A miniature full-face drilling arrangement device for model testing and its application

A technology of model test and drilling arrangement, which is applied in soil material testing, material inspection products, etc., to achieve the effect of high degree of automation, high efficiency, scientific and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

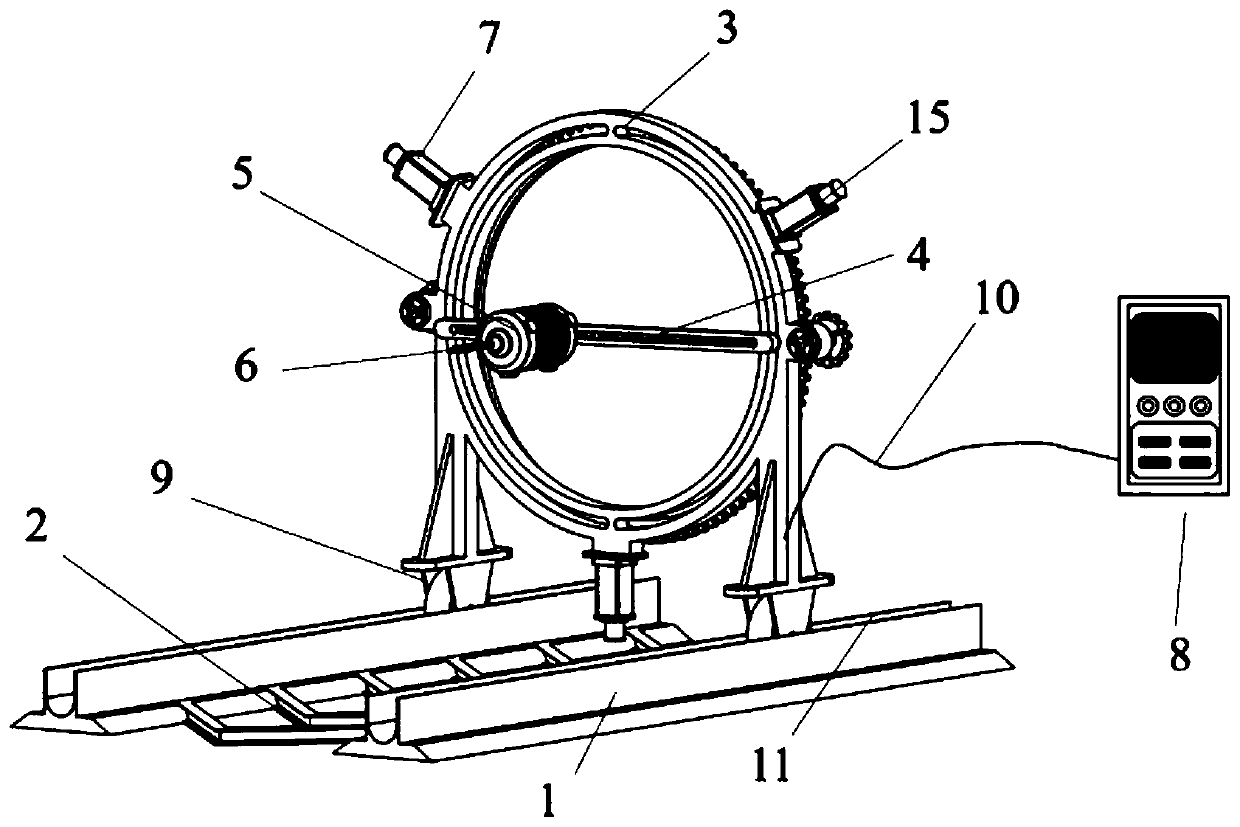

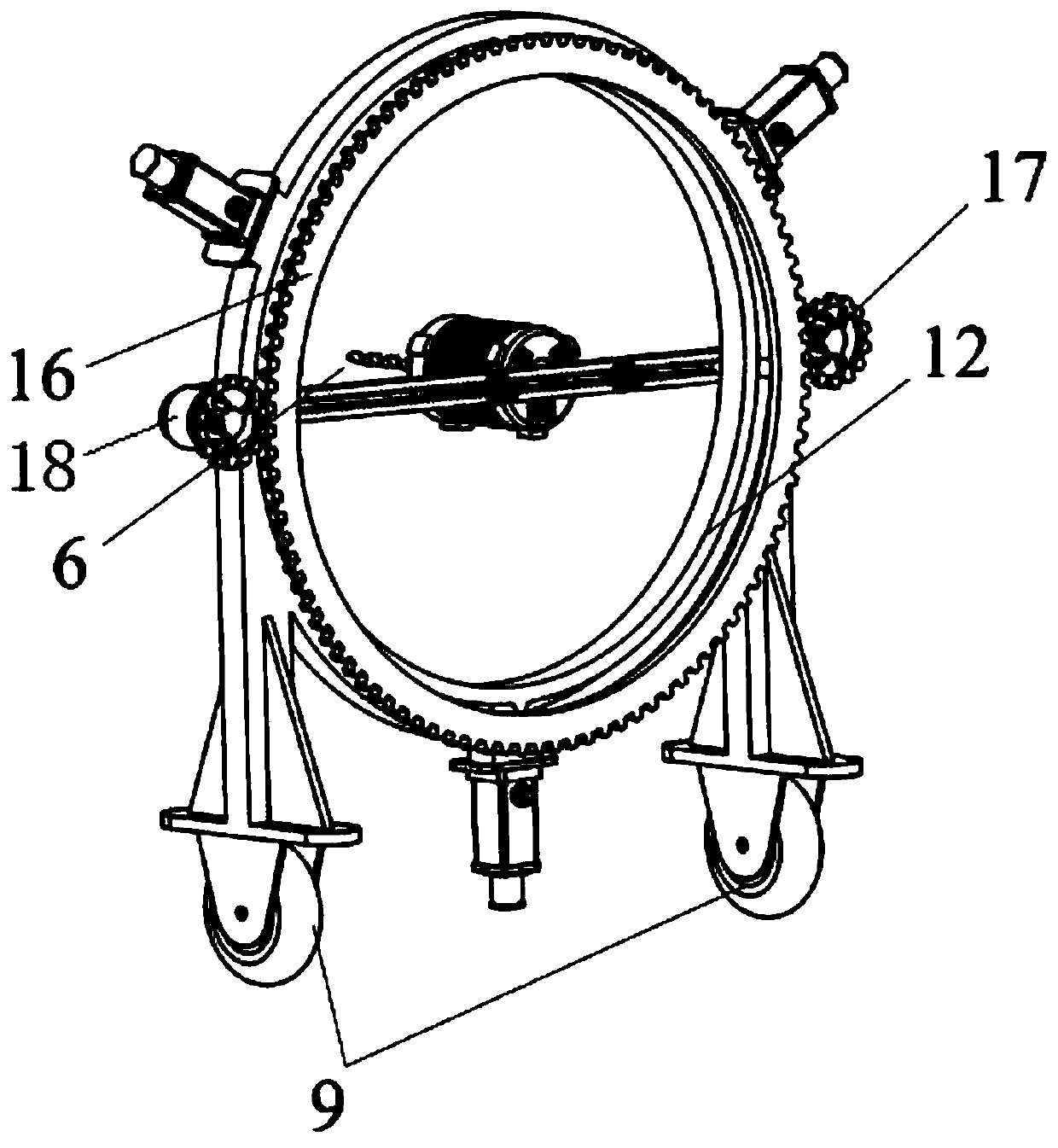

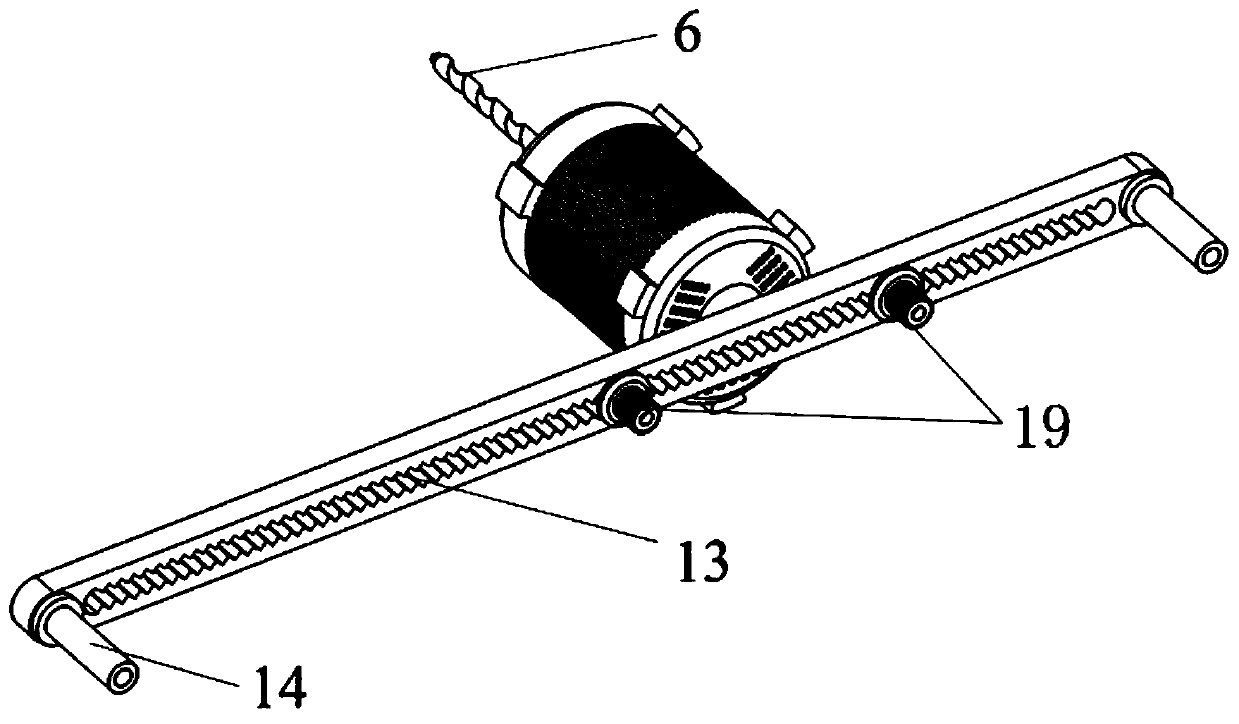

[0034] like Figure 1 to Figure 4 As shown, this embodiment provides a miniature full-section drilling layout device for model testing, the drilling layout device mainly includes three parts: a track mechanism, a drilling mechanism and a controller, wherein the drilling mechanism is arranged on the track mechanism And move along the track mechanism, thereby adjusting the whole drilling mechanism to move to the full-section working position of the model experiment area. The drilling mechanism is the main operating part, which includes a circular track part, a radial track part, a drill head and a support part. The two ends of the radial track part are located on the circular track part and can rotate circumferentially along the circular track part. The drill bit The part is installed on the radial track part and can move linearly along the radial track part. The support part is located outside the ring track part to fix the whole drilling mechanism. The controller is respective...

Embodiment 2

[0043] A miniature full-section drilling arrangement device for model testing, the structure is as described in Example 1, the difference is that: three circles of concentric track grooves 12 are opened on the annular guide rail 3 . Later, radial guide rails 4 with different diameters can be selected according to different experimental models, and the high-strength bolts 14 at both ends of the radial guide rail 4 can be fixedly connected to the driven flywheel 16 through the corresponding track grooves 12, so as to realize the full range of different model areas. section work.

Embodiment 3

[0045] A method for using a miniature full-face drilling arrangement device for model testing, using the drilling arrangement device described in Embodiment 1, and its specific operation process is as follows:

[0046] (1) Lay the track mechanism in the model test area. According to the distance that the drilling mechanism needs to travel, you can choose a multi-unit track mechanism to connect it. Select a suitable high-strength drill bit 6 to install on the micro motor 5 according to the experimental requirements;

[0047] (2) The whole drilling mechanism is placed on the track mechanism, the pulley 9 is placed in the strip rail groove 11, and then the whole drilling mechanism is moved to the work area of the model test;

[0048] (3) After the drilling mechanism reaches the work area, the controller 8 controls the support part 7 to start, and the telescopic arm 15 (piston rod) of the servo electric cylinder stretches out to lift the drilling mechanism in the model test tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com