Novel automotive glass cladding assembly

An automotive glass and edge wrapping technology, which is applied to vehicle parts, transportation and packaging, and engine sealing, etc., can solve the problems of increasing the processing difficulty and production cost of the wrapping assembly, coating damage and falling off, etc., so as to improve the sense of unity, The effect of reducing the amount of use and reducing the punching depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

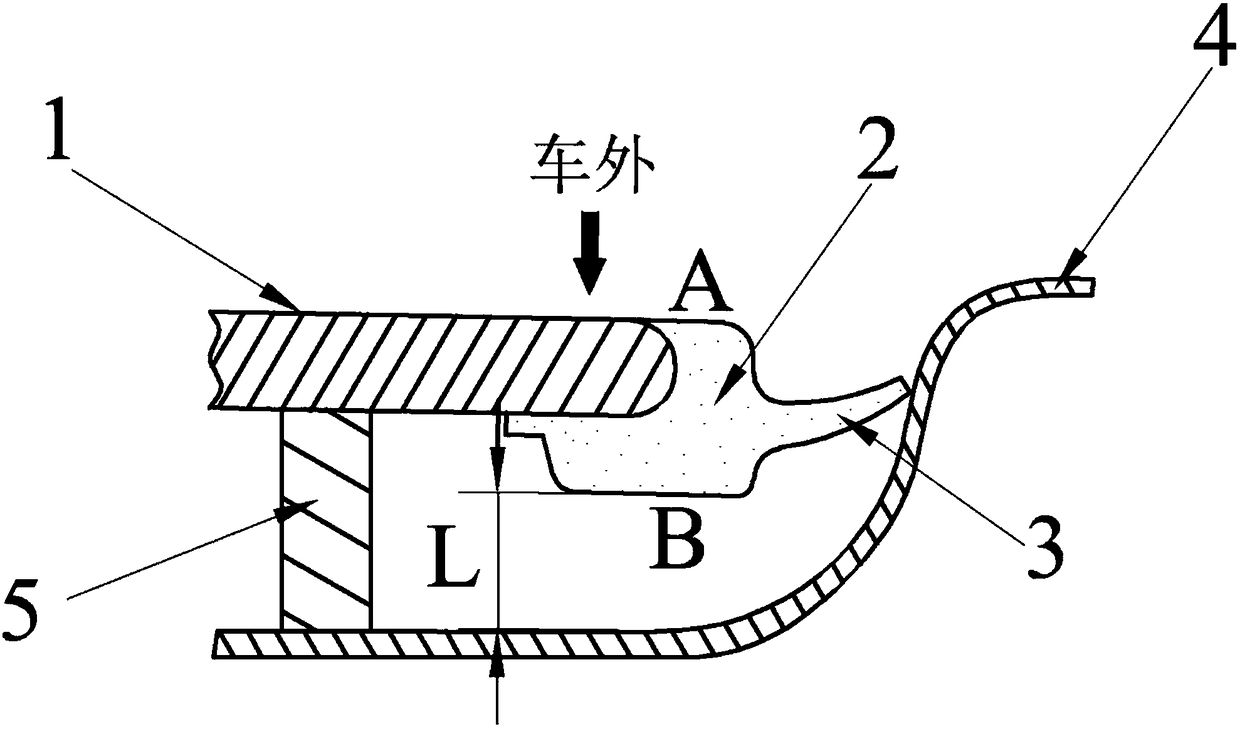

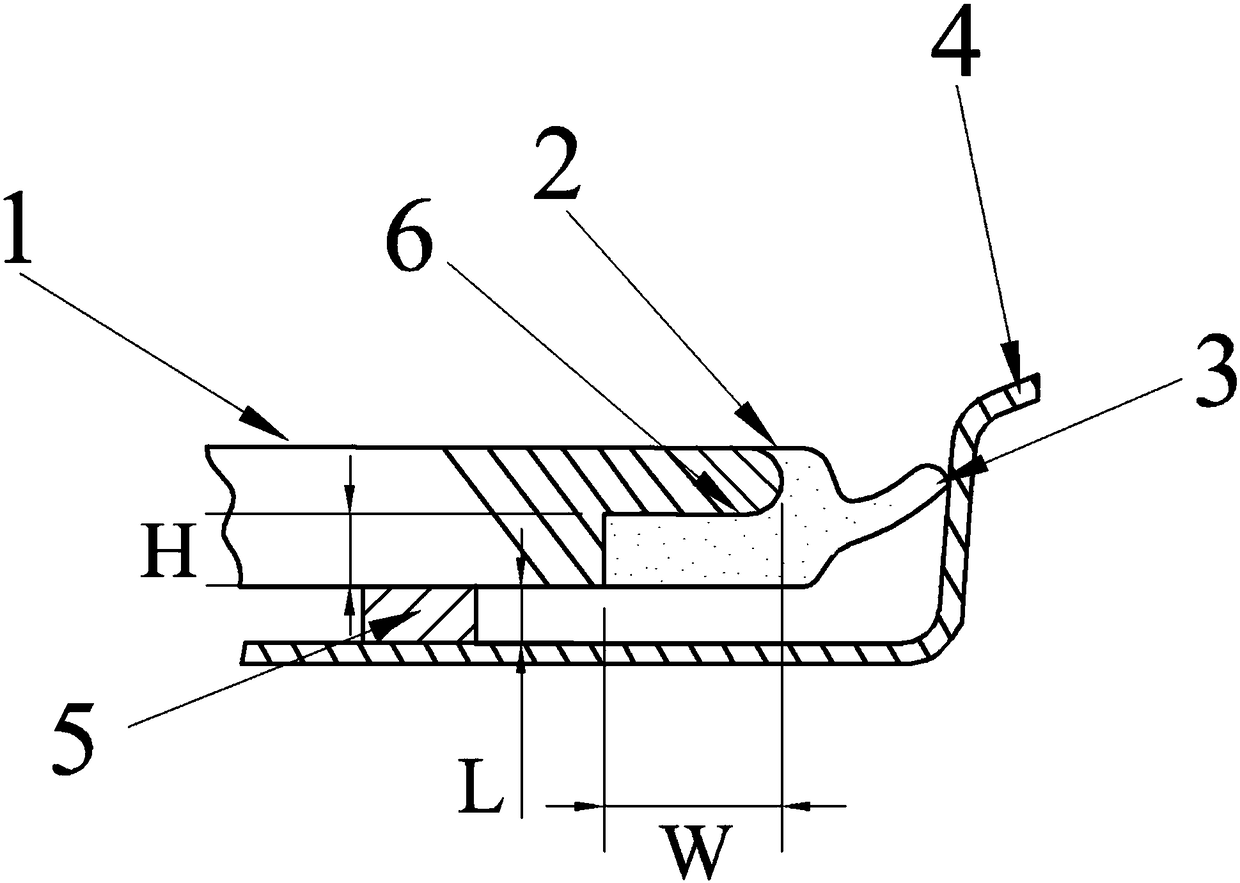

[0023] like figure 2 Shown, a kind of novel automobile glass edging assembly of the present invention is used to be installed on the window frame of automobile body, comprises glass plate 1 and the edging 2 that is fixed on glass plate 1 edge, and the glass plate shown in the figure 1 is a single piece of tempered glass with a thickness of 3.5mm, but it can be understood that it is not limited to the structural composition described in the figure, and the glass plate 1 can also be a laminated glass composed of two or more pieces of glass and an intermediate layer.

[0024] The glass plate 1 has an outer surface facing the outside of the vehicle body and an inner surface facing the inside of the vehicle body. A recess 5 is provided around the edge of the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com