Cold-hot stage type high-speed calorimeter capable of being combined with other microstructure characterization techniques

A technology of cold and hot table type and microstructure, which is applied in the direction of calorimeter, heat measurement, instrument, etc., and can solve the problems of sample structure change, sample temperature influence, sample temperature out of control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

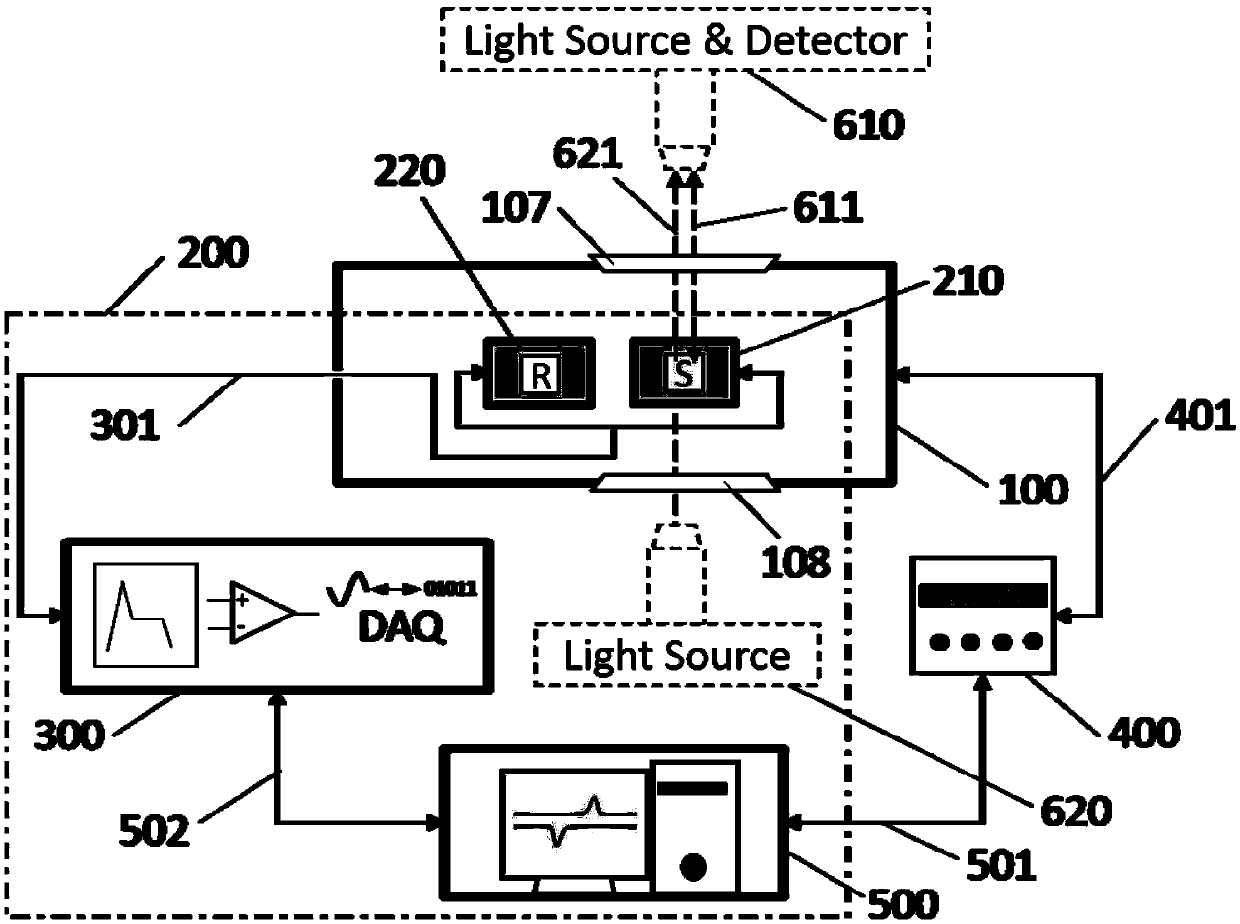

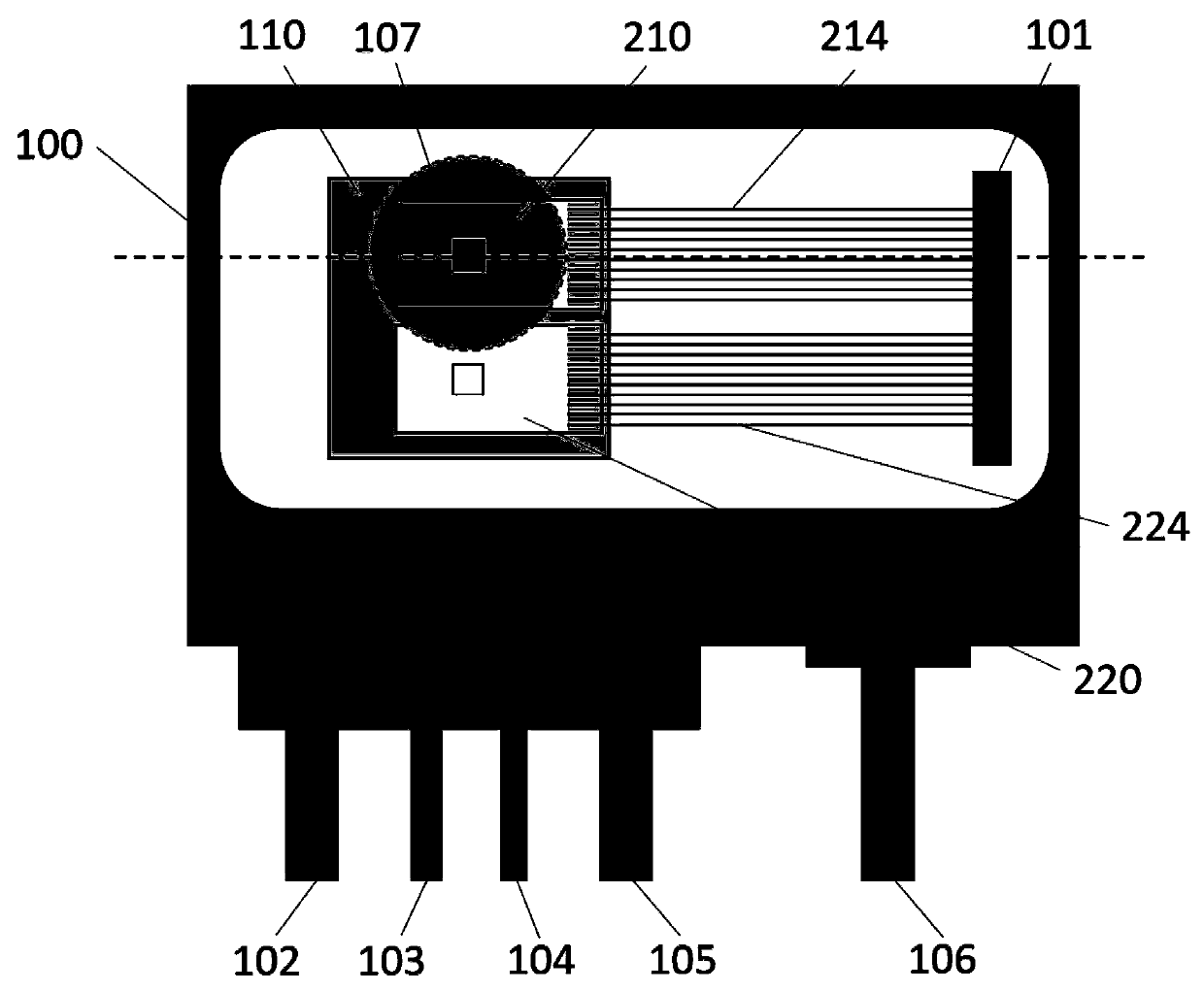

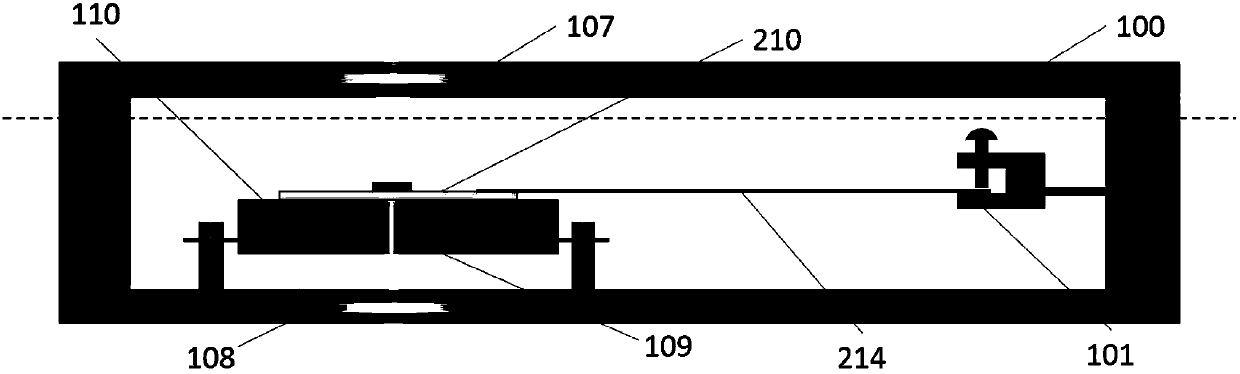

[0023] figure 1 It is a block diagram of the hot and cold table type high-speed calorimeter described in the example of the present invention. The thin film sensor (210) for loading the sample and the thin film sensor (220) for reference are placed on the surface of the cold and hot stage (110) in the sample chamber (100) (see figure 2 ), the ambient temperature of the two thin film sensors (210 and 220) is controlled by the sample chamber temperature control system (400). The high-speed temperature control and measurement system (300) controls and collects the temperature of the heating area of the two thin film sensors (210 and 220) according to the temperature program setting valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com