Device and method for testing impact performance of spot welded joints of thin metal plates

A technology for impact performance of metal sheets, applied in the field of impact performance testing devices for spot welded joints of metal sheets, can solve the problems affecting the accuracy of impact force measurement results, affecting the transmission of impact energy, and the complex structure of force measurement circuits, etc., to achieve inertia force Small influence, improved measurement accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

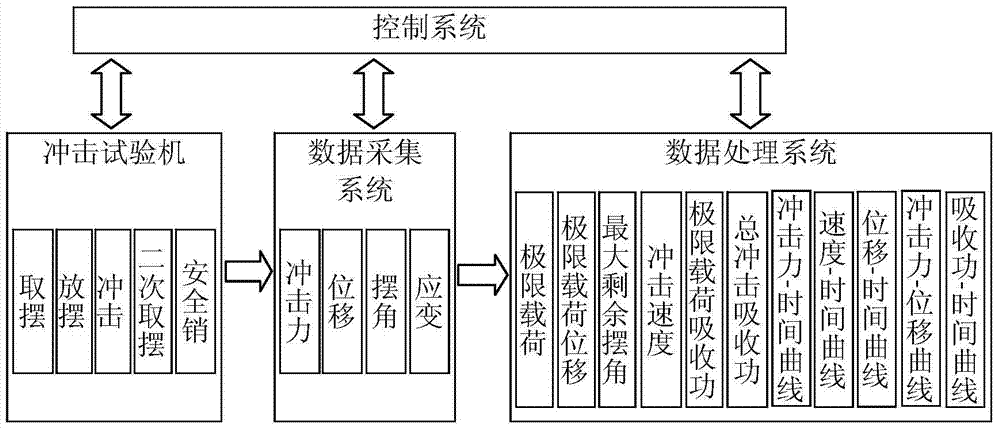

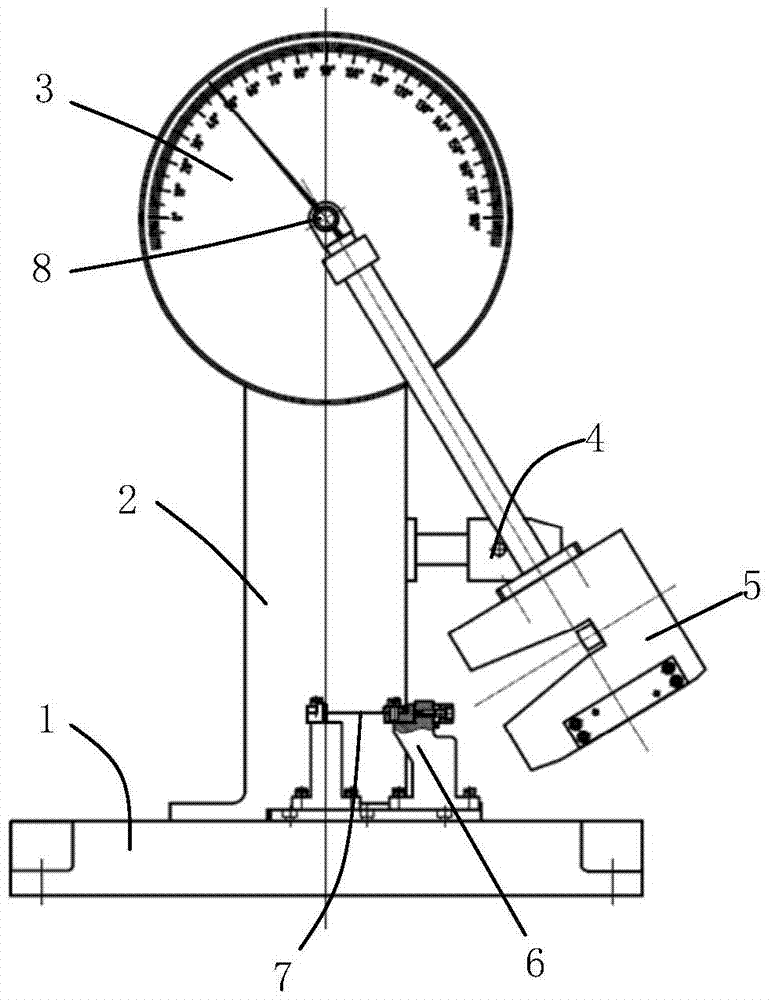

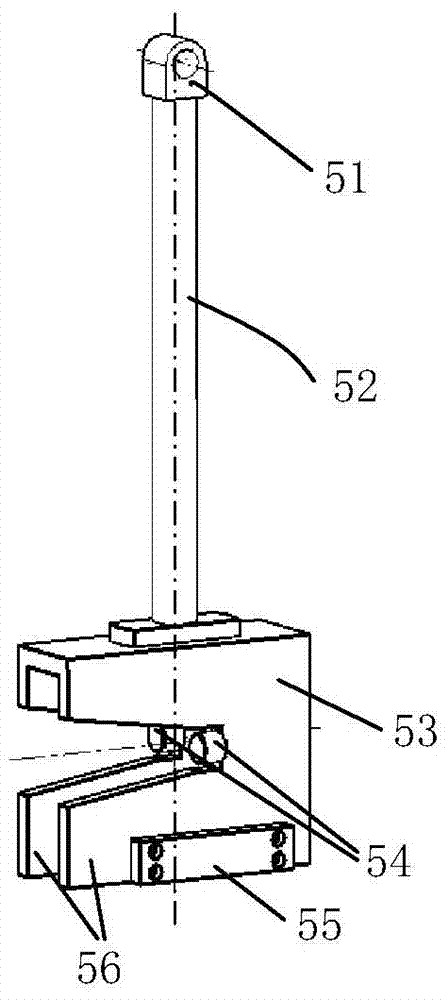

[0039] combine figure 1 with figure 2 , The metal sheet spot welding joint impact performance testing device of the present invention includes an impact testing machine, an impact fixture 6, a control system, a data acquisition system and a data processing system. The impact testing machine is composed of a base 1, a column 2, a pendulum shaft 8, a pendulum 5, a pendulum angle dial 3, a pendulum taking mechanism and a safety pin 4. The column 2 is fixedly installed on the base 1, the swing angle dial 3 is installed on the upper end of the column 2, the pendulum taking mechanism (not shown) composed of a servo motor and a clutch is installed on the upper part of the column, and the safety pin 4 for locking the pendulum Installed in the middle of the column. Such as image 3 , Figure 4 with Figure 5 As shown, the pendulum 5 is composed of a pendulum 52 and a pend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com