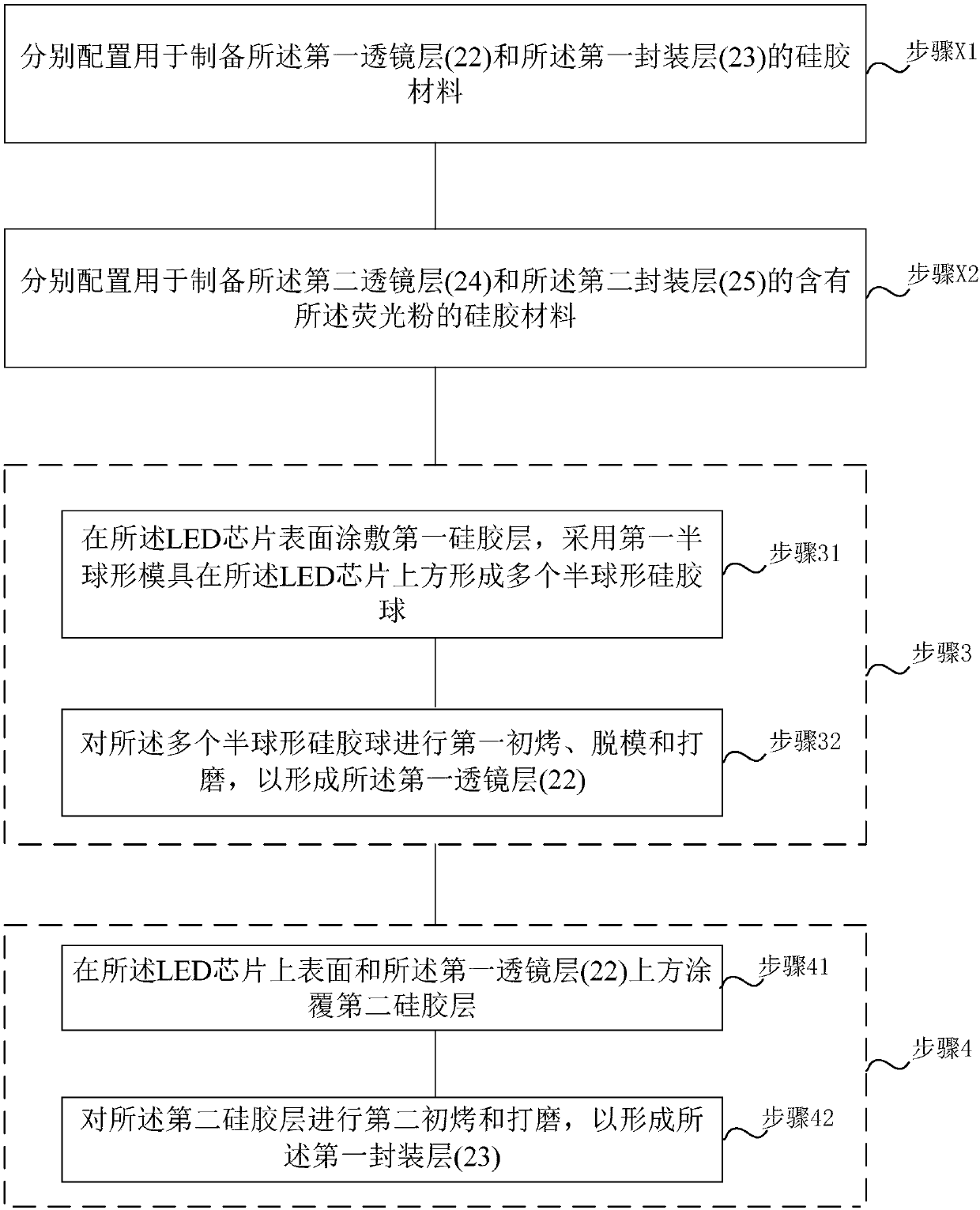

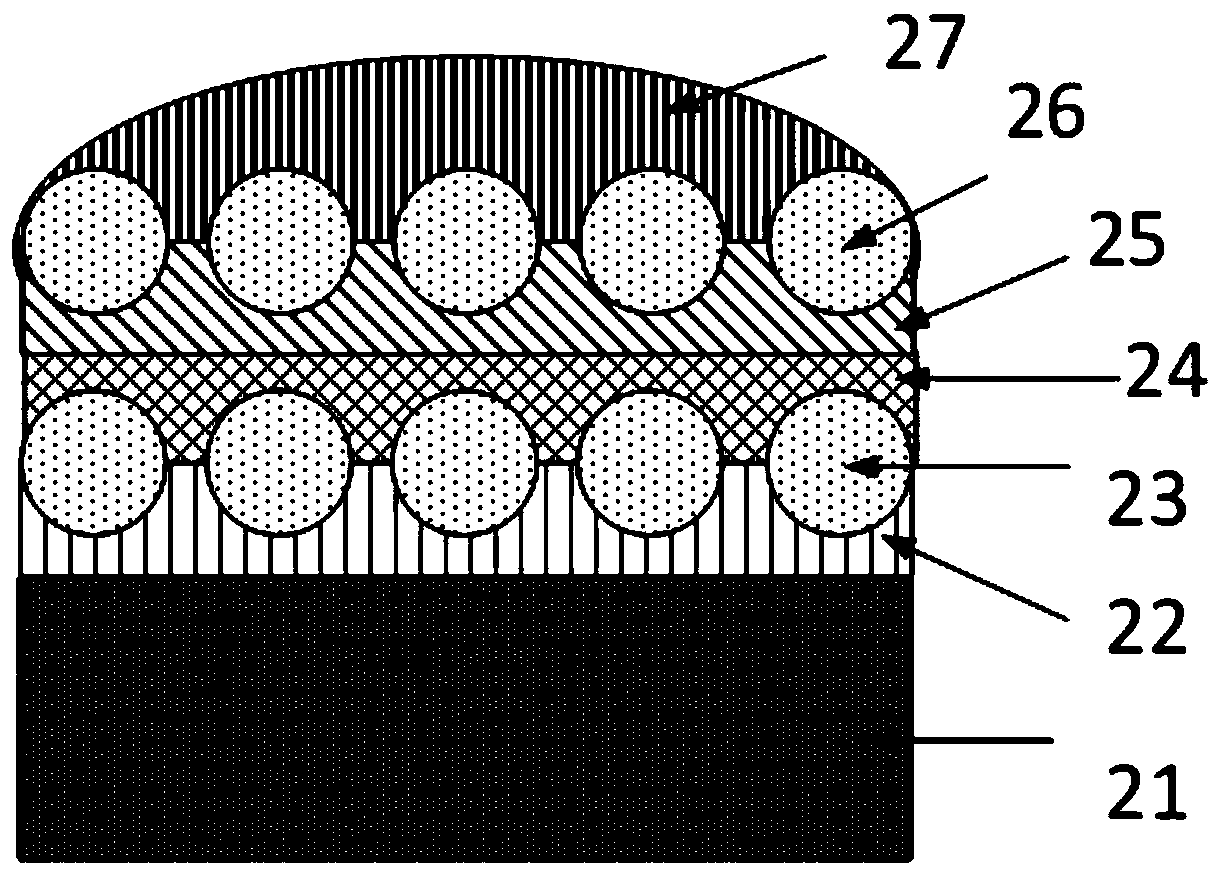

The invention relates to an LED packaging method. The method comprises steps: a cooling substrate (21) is prepared; an LED chip is prepared; a first lens layer (22) is formed on the upper surface of the LED chip; a first packaging layer (23) is formed on the upper surface of the LED chip and above the first lens layer (22); a second lens layer (24) is formed above the first packaging layer (23); asecond packaging layer (25) is formed above the second lens layer (24), and the second packaging layer (25) contains phosphor; and the LED packaging structure provided with the first lens layer (22),the first packaging layer (23), the second lens layer (24) and the second packaging layer (25) is subjected to long roasting to complete packaging of the LED. Through forming multiple layers of hemispherical lenses, the light beams are more concentrated and can perform uniform irradiation, the light extraction efficiency is improved, increasing of extra lenses is avoided, and the production costis reduced.

Owner:XIAN CREATION KEJI CO LTD

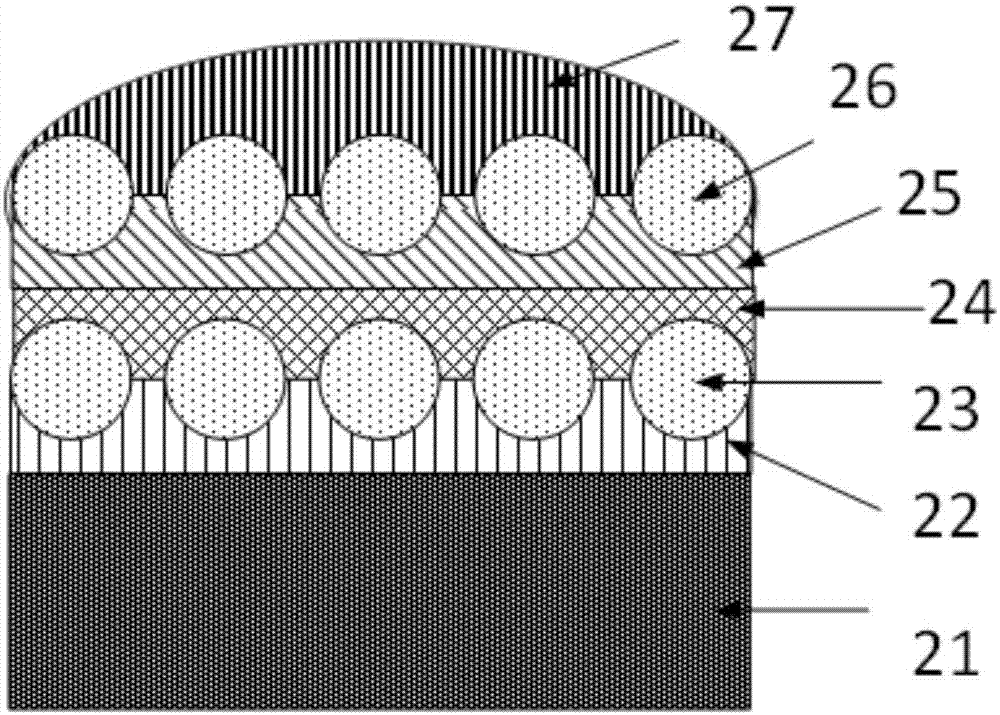

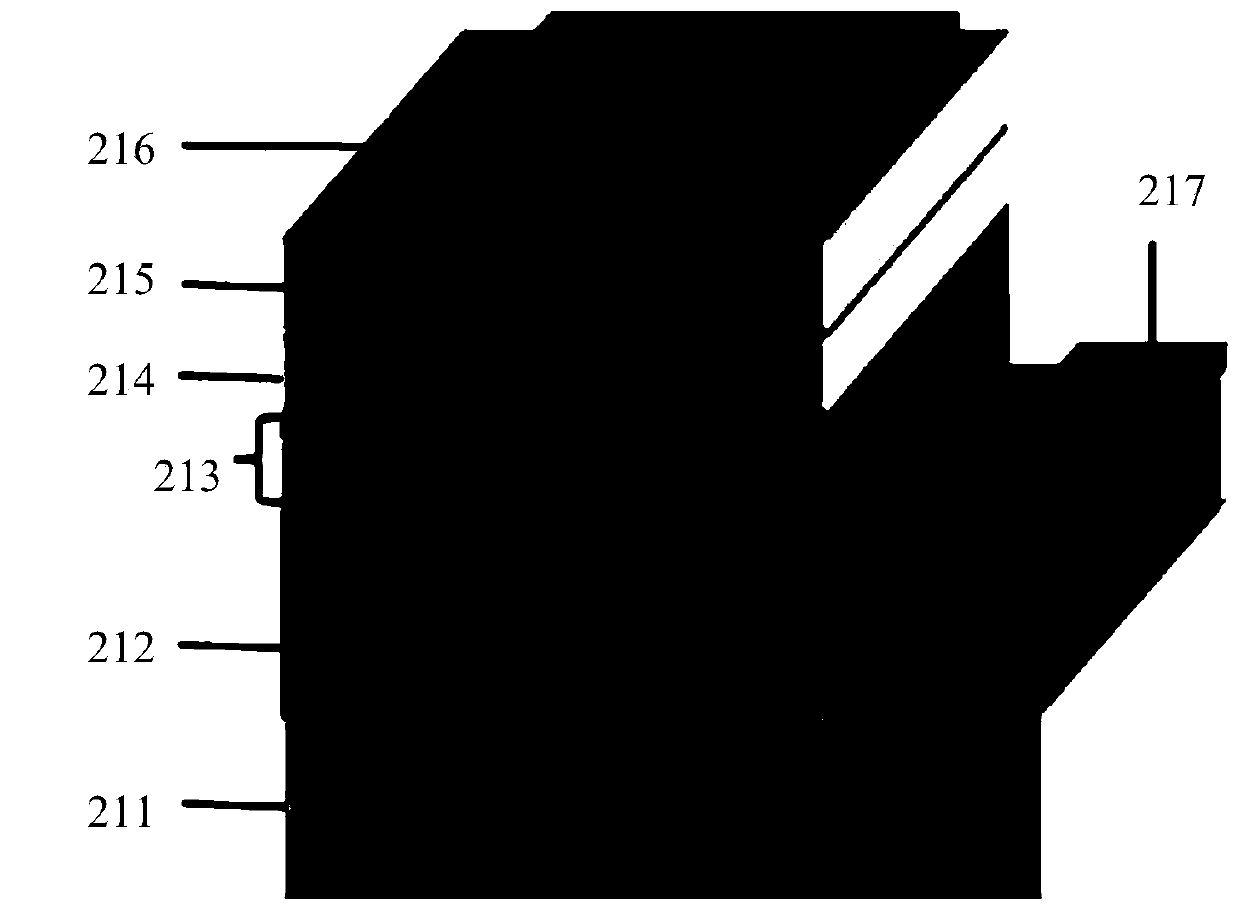

LED packaging structure and high-concentration LED lamp

InactiveCN108011015ASolve the drop in quantum efficiencyHigh light transmittanceSemiconductor devicesHigh concentrationQuantum efficiency

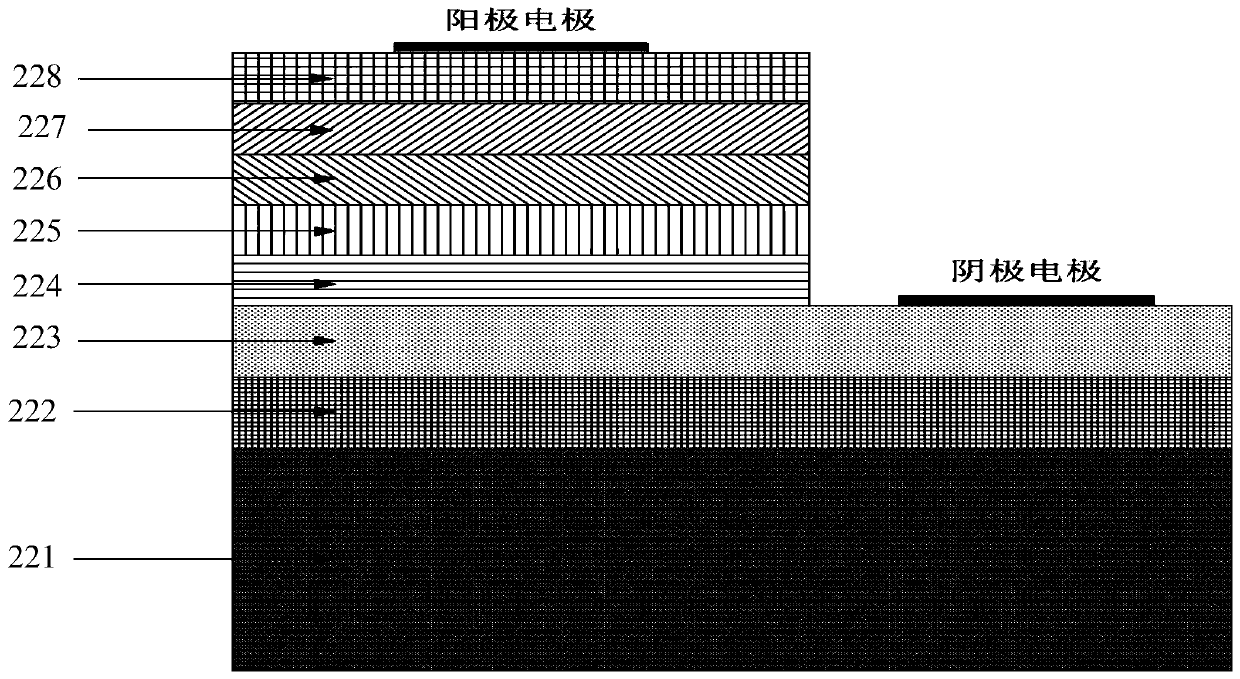

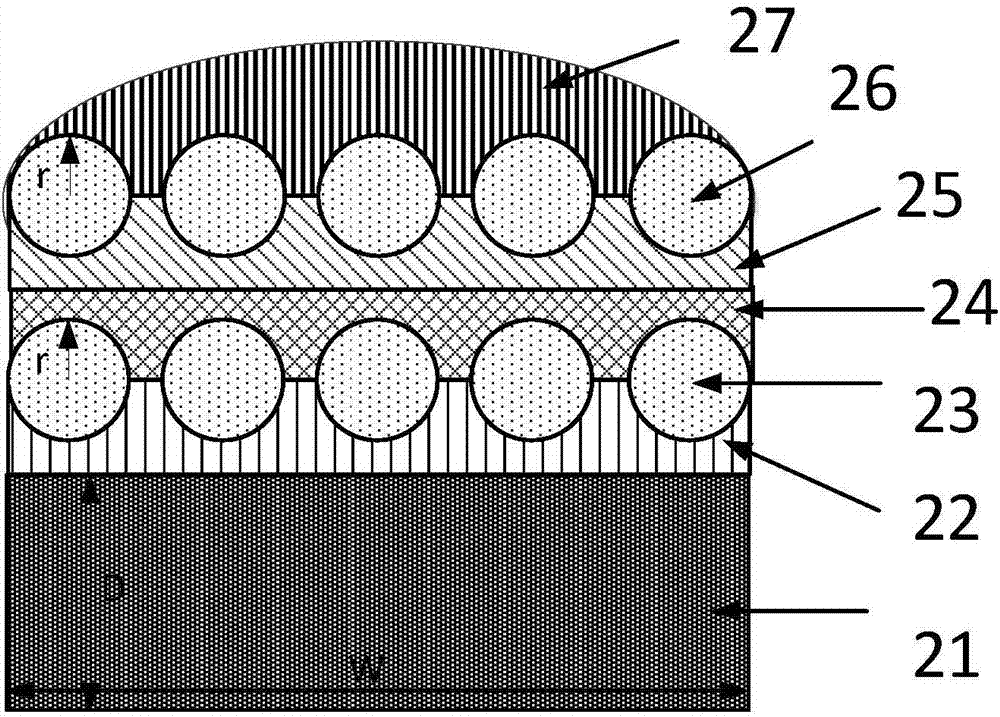

The invention relates to an LED packaging structure and a high-concentration LED lamp. The LED packaging structure comprises heat sink (21), an LED chip, a first silica gel layer (22), a first lens layer (23), a second silica gel layer (24), a third silica gel layer (25), a second lens layer (26) and a fourth silica gel layer (27), wherein the LED chip is arranged on the heat sink (21); the silicagel layer (22) coats the LED chip and the heat sink (21); the first lens layer (23) is prepared on the first silica gel layer (22); the second silica gel layer (24) and the third silica gel layer (25) are sequentially arranged on the first lens layer (23); the second lens layer (26) is arranged on the third silica gel layer (25); and the fourth silica gel layer (27) is arranged on the second lenslayer (26). According to the LED packaging structure provided by the invention, fluorescent powder is separated from the LED chip, so that the problem that the quantum efficiency of the fluorescent powder is reduced due to high temperature is solved; and silica gel in contact with the LED chip is high-temperature resistant silica gel, so that the problem that the light transmittance is reduced due to ageing and yellowing of the silica gel is solved.

Owner:XIAN CREATION KEJI CO LTD

LED packaging structure

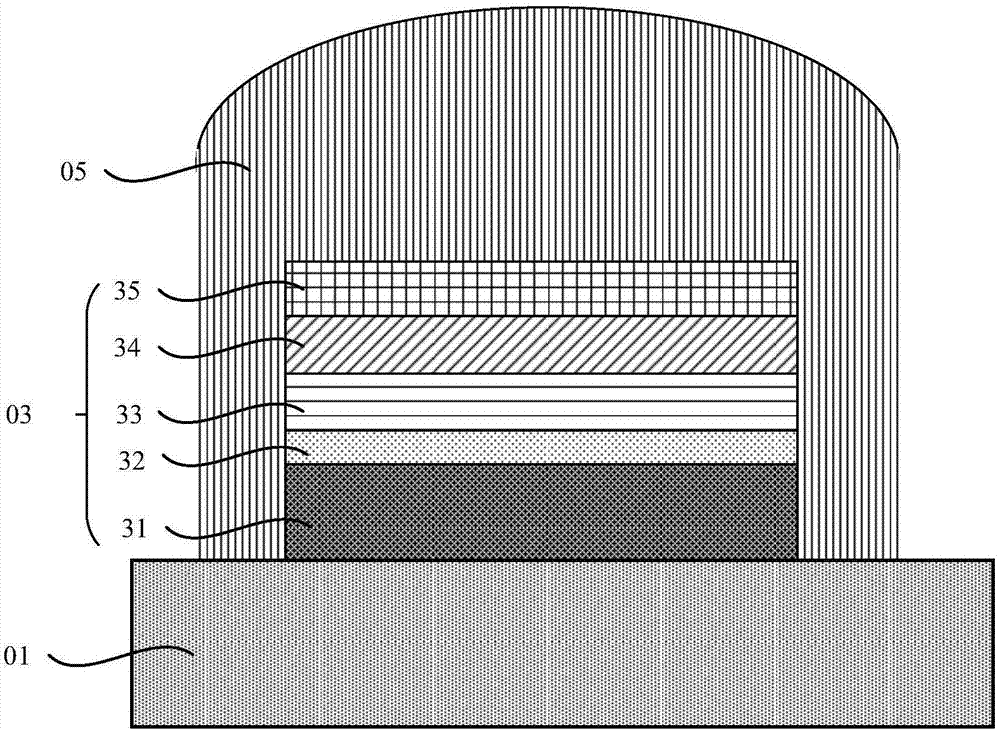

ActiveCN108011016ASolve the drop in quantum efficiencyContinuously adjust colorSemiconductor devicesRefractive indexTransmittance

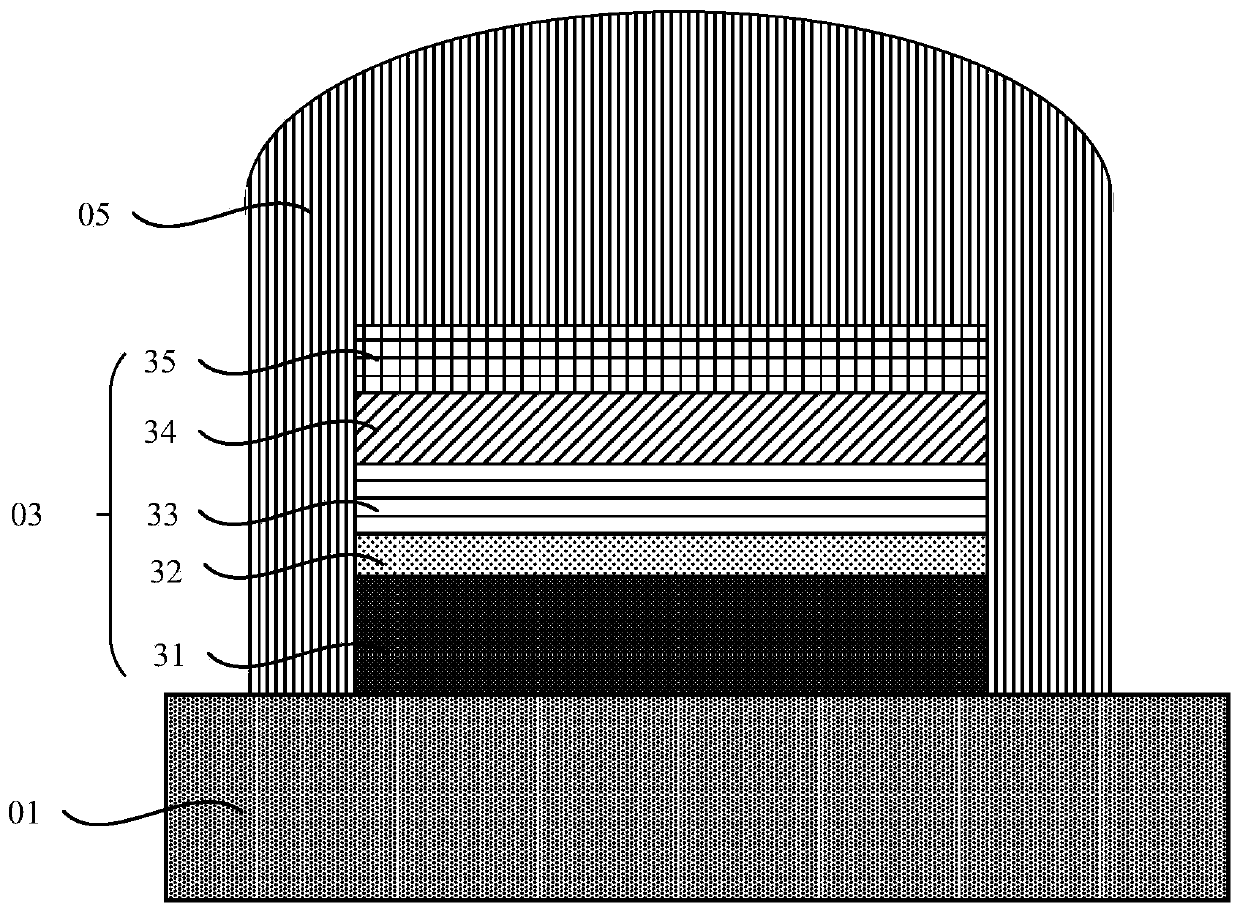

The invention relates to an LED packaging structure, which comprises a heat dissipation substrate 01, an ultraviolet lamp core 03 and a silica gel layer 05, wherein the ultraviolet lamp core 03 is arranged on the upper surface of the heat dissipation substrate; and the silica gel layer 05 is arranged on the heat dissipation substrate and the upper surface of the ultraviolet lamp core. According tothe LED packaging structure provided by the invention, the refractive indexes are sequentially increased through multiple lens layers, so that the light transmittance of the LED lamp core can be improved, and more light emitted from the LED lamp core can shine out through a packaging material.

Owner:广东安林电子科技股份有限公司

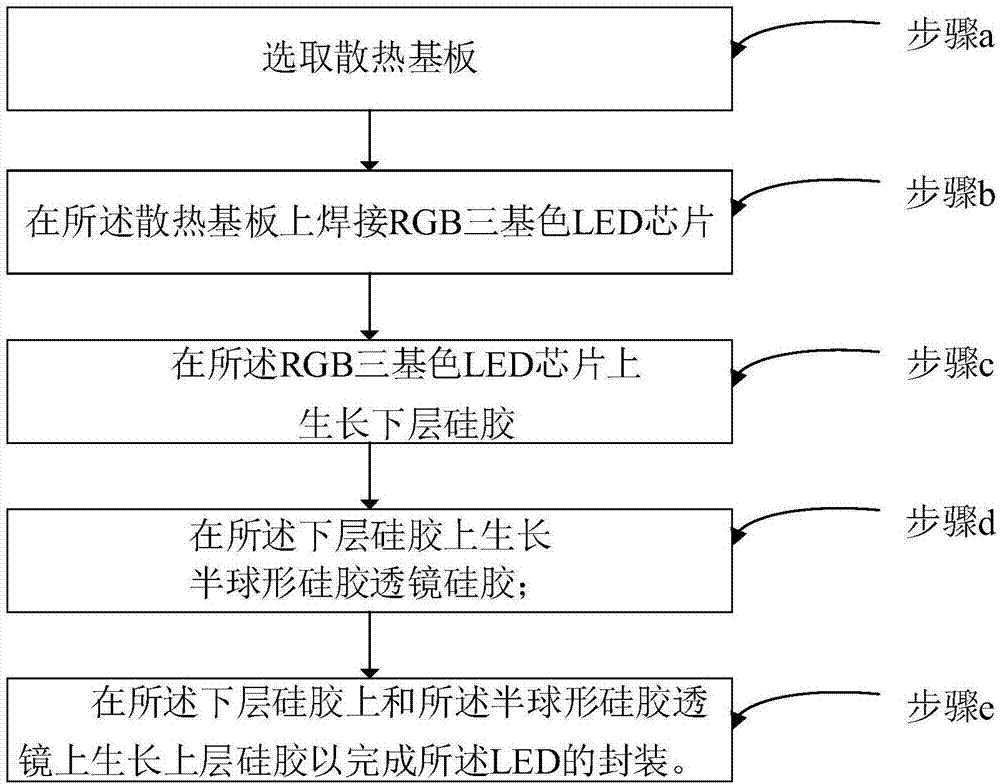

LED packaging method

InactiveCN107994013AImprove thermal conductivityLarge heat capacitySolid-state devicesSemiconductor devicesSilica gelPrimary color

The invention relates to an LED packaging method. The method comprises the following steps of selecting a heat dissipation substrate, welding an RGB three-primary-color LED chip on the heat dissipation substrate, growing a lower silica gel layer on the RGB three-primary-color LED chip, growing a semi-spherical silica gel lens on the lower silica gel layer, and growing an upper silica gel layer onthe lower silica gel layer and the semi-spherical silica gel lens so as to complete the encapsulation of an LED. According to the LED packaging structure of the invention, due to the fact that an aluminum heat dissipation substrate with an inclined through hole structure is adopted, the heat dissipation substrate effect of the LED is improved. By adopting the semi-spherical silica gel lens structure, the light of the LED chip can be better irradiated out through the packaging material. Therefore, the transmission rate of the light is improved.

Owner:XIAN CREATION KEJI CO LTD

LED packaging structure

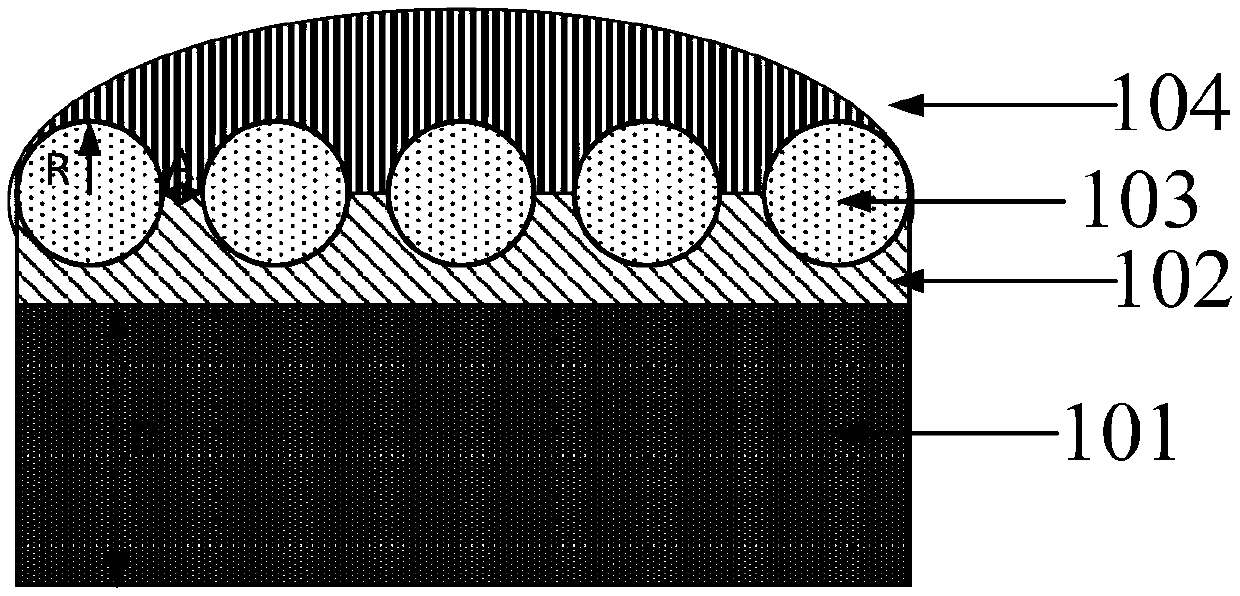

InactiveCN107946437AImprove thermal conductivityImprove cooling effectSemiconductor devicesTransmittanceSilica gel

The present invention relates to a LED packaging structure which comprises a heat-dissipating substrate 101, an ultraviolet chip which is located on the upper surface of the heat-dissipating substrate101, a lower-layer silica gel 102 which is located on the upper surface of the ultraviolet chip, an upper-layer silica gel 104 which is on the upper surface of the lower-layer silica gel 102, and hemispherical silica gel lenses 103 at the an interface between the lower-layer silica gel 102 and the upper-layer silica gel 104. According to the LED packaging structure, the heat-dissipating effect ofan LED is improved by using an iron heat-dissipating substrate with a through-hole structure, by using a hemispherical silica gel lens structure, the light emitted by an LED chip can pass through a packaging material well, and the transmittance of the light is improved.

Owner:XIAN CREATION KEJI CO LTD

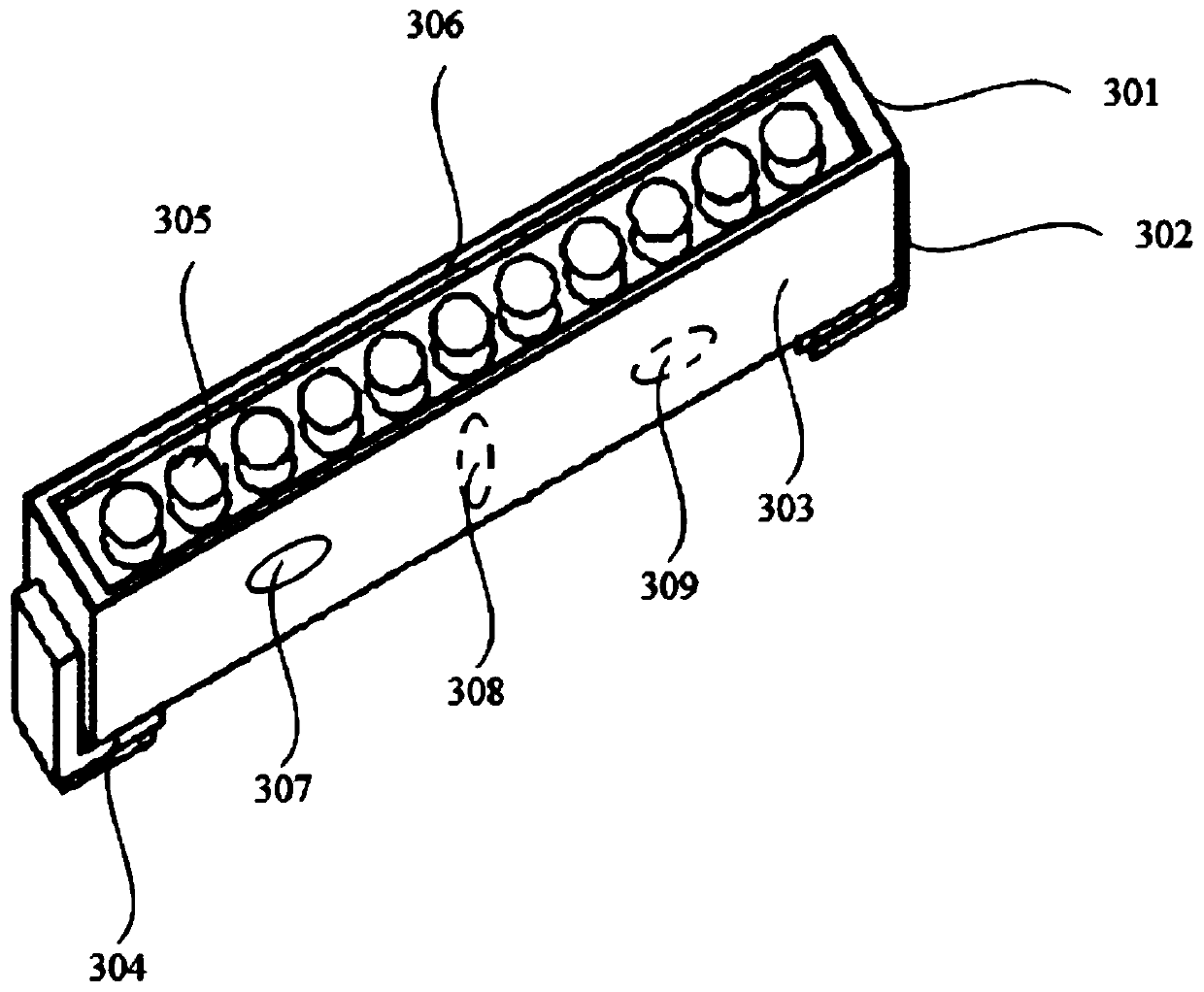

A high power led wall washer

ActiveCN107830452BImprove cooling effectEasy to useElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringMechanical engineering

The invention discloses a high-power LED wall washer lamp. The high-power LED wall washer lamp comprises a shell 301, a wall washer lamp body 303, support frames 302 arranged at two ends of the shell301, mounting pieces 304 arranged at the bottoms of the support frames 302, a lamp tube 305 arranged in the shell 301, and a lamp cover 306 arranged at the top of the wall washer lamp body 303 and connected with the shell 301. A high-power LED lawn lamp can be used for a long time through additional arrangement of a protection device; and in addition, as most wall washer lamps are mounted on wallsof high-rise buildings, switches for wirelessly controlling the LED wall washer lamps are selected to achieve convenience to use and maintain and broad market prospect.

Owner:广东华之创科技照明有限公司

A kind of led packaging structure

ActiveCN108011016BSolve the drop in quantum efficiencyContinuously adjust colorSemiconductor devicesTransmittanceRefractive index

The invention relates to an LED packaging structure, which comprises a heat dissipation substrate 01, an ultraviolet lamp core 03 and a silica gel layer 05, wherein the ultraviolet lamp core 03 is arranged on the upper surface of the heat dissipation substrate; and the silica gel layer 05 is arranged on the heat dissipation substrate and the upper surface of the ultraviolet lamp core. According tothe LED packaging structure provided by the invention, the refractive indexes are sequentially increased through multiple lens layers, so that the light transmittance of the LED lamp core can be improved, and more light emitted from the LED lamp core can shine out through a packaging material.

Owner:广东安林电子科技股份有限公司

A high-power led double-layer hemispherical packaging process

ActiveCN108011026BFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesEngineeringSilica gel

The invention relates to a high-power LED double-layer hemispherical structure packaging technology, which comprises the following steps of (a) preparing a packaging heat dissipation substrate and welding an LED lamp core on the packaging heat dissipation substrate; (b) coating the packaging heat dissipation substrate with first lens silica gel and forming a plurality of first hemispherical lenses, wherein the first hemispherical lenses are of a hemispherical convex lens structure; (c) coating the upper parts of the first hemispherical lenses with a first silica gel layer; (d) coating the first silica gel layer with second lens silica gel and forming a plurality of second hemispherical lenses, wherein the second hemispherical lenses are of a hemispherical convex lens structure; and (e) coating the upper parts of the second hemispherical lenses with a second silica gel layer, wherein at least one layer of the second hemispherical lenses and the second silica gel layer contains fluorescent powder and the LED lamp core is an ultraviolet lamp core. According to the high-power LED double-layer hemispherical structure packaging technology, secondary shaping is not needed, so that the technology is simple and the cost is low.

Owner:XIAN CREATION KEJI CO LTD

A high-power blue LED multi-layer packaging structure

ActiveCN107994113BFast convergenceSolve the technical problem that the lighting brightness is not concentrated enoughSemiconductor devicesQuantum efficiencyEngineering

The invention discloses a multilayer packaging structure of a high-power blue-light LED. The structure comprises a plurality of groups of lens layers (1), a heat dissipation substrate (21) and an outer packaging layer (3). The lens layers (1) are arranged on the heat dissipation substrate (21). The outer packaging layer (3) is further arranged on the topmost part of the plurality of groups of lenslayers (1). Each group of the lens layers comprises a lower packaging layer (11), an upper packaging layer (12) and a spherical lens (13). At least a part of a spherical lens (23) is embedded into the lower packaging layer (22). The upper packaging layer (24) is located in the non-embedded part of the spherical lens (23) and is above the lower packaging layer (22). According to the multilayer packaging structure of the high-power blue-light LED provided in the invention, the spherical lens is adopted. Therefore, the technical problem that the illumination brightness of a light source is not centralized enough is solved. Meanwhile, the secondary shaping is not needed, so that the structure is simple. The production cost is reduced. In addition, compared with the prior art, fluorescent powders do not need to be coated on a chip. The problem that the brightness is reduced due to the fact that the quantum efficiency of fluorescent powders caused by high temperature is reduced is solved.

Owner:深圳市天瀛深源科技有限公司

A kind of LED encapsulation method

ActiveCN108011010BImproved luminous dispersionSolve the drop in quantum efficiencySemiconductor devicesLight beamEngineering

The invention relates to an LED package method. The LED package method comprises the steps of preparing a cooling substrate (21); preparing an LED chip, fixedly connecting the LED chip onto the cooling substrate (21); forming a first silica gel layer (22) on an upper surface of the LED chip; forming a semi-spherical lens layer (23) on an upper surface of the first silica gel layer (22), wherein the semi-spherical lens layer (23) comprises a plurality of semi-spherical lenses; forming a second silica gel layer (24) above the semi-spherical lens layer (23) and the first silica gel layer (22), wherein the second silica gel layer (24) contains fluorescent powder; and baking an LED package structure comprising the first silica gel layer (22), the semi-spherical lens layer (24) and the second silica gel layer (24) for a long time so as to complete package of an LED. According to the LED package method disclosed by the embodiment of the invention, the semi-spherical lens layer is arranged between the first silica gel layer and the second silica gel layer, the fluorescent powder is arranged in the second silica gel layer, so that light beams are more concentrated and uniformly irradiate, moreover, the fluorescent powder is prevented from being in direct contact with the LED chip, and the light extraction efficiency is improved.

Owner:YANGZHOU HUACAI OPTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com