water treatment system

A technology of water treatment system and water treatment device, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. It can solve the operation and maintenance business and consumables such as the small number of installations and the generation of proofreading. fees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

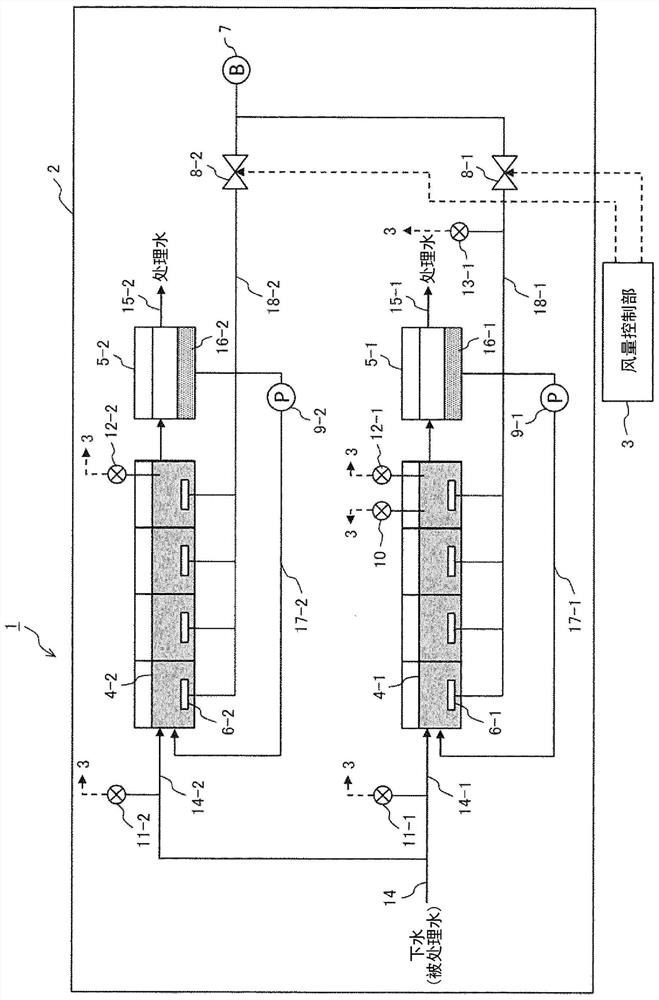

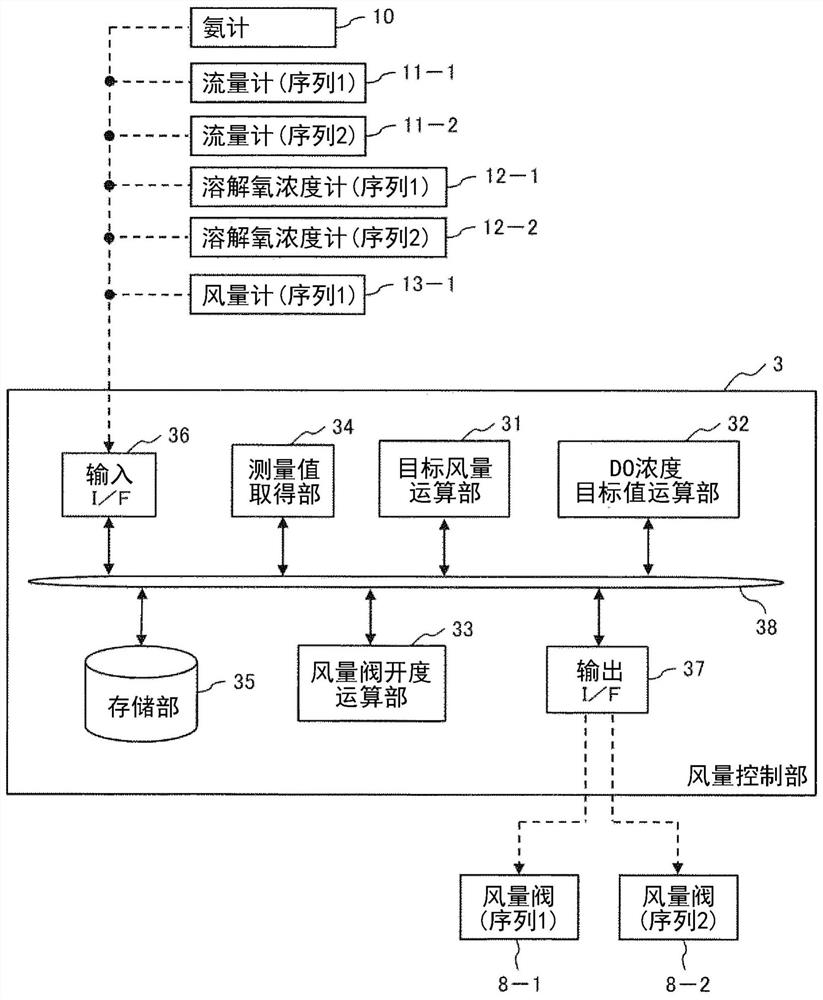

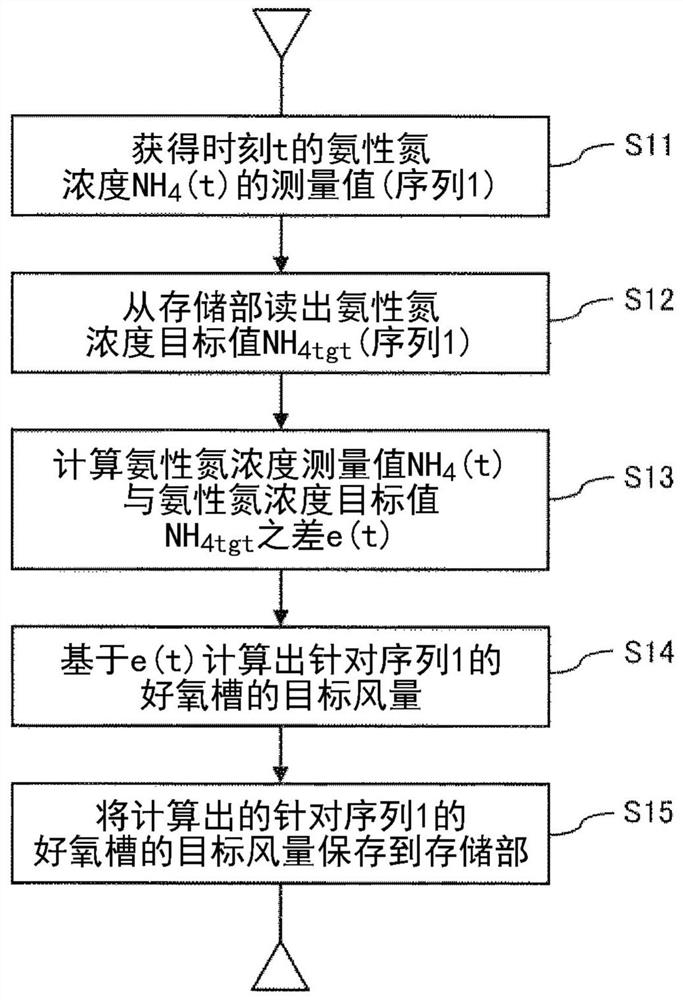

[0032] figure 1 A schematic overall configuration diagram of the water treatment system of Example 1 according to an example of the present invention is shown in . figure 1 In , solid lines indicate piping, and broken lines indicate signal lines. The water treatment system 1 according to this embodiment includes: a water treatment device 2 that removes organic matter and ammoniacal nitrogen by using activated sludge such as domestic wastewater or industrial wastewater (water to be treated) by a general-purpose activated sludge method, and an air volume control unit. 3.

[0033] (water treatment device)

[0034] Such as figure 1 As shown, the water treatment device 2 has: starting from the inflow side of the sewage as the water to be treated, a sequence 1 consisting of an aerobic tank (reaction tank) 4-1 and a final sedimentation tank 5-1 in order; Sequence 2 consisting of aerobic tank (reaction tank) 4-2 and final sedimentation tank 5-2 starts from the inflow side of sewag...

Embodiment 2

[0123] Figure 6 A schematic overall configuration diagram of a water treatment system according to Example 2 according to another example of the present invention is shown in FIG. Figure 7 shown in Figure 6 The functional block diagram of the air volume control unit shown. In the water treatment system of the present embodiment, there is an air volume meter 13-2 provided in the serial 2 diffuser piping 18-2 constituting the water treatment device 2, and the air volume control unit 3a includes a first target air volume calculation unit 31a and a first target air volume calculation unit 31a and The point that the second target calculation unit 31b replaces the target air volume calculation unit 31 and the DO concentration target value calculation unit 32 in the first embodiment is different from the first embodiment. The same reference numerals are assigned to the same constituent elements as those in Example 1, and descriptions that overlap with those in Example 1 will be ...

Embodiment 3

[0179] Figure 11 shows the processing flow chart of the second target air volume calculation unit constituting the air volume control unit of Embodiment 3 according to other embodiments of the present invention, Figure 12 A flow chart of the process of the air volume valve opening calculation unit constituting the air volume control unit of the third embodiment is shown in . In addition, the configuration of the water treatment device according to this embodiment is the same as that shown in the above-mentioned embodiment 2. Figure 6 The composition is the same. In addition, the configuration of the air volume control unit of this embodiment is the same as that shown in the above-mentioned embodiment 2. Figure 7 The functional block diagrams are the same. In the present embodiment, in addition to the corrected target air volume for sequence 2 shown in embodiment 2, it is configured based on the target air volume for sequence 1 shown in embodiment 1 or 2. For the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com