White-light LED package structure

A technology of LED packaging and LED wicks, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of insufficient contact of the bottom surface of the heat sink, insufficient concentration of light source illumination brightness, and affecting light transmission efficiency, etc., to increase the external quantum efficiency , Inhibit the total reflection effect, improve the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

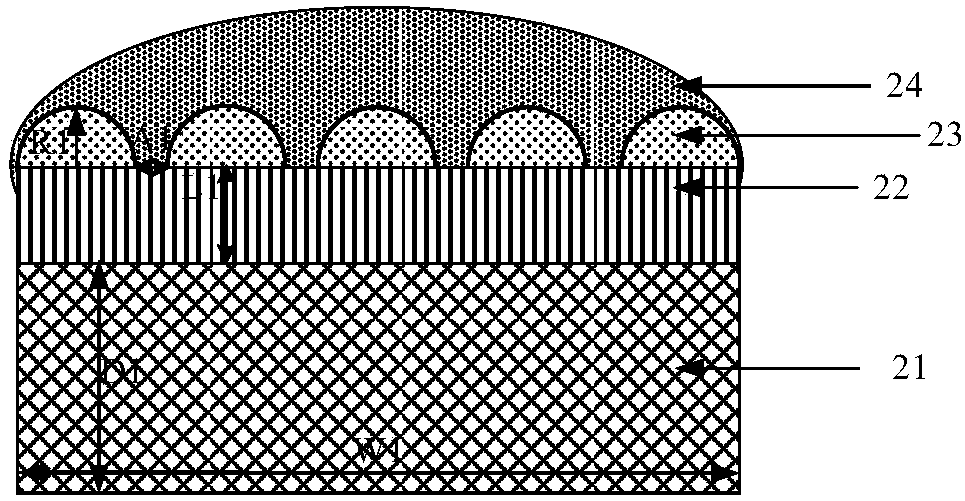

[0039] See figure 1 , figure 1 A schematic diagram of a package structure of a white light LED provided by an embodiment of the present invention.

[0040] The structure includes:

[0041] heat dissipation substrate 21;

[0042] The LED lamp wick is arranged on the upper surface of the heat dissipation substrate 21;

[0043] The lower layer of silica gel 22 is arranged on the upper surface of the LED lamp wick;

[0044] The hemispherical silica gel ball 23 is arranged on the upper surface of the lower layer silica gel 22;

[0045] The upper layer of silica gel 24 is disposed on the upper surface of the lower layer of silica gel 22 and the hemispherical silica gel balls 23 .

[0046] Wherein, the material of the heat dissipation substrate 21 is metal copper, and the thickness is 0.5-10 mm.

[0047] Further, the heat dissipation substrate 21 is provided with a plurality of circular through holes along the width direction of the heat dissipation substrate 21 and parallel to...

Embodiment 2

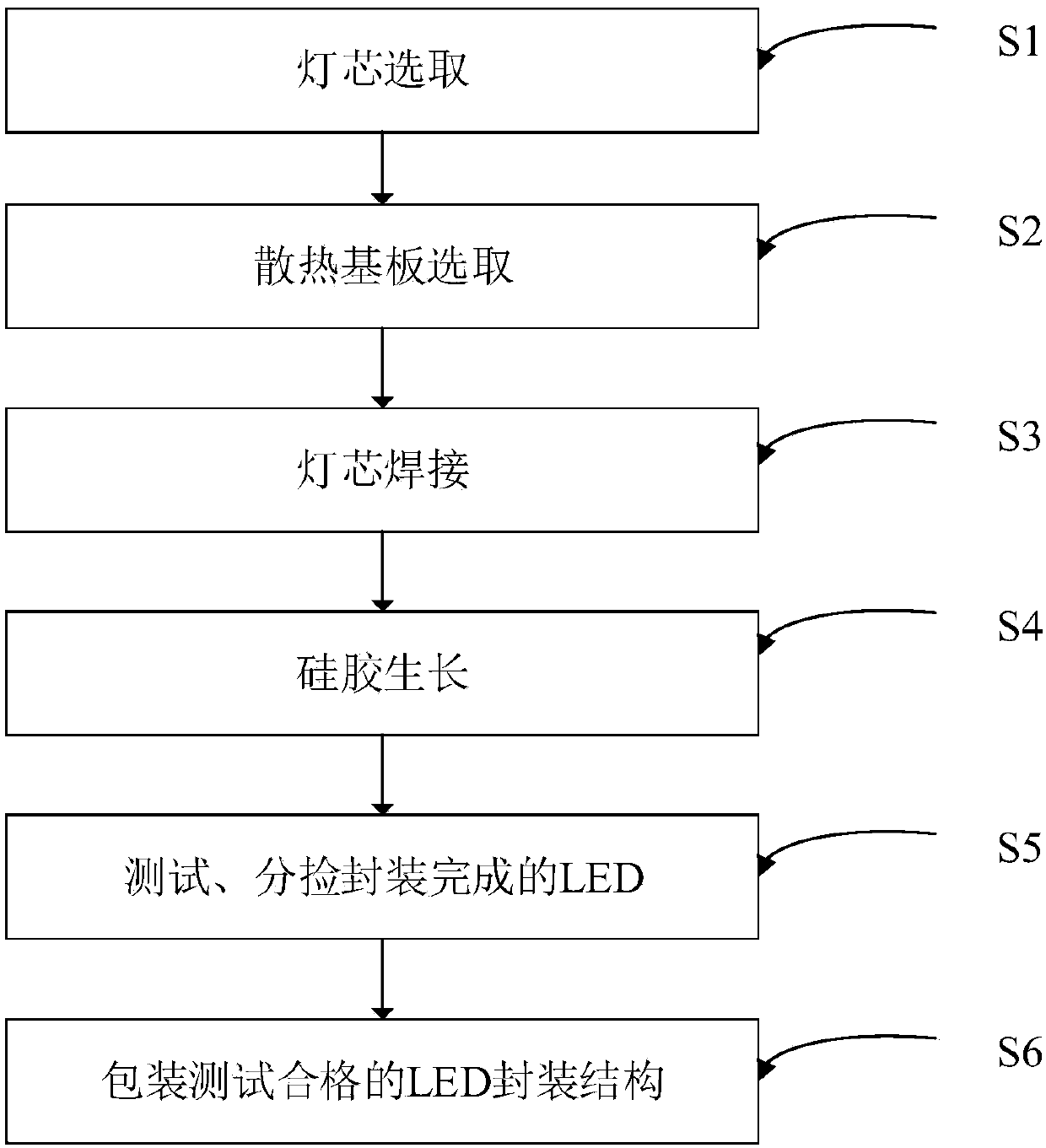

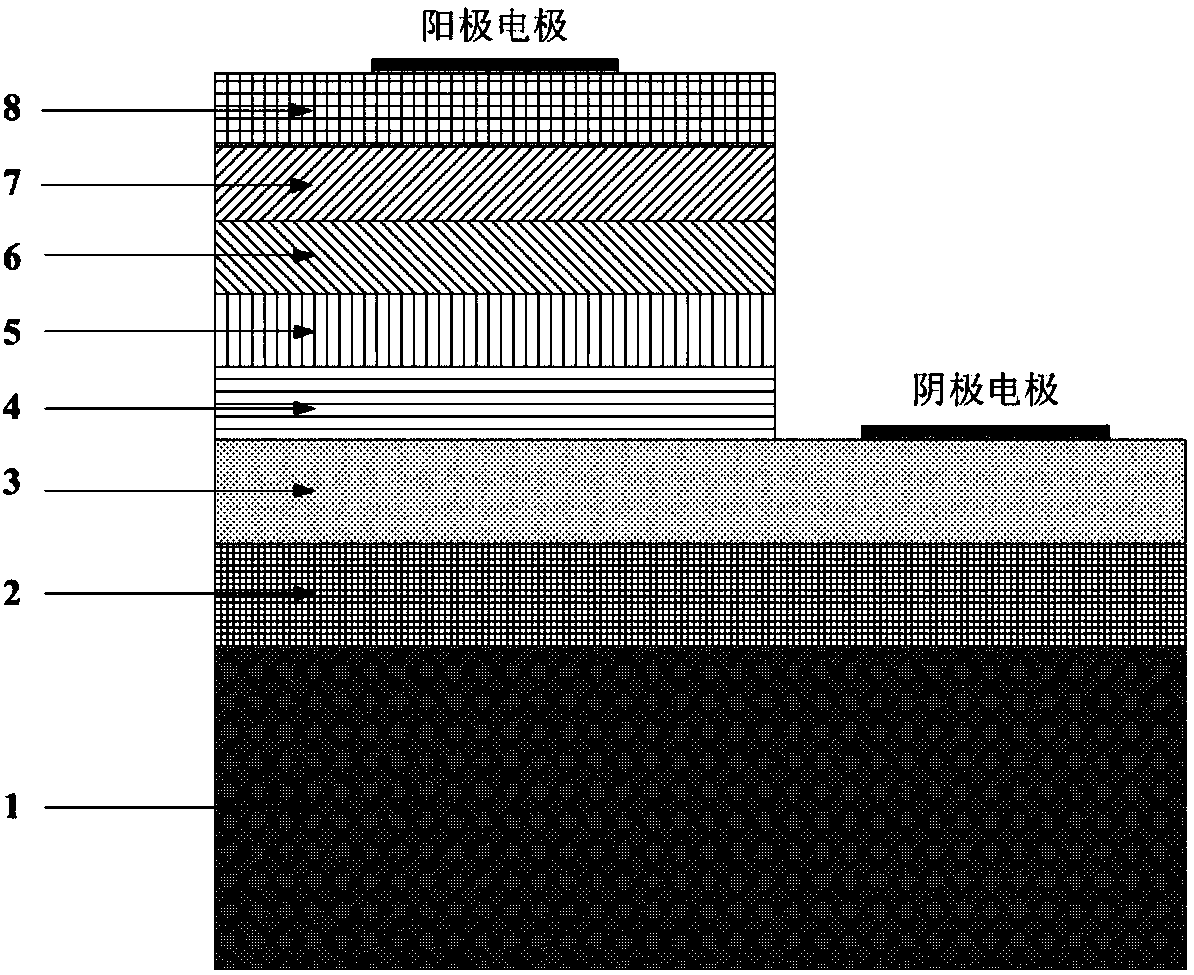

[0064] See figure 2 and image 3 , figure 2 A flowchart of another white light LED packaging method provided by the embodiment of the present invention, image 3 A schematic structural diagram of a GaN-based blue light chip provided in an embodiment of the present invention. On the basis of the above embodiments, this embodiment will introduce the process flow of the present invention in more detail. The method includes:

[0065] S1, LED wick selection

[0066] A GaN-based blue light chip is selected as the LED wick. The structure of the GaN-based blue light chip is as follows: image 3 As shown, the chip includes: substrate material 1, GaN buffer layer 2, N-type GaN layer 3, P-type GaN quantum well wide-bandgap material 4, InGaN layer 5, P-type GaN quantum well wide-bandgap material 6, AlGaN barrier layer Material 7, P-type GaN layer 8.

[0067] S2, heat dissipation substrate selection

[0068] S21. Preparation of bracket / heat dissipation substrate

[0069] Metal c...

Embodiment 3

[0114] please continue figure 1 and see together Figure 4 , Figure 5 , Figure 4 A schematic structural diagram of a heat dissipation substrate provided by an embodiment of the present invention; Figure 5 It is a schematic diagram of another white light LED package structure provided by the embodiment of the present invention. In this embodiment, the package structure of the white light LED is described in detail on the basis of the above-mentioned embodiment. The package structure of the white light LED is as follows: figure 1 As shown, it includes: a package heat dissipation substrate 21 with an LED lamp wick, a lower layer of silica gel 22, a hemispherical silica gel ball 23, and an upper layer of silica gel 24. Among them, the radius R of the hemispherical silicone balls 23 is greater than 10 microns; the distance L1 between the hemispherical silicone balls 23 and the LED lamp wick is greater than 10 microns; the distance between the hemispherical silicone balls 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com