A construction method of shallow buried long-span tunnel suitable for upper soft and lower hard composite stratum

A composite ground and tunnel construction technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as water leakage at large arch feet, impact damage of vault structures, limited space, etc., to improve positioning accuracy, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

[0040] In this embodiment, the stratum to be constructed is an upper soft stratum and a lower hard stratum, wherein the upper part is sandy pebbles, silty sand layers, strongly weathered and fully weathered rocks, etc. at the end of the Quaternary period, and the lower part is moderately weathered or slightly weathered rocks.

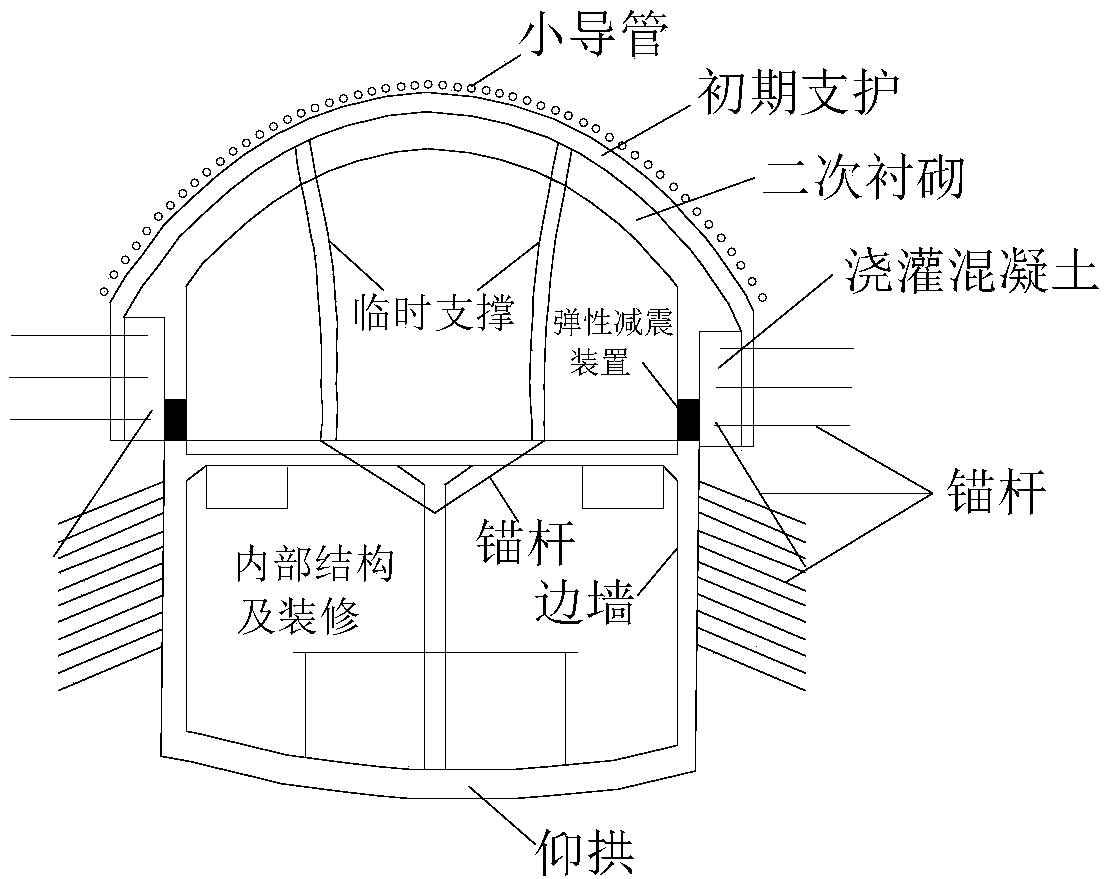

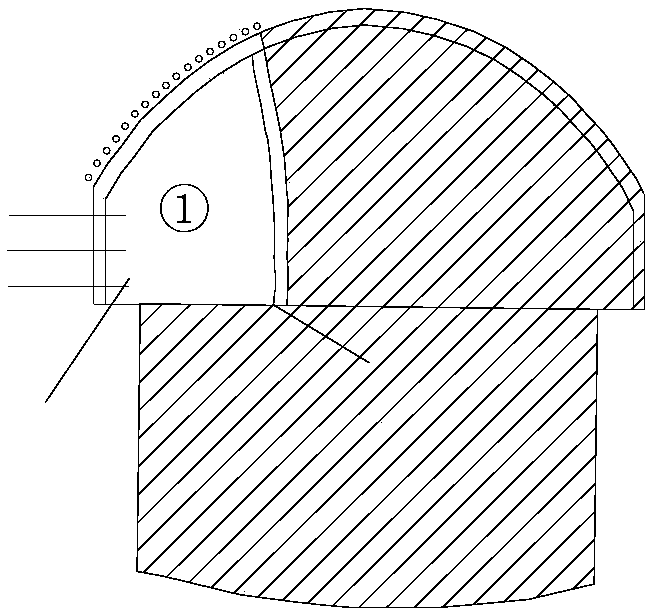

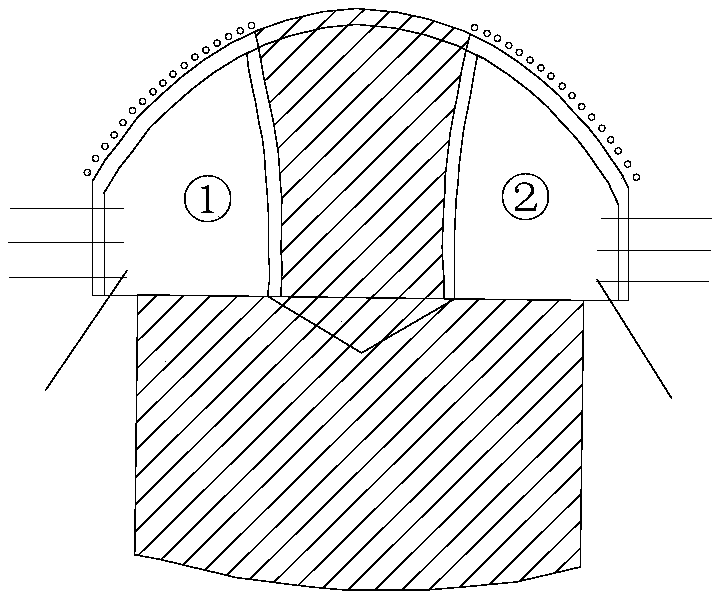

[0041] Aiming at the upper-soft and lower-hard composite stratum, in this embodiment, the tunnel arch to be excavated and the lower rock mass are divided into left, middle and right parts, excavated in sections, and excavated in a circular manner. figure 1 It shows the structural layout of the tunnel section during the whole construction proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com