Tension compression type self-reset and anti-buckling energy dissipation bracing

An anti-buckling energy consumption and self-resetting technology, applied in the direction of earthquake resistance, building types, building components, etc., can solve the problems of small output, limited use range, and only tension, etc., to achieve large restoring force, simple design method, Reduces the effect of residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

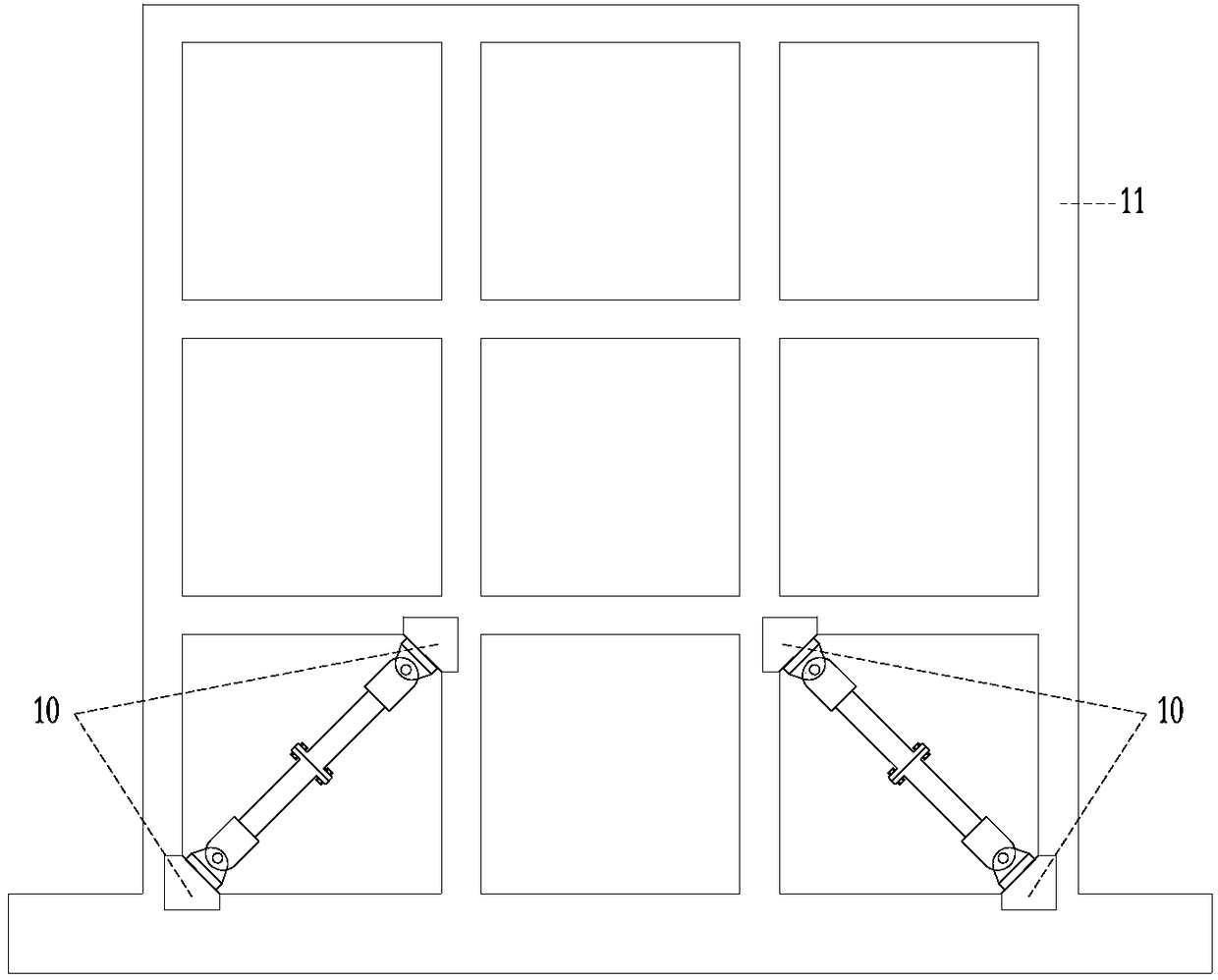

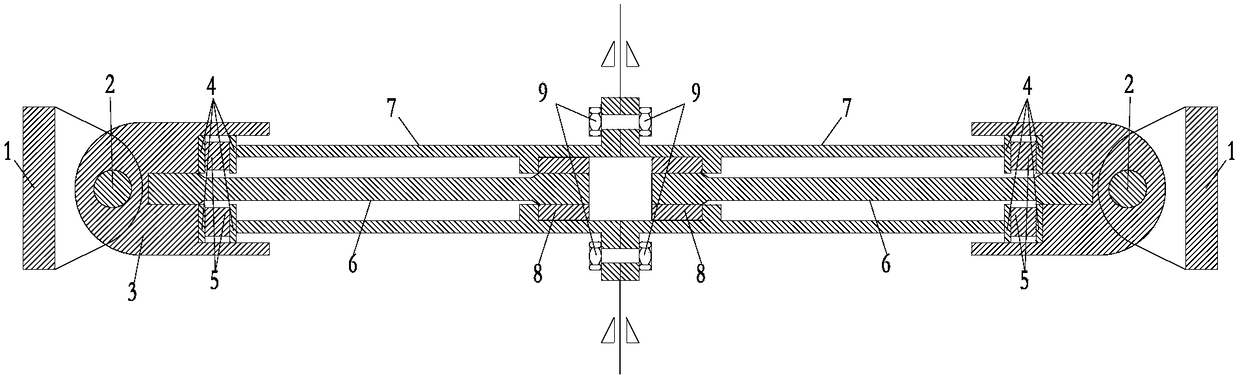

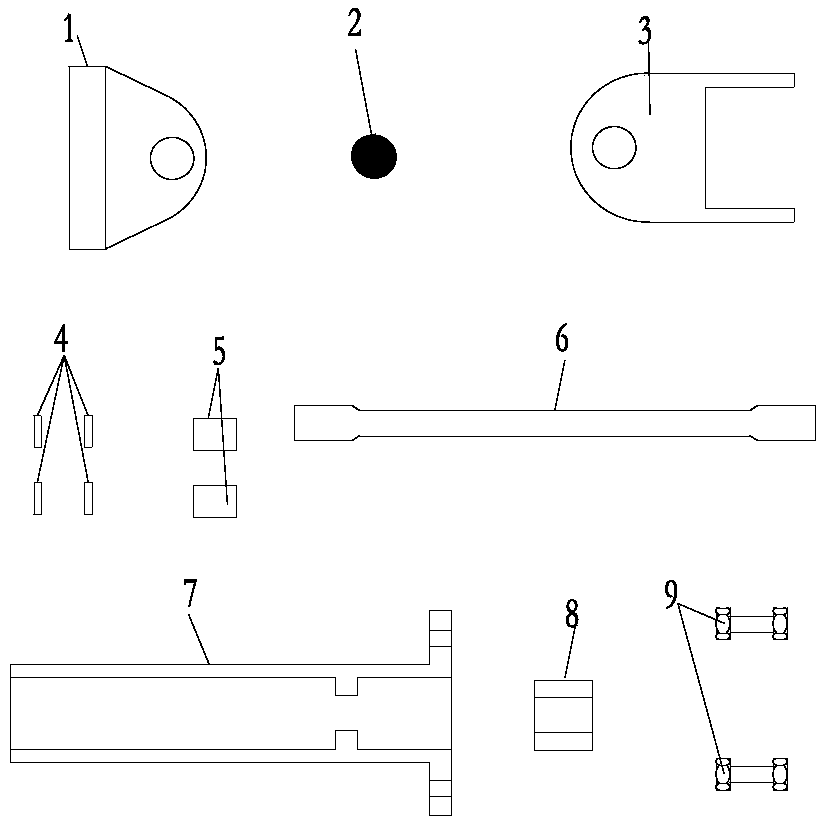

[0028] see Figure 2-Figure 3 , tension and compression type self-resetting anti-buckling energy dissipation support, including hinged support 1, connecting plate 3, memory alloy bar 6, anti-buckling steel sleeve 7, steel plate rubber support; the memory alloy bar 6 is installed on the anti-buckling Inside the buckling steel sleeve 7, one end is connected to the connecting plate 3, and the other end is a movable end, and the movable end is limited by the stretching of the buckling-resistant steel sleeve; the end of the buckling-resistant steel sleeve 7 passes through the steel plate rubber support It is connected with the connecting plate 3 and is limited by the extrusion of the connecting plate 3; the hinged support 1 is hinged with the connecting plate 3.

[0029] In this example, see figure 2 , the tension-compression type self-resetting anti-buckling energy-dissipating support is a left-right symmetrical structure, the left unit part and the right unit part are connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com