Fully biodegradable garbage bag film blowing device

A garbage bag and all-biological technology, applied in the field of fully biodegradable garbage bag blown film device, can solve the problems of film looseness, insufficient cooling, affecting film quality, etc., and achieve the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained in detail below in conjunction with the drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

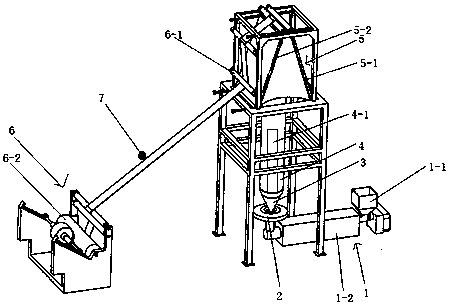

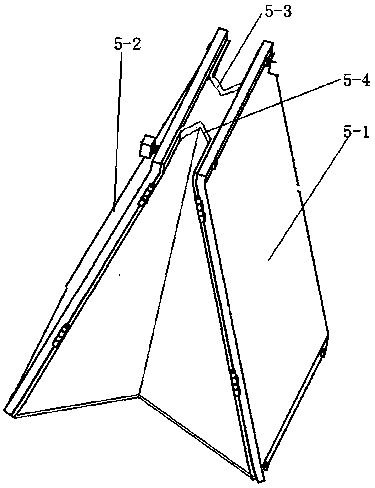

[0016] Such as Figure 1-2 As shown, a fully biodegradable garbage bag film blowing device in the present invention includes a feeding device 1 for feeding materials, a film blowing port connected to the feeding device 1, 2, and a film provided at the film blowing port 2. The bubble protection device 3, the film blowing channel 4, the herringbone 5 and the traction device 6. The feeding device 1 includes a feeding port for placing plastic particles and a feeding channel for transferring the feeding port to the film blowing port 2; The film blowing port 2 is provided with a wind disk for blowing bubbles, the film bubble protection device 3 is connected to the film blowing channel 4 and the film blowing port 2, and the film gun pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com