High-power LED double-layer hemispherical structure packaging technology

A packaging process and high-power technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the light extraction efficiency of packaging, the quantum efficiency of phosphor powder, and affecting the lumen efficiency of packaging, so as to solve the problem of quantum efficiency decline and cost Low, good convergence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

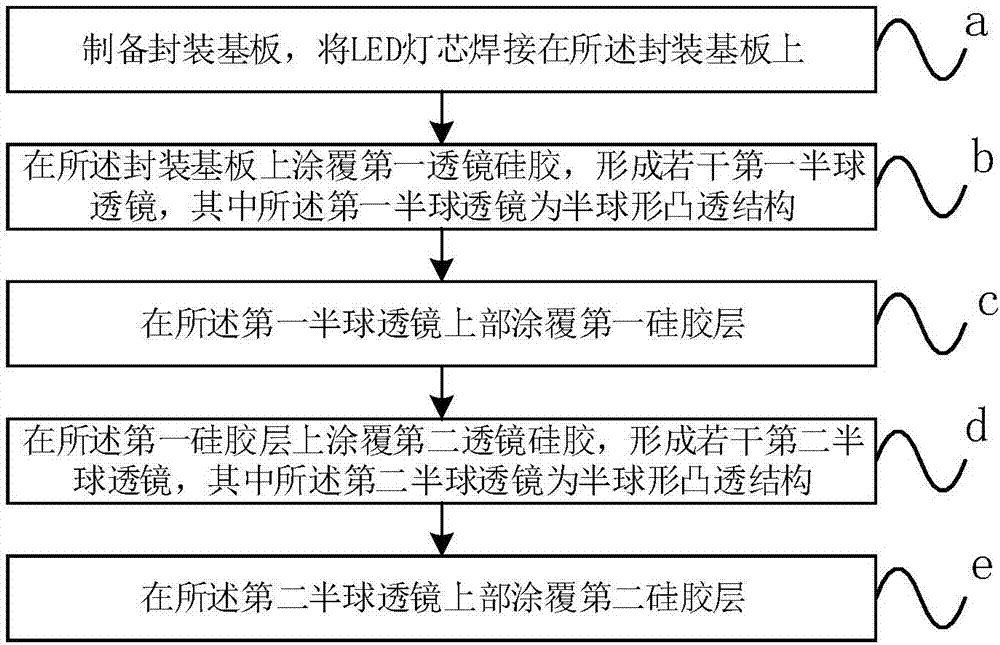

[0050] figure 1 A flow chart of a high-power LED double-layer hemispherical structure packaging process provided by an embodiment of the present invention includes the following steps:

[0051] a. Prepare the package heat dissipation substrate, and weld the LED wick on the package heat dissipation substrate;

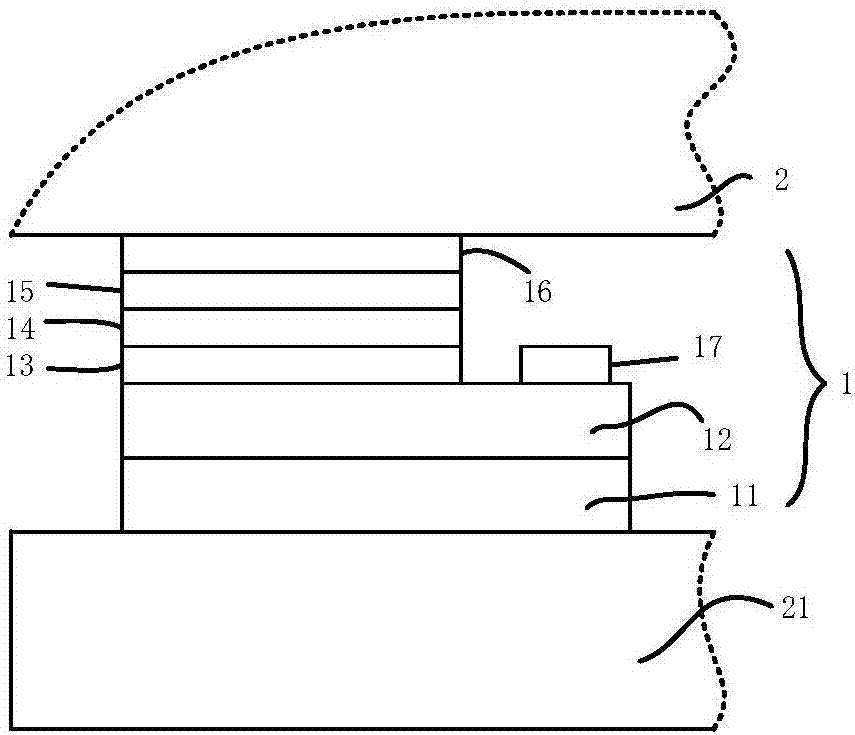

[0052] b. Coating the first lens silica gel on the package heat dissipation substrate to form a plurality of first hemispherical lenses, wherein the first hemispherical lenses are hemispherical convex structures;

[0053] c. Coating a first silica gel layer on the top of the first hemispherical lens;

[0054] d. Coating second lens silica gel on the first silica gel layer to form a plurality of second hemispherical lenses, wherein the second hemispherical lenses are hemispherical convex structures;

[0055] e. Coating a second silica gel layer on the upper part of the second hemispherical lens;

[0056] Wherein, at least one of the second hemispherical lens and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com