Wood floor conveying and paint coating device

A painting device and a technology for wooden floors, which are applied to the device and coating of the surface coating liquid, can solve the problems of low labor efficiency, inability to paint continuously, and affecting the health of workers, so as to achieve excellent material retrieving, The effect of compact overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

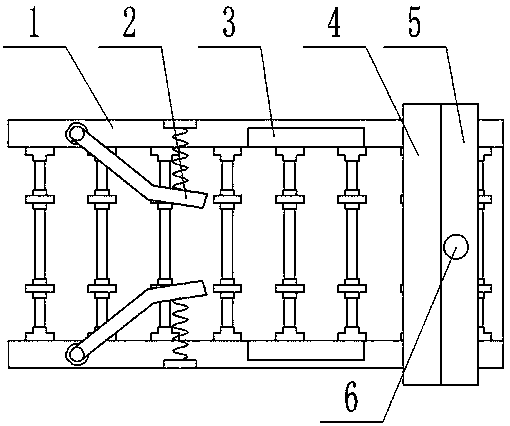

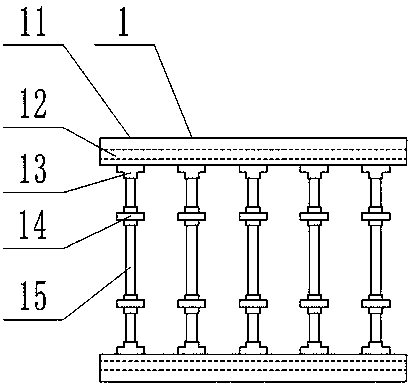

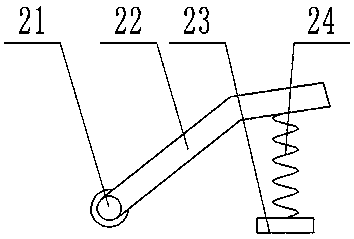

[0013] see Figure 1-3 , a wooden floor conveying and painting device, comprising a conveying belt 1, a feeding device 2, a swatch 3, a brushing roller 4 and a coating roller 5, and the conveying belt 1 includes two conveying guide rails 11 arranged in parallel and running on The transmission chain 12 in the transmission guide rail 11 is provided with a plurality of positioning sockets 13 on the transmission chain 12, and positioning holes are provided on the positioning sockets 13. The conveyor belt 1 also includes a transmission rod 15 and The support block 14 supporting the wooden floor being sprayed, the number of transmission rods 15 is half of the positioning sleeve 13, and the two ends of the transmission rod 15 are set in the positioning holes of the positioning sleeve 13 to fix the transmission rod 15 on the two transmission chains 12 , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap