Photocuring 3D printing device and printing method

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of low printing efficiency, printing Z-axis accuracy (layer thickness accuracy deviation, affecting printing accuracy, etc., to improve the molding efficiency and shorten the waiting time effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

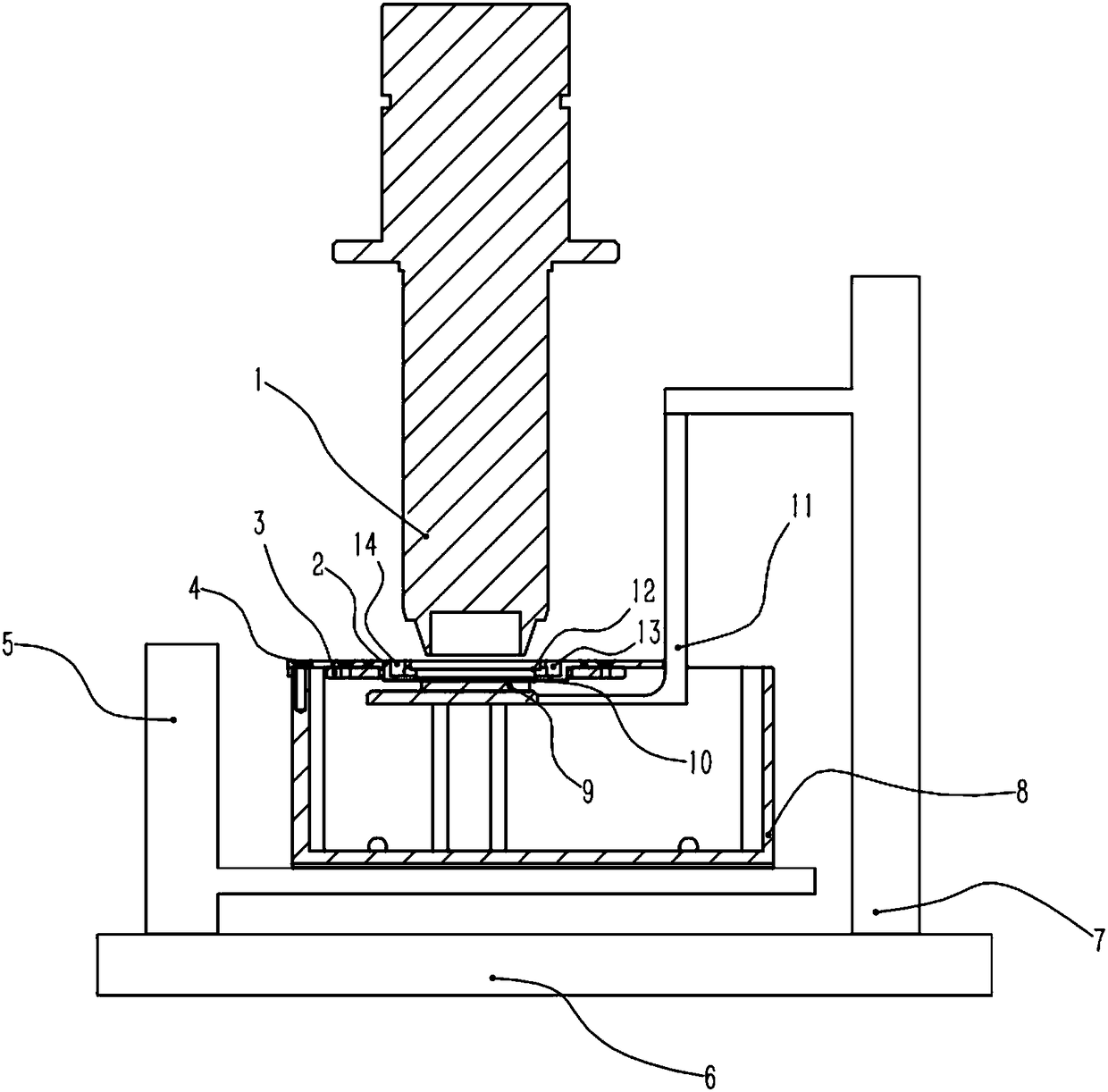

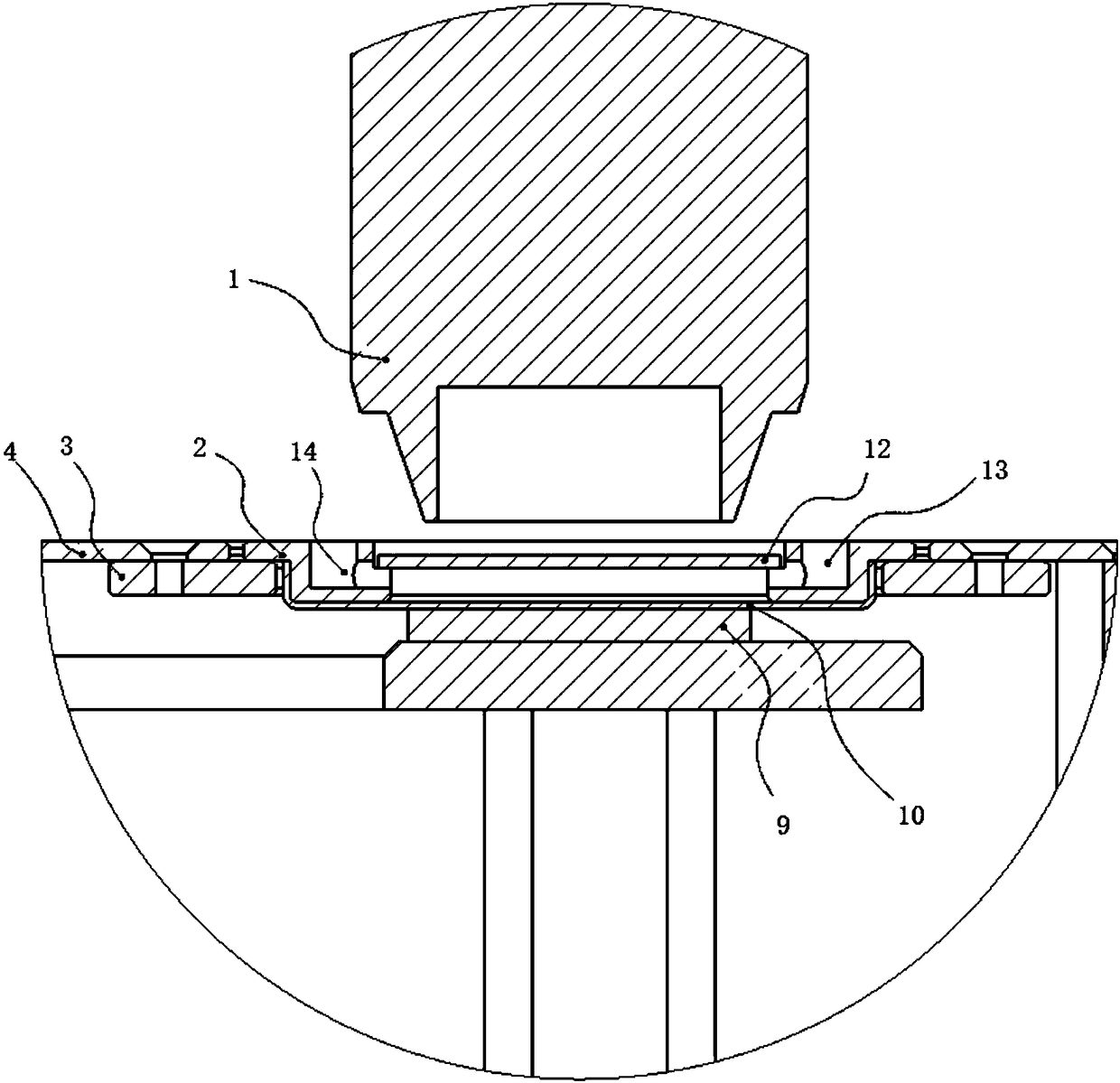

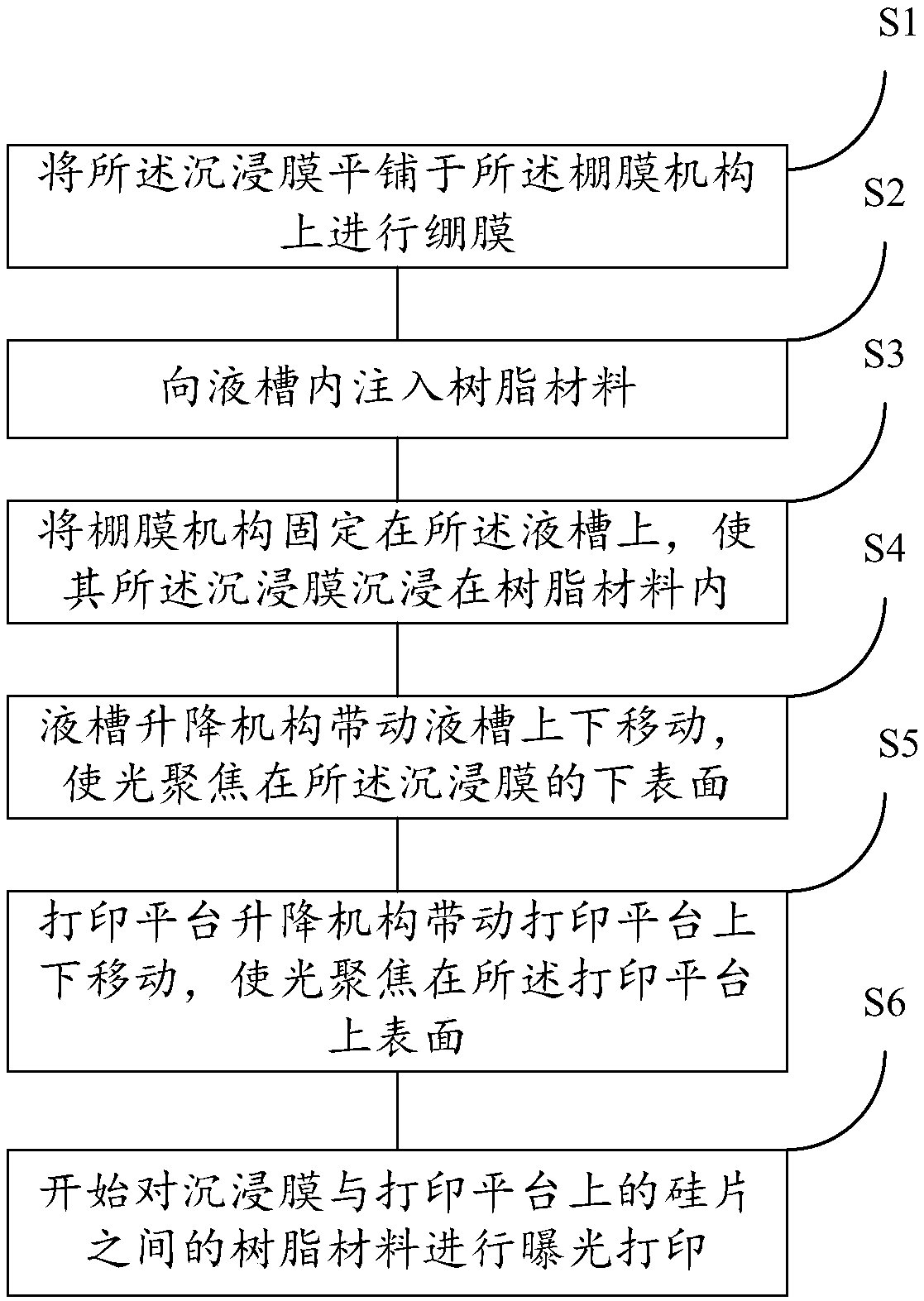

[0028] Such as Figure 1 to Figure 2 As shown, the present invention discloses a light-curing 3D printer, including a liquid tank 8, a liquid tank lifting mechanism 5, a printing platform 11 and a printing platform lifting mechanism 7, the printing platform 11 is placed in the liquid tank 8, and the The upper end of the liquid tank 8 is provided with a film-immersing mechanism, the film-immersing mechanism includes a stretch film mechanism and an immersion film 10 fixed on the stretch film mechanism, the printing platform 11 is located at the lower end of the immersion film 10, and the liquid Resin materials for printing products are housed in the groove 8, and a silicon chip 9 is arranged on the printing platform 11, and the silicon chip 9 corresponds to the position of the immersion film 10, and the immersion film 10 is immersed in the place by a stretch film mechanism. In this way, the resin layer above the silicon wafer 9 on the printing platform 11 can be compressed and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com