Rotary type combined press

A rotary, press technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, poor product consistency, small press space, etc., and achieve the effect of rapid use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

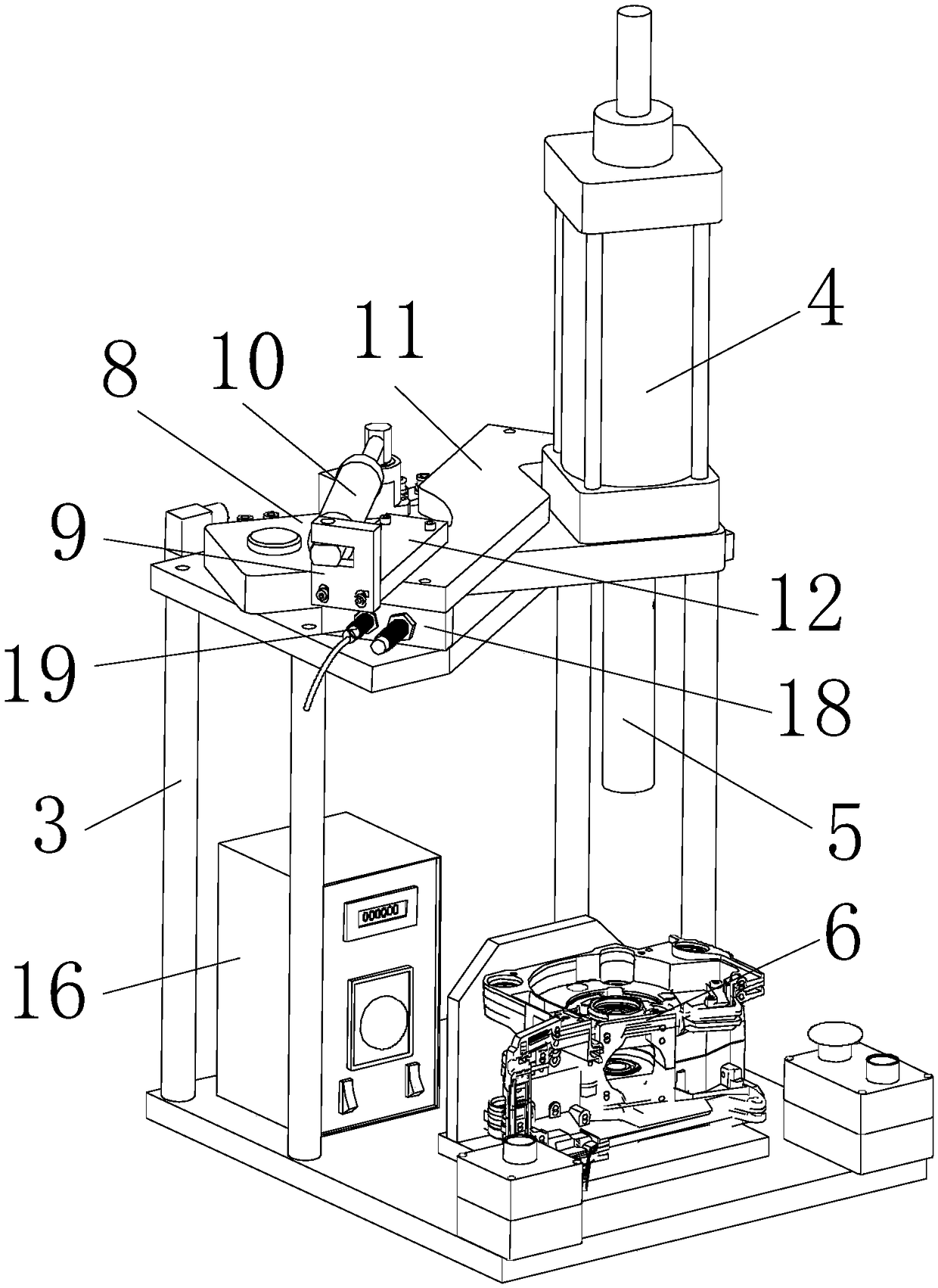

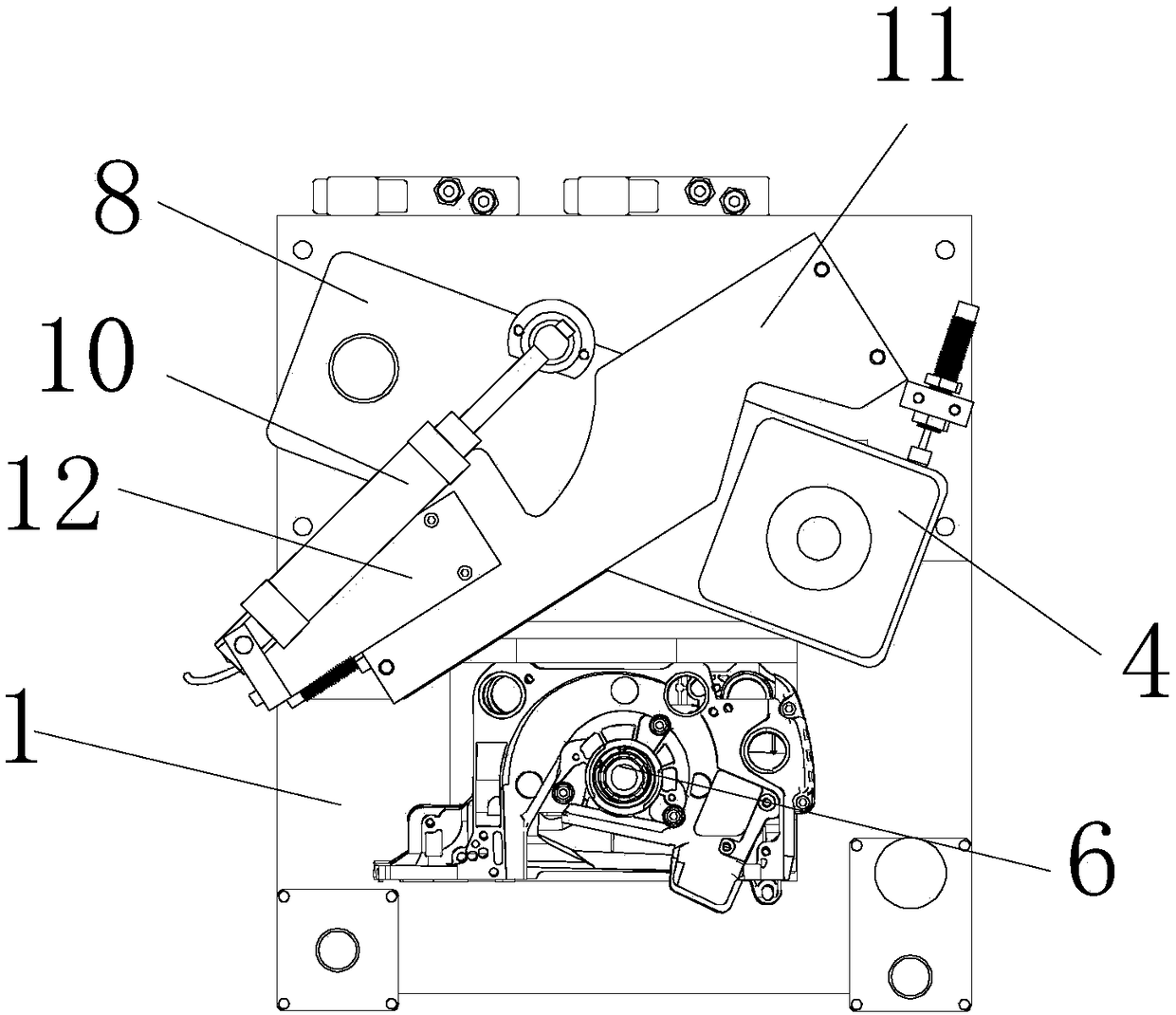

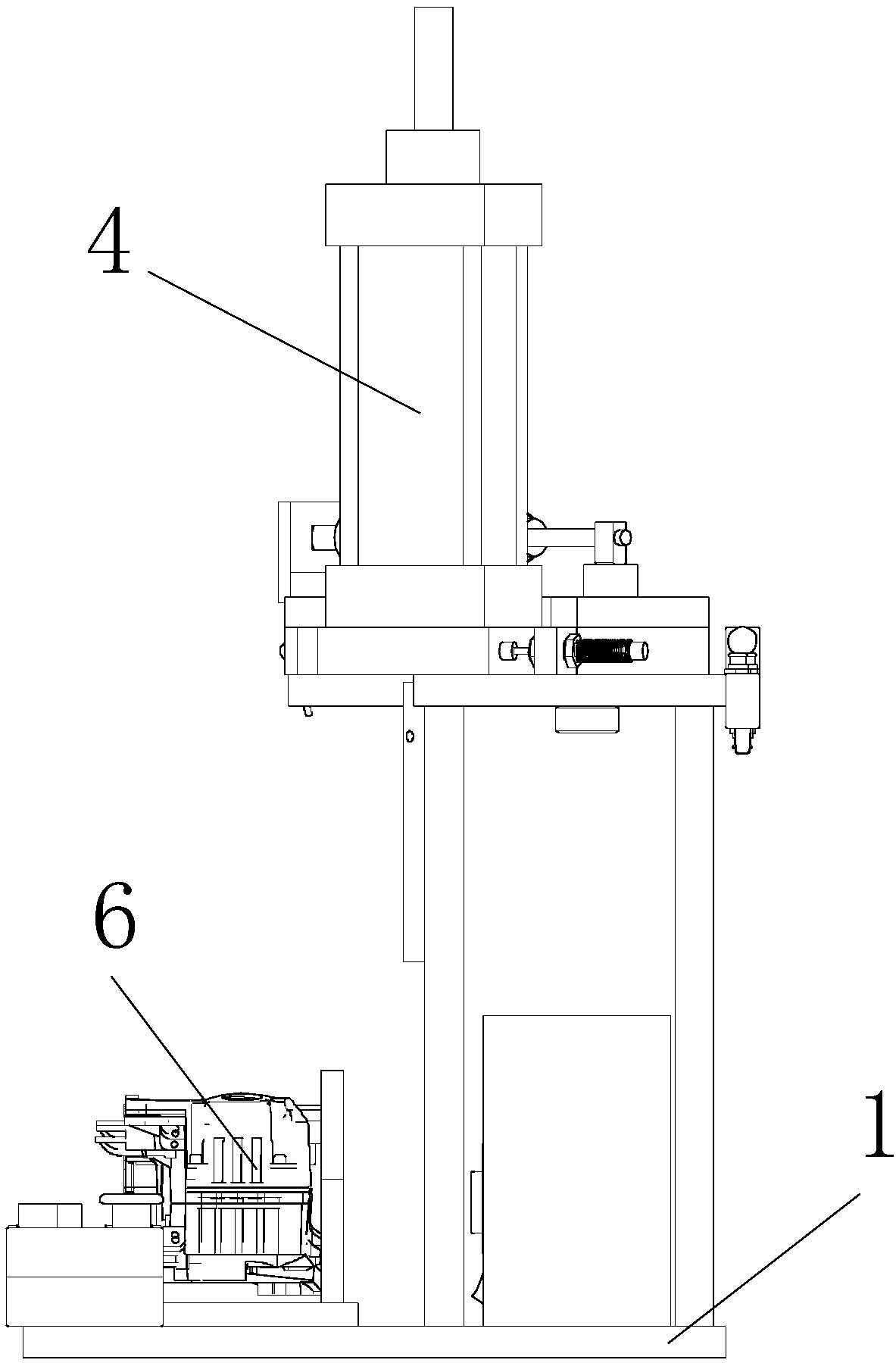

[0033] With reference to the accompanying drawings, a rotary combination press includes a horizontally laid bottom plate 1, the bottom plate 1 includes a front half and a rear half, the upper surface of the front half is provided with a placement for stamping parts for stamping Position 6; a top plate 2 is erected on the upper surface of the second half, the top plate 2 is parallel to the bottom plate 1, and the placement position is outside the projection of the top plate 2 on the bottom plate 1 (that is, the top plate 2 is not Covering the placement position 6); the stamping cylinder 4 for stamping to the placement position 6 is rotatably arranged on the top plate 2 through a rotating device;

[0034] Described rotating device comprises the main board 8 that is laid horizontally on the upper surface of top board 2, and described main board 8 is rotatably arranged on top board 2, and the left end of described main board 8 is hinged with a corner of the left rear side of top bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com