An experimental device and method for the effect of convective combustion on combustion transition to detonation

A technology of combustion-to-detonation and experimental equipment, which is applied in the direction of using combustion for chemical analysis, and can solve the problems of inability to study the mechanism and process of combustion-to-detonation, inability to simulate experiments and quantitative evaluation, quantitative evaluation of influence and function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

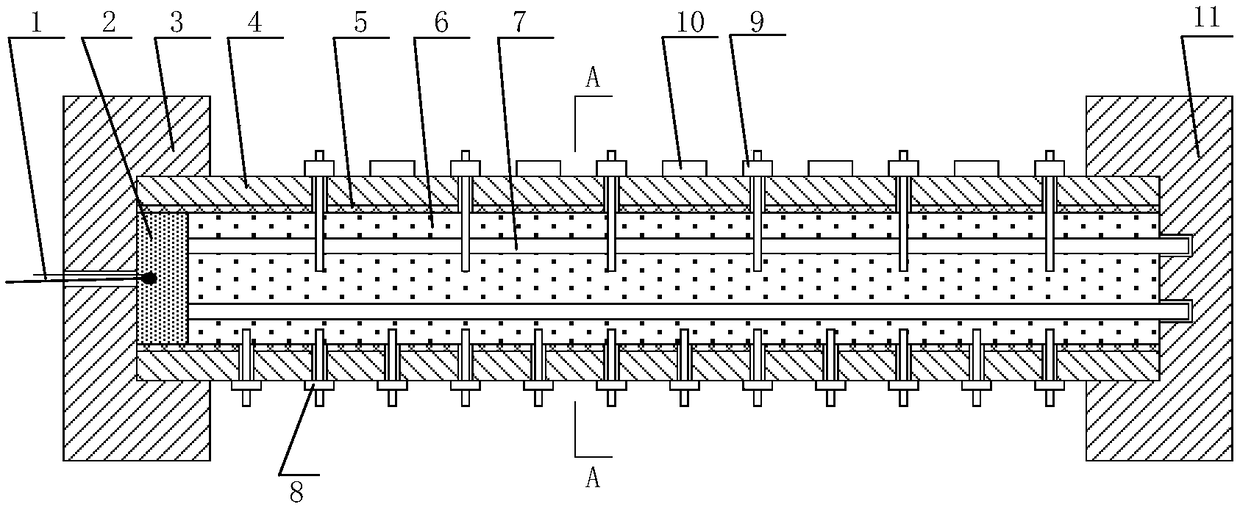

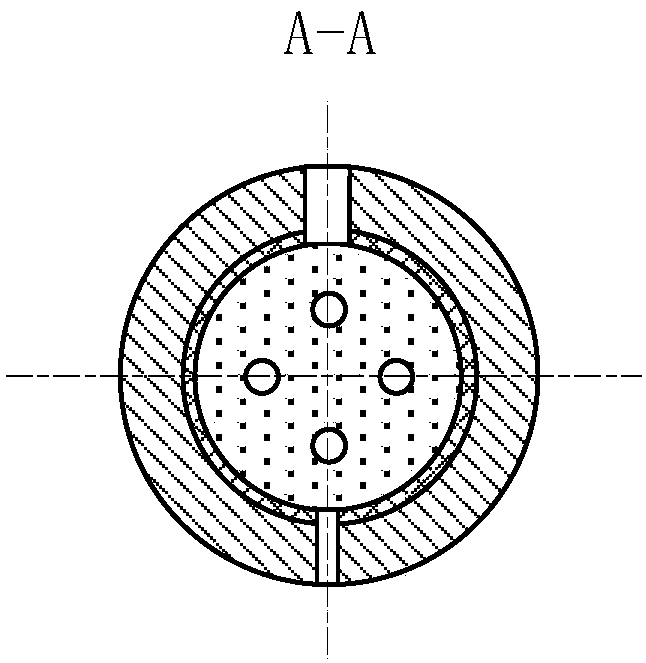

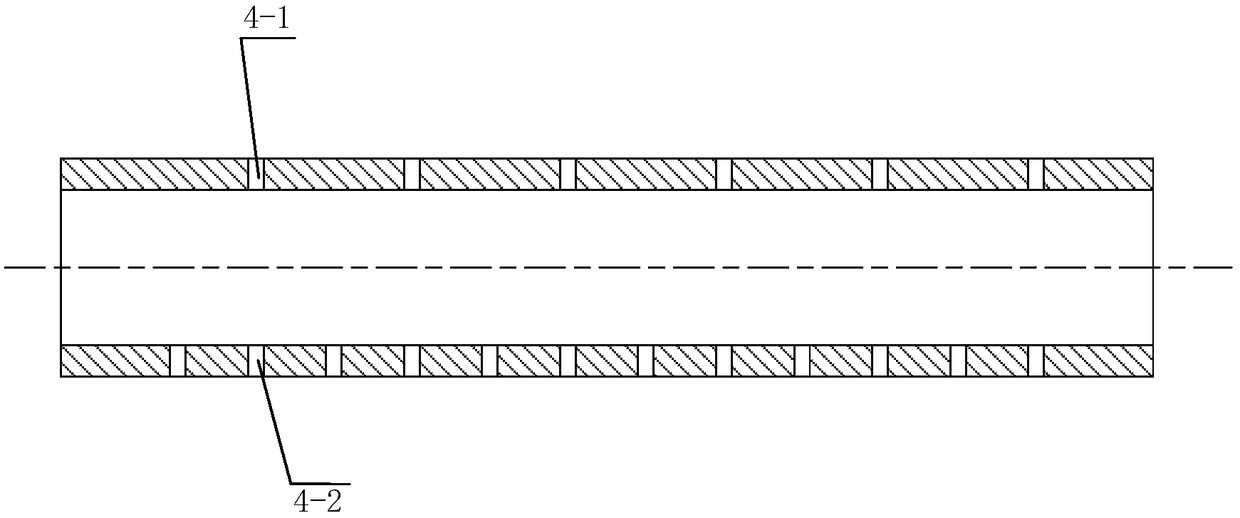

[0033] like Figure 1a , Figure 1b , figure 2 , Figure 3a , Figure 3b , Figure 4a , Figure 4b and Figure 5 As shown, this embodiment of the present invention is an experimental device for measuring the influence of convective combustion on combustion-to-detonation, including ignition head 1, ignition powder 2, start end cap 3, combustion-to-detonation tube 4, phenolic resin sleeve Pipe 5, experimental sample 6, punching network pipe 7, speed measuring probe 8, pressure sensor 9, strain gauge 10 and end cap 11; punching network pipe 7 passes through the stepped hole 11-2 on the end cap 11 and the end cap 11 connection; the threaded hole 11-1 on the end cover 11 has an internal thread, which is connected to the end of the combustion-to-detonation tube 4 through the internal thread; the belt formed by pressing in the phenolic resin casing 5 is connected with the punching network pipe 7 The experimental sample 6 with the same outer diameter hole is loaded into the com...

Embodiment 2

[0048] The end cover 11 is connected to the end of the combustion-to-detonation tube 4 through the threaded hole 11-1; there is a step hole 11-2 on the central axis of the end cover 11, and the punching network pipe 7 passes through the step on the end cover 11 The hole 11-2 is installed on the end cover 11; the phenolic resin sleeve 5 is installed in the combustion-detonation tube 4, and the experimental sample 6 of bulk particles is freely loaded into the phenolic resin sleeve 5; the combustion-detonation tube 4 Reserve a 20mm high space at the beginning to place the ignition head 1 and the ignition powder 2, the ignition head 1 is located in the center of the ignition powder 2, the ignition powder 2 is in contact with the end surface of the experimental sample 6, and the lead wire of the ignition head 1 passes through the center of the end cover 3 at the beginning The step through hole 3-1 leads out, and the beginning end cover 3 is connected to the beginning end of the comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com