Falling prevention screw

A technology for preventing protruding and screws, applied in the direction of screws, nuts, bolts, etc., can solve laborious and complicated problems, achieve the effects of reducing processing difficulty, improving the meshing force between threads, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

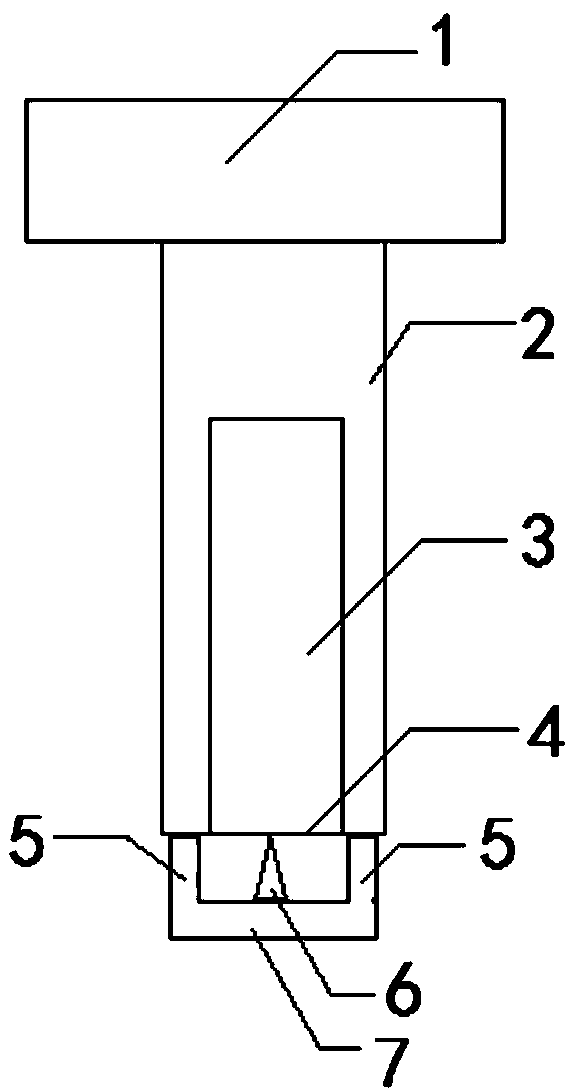

Embodiment 1

[0025] This embodiment provides an anti-extraction screw, such as figure 1 , including a nut 1 and a screw body 2, the screw body 2 is a cylinder, and threads are provided on the side of the cylinder, the nut 1 is fixedly connected with one end of the screw body 2, and a concave hollow cavity 3 is set in the screw body 2 The end of the concave hollow cavity 3 away from the nut 1 is provided with a film 4 for the concave hollow cavity 3; the film 4 is provided with a penetrating mechanism, and the penetrating mechanism is pressed to puncture the film 4 when the screw is screwed to the bottom of the screw hole ; The concave hollow cavity 3 is filled with liquid thread glue.

[0026] This embodiment: In this embodiment, a cavity with a concave shape is provided in the middle of the screw body 2 . The inside of the cavity is filled with thread glue, and a film 4 is set on the plane of the cavity for sealing, and then a mechanism is arranged behind the film 4 to pierce the film 4 ...

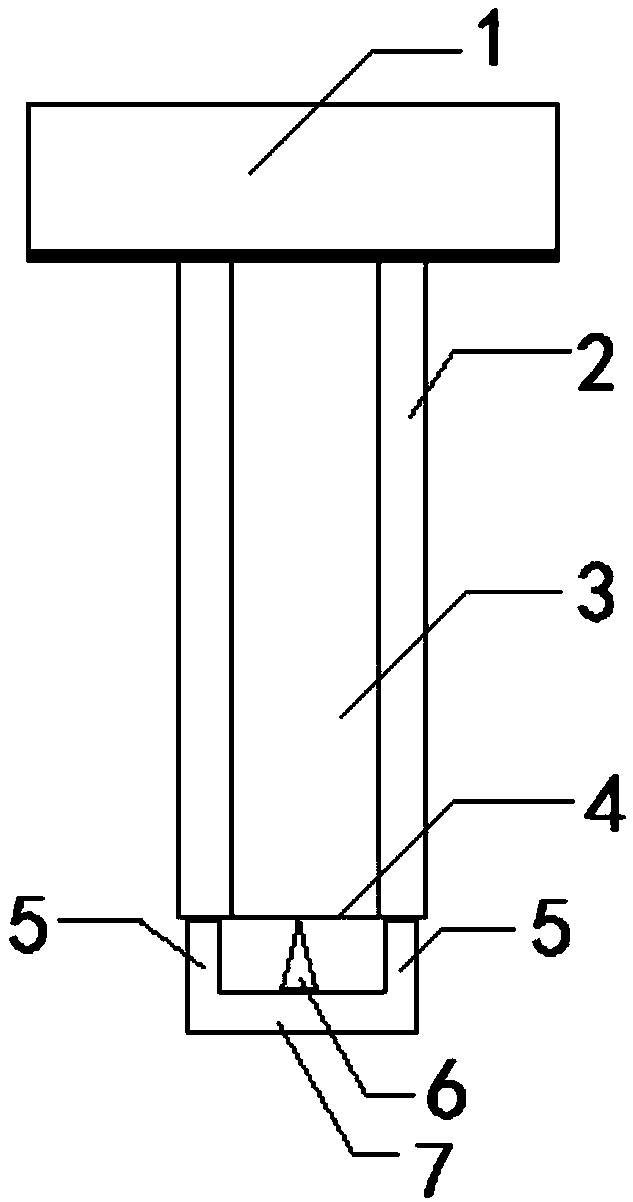

Embodiment 2

[0032] Such as figure 2 In this embodiment, the concave hollow cavity 3 is formed by the through screw body 2 and the nut 1 sealed, and the screw body 2 and the nut 1 are connected by welding. All the other schemes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com