Casting furnace capable of utilizing non-synchronous bending for obtaining liquid deep undercooling

A synchronous bending and casting furnace technology, applied in foundry equipment, casting melt containers, manufacturing tools, etc., can solve problems such as inability to apply non-magnetic materials and inability to provide high magnetic field strength, to increase magnetic field strength, achieve small and The effect of uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

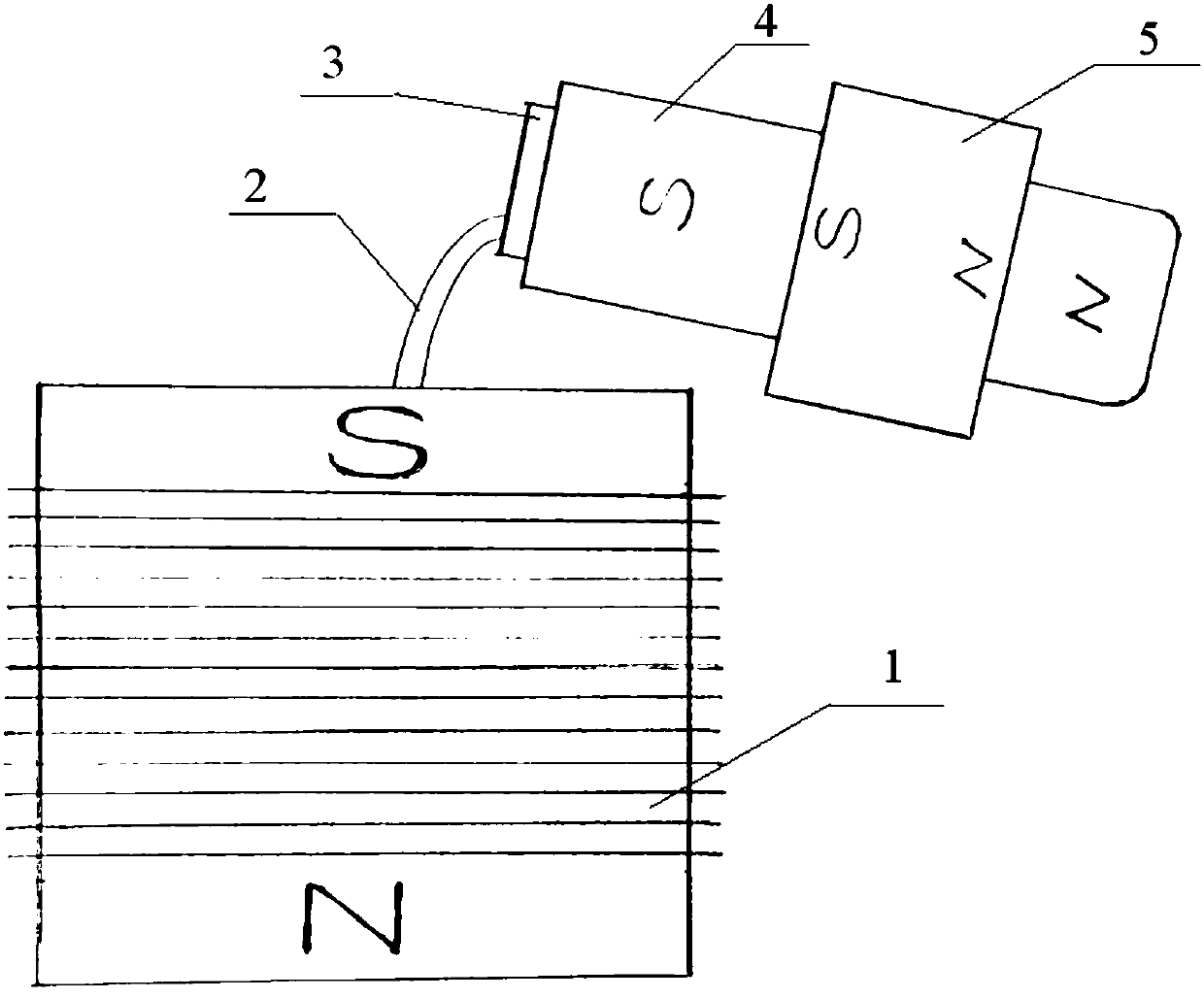

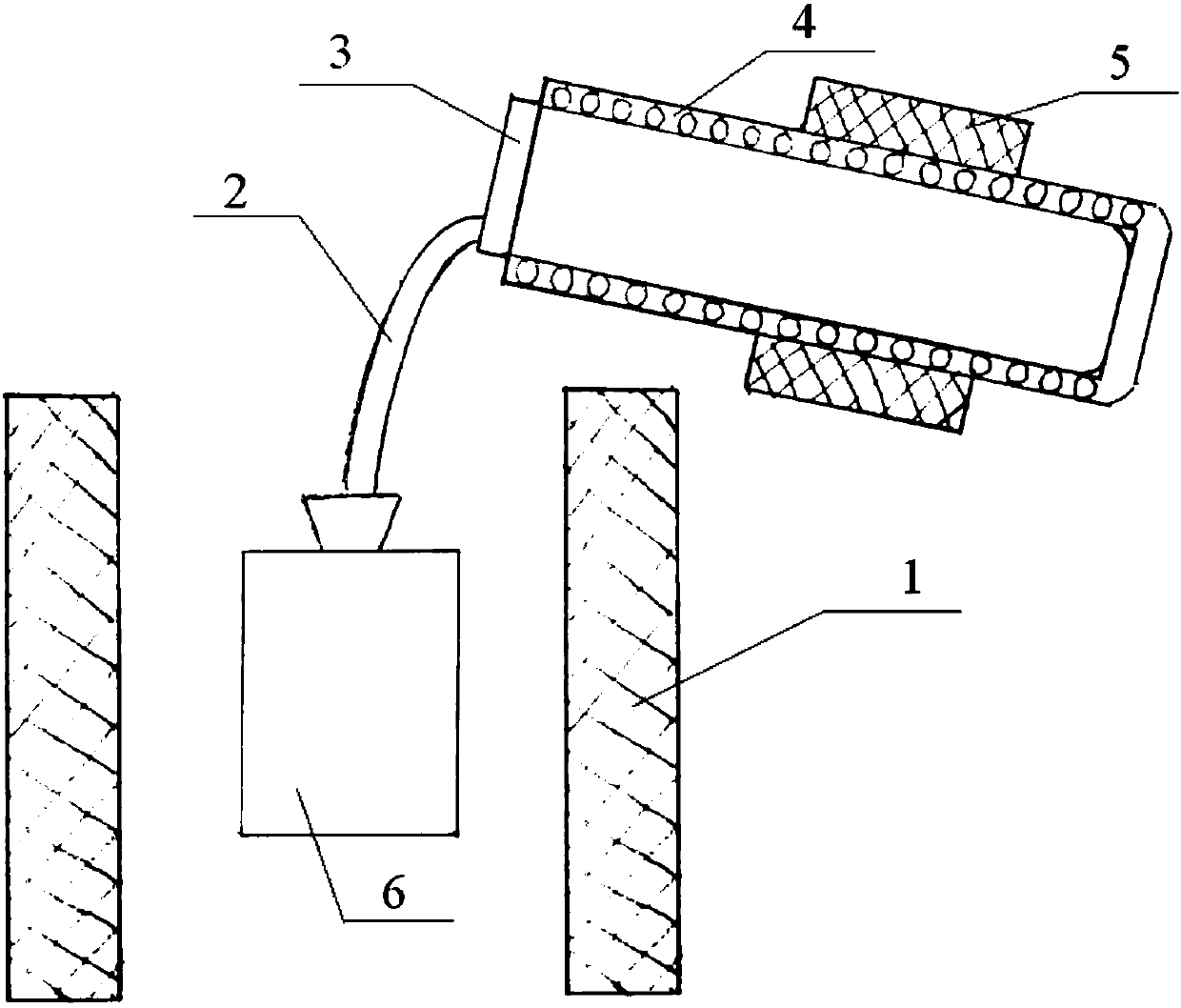

Method used

Image

Examples

Embodiment 1

[0071] Step 1. Bury the casting mold into a sand box, then push the sand box into a heating furnace and heat it to 1100°C for 4 hours;

[0072] Step 2. Open the furnace door, pull out the sand box embedded with the casting mold after the completion of step 1 out of the heating furnace, and place it on the casting mold base of the casting furnace with a plunger;

[0073] Step 3. Open the furnace cover, tilt the melting crucible at an angle of 45 degrees, push 50 kg of master alloy for melting and casting into the crucible along the mouth of the crucible, and at the same time add 10 grams of deoxidized carbon into the crucible, and then reset the crucible;

[0074] Step 4. The infrared temperature measurement and the galvanic temperature measurement response are normal, replace the blackened lens of the peephole, wipe the vacuum sealing surfaces, and then close the furnace cover and furnace door;

[0075] Step 5. Turn on the cooling water system, the inner cooling water pressure...

Embodiment 2

[0080] Step 1. Bury the casting mold into a sand box, then push the sand box into a heating furnace and heat it to 1200°C for 3 hours;

[0081] Step 2. Open the furnace door, pull out the sand box embedded with the casting mold after the completion of step 1 out of the heating furnace, and place it on the casting mold base of the casting furnace with a plunger;

[0082] Step 3. Open the furnace cover and tilt the melting crucible at an angle of 45 degrees; push 50 kg of master alloy for melting and casting into the crucible along the mouth of the crucible, and at the same time add 6 grams of deoxidized carbon into the crucible; then reset the crucible;

[0083] Step 4. The infrared temperature measurement and the galvanic temperature measurement response are normal, replace the blackened lens of the peephole, and wipe the vacuum sealing surfaces; then, close the furnace cover and furnace door;

[0084] Step 5. Turn on the cooling water system, the inner cooling water pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com