Package process of large-power blue-light LED dual-layer structure

A packaging process and double-layer structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the light extraction efficiency of packaging, affecting the lumen efficiency of packaging, and decreasing the quantum efficiency of phosphors, so as to solve the problems of reducing the quantum efficiency, Low cost, solve the effect of luminous dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

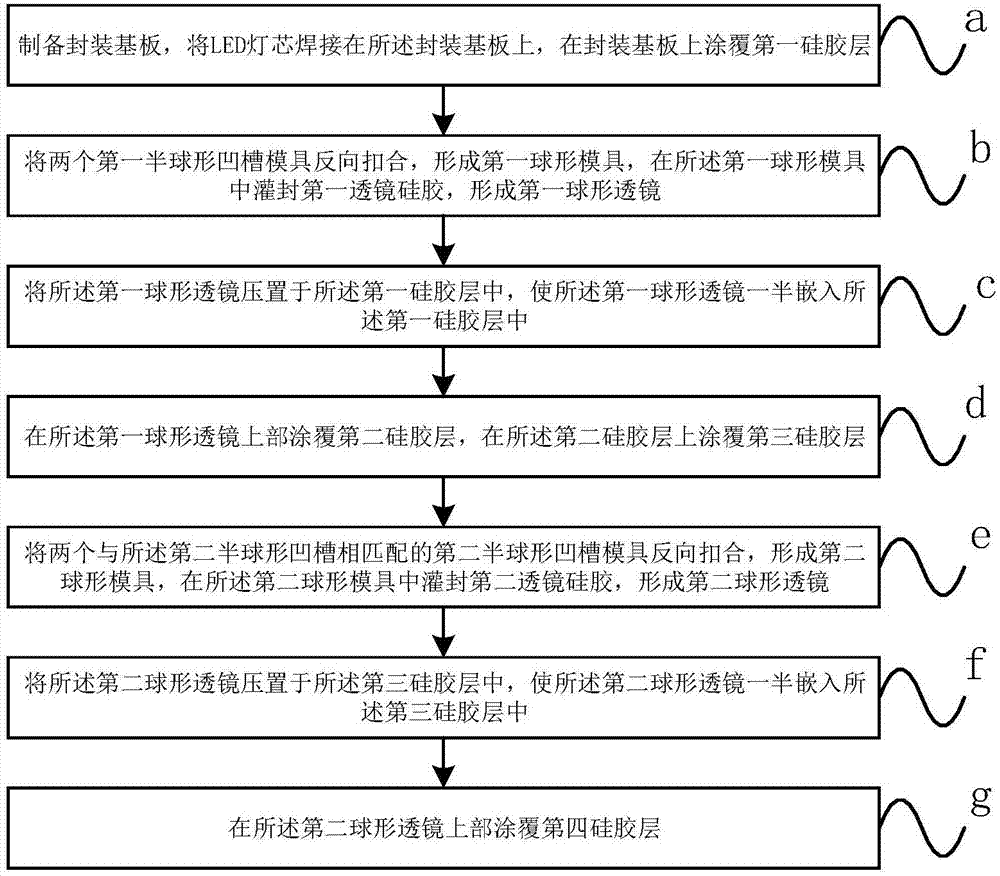

[0044] figure 1 A flow chart of a high-power blue LED double-layer structure packaging process provided by the embodiment of the present invention, including the following steps:

[0045] a. Prepare the heat dissipation substrate for packaging, weld the LED wick on the heat dissipation substrate for packaging, and coat the first silica gel layer on the heat dissipation substrate for packaging;

[0046] b. Fasten the two first hemispherical groove molds in reverse to form a first spherical mold, and seal the first lens silica gel in the first spherical mold to form a first spherical lens;

[0047] c. Pressing the first spherical lens into the first silica gel layer, so that half of the first spherical lens is embedded in the first silica gel layer;

[0048] d. Coating a second silica gel layer on the top of the first spherical lens, and coating a third silica gel layer on the second silica gel layer;

[0049] e. Reversely fasten two second hemispherical groove molds to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com