An anti-skid groove type embedded part

A technology of embedded parts and anti-skid grooves, which is applied in the direction of construction and building structure, can solve the problems of gasket production, installation and use, increase costs, etc., and achieve good locking effect, anti-skid effect, and easy installation and construction operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

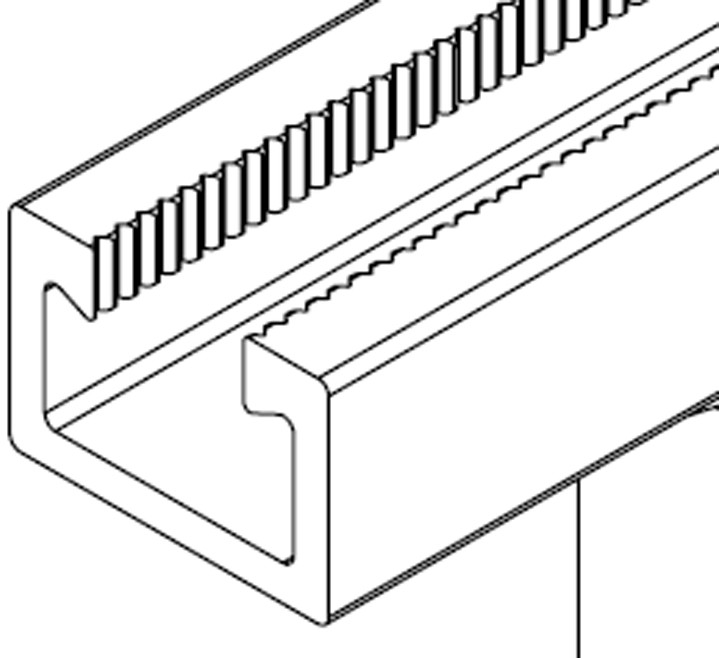

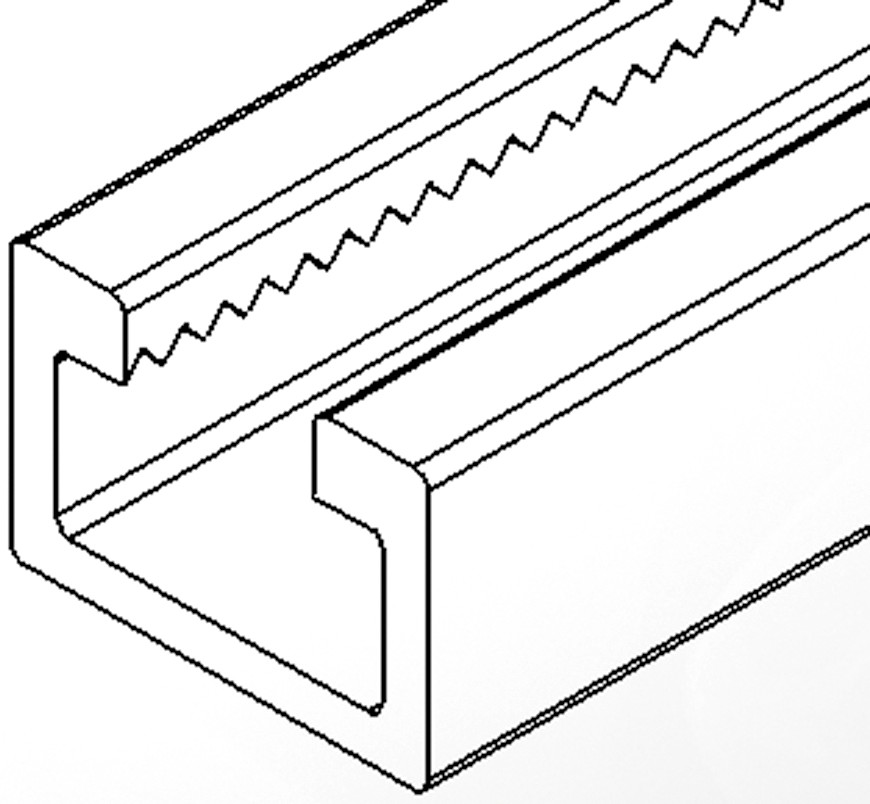

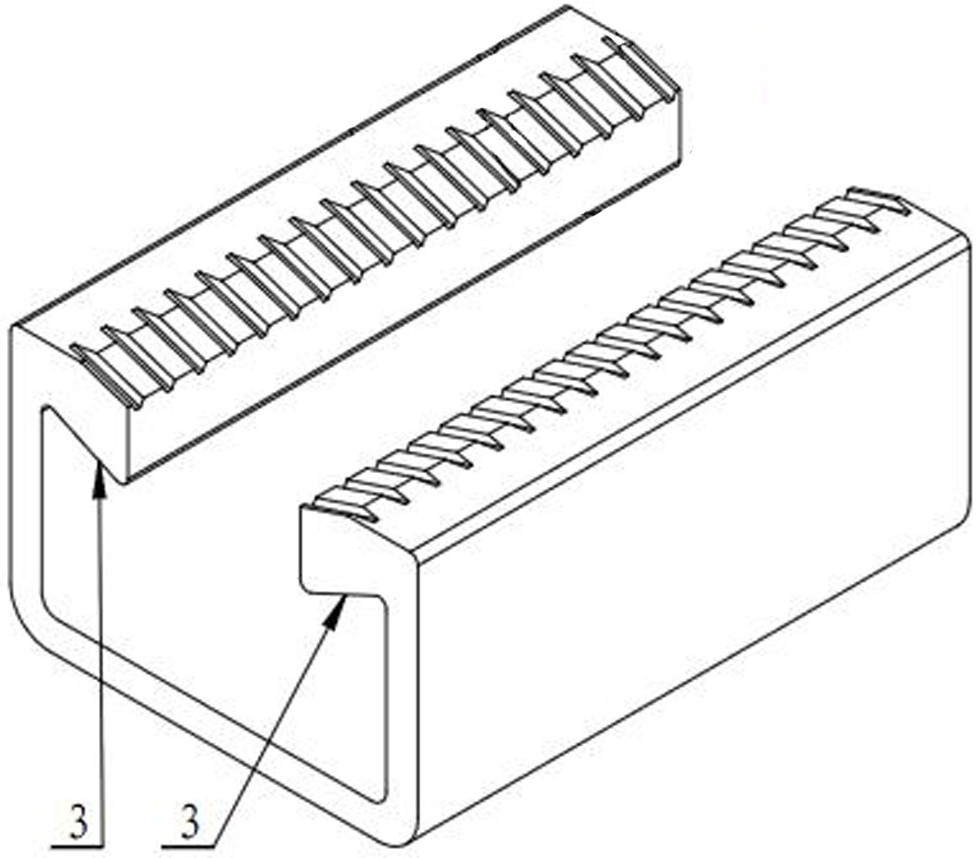

[0030] Embodiment 1: An anti-skid groove type embedded part, including a groove 1, such as image 3 As shown, the channel 1 is a C-shaped channel, the channel 1 is pre-welded on the steel structure or embedded in the concrete pouring surface, one end of the channel 1 is provided with an opening, and the opening and the installation surface of the channel 1 are outward; the channel 1 The bottom is provided with riveted or welded anchors 3 (see Figure 4 and Figure 7 ) to enhance the bond with concrete. The opening is provided with a clip hook 1B inclined to the bottom surface of the channel 1, and the connection and fastening effect with the T-bolt 2 is better, and the overall strength and bearing capacity of the channel 1 are better. The side of the opening of the channel 1 is provided with anti-slip teeth I1A. The end face shape of the anti-slip teeth I1A is a triangle or other tooth shapes, and the triangle is the best solution to make the bite more firm. The anti-slip t...

Embodiment 2

[0033] Embodiment 2: the difference between this embodiment and embodiment 1 is: as Figure 11 As shown, the channel 1 is provided with a gasket 3, the gasket 3 is arranged on the top surface of the channel 1 at the opening end, the gasket 3 is provided with a boss matching the opening of the channel 1, and the boss snaps into the opening Inside, the side of the boss is provided with an anti-skid tooth III that matches the anti-skid tooth I1A. The washer 3 is provided with a through hole matching the T-shaped screw 2, the washer 3 passes through the stud part of the T-shaped bolt 2 through the through hole, and the washer 3 engages with the groove 1 through the anti-slip tooth III and the anti-slip tooth I1A connect. The gasket 3 can double the anti-slip and locking effect of the embedded part of the present invention.

[0034] Installation method: After connecting the embedded parts in Example 1, insert the gasket 3 into the stud part of the T-shaped bolt 2 through the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com