Axially opposed piston barrel cam driven five-stroke engine

A piston barrel and driving technology, which is applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of residual exhaust, large machine vibration, and high exhaust temperature, so as to reduce exhaust temperature, increase power, and improve The effect of fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

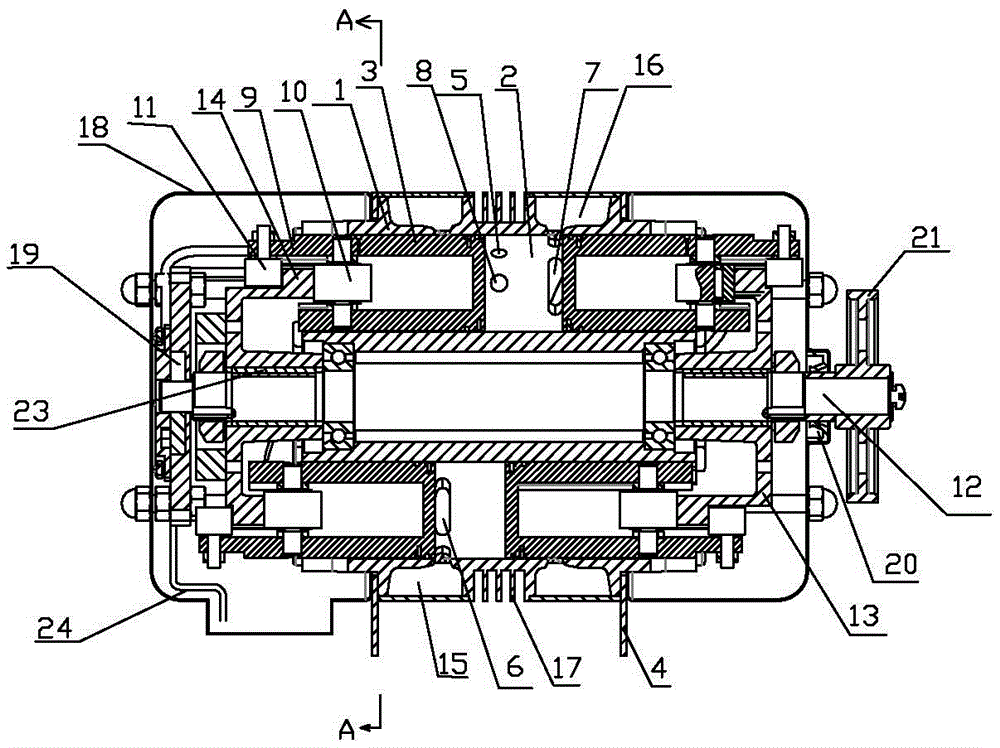

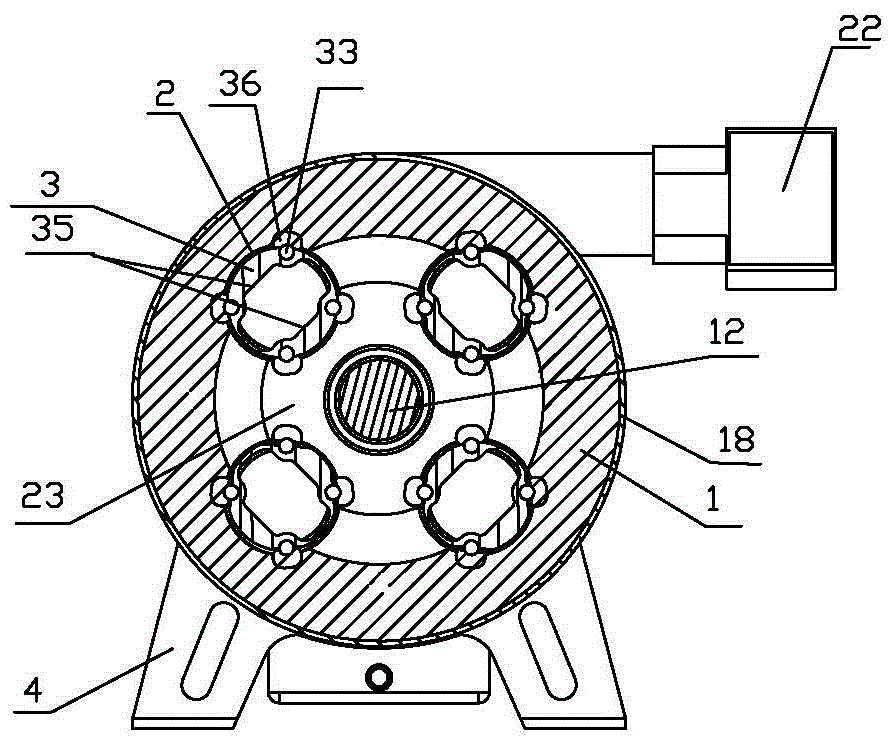

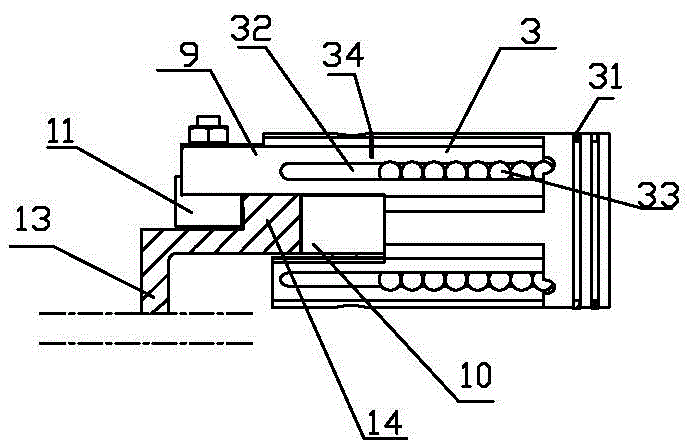

[0032] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A four-cylinder example is given. refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The present invention was made. The axially opposed piston cylindrical cam-driven five-stroke engine includes a cylindrical body 1, a cylinder 2, a piston 3 and a base 4. The piston 3 is provided with two left and right, and is arranged in the cylinder 2 in an opposite manner. The body 1 is fixed on the base 4, and is characterized in that: the cylindrical body 1 is provided with cylinders 2 that are arranged at equal distances and open at both ends; The left and right pistons 3, the cylinder 2 between the left and right pistons 3 is a working chamber, and an air inlet 6 is provided on the wall of the cylinder 2 corresponding to one end of the working chamber, and the other end of the working chamber corresponds to the working chamber. The wall of the cylinder 2 is provided with an exhaust port 7, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com