Epoxy resin composition, preparation and use thereof

A technology of epoxy resin and composition, applied in the field of epoxy resin composition, can solve the problems of poor adhesion and thermal fatigue, affecting the performance and life of the package, affecting the appearance of the package, etc., so as to improve the void performance and reduce the number of voids. Effect

Active Publication Date: 2018-05-11

HENKEL HUAWEI ELECTRONICS

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

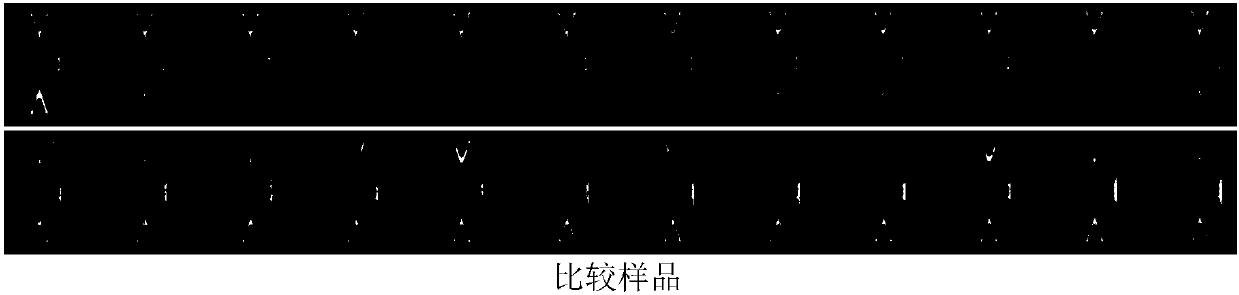

For example, external voids can affect the appearance of the package, while internal voids can act as weak points leading to poor attachment and thermal fatigue, thereby affecting the performance and lifetime of the package

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

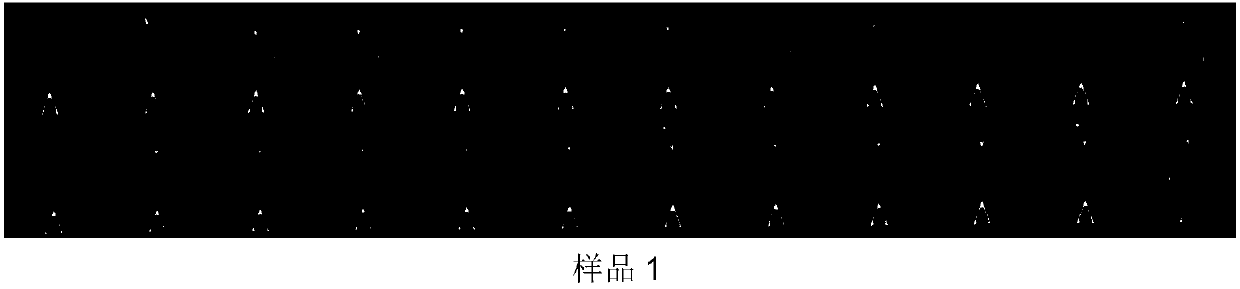

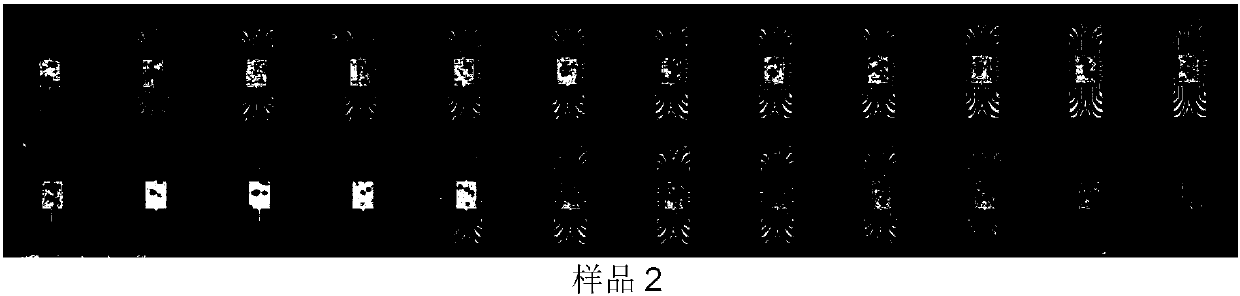

Embodiment 1-7 and comparative example 1

[0109] The formulations of the epoxy resin compositions of Examples 1-7 and Comparative Example 1 are listed in Table 1.

[0110] Epoxy resin compositions were prepared by mixing all components listed in Table 1 for 20-30 minutes, extruding through a twin-screw extruder at 100°C, followed by cooling, grinding and post-mixing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

An epoxy resin composition is provided, and the composition comprises an epoxy resin, a phenolic resin, a catalyst, a filler, optionally a defoaming agent, and optionally an additive. The epoxy resincomposition can be used in various electronic applications, such as surface mount device package, such as SOP8, SOP14, SOP16, SOP20, SOP28 package.

Description

technical field [0001] The invention relates to an epoxy resin composition, its preparation method and application. The epoxy resin composition of the present invention can be used in various electronic applications, such as surface mount device packaging, such as SOP 8, SOP14, SOP16, SOP20, SOP28 packaging. Background technique [0002] Voids can easily be found on the outside and inside of semiconductor packages of epoxy molding compounds. The presence of voids can lead to various effects. For example, external voids can affect package appearance, while internal voids can act as weak points leading to poor attachment and thermal fatigue, thereby affecting package performance and lifetime. [0003] Therefore, it is very important to reduce the number of voids in the package. In order to reduce the number of voids in epoxy molding compounds (EMC), much work has been done by different methods. [0004] Kuo-Yuan Lee and co-workers, in U.S. Patent No. 20120077312 A1, provid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L63/00C08K3/013C08K5/00

CPCC08G59/621C08G59/688C08K3/04C08K3/36C08L63/00

Inventor 刘成杰丁全青房文祥

Owner HENKEL HUAWEI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com