Coil spring forming device for pocket spring

A pocket spring and forming device technology, which is applied in the field of coil spring forming, can solve the problems of high labor cost, time-consuming and laborious, and inability to arrange materials by itself, and achieve the effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

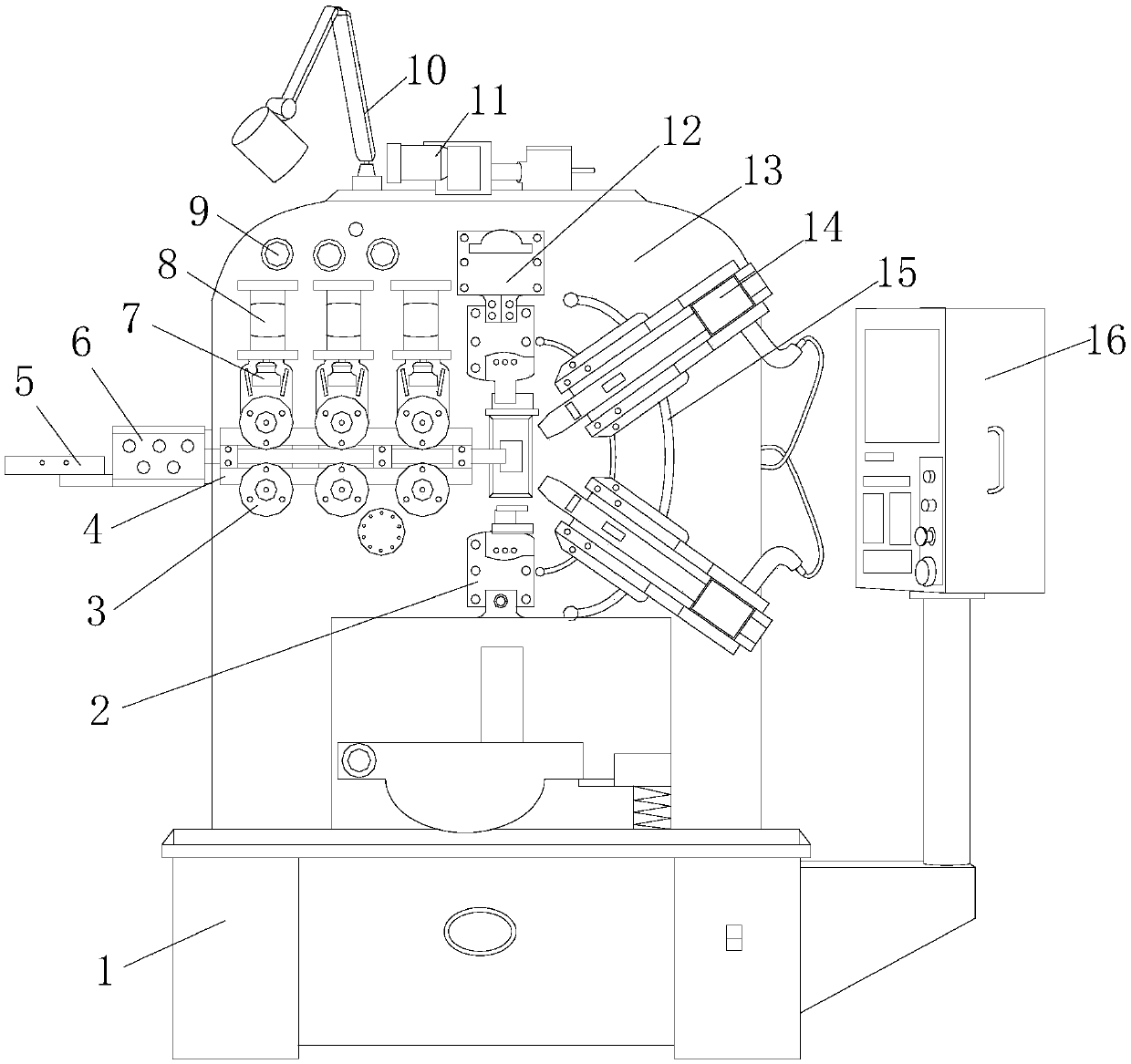

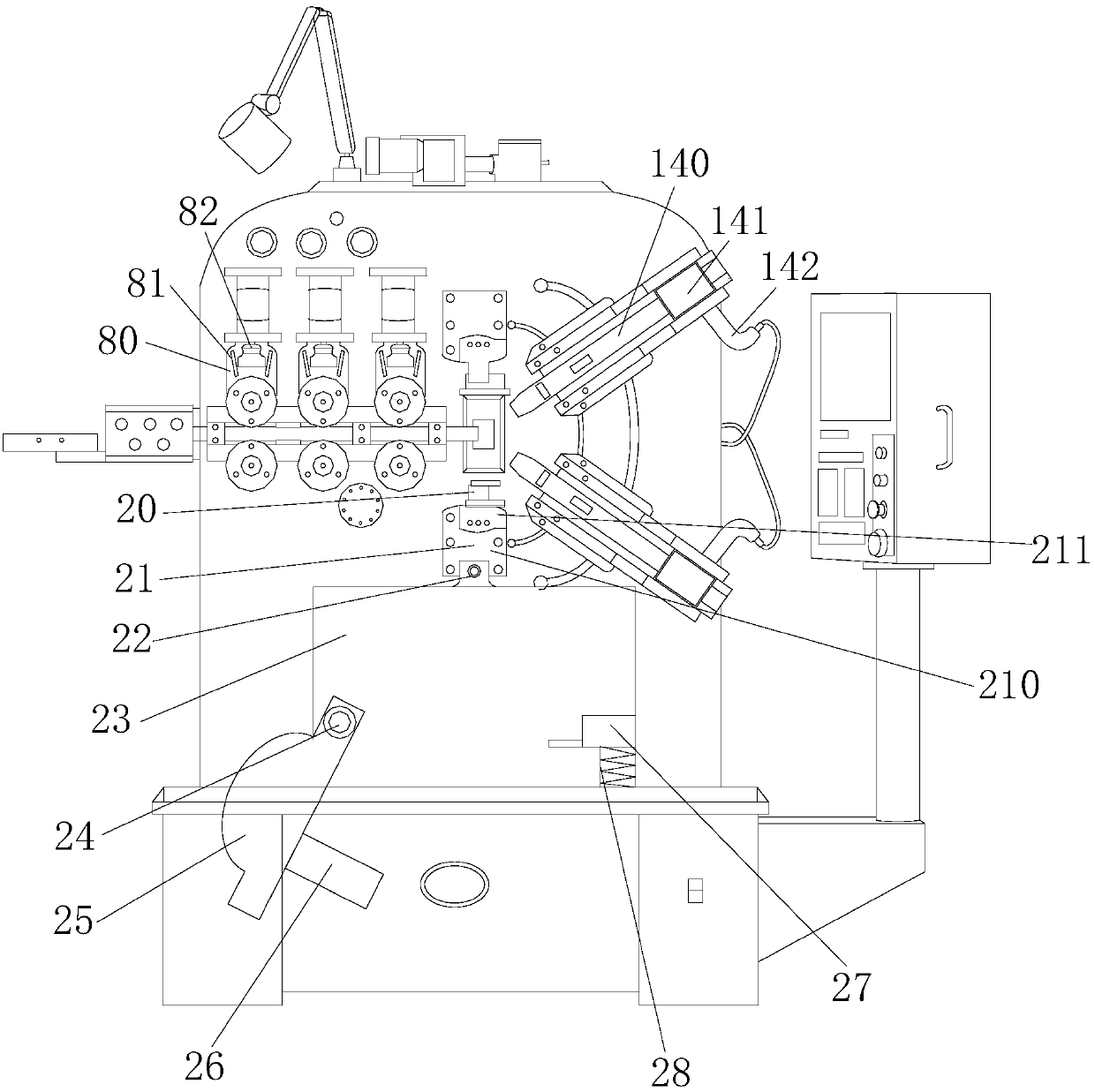

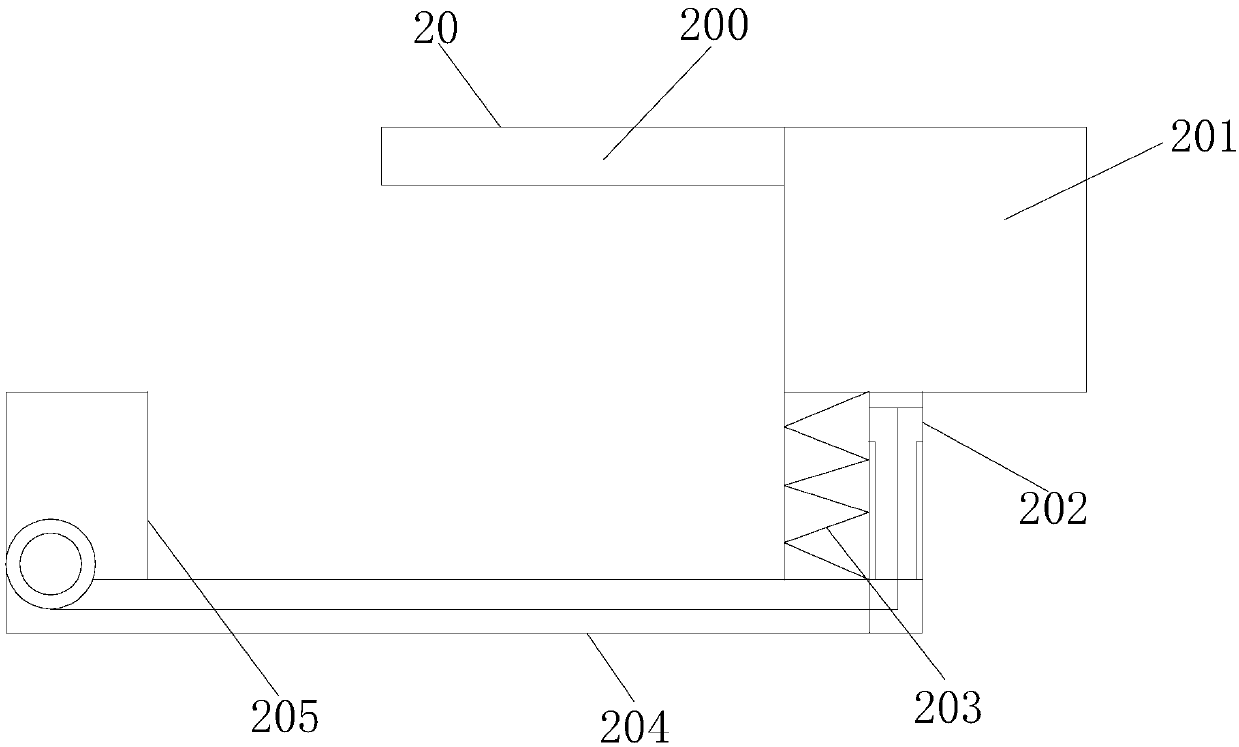

[0020] see Figure 1-Figure 4, the present invention provides a coil spring forming device for pocket springs: its structure includes a spring box 1, a rod drop device 2, a guide wheel 3, a wire feeding plate 4, a wire feeding plate 5, and a wire feeding plate Plate 6, oil drip box 7, oil leak 8, oil gauge 9, lighting lamp 10, motor 11, clamping decorative plate 12, transmission box body 13, intelligent positioning thread trimmer 14, arc groove 15, control cabinet 16, all A transmission box 13 is provided behind the spring box 1, the control cabinet 16 is fixedly connected to the side of the transmission box 13, and the rod drop device 2, a wire feeding plate 4, and a clamping decorative plate 12 are locked in the transmission box. On the front side of the body 13, the guide wheels 3 are provided with six, which are respectively movably connected to the front side of the first wire feeding plate 4, and are distributed in two rows. The two wire feeding plates 5 and the three wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com