Three-split-wire pulley vehicle

A three-split, wire technology, applied in the field of wire speeding, can solve the problems of unsafety and high labor intensity, and achieve the effects of light size, improved safety, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

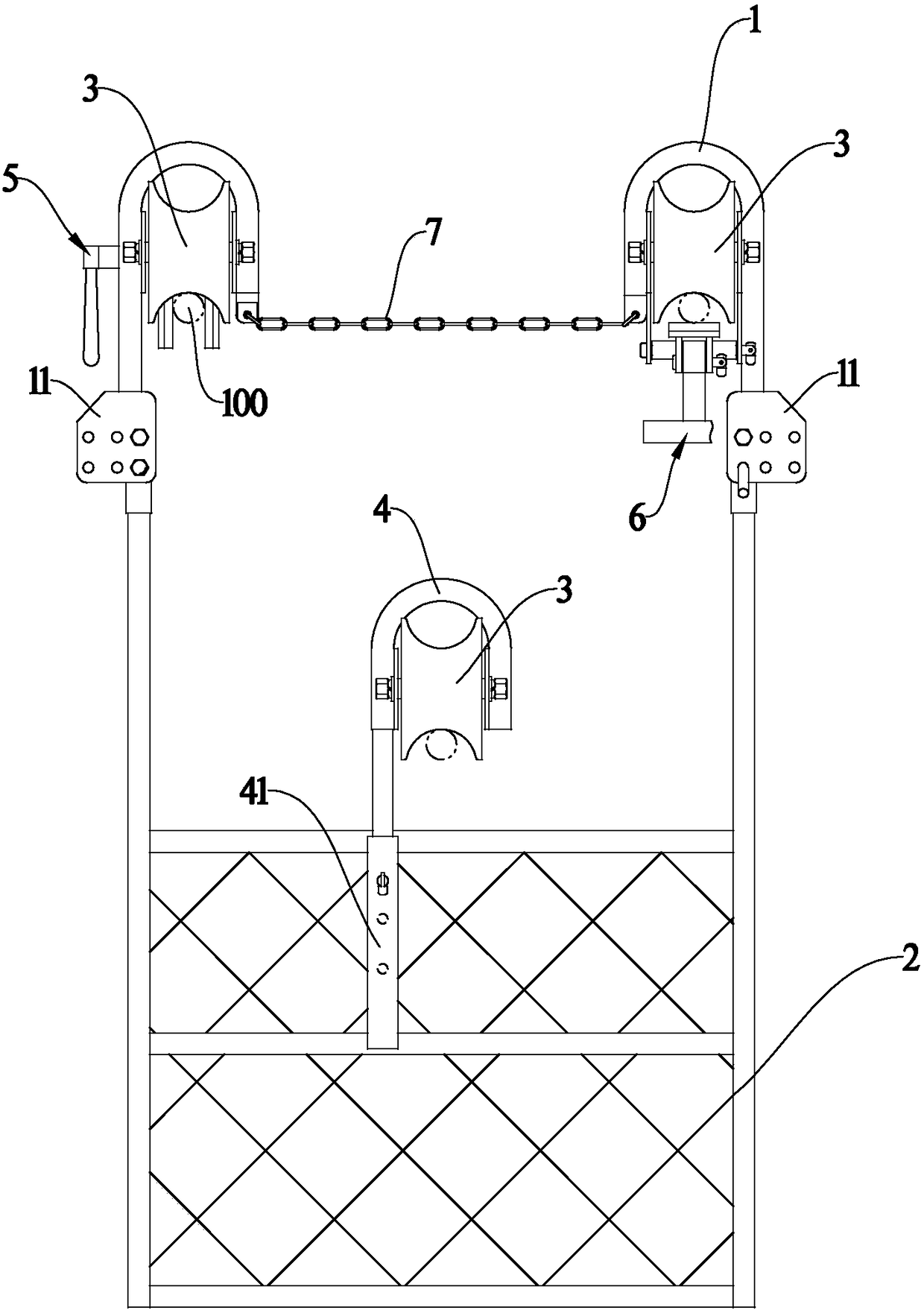

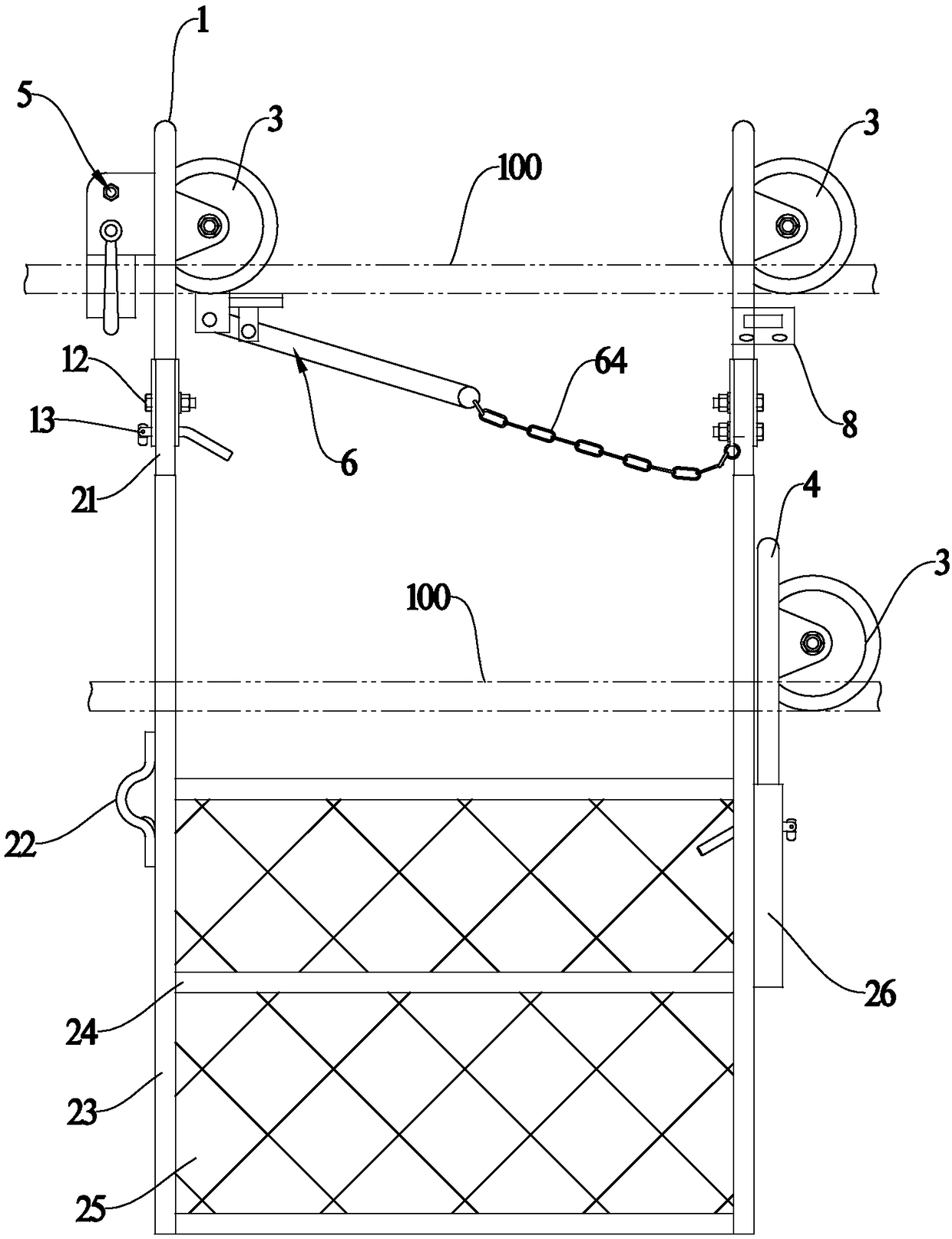

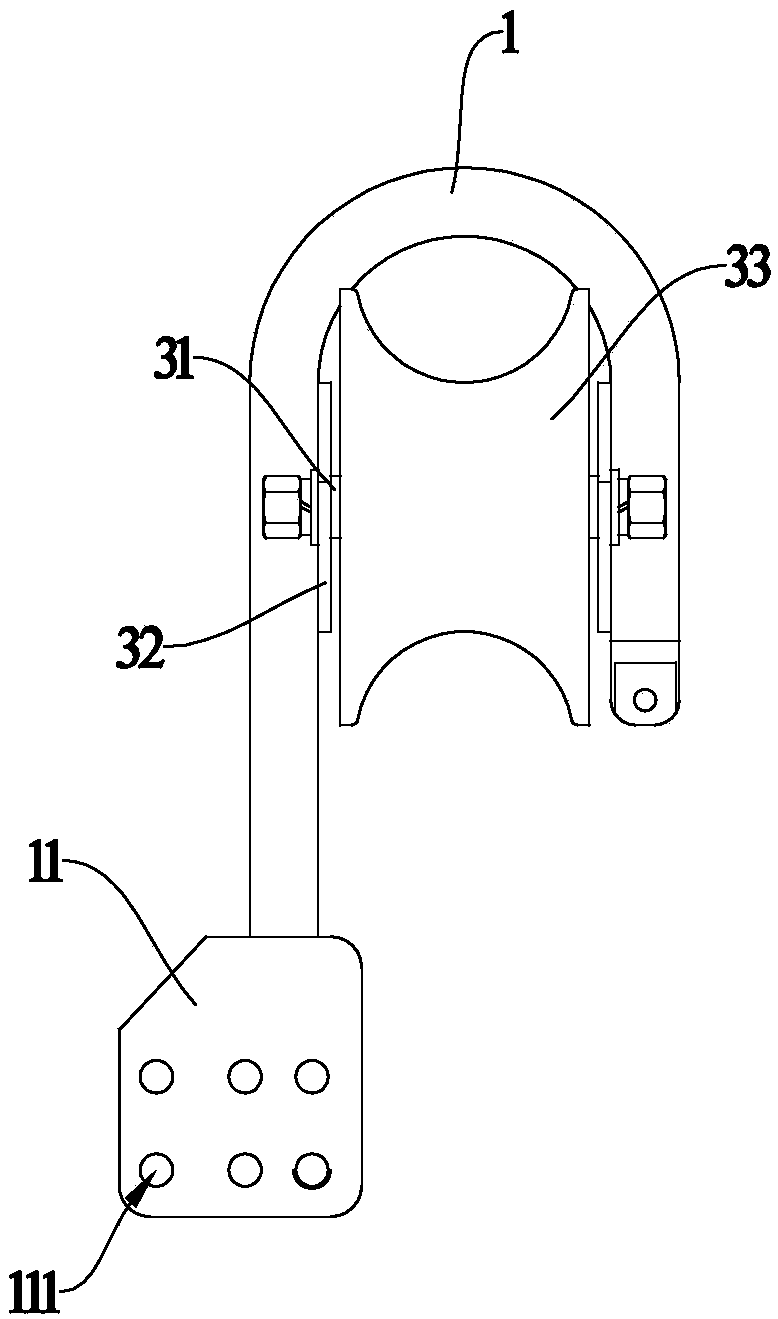

[0024] Such as Figure 1-6 As shown, a preferred embodiment of the present invention includes an upper frame 1 and a lower frame 2, the upper frame 1 is provided with pulley assemblies 3 on both sides, for hanging on the wires 100 on both sides, and the lower frame 2 is fixedly installed It is located below the upper frame 1, and the lower frame 2 is a frame structure for accommodating operators and equipment. A set of transverse connecting holes 111 arranged in the transverse direction, the lower frame 2 can be optionally fixedly installed in a set of corresponding transverse connecting holes 111, the lower frame 2 is also provided with an adjustable frame 4, the adjustable frame 4 A pulley assembly 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com