Directional furnace and single crystal casting method both using asynchronous bending technology

A technology of simultaneous bending and technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of low temperature gradient and achieve the effect of increasing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

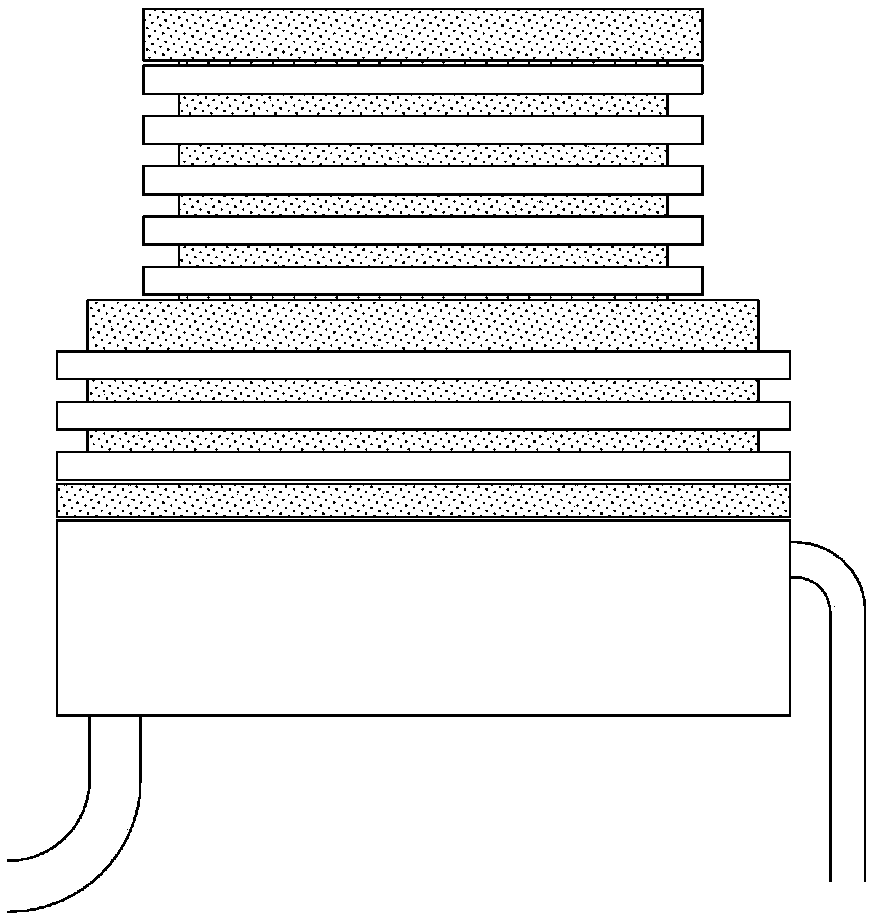

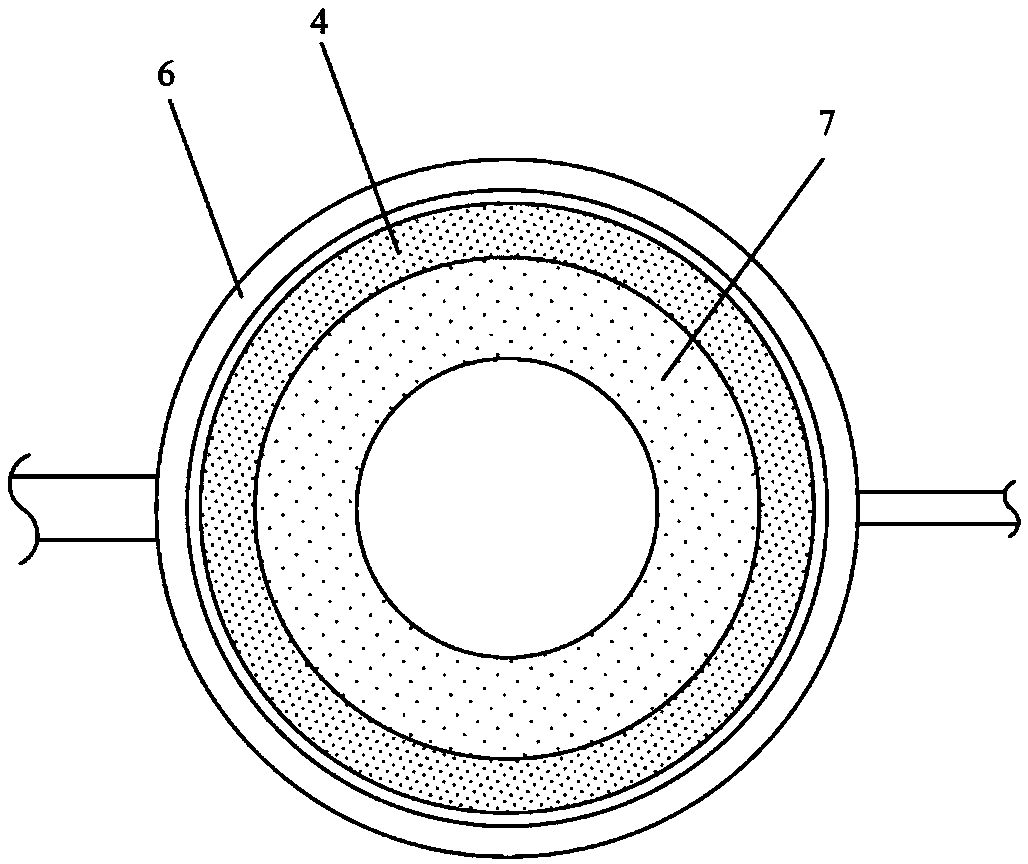

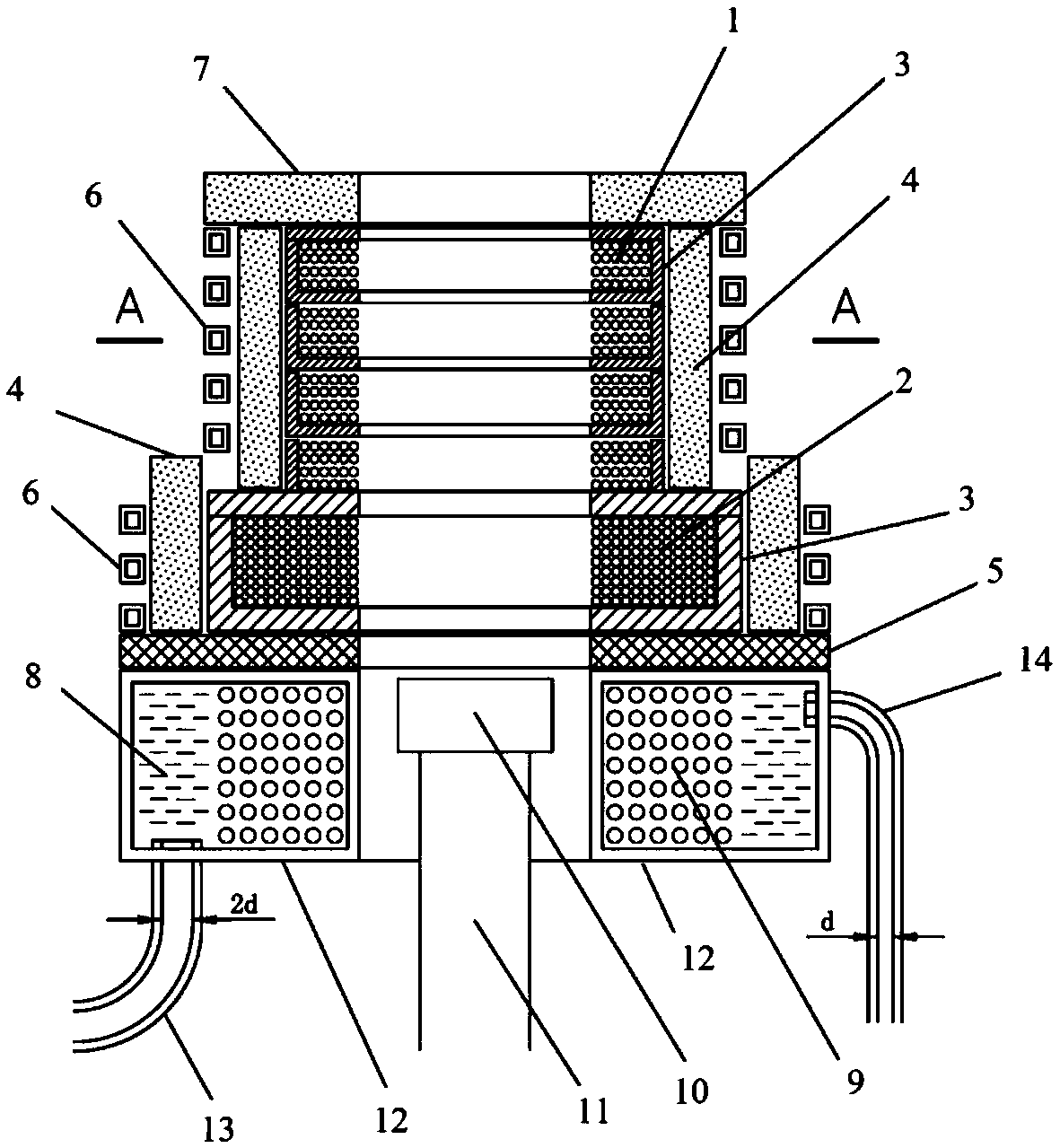

[0041] The present invention provides an orientation furnace using asynchronous bending technology, such as figure 1 and 3As shown, it includes a casting chamber, a reverse static magnetic field chamber 12 and a pull-down water-cooled crystallizer 10 located in the middle of the reverse static magnetic field chamber 12; the casting chamber includes a first energized coil 1, a second energized coil 2 and a bearing The slot 3, the first energized coil 1 and the second energized coil 2 internal space constitute a static magnetic field application area, and the static magnetic field application area is also a temperature heating area; the first energized coil 1 and the second energized coil 2 are respectively located in the bearing groove 3, The first energization coil 1 is located above the second energization coil 2; the reverse static magnetic field chamber 12 includes a third energization coil 9 and an insulating cooling unit, and the third energization coil forms a static mag...

Embodiment 2

[0079]S1. Place 10 kg of master alloy in the melting crucible, then put 1 gram of deoxidized carbon on the master alloy, then check whether the temperature measuring device and peephole are normal and available, turn on the furnace body and vacuum system, and turn on the square coolant copper Tube 6 and the insulation cooling unit of the pull-down water-cooled crystallizer 10, and open the cooling water circulation system of the square cooling liquid copper pipe 6 and the pull-down water-cooled crystallizer 10, and open the transformer of the ring-shaped non-magnetic stainless steel reverse static magnetic field chamber 12 for insulation cooling Forced circulation system of oil 8 and external circulation water cooling system for forced cooling of the cooling oil.

[0080] S2. Place the casting mold shell on the drop-down water-cooled crystallizer 10 below the casting chamber, align the center to ensure that the casting mold shell will not scratch the surrounding devices when it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com