Folding device and folding method for flat piece product

A folding device and product technology, applied in packaging and other directions, can solve the problems of high equipment failure rate, unstable sealing quality, and inability to ensure the sealing of products with sealing tape, and achieve the effect of effective control of failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

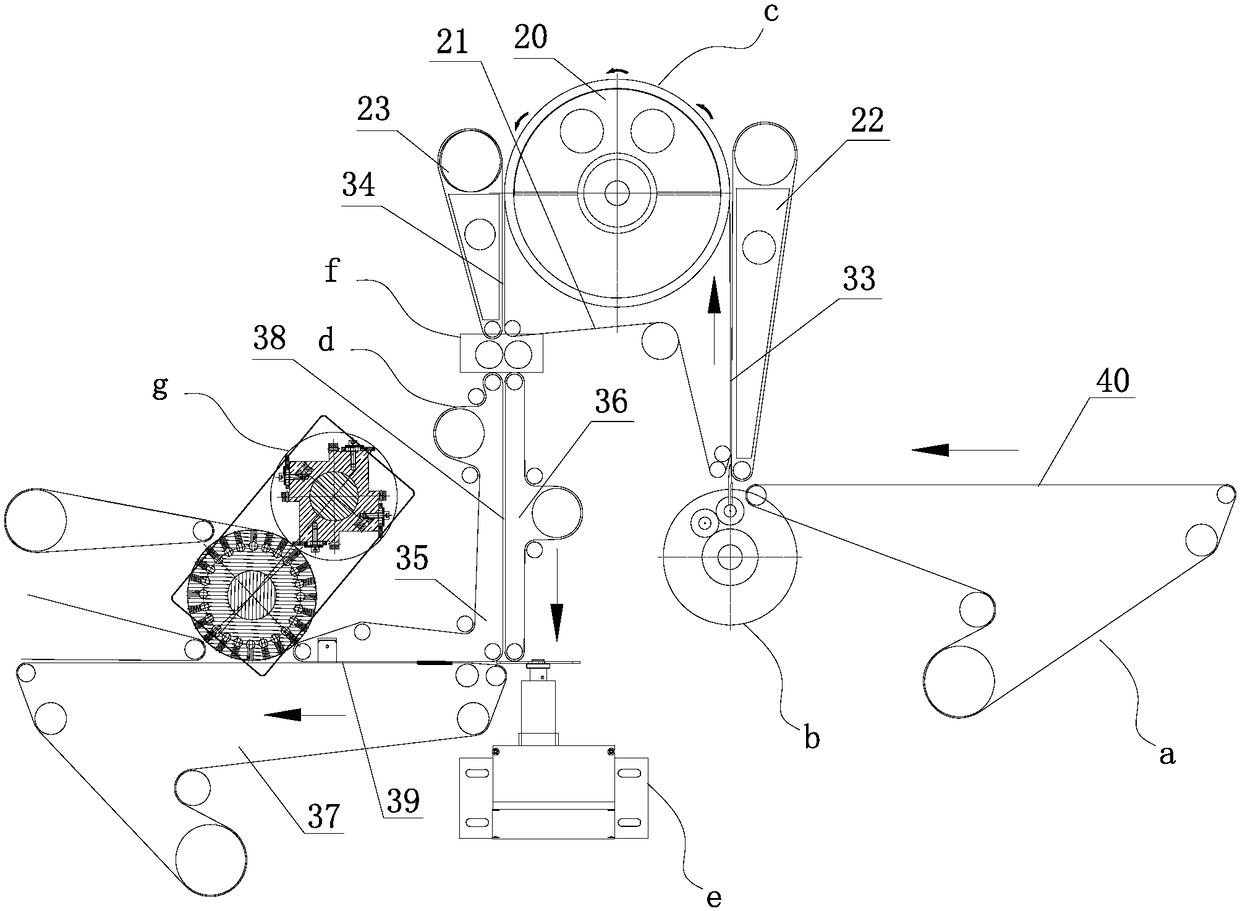

[0036] In this embodiment, a folding device for flat sheet products, such as figure 1 As shown, along the conveying direction of flat sheet products (such as figure 1 shown by the arrow in ), including the product input mechanism a, the first folding mechanism b, the transfer conveying mechanism c, the corner conveying mechanism d and the second folding mechanism e arranged in sequence, and the first folding mechanism is arranged between the product input mechanism and the transfer conveying mechanism Below the connection of the mechanism, the second folding mechanism is located on the corner side of the corner conveying mechanism; among them, the product input mechanism, the transfer conveying mechanism and the corner conveying mechanism all adopt vacuum negative pressure conveying mode, and the first folding mechanism is rotary The vertical plate insertion mechanism, and the second folding mechanism is a rotary horizontal plate insertion mechanism. In addition, a pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com