Two-dimensional finite element modeling method of wide chord fan blade

A technology for fan blades and modeling methods, which is applied in special data processing applications, instruments, electrical digital data processing, etc. Improve the strength simulation accuracy, the operation method is simple and easy, and the technical principle is clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A two-dimensional finite element modeling method suitable for wide-chord fan blades, including the following steps:

[0024] Step 1. Two-dimensional finite element mesh division

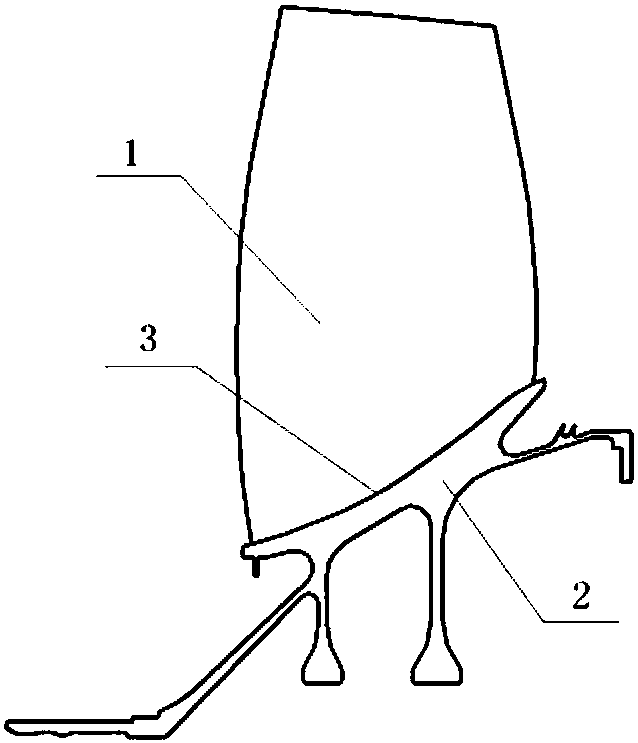

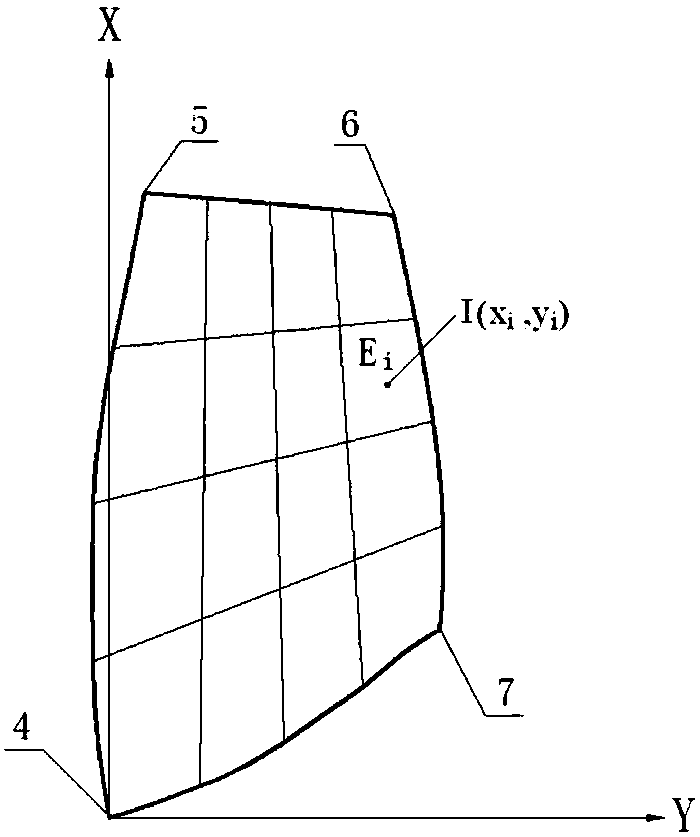

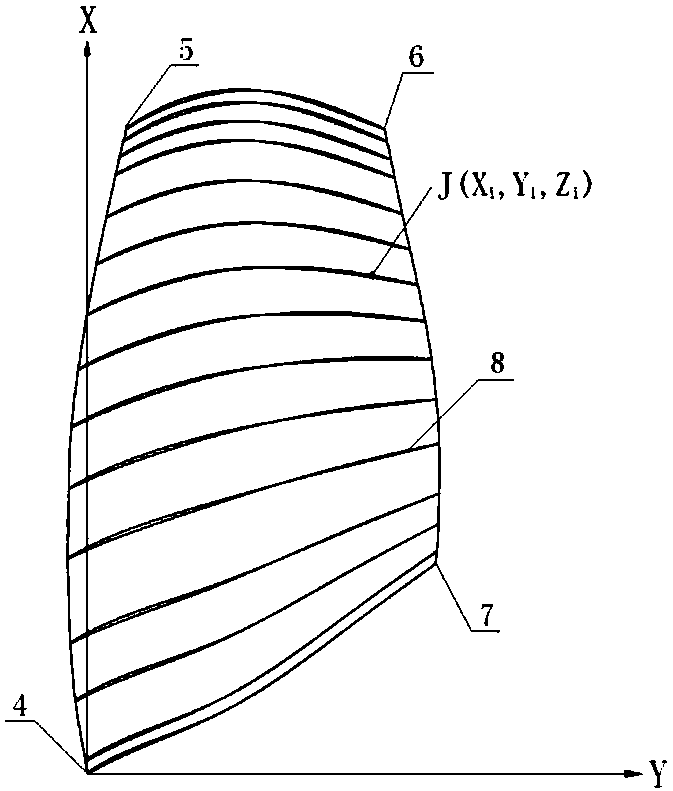

[0025] Wide chord fan rotor structure such as figure 1 , consisting of a wide-chord fan blade (1) and a disc (2). The two-dimensional structure of the wide-chord fan rotor is separated along the rim flow channel (3), where the four corner points of the wide-chord fan blade (1) meridian projection contour are arranged clockwise from the leading edge of the blade root (4), respectively Root leading edge (4), blade tip leading edge (5), blade tip trailing edge (6), blade root trailing edge (7), such as figure 2 , a Cartesian coordinate system is established with the leading edge (4) of the blade root as the origin, the X-axis is along the vertical direction, and the Y-axis is along the horizontal direction. The meridional plane is established by the meridian projection profile of the wide-cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com