Force-sensor-based flexible mechanical paw and using method

A mechanical gripper and flexible technology, applied in the field of mechanical structure, can solve the problems of difficult installation and maintenance, many parts and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The mechanism principle and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

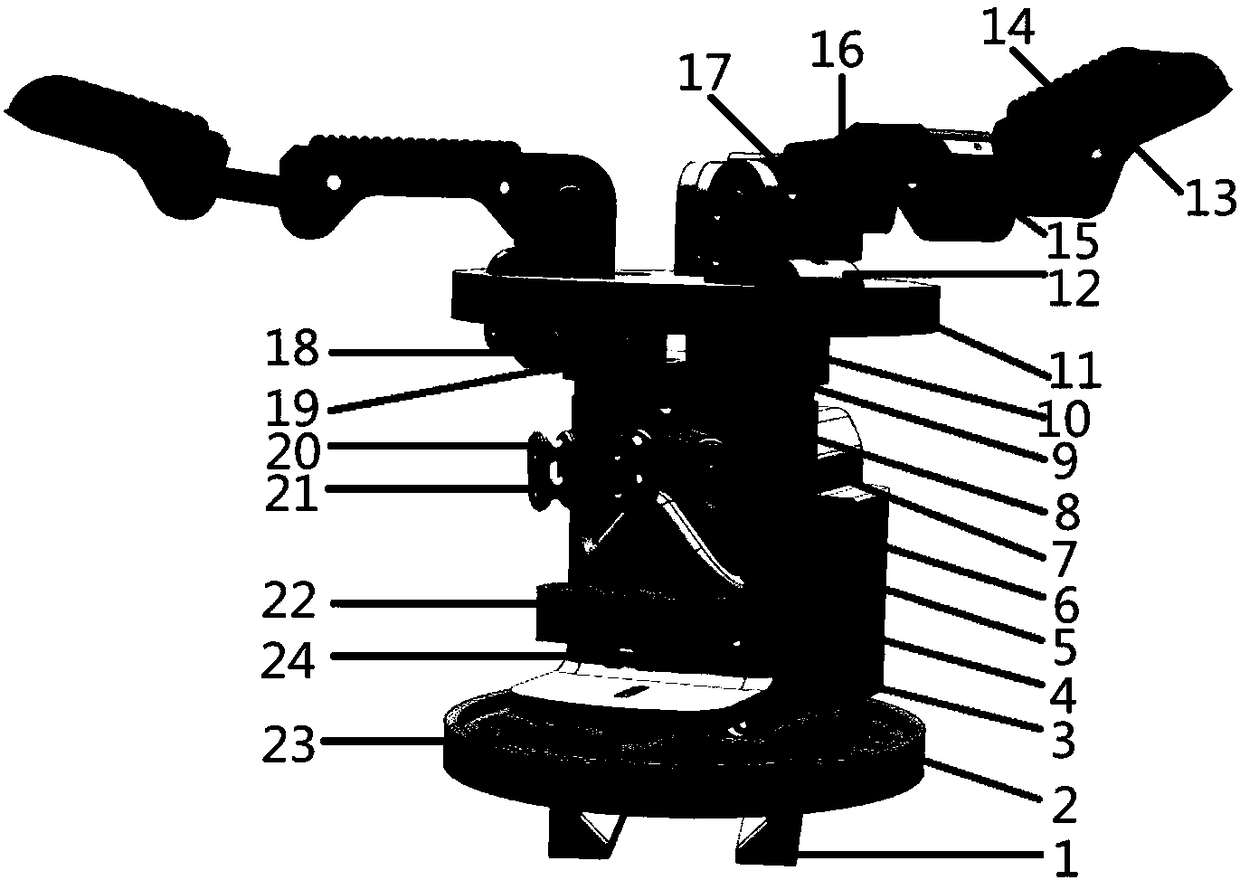

[0014] see figure 1 , the present invention is made up of several mechanisms.

[0015] Initialization process: Confirm that the installation is complete and the components are in good condition, and control the motor to reversely rotate at a certain angle so that the fingers can automatically return to their positions;

[0016] The grasping process adjusts the output torque of the steering gear through the pressure feedback of the finger surface, and the steering gear rotates to tighten the winch (5), so that the fixed pulley (7)-fixed pulley (8)-fixed pulley (23)-fixed rod ( 24) the tendon rope is tightened, thereby driving the transfer element (22) to move downward, and the downward movement of the transfer element (22) drives the synchronous downward movement of the three movable pulleys (20) (21) (6), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com