LED package body and high-light-transmittance LED lamp

A technology of LED packages and LED chips, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of quantum efficiency reduction, reduced luminous efficiency, LED light source distribution dispersion, etc., and achieve the effect of improving luminous dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

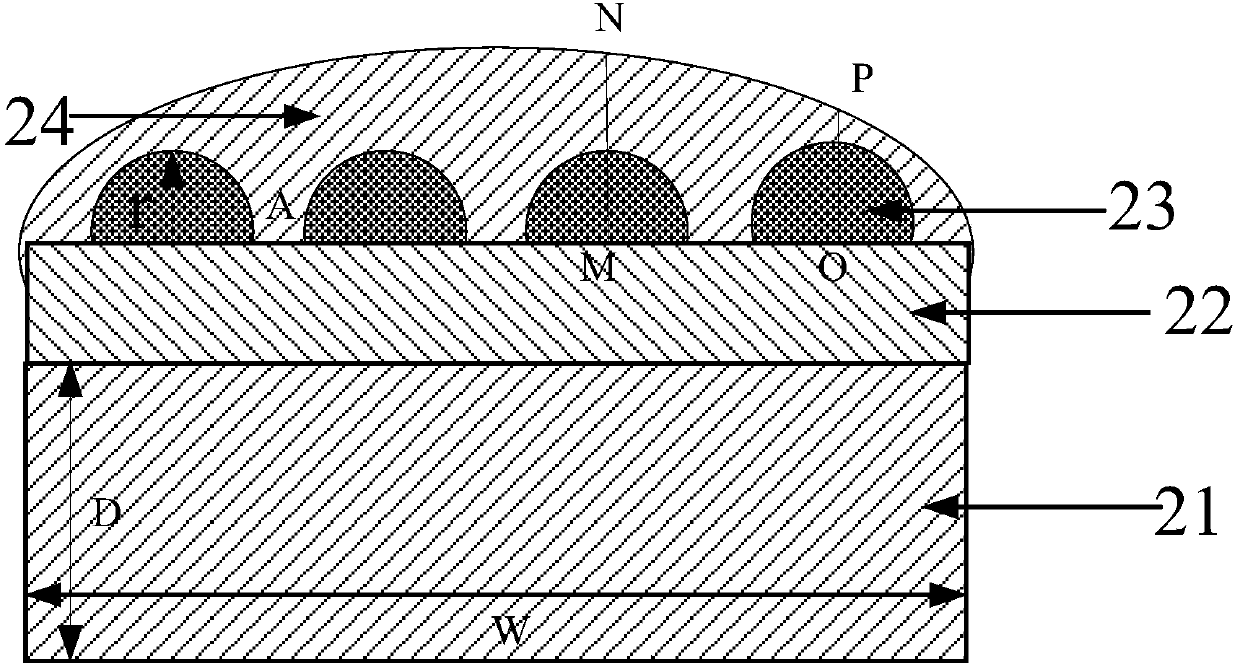

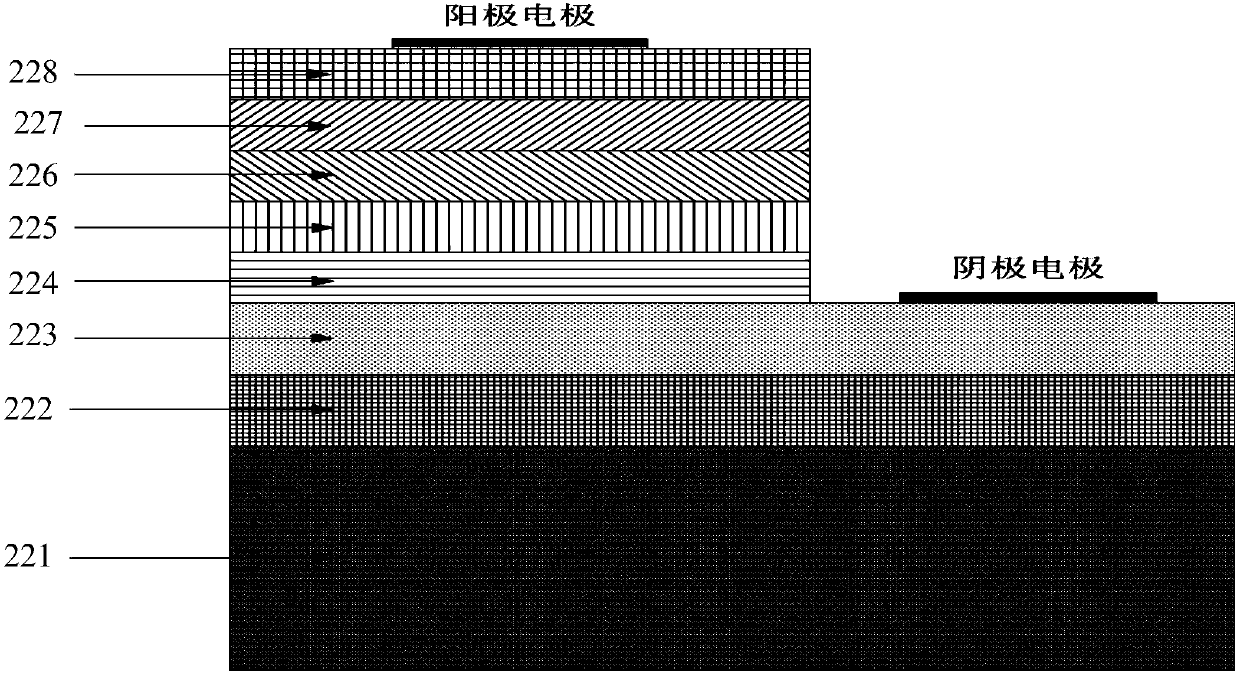

[0035] See figure 1 , figure 1 A schematic structural diagram of an LED package provided by the present invention, the package includes:

[0036] heat sink (21);

[0037] LED chips, arranged on the heat sink (21);

[0038] A first silica gel layer (22), coated on the LED chip and the heat sink (21);

[0039] A second silica gel layer (23), arranged on the first silica gel layer (22);

[0040] The third silica gel layer (24) is arranged on the second silica gel layer (23).

[0041] Further, on the basis of the above embodiment, the first silica gel layer (22) does not contain phosphor, and the second silica gel layer (23) or the third silica gel layer (24) contains phosphor.

[0042] In this embodiment, the LED chip is not in direct contact with the fluorescent powder, which solves the problem of the decrease in the quantum efficiency of the fluorescent powder caused by high temperature; the silica gel in contact with the LED chip is preferably high-temperature-resistant s...

Embodiment 2

[0062] See Figure 5 , Figure 5 It is a schematic flow chart of an LED packaging method provided by the embodiment of the present invention. The LED package in Embodiment 1 is prepared by the method provided in this embodiment, and the method includes:

[0063] Select the LED chip;

[0064] selecting a heat sink and cleaning said heat sink;

[0065] Welding the leads of the LED chip to the heat sink;

[0066] A silica gel layer is potted on the heat sink, so that the light emitted by the LED chip is emitted outward through the silica gel layer.

[0067] In this embodiment, the fluorescent powder is placed in the silica gel layer instead of directly coating the fluorescent powder on the LED chip, thereby avoiding the absorption of backscattered light by the LED chip and improving the light extraction efficiency of the package. In addition, the adoption of this embodiment avoids the problem that the high temperature generated by the LED chip significantly reduces the quantu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com