cable trench cover bridge

A trench cover slab bridge and cable technology, which is applied in the field of cable trench cover slab bridges, can solve the problems of cable trench cover rigidity damage, steel plates can not realize the bearing function, etc., to improve traffic efficiency, improve the environment and work efficiency, and flexibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

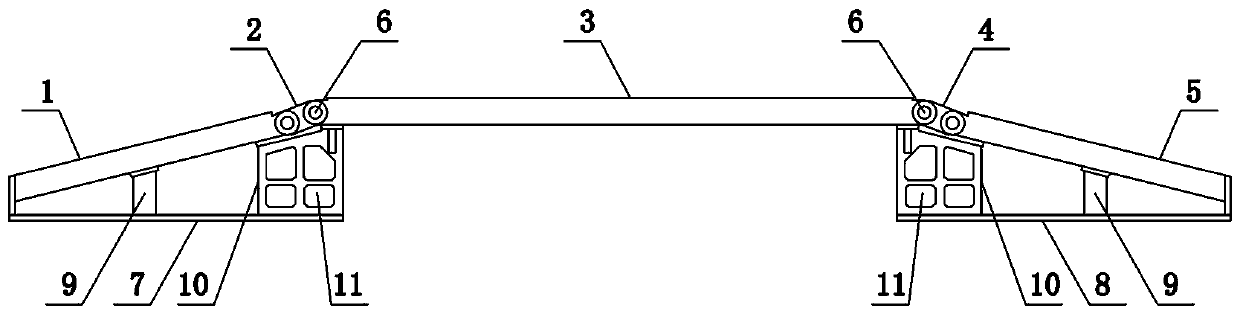

[0029] Such as Figure 1 to Figure 3 As shown, the present invention comprises a left cover plate 1, a left connecting plate 2, an intermediate cover plate 3, a right connecting plate 4 and a right cover plate 5 from left to right, and the two ends of the left connecting plate 2 pass through the rotating shaft 6 and the left cover respectively. The plate 1 and the middle cover 3 are rotationally connected, the two ends of the right connecting plate 4 are respectively hinged 5 with the middle cover 3 and the right cover 5 through the rotating shaft 6, and the lower end of the left cover 1 is provided with a left support 7 and a right cover 5 Right support plate 8 is set on the lower end face of the bottom surface, support column 9 and support frame 10 are all set between left cover plate 1 and left support plate 7, between right cover plate 5 and right support plate 8, and the height of support column 9 is less than support frame The height of 10, the support frame 10 is arrang...

Embodiment 2

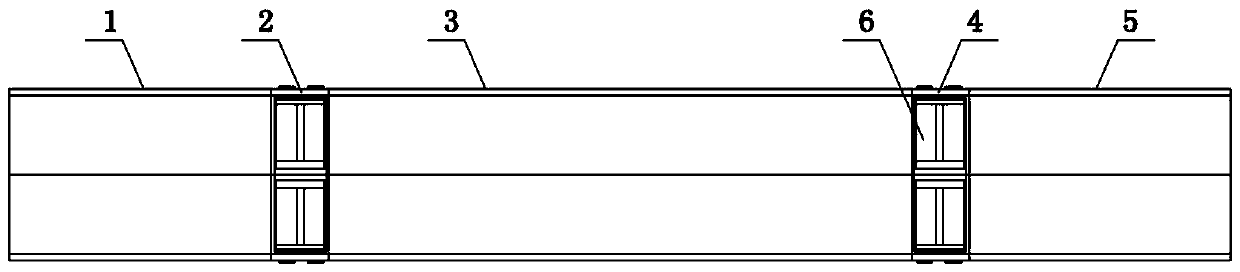

[0031] Such as Figure 4 with Figure 5 As shown, the present invention comprises a left cover plate 1, a left connecting plate 2, an intermediate cover plate 3, a right connecting plate 4 and a right cover plate 5 from left to right, and the two ends of the left connecting plate 2 pass through the rotating shaft 6 and the left cover respectively. The plate 1 and the middle cover 3 are rotationally connected, the two ends of the right connecting plate 4 are respectively hinged 5 with the middle cover 3 and the right cover 5 through the rotating shaft 6, and the lower end of the left cover 1 is provided with a left support 7 and a right cover 5 Right support plate 8 is set on the lower end face of the bottom surface, support column 9 and support frame 10 are all set between left cover plate 1 and left support plate 7, between right cover plate 5 and right support plate 8, and the height of support column 9 is less than support frame The height of 10, the support frame 10 is ar...

Embodiment 3

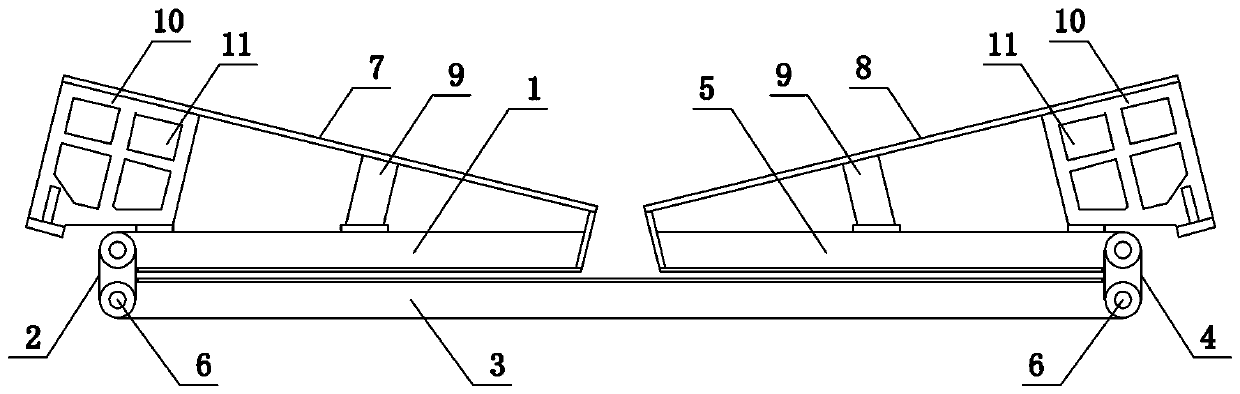

[0034]The present invention comprises left cover plate 1, left connecting plate 2, middle cover plate 3, right connecting plate 4 and right cover plate 5 successively from left to right, and the two ends of left connecting plate 2 pass rotating shaft 6 and left cover plate 1 and The middle cover plate 3 is rotationally connected, and the two ends of the right connecting plate 4 are respectively hinged 5 with the middle cover plate 3 and the right cover plate through the rotating shaft 6. The right support plate 8 is set, the support column 9 and the support frame 10 are all arranged between the left cover plate 1 and the left support plate 7, between the right cover plate 5 and the right support plate 8, and the height of the support column 9 is less than the height of the support frame 10 , the support frame 10 is arranged close to the middle cover plate 3, the support frame 10 between the left cover plate 1 and the left support plate 7 simultaneously supports the right end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com